AN INTELLIGENT INFORMATION SYSTEM FOR ENABLING

PRODUCT MASS CUSTOMIZATION

Haifeng Liu, Wee-Keong Ng

School of Computer Engineering, Nanyang Technological University, 50 Nanyang Avenue, Singapore 639798

Bin Song, Xiang Li

Singapore Institute of Manufacturing Technology, 71 Nanyang Drive, Singapore 638075

Wen-Feng Lu

Department of Mechanical Engineering, National University of Singapore, 10 Kent Ridge Crescent, Singapore 119260

Keywords:

Intelligent Information System, Product Life Cycle Management, Knowledge Management in Design, Mass

Customization.

Abstract:

We propose to develop an intelligent design decision-support system to enable mass customization through

product configuration using intelligent computational approaches. The system supports customer-driven prod-

uct development throughout the product’s life cycle and enables rapid assessment and changes of product

design in response to changes in customer requirements. The overall system consists of four subsystems:

customer requirement analysis subsystem, product configuration subsystem, product lifecycle cost estimation

subsystem and product data management subsystem. Various challenging issues for developing the system are

investigated, and a number of methodologies and techniques to resolve the issues are presented. The proposed

system will allow SMEs to effectively compete with larger companies who command superior resources.

1 INTRODUCTION

Due to the globalization of business, mass customiza-

tion has become a crucial business strategy for prod-

uct manufacturers that aims at satisfying individual

customer needs with near mass production efficiency

(Pine, 1993). It recognizes each customer as an in-

dividual and provides each of them with attractive

‘tailor-made’ features that can only be offered in the

pre-industrial craft system. As mass customization al-

lows companies to garner scale of economy through

repetition, it is capable of reducing costs and lead

time. Hence, mass customization achieves a higher

margin and is more advantageous. With the increas-

ing flexibility built into modern manufacturing sys-

tems and programmability in computing and commu-

nication technologies, companies with low-medium

production volumes may attain an edge over competi-

tors by implementing mass customization (Jiao and

Tseng, 1999). However, mass customization has pre-

sented many difficult challenges to companies. Two

major challenges are:

• Product innovation and customization must ad-

dress increasingly complex customer require-

ments (Leckner and Lacher, 2003).

• Successful launching of new products relying on

complex information spanning a product’s life cy-

cle and development of value chain (Newcomb

et al., 1996).

In order to implement successful mass customization,

companies must develop the necessary infrastructure

to satisfy the requirements of time-to-market, vari-

ety, and economy of scale along with customer’s con-

straints (Jiao and Tseng, 1999; Lau, 1995; Chung

et al., 2005). Many companies fail to realize this

customer-driven product development as they lack in-

novation capability and have limited use of technol-

ogy tools. The situation becomes more critical for

small and medium-size enterprises (SMEs) (Svens-

son, 2001; Svensson and Barfod, 2002).

To address the above challenging issues, we pro-

pose to develop an intelligent design decision-support

316

Liu H., Ng W., Song B., Li X. and Lu W. (2007).

AN INTELLIGENT INFORMATION SYSTEM FOR ENABLING PRODUCT MASS CUSTOMIZATION.

In Proceedings of the Ninth International Conference on Enterprise Information Systems - AIDSS, pages 316-321

DOI: 10.5220/0002374003160321

Copyright

c

SciTePress

system to enable mass customization through prod-

uct configuration using intelligent computational ap-

proaches. The system supports customer-driven prod-

uct development throughout the product’s life cycle

and enables rapid assessment and changes of prod-

uct design in response to changes in customer require-

ments. The paper is organized as follows: We review

related work in Section 2 and present the architecture

and elements of the proposed system in Section 3. In

Section 4, we investigate various challenging issues

for developing the system, and propose a number of

methodologies and techniques to resolve the issues.

We conclude the paper in Section 5.

The proposed system will assist companies in ac-

cumulating capabilities of quick response to customer

preference and rapid development of product design

that is “right-the-first-time”; this is a crucial key to

successful mass customization. It will also allow

SMEs to effectively compete with larger companies

who command superior resources.

2 RELATED WORK

Although mass customization presents a new

paradigm for the manufacturing industry, it has also

received criticism that it is a revolutionary paradigm

without a coherent framework (Kotha, 1994). Whilst

there is a huge amount of managerial literature on

mass customization, it still remains an open issue as

to how information systems should be designed and

implemented for the realization of mass customiza-

tion. (Tseng, 1998) addresses the issue of how to

implement mass customization with the support of

concurrent engineering (CE) where it focuses on

developing a mass customization oriented product

family architecture and applies machine learning

techniques to cluster design parameters according

to their ability to satisfy functional requirements.

