OOPUS-DESIGNER

User-friendly Master Data Maintenance through Intuitive and Interactive

Visualization

Wilhelm Dangelmaier, Benjamin Klöpper, Björn Kruse, Daniel Brüggemann and Tobias Rust

Heinz Nixdorf Institute, University of Paderborn, Fürstenallee 11 Paderborn, Germany

Keywords: ERP, PPC, visualization, human computer interaction, master data.

Abstract: Valid and consistent master data are pre-requisite for efficient working Enterprise Resource Planning (ERP)

and Production Planning and Control (PPC) systems. Unfortunately users are often confused by a large

number of forms or transactions in these systems. Confusing interfaces lead to faulty master data. In this

paper we introduce a tool that provides intuitive and interactive visualization for the master data

administration of a PPC system.

1 INTRODUCTION

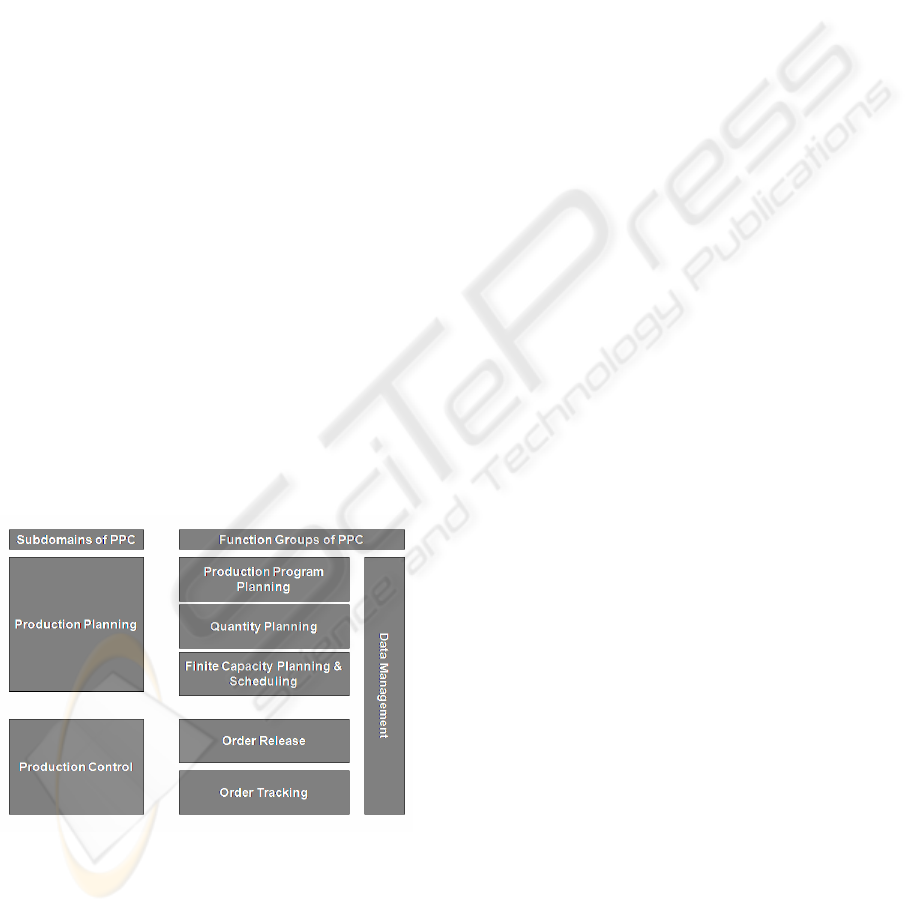

Production Planning and Control is a complex task

encompassing several function groups (Higgens et

al., 1996) as shown in Figure 1. Data Management is

a function group that is orthogonal to all other

function groups of PPC. Accuracy and efficiency of

the functions fulfillment depends directly on the

quality of data provided by the data management.

Figure 1: Production Planning and Control Tasks.

The problem of consistency management for mass

data is considered to be solved. Standard PPC and

ERP System (e.g. SAP ECC 5.0 and SAP APO

(Ball, 2006), SAGE (Wallace and Kremzar, 2001) or

Navision (Diffender and El-Assai, 2005)) solved this

problem and for individual implementations the

design techniques for databases offer precise

instructions for implementing redundancy free

databases (Connolly and Begg, 2001).