(Jiao et al., 2002) discusses the opportunities and

challenges of mass customization for the manufac-

turing industry and service providers. It also outlined

a technological road map for implementing mass

customization based on building block identification,

product platform development, and product life-cycle

integration. (McMahon and Giess, 2005) focuses on

the management of product lifecycle management

(PLM) data for long term access and related system

and management issues are addressed. (Roach et al.,

2005) presents a new design system that integrates

existing computer design tools and information man-

agement tools to produce design variants. The system

facilitate companies to develop a mass customization

design process. Traditional expert systems have

also been adopted to automate the product design

(Akagi and Fujita, 2002). However, they are rigid and

difficult to apply to mass customization. Compared

to past research, our work focuses on practically

implementing mass customization with referred

product lifecycle cost information using intelligent

computational approaches.

3 SYSTEM FRAMEWORK

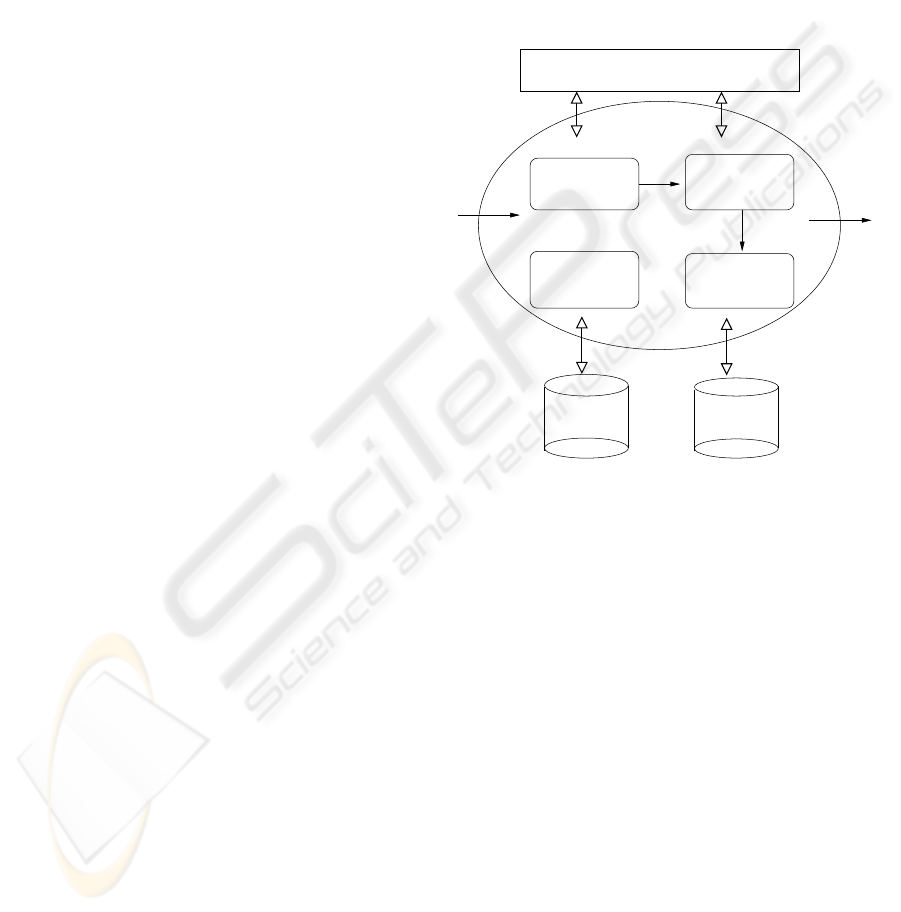

CR

Product Lifecycle

Knowlege Base

Database

Product Lifecycle

GUI

DS

Valid PC

PC

Customer Requirement

Analysis Subsystem

Product Configuration

Subsystem

Lifecycle CostProduct Data

Management Subsystem Estimation Subsystem

Figure 1: An intelligent system for enabling mass cus-

tomization.

We propose an intelligent information system as the

enabling technology for mass customization. The

main feature of the system is its principal role as

a supporting facility for manufactures to rapidly de-

velop product variants of a product family in re-

sponse to customer requirements. The framework of

the overall system is depicted in Figure 1. It con-

sists of two major components: An integrated product

lifecycle database and an integrated product lifecycle

knowledge base, and four subsystems: product data

management subsystem, customer requirement anal-

ysis subsystem, product configuration subsystem and

product lifecycle cost estimation subsystem. These

components are further described as follows.

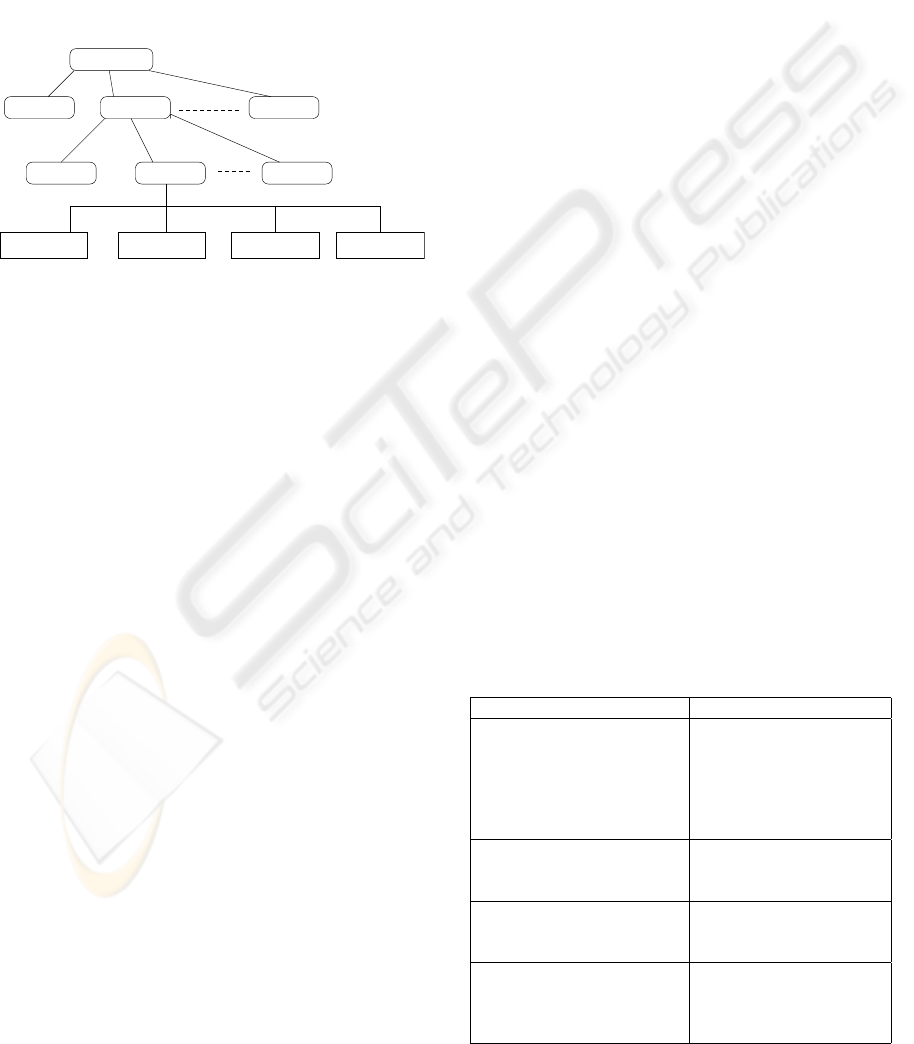

Integrated Product Lifecycle Database (PLD).

Product lifecycle data that are conventionally scat-

tered in different departments (and possibly in dif-

ferent companies within a supply chain) are collected

and stored into PLD (possibly through a product life-

cycle management system) consisting of essentially

AN INTELLIGENT INFORMATION SYSTEM FOR ENABLING PRODUCT MASS CUSTOMIZATION

317

product family and components data as well as rela-

tionships among components, customer requirements,

product cost data and other information required by

the computation of the system. Figure 2 illustrates

the conceptual product family data model linked with

various lifecycle data where product components are

defined as the basic units that are treated by the lifecy-

cle processes. PLD is highly dynamic and should be

sustained along the product lifecycle processes (de-

sign, manufacturing, procurement, service, and recy-

cle).