A problem that is rarely considered in the context of

PPC and ERP system is the question, how to support

the process of modelling a production system. In

(Dangelmaier et al., 2007) we introduced a

developed process for individualized PPC-Tools.

The development process is characterized by the

following steps:

1. Identify the dispatchers’ actual

requirements

2. Find the most suitable problem definitions

3. Define a flexible formal model

4. Transfer the model into a database scheme

5. Provide easy access to the database

We introduced a flexible formal model that

constitutes a connection between the requirements of

the dispatchers and formal problem definitions. The

model is called “Model for Serial Manufacturing”.

This paper introduces a tool that provides easy

access to the database of a PPC system called

OOPUS-WEB. The tool, named OOPUS-

DESIGNER adds contextual information through an

interactive visualization and is capable of modifying

the underlying data directly. OOPUS-DESIGNER

avoids the shortcomings of data administration in

form or transaction driven ERP or PPC systems.

Facing several forms or transactions, the user lacks

insight of the data he is currently entering.

294

Dangelmaier W., Klöpper B., Kruse B., Brüggemann D. and Rust T. (2007).

OOPUS-DESIGNER - User-friendly Master Data Maintenance through Intuitive and Interactive Visualization.

In Proceedings of the Ninth International Conference on Enterprise Information Systems - HCI, pages 294-297

DOI: 10.5220/0002380102940297

Copyright

c

SciTePress

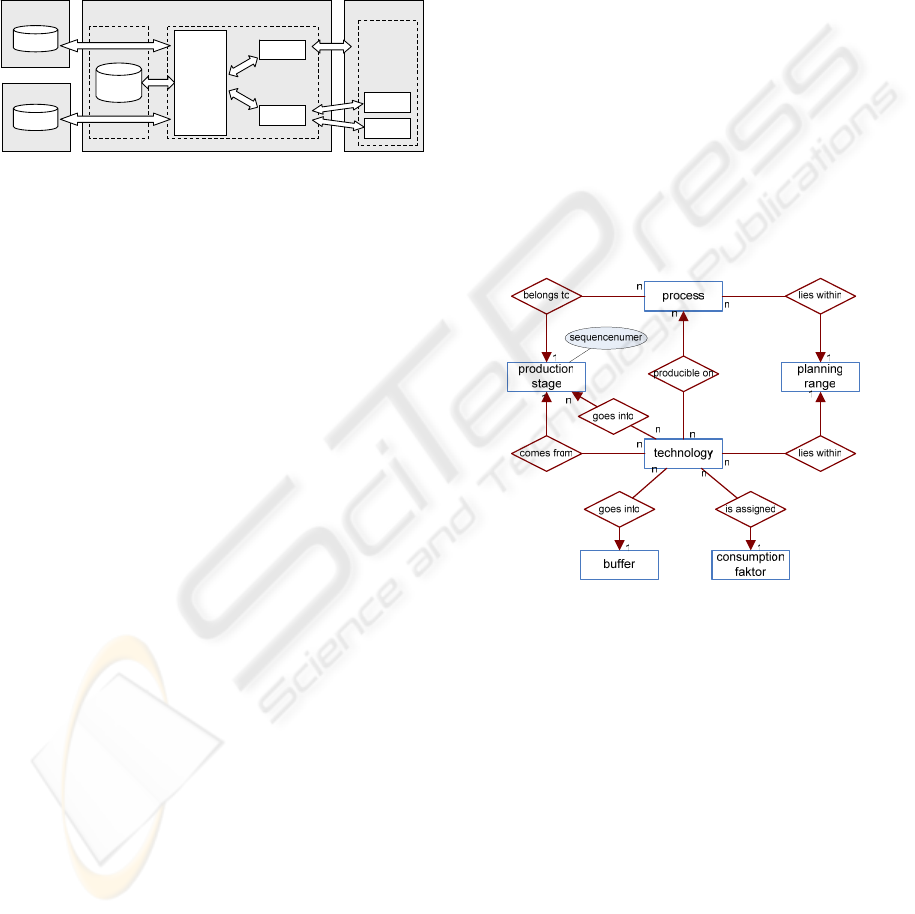

2 THE OOPUS-WEB SYSTEM

OOPUS-WEB is built in pure Java to achieve a great

flexibility. The architecture of OOPUS-WEB is

illustrated in figure 2. The architecture is designed

to provide hosting services for small companies,

which cannot effort expensive IT-systems and

maintenance.