Product Family

Product A

Product B Product X

Component A Component B Component K

Phisical Features Process Plans Lifecycle Costs Other Documents

Figure 2: An integrate product lifecycle data model.

Integrated Product Lifecycle Knowledge Base

(PLK). PLK is tasked to provide intelligence to the

whole system and is employed to store product life-

cycle knowledge; specifically for now, the domain

specific relationships between customer requirements

(CR), design specifications (DS), and product config-

urations (PC). The knowledge is extracted from PLD

and built using self-learning algorithms using the sub-

systems. The PLK is constantly updated from ever-

evolving data in PLD.

Product Data Management Subsystem (PDM).

The subsystem provides users with the functionali-

ties of creating, updating, maintaining and viewing

information stored in PLD. Among them, the fore-

most functionality of PDM is to define product fam-

ilies and edit product/component properties within a

family. Various formats of data and documents (such

as word document, and CAD drawings) should also

be viewed through an integrated viewer without call-

ing any external applications.

Customer Requirement Analysis Subsystem

(CRA). Generally customers do not have suffi-

cient product expertise. They cannot express their

preferences in terms of technical specifications.

(Rogoll and Piller, 2002) have shown that there is

no standard software solution for designing products

that is able to fulfill optimal requirements from

customer’s perspectives. The CRA subsystem aims

to efficiently and effectively capture and understand

customer requirements and focuses on transforming

the requirements into concrete design specifications

from which a successful design can result.

Product Configuration Subsystem (PCS). This

subsystem aims to generate qualified product config-

uration from a given set of design specifications that

are produced by CRA. The configuration solution has

to produce the list of selected components, the struc-

ture and topology of the product (Sabin and Freuder,

1996). PCS should be used throughout the product

definition activities in a product’s lifecycle; not only

in design and development, but also in sales force au-

tomation and manufacturing, including supply chain

considerations. In order to achieve success in prod-

uct configuration, product/product family model men-

tioned in Section 3 has to be constructed to capture

product structure knowledge. Product variants can be

instantiated from this model.

Different approaches have been adopted to solve

the product configuration problem (Blecker et al.,

2004; Sabin and Weigel, 1998). Compared to existing

product configurators, rather than manually acquiring

configuration knowledge, novel techniques are em-

ployed by PCS to automatically generate configura-

tion knowledge from existing product configuration

data (please see details in Section 4.2).

Product Lifecycle Cost Estimation Subsystem

(PLC). The subsystem aims to provide the lifecy-

cle cost (LCC) information of a product configuration

at the early design stage. LCC of a product configura-

tion is confined as the total cost of developing, man-

ufacturing, delivering, servicing and recycling or dis-

posing. Table 1 shows the common cost members of

PLC (Perera et al., 1999).

Table 1: Cost members of PLC.

Product Lifecycle Stages Cost Members

Design stage Engineering design cost

Drawing cost

Computer processing cost

Design modification cost

Production preparation cost

Management cost

Manufacturing stage Material cost

Facility cost

Production cost

Marketing and after-sale stage Marketing cost

Distribution cost

Maintenance cost

Disposal and recycling stage Retrieval cost

Disassembly cost

Reprocessing cost

Landfill cost

ICEIS 2007 - International Conference on Enterprise Information Systems

318

Given a set of DS, it is possible for PCS to de-

rive multiple configuration solutions. Hence, taking

advantage of PLD, PLC analyzes and evaluates each

product configuration elements in accordance with

the associated cost calculated based on historical data

available from PLD. The cost-effective ones are con-

sidered as valid configurations. In order to achieve

a satisfactory accuracy, we propose to estimate LCC

based on the approach of combining activity based

costing (ABC) technique (Emblemsvag, 2003) and in-

telligent self-learning techniques, such as neural net-

work (Lotfy and Mohamed, 2002), support vector ma-

chine (Scholkopf and Smola, 2002), and so on. PLC

helps track and analyze the cost of activities associ-

ated with each phase of a product’s lifecycle. Con-

sequently, visibilities across these activities are in-

creased, their performances improved and the product

lifecycle costs reduced.

All the subsystems have their own graphical user

interfaces. They operate independently and are trans-

parent to one another, and are interconnected through

PLD and PLK. This enables the whole system to be

easily maintained and extended.

4 ISSUES AND APPROACHES

In order to build the system framework described in

Section 3, we investigate major research issues and

propose approaches to resolve them below.

4.1 Automating Transformation of

Customer Requirements Into

Design Specifications

It is an indispensable task to capture and understand

customer requirements and subsequently to transfer

them into design specifications for successful product

design. The procedure involves a tedious elaboration

process enacted between customers, marketers and

designer. On the other hand, customer requirements

information must be managed throughout the entire

product development process, involving such tasks as

creating, disseminating, maintaining and verifying re-

quirements. A latest review (Jiao and Chen, 2006) has

listed widely used techniques to manage customer re-

quirement information, and suggested a future route

of intelligent knowledge management. However, ex-

isting techniques still need a lot of human interaction

and suffer from a lack of computer-aided automation

support.

We propose to apply a combination of association-

rule mining and Quality Function Deployment (QFD)

approach (Prasad, 1998) in CRA to facilitate the au-

tomation of transforming CR into DS. First of all,

there is a need to construct standard models to repre-

sent CR and DS. CR are linguistic statements, such as

“The drill is powerful”, etc., while a DS consists of a

design metric (with unit), a weighting of importance,

and an target value, such as “Maximum speed - 5 -

900rpm” means the maximum speed of the new drill

should be 900rpm while the importance of this DS is

“5”. The instances of CR and DS of a product fam-

ily are stored in PLD. The standardized definitions

provides a base for dynamically deriving the relation-

ships between CR and DS metrics from the historical

case as a product design is completed. These mapping

relationships are build up as association rules in PLK

by a supervised learning algorithm. After DS metrics

are identified, we adopt widely-used QFD method to

prioritize specification metrics and derive their target

values. With complete information provided (includ-

ing CR, degrees of metrics in satisfying specific cus-

tomer needs, customer evaluations and benchmark-

ings of existing products), we can derive the target

values of metrics using House of Quality matrix cal-

culation method in QFD.

4.2 Automating Generation of

Constraint-based Configuration

Knowledge

The core of configuration task is to select and arrange

combinations of components which satisfy given de-

sign specifications. A number of significant works

and results have been produced (Blecker et al., 2004;

Sabin and Weigel, 1998), especially the problem solv-

ing algorithm in constraint-based configuration, has

been greatly enhanced in term of efficiency and accu-

racy. In this approach, product configuration tasks can

be treated as a constraint satisfaction problem (CSPs)

(Tseng et al., 2005; Xie et al., 2005). Each component

is defined by a set of properties and a set of ports for

connecting to other components. Constraints among

components restrict the ways various components can

be combined to form a valid configuration. The ini-

tial requirement specifications and optimization crite-

ria are treated as constraints in the process. The so-

lution is the final configuration that all constraints are

fulfilled.

Despite the success of the mentioned approaches,

the configuration knowledge acquisition is usually

done manually. We propose to adopt a similar asso-

ciation rule mining approach as in Section 4.1 to dis-

cover useful patterns between DS and product compo-

nents, as well as the correlation among product com-

ponents. An indicator, namely support degree, is used

AN INTELLIGENT INFORMATION SYSTEM FOR ENABLING PRODUCT MASS CUSTOMIZATION

319

to indicate the probability of exist of the relationship

between one specification and one component. The

relationship exists when the support degree is larger

than the predefined threshold. Existing set of data

in PLD which has captured the mapping between the

two is used as training data set. These patterns are

translated into constraints knowledge and stored into

PLK, and used for configuration reasoning in PCS.

An example rule can be “if the maximum speed of

drill is 900rpm, then the DC motor A1 is selected”.

Many other rules that we have not been easily aware

of can be discovered as the association rules forma-

tion through finding out the large item sets by setting

the minimum support and confidence thresholds. Fi-

nally, a qualified (but may not be cost-effective) PC

can be derived. A partial configuration for an in-

stance of a cordless drill family can be: “DC motor

(A1) + Housing set (H3) + Gear assay (G9)” where

inside brackets are the identifiers of selected compo-

nent variants.

4.3 Estimation of Lifecycle Cost

It is well known (Dowlatshahi, 1992) that the design

of the product influences between 70% and 80% of

the total cost of a product. Therefore, design deci-

sions at the early stage of life cycle made by con-

sidering lifecycle cost implications may substantially

reduce the LCC of the product they design. Either

underestimate or overestimate of LCC will lead to fi-

nancial loss of the company. Three review papers (Ni-

azi et al., 2006; Layer et al., 2002; Asiedu and Gu,

1998) have summarized the existing techniques of es-

timating LCC using certain criteria. We observed that

all techniques are dedicated to particular applications.