Browser

Java Application Server

Server Client

Applets

Tapestry

database

Gantt

Hibernate

Servlet

Designer

database

ext. Server

ext. Server

database

Figure 2: Architecture of the OOPUS-WEB system.

Hibernate is an object/relational mapping tool for

Java environments. Object/relational mapping refers

to the automated persistence management of objects

in interaction with a relational database. Meta data,

describing a mapping between objects and database

tables, is used for the persistence management

(Bauer and King, 2005). Hibernate provides a great

flexibility to OOPUS-WEB. Due to the mapping

data, the same object oriented representation can be

used in combination with different database

definitions. Thus it becomes possible to integrate the

databases of companies – where available – easily

into OOPUS-WEB. For small companies with no

information systems at all, the standard

configuration provides a database on the web server.

OOPUS-DESIGNER is dedicated to this

configuration.

Tapestry was used to implement the user

interface. Tapestry is a component oriented

framework for creating dynamic, robust, highly

scalable web applications in Java. It is an extension

to servlet containers (such as Tomcat) or application

servers (like JBoss, WebSphere, or WebLogic)

(Ship, 2004). Tapestry provides a well structured

implementation of the established Model-View-

Controller (MVC) (Krasner and Pope, 1988)

paradigm for user interface, which makes the user

interface of OOPUS-WEB flexible and configurable.

There are additional software components, which

enhance the websites interactivity. For example a

Gantt chart component is used to visualize and

maintain the current planning status.

Figure 3 gives a snapshot of the entity

relationship diagram of the OOPUS-WEB data

model. Entities are shown as rectangles and

relationships between them as rhombi. The model

contains the following entities:

Production stages (PS) divide the real production

into separate steps. They have an attribute called

sequence number, which ensures the order of the

production stage

Processes (P) are the equivalent of real production

lines. A production stage must contain at least one

process

Planning ranges (PR) represent the grouping of

multiple processes, arranging them into logical

segments. Every process has to be assigned to

exactly one planning range

Consumption factors (CF) represent products and

intermediate products

Buffers (B) are representations of any object that

has buffering capabilities. They can temporarily

hold any consumption factor between two

production stages

Technologies (T) model the flow of material in

the production system

Figure 3: ERM showing the master data of OOPUS-WEB.

The central entity of this example is the technology

(T). Although the diagram shows technology as an

entity, technologies are no physical objects – they

are abstract representations of the materials’ (the

consumption factors) flow through the system.

Considering one technology t, there is exactly one

consumption factor cf assigned to it, as well as

exactly one buffer b, one planning range pr, one

production stage ps and at least one process p. Each

process p must be assigned to planning range pr and

production stage ps. Production stage ps is the

producing production stage of technology t (more

correct, producing consumption factor cf, since

technology is no physical entity). Finally, there is

any number of consuming production stages

OOPUS-DESIGNER - User-friendly Master Data Maintenance through Intuitive and Interactive Visualization

295

assigned to technology t. As the name suggest, they

consume the consumption factor.

3 PROBLEM STATEMENT

Data administration in OOPUS-WEB encompasses

two main tasks:

1. Modelling the structure of production systems

2. Enter and update material and material work

plans (represented by technologies)

The first task is performed infrequently. After the

initial modelling of the production system, there

may be changes in the production system (e.g. new

machines), which cause changes in the model of the

production system. There are a large number of

constraints, which have to be considered to create a

sound model of the production system. All

functionalities of OOPUS-WEB depend on a sound

model of the system, thus a flawless modelling is

important and should be supported by the system. To

provide up-to-date information to the planning

modules, the second task is performed frequently.