They are developed either for specific segments in a

life cycle, or for specific machining and manufactur-

ing processes, or for specific parts and products, or for

specific manufacturing systems. According to (Niazi

et al., 2006), one main trend is to apply ABC tech-

nique in order to achieve more accurate estimation re-

sult.

Recently an ABC based framework has been pro-

posed to calculate the full product lifecycle cost (Xu

et al., 2006). However, it is difficult to apply the

approach due to the lack of sufficient activity in-

formation to conduct a ABC study at the early de-

sign stage. We propose to apply the state-of-the-art

machine learning techniques and ABC technique to-

gether in PLC subsystem depending on information

available. When sufficient activity and resource in-

formation can be clearly identified to develop a new

product variant, ABC approach would be used, and

the LCC of a product/component is calculated based

on the equation below:

LCC =

n

∑

i=1

UR

i

× CAQ

i

(1)

where n is the total number of lifecycle activities in

the product, UR

i

is the unit cost rate of the i

th

activity

while CAQ

i

is the estimated consumption quantity of

the i

th

activity. Otherwise, intelligent regression algo-

rithms would be employed to predict the LCC based

on historical data. We will conduct a benchmark-

ing study on various learning algorithms including re-

gression, artificial neural network, and support vec-

tor regression (SVR) on estimating LCC (No existing

work using SVR to estimate LCC has been reported).

Particularly, we will focus on learning in an on-line

setting (Ma et al., 2003) because it refrains from re-

training from scratch when each time a new sample is

added to the training set. This is mostly desired when-

ever the LCC of a new product becomes available and

the estimation model needs to be updated. To the best

of our knowledge, no work has been done on studying

the issue. The best on-line learning algorithms would

be implemented in a prototype of PLC.

5 CONCLUSION

We propose to develop an intelligent information sys-

tem to assist enterprises in realize mass customiza-

tion. Due to its open architecture, the system can be

easily deployed with existing enterprise information

systems, such as ERP, PLM, and so on. By learning

from the accumulated product lifecycle data and em-

ploying design knowledge in PLK as well as taking

account into the product lifecycle cost, the system is

able to rapidly respond to changing customer require-

ments and efficiently produce right product variants.

The system is now its preliminary stage of develop-

ment. Various learning algorithms are being investi-

gated and a prototype is under implementation. The

overall objective of the system benefits enterprises by

enable them to accumulate product design and devel-

opment capability by adopting a product life cycle

knowledge-centric approach.

ACKNOWLEDGEMENTS

The work is funded by A*STAR Thematic Research

Programme on Integrated Manufacturing and Ser-

vices Systems (IMSS).

ICEIS 2007 - International Conference on Enterprise Information Systems

320

REFERENCES

Akagi, S. and Fujita, K. (2002). Automated functional de-

sign of engineering systems. Journal of Mechanical

Design, 13:119–133.

Asiedu, Y. and Gu, P. (1998). Product life cycle cost anal-

ysis: state of the art review. International Journal of

Production Research, 36(4):883–908.

Blecker, T., Abdelkafi, N., Kreuter, G., and Friedrich, G.

(2004). Product configuration systems: state-of-the-

art,conceptualization and extensions. In Proceedings

of the Eighth Maghrebian Conference on Software

Engineering and Artificial Intelligence, pages 25–36,

Tunisia.

Chung, S. H., Byrd, T. A., Lewis, B. R., and Ford, F. N.

(2005). An empirical study of the relationships be-

tween it infrastructure flexibility, mass customiza-

tion, and business performance. The DATABASE for

Advances in Information Systems - Summer 2005,

36(3):26–44.

Dowlatshahi, S. (1992). Product design in a concur-

rent engineering environment: an optimization ap-

proach. International Journal of Production Research,

30(8):1803–1818.

Emblemsvag, J. (2003). Life Cycle Costing - Using

Acitivity-Based Costing And Monte Carlo Methods to

Manage Future Costs and Risks. John Wiley & Sons,

Inc.

Jiao, J. and Chen, C.-H. (2006). Customer requirement

management in product development: A review of re-

search issues. Concurrent Engineering: Research and

Applications, 14(3):173–185.

Jiao, J., Ma, Q., and Tseng, M. (2002). Towards high value-

added products and services: mass customization and

beyond. Technovation.