Both tasks – modelling the structure of production

systems and work plans as well as the flow of

material through a production system – have an

intuitive graphical representation. Graphical editors

are already successfully applied to the modelling of

workflows in ERP systems (Ryckayzen et al., 2002).

Nevertheless, most ERP and PPC systems do not

offer a proper interface for an intuitive fulfilment of

the tasks stressed in this section.

Every ERP/PPC system hast to meet a challenge:

clearly present vast data and maintain the data

consistency. Often it is not possible to present all

required information at once. This issue is usually

solved by splitting the interface over several forms

or transactions.

In general, users working with a system for a

long time know the meaning of each input field and

the restrictions for the input values. They use the

data intuitively and efficiently. But it took them a

specific time to get to this point – through learning

and gaining experience. New users do not have this

experience and need time and training to be able to

work with the system. They need even more time

and experience to use the system efficiently.

The context of entered data is easily lost, when

the inexperienced users have to switch frequently

between different forms or transactions. The missing

context leads to faulty entries and thus to an

inaccurate modelling of the production systems. This

problem becomes even more severe when large

amount of new data has to be entered.

4 THE VISUAL APPLICATION

This chapter describes OOPUS-DESIGNER. It

provides an intuitive representation for production

systems and material flows. The workflow of

modelling is no longer artificially split into parts.

Prefuse (Heer, 2004), a Java-based toolkit for

building interactive information visualization

applications, was used to implement the OOPUS-

DESIGNER. It is based on the information

visualization reference model, which has given proof

of its abilities in other graphical frameworks (Card

et al, 1999). Furthermore, prefuse support the

development of Java applets that can easily be

transferred and run on client computer browsers

(Heer et al, 2005).

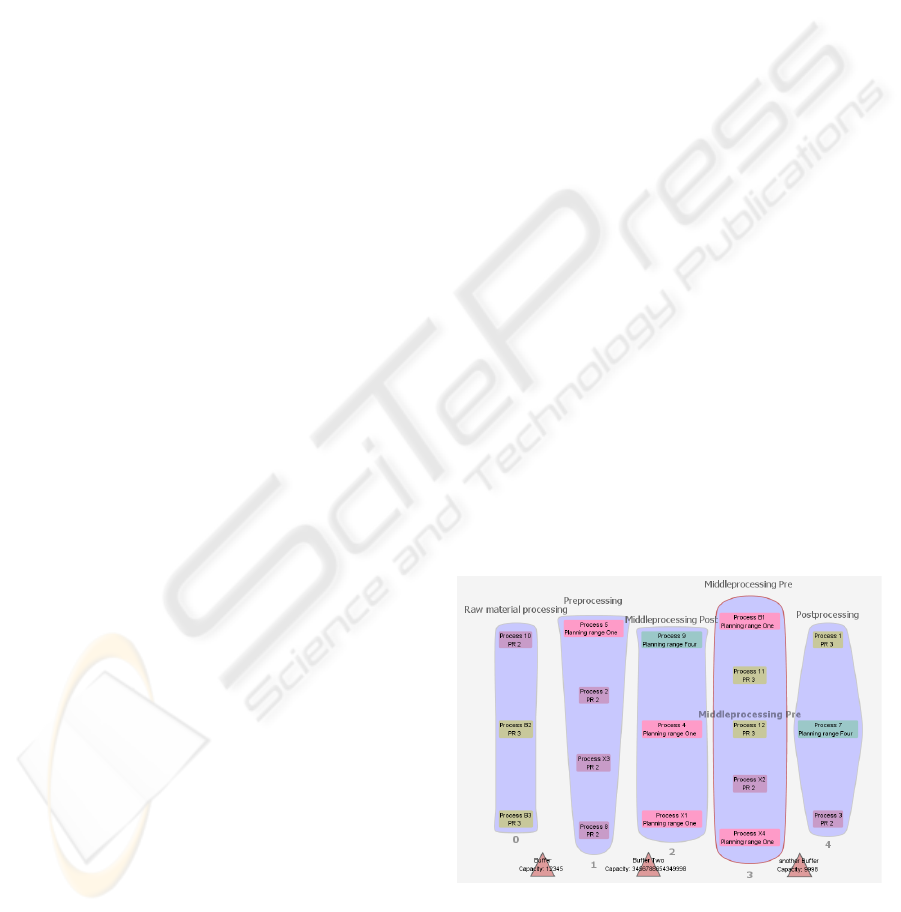

The visual elements are arranged as follows:

production stages are arranged horizontally,

according to their sequence number value. The

processes are aligned vertically within each

production stage and are shown as small rounded

rectangles. To visualize the planning ranges, each

process is coloured. Each colour represents a

planning range. The buffers are represented through

triangles. Figure 4 shows a screenshot.