Jiao, J. and Tseng, M. M. (1999). A methodology of devel-

oping product family architecture for mass customiza-

tion. Journal of Intelligent Manufacturing, 10:3–20.

Kotha, S. (1994). Mass customization: The new frontier in

business competition. Business Process Management

Journal, 19(3):588–592.

Lau, R. S. (1995). Mass customization: the next industrial

revolution. Industrial Management, 37(5):18–19.

Layer, A., Brinke, E. T., Houten, F. V., Kals, H., and Haasis,

S. (2002). Recent and future trends in cost estimation.

International Journal of Computer Integrated Manu-

facturing, 15(6):499–510.

Leckner, T. and Lacher, M. (2003). Simplifying configu-

ration through customer oriented product models. In

Proceedings of the 14th International Conference on

Engineering Design, Stockhelm, Sweden.

Lotfy, E. A. and Mohamed, A. S. (2002). Applying neural

networks in case-based reasoning adaptation for cost

assessment of steel buildings. Int. J. Comput. Numer.

Anal. Appl., 24(1):28–38.

Ma, J., Theiler, J., and Perkins, S. (2003). Accurate on-

line support vector regression. Neural Compuatation,

15:2683–2703.

McMahon, C. and Giess, M.and Culley, S. (2005). Infor-

mation management for through life product support:

the curation of digital engineering data. Int. J. Product

Lifecycle Management, 1(1):26–42.

Newcomb, P. J., Bras, B., and Rosen, D. W. (1996). Im-

plications of modularity on product design for the

life cycle. In Proceedings of AMSE Design Engi-

neering Technical Conferences,DETC96/DTM-1516,

Irvine, CA.

Niazi, A., Dai, J. S., Balabani, S., and Seneviratne, L.

(2006). Product cost estimation: Technique classifi-

cation and methodology review. Journal of Manufa-

turing Science and Engineering, 128:563–575.

Perera, H. S. C., Nagarur, N., and Tabucanon, M. T. (1999).

Component part standardization: a way to reduce the

life-cycle costs of products. International Journal of

Production Economics, 60(4):109–116.

Pine, J. (1993). Mass Customization: The New Frontier

in Business Competition. Boston: Harvard Business

School Press.

Prasad, B. (1998). Review of qfd and realted deploy-

ment techniques. Journal of Manufacturing Systems,

17(3):221–234.

Roach, G., Cox, J., and Sorensen, C. (2005). The product

design generator: a system for producing design vari-

ants. Int. J. Mass Customisation, 1(1):83–106.

Rogoll, T. and Piller, F. T. (2002). Konfigurationssys-

teme fuer Mass Customization und Variantenproduk-

tion. Muenchen: ThinkConsult.

Sabin, D. and Freuder, E. (1996). Configuration as compos-

ite constraint safisfaction. In Proceedings of the Artif-

ical Intelligence and Manufacturing Research Plan-

ning Workshop.

Sabin, D. and Weigel, R. (1998). Product configuration

framework - a survey. IEEE Intelligent Systems,

13(4):42–49.

Scholkopf, B. and Smola, A. (2002). Learning with Kernels.

MIT Press.

Svensson, C. (2001). A discussion of future challenges to

built to order smes. mass customization: A threat or

a challenge? In Proceedings of The Fourth SMESME

International Conference, Denmark.

Svensson, C. and Barfod, A. (2002). Limits and opportuni-

ties in mass customization for ”build to order” smes.

Computers in Industry, 49(1):77–89.

Tseng, H.-E., Chang, C.-C., and Chang, S.-H. (2005). Ap-

plying case-based reasoning for product configuration

in mass customization environments. Expert Systems

with Applications, 29:913–925.

Tseng, Mitchell M.and Jiao, J. (1998). Concurrent design

for mass customization. Academy of Management Re-

view, 4(1):10–24.

Xie, H., Henderson, P., and Kernahan, M. (2005). Modeling

and solving engineering product configuration prob-

lems by constraint satisfaction. International Journal

of Production Research, 43(20):4455–4469.

Xu, X., Chen, J.-Q., and Xie, S. (2006). Framework of a

product lifecycle costing system. Journal of Comput-

ing and Information Science in Engineering, 6:69–77.

AN INTELLIGENT INFORMATION SYSTEM FOR ENABLING PRODUCT MASS CUSTOMIZATION

321