The user can easily depict to which production

stage a process belongs and which processes belong

to the same planning range. The production stage

with sequence number 3 is currently under the

mouse pointer and thus highlighted. The displays is

freely zoomable and panable and the items provide

different kinds of interactivity, such as context

menus, mouse over effects or high-lighting

depending on the current state or selection.

Figure 4: Visualization of a production system by

OOPUS-DESIGNER.

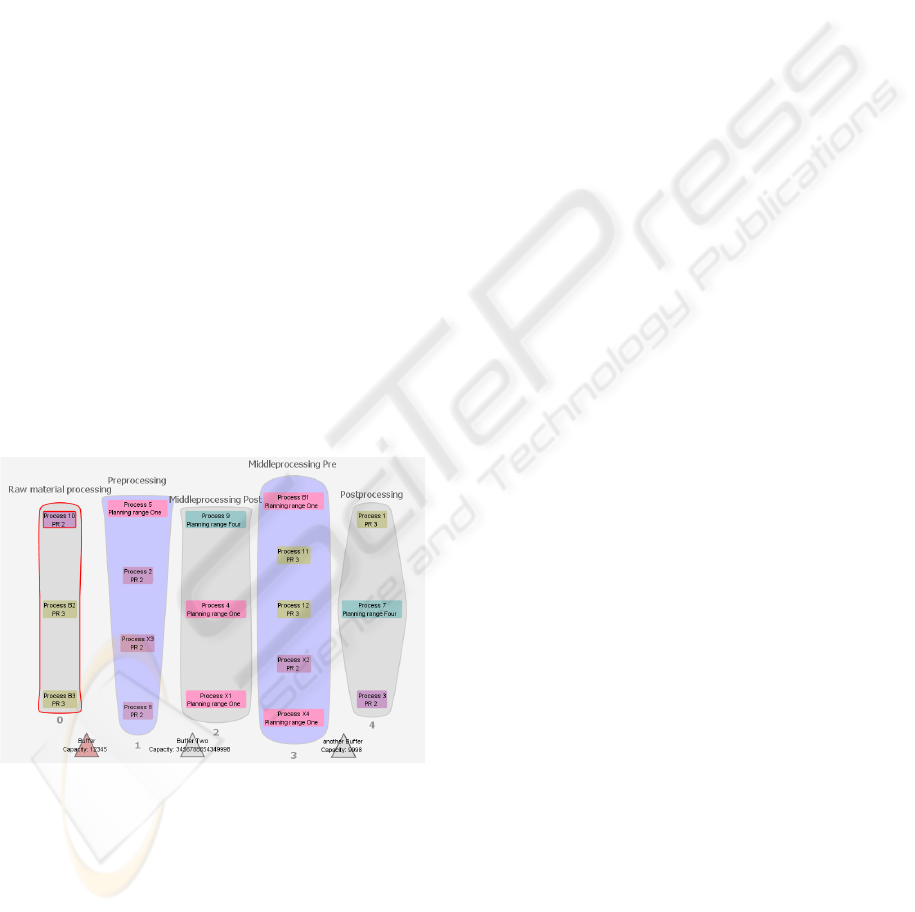

The usability of OOPUS-DESIGNER is

demonstrated on the example of entering a

ICEIS 2007 - International Conference on Enterprise Information Systems

296

technology: The process of creating a technology is

tedious, because the user has to enter vast data

considering dependency to existing data. In form or

transaction driven systems, the user picks an entity

from large data sets with hundreds of entries. The

user is responsible to define reasonable filter criteria

for the data sets. In OOPUS-DESIGNER, the user

can simply click on the desired objects to create the

relationship. Figure 5 shows the display while a user

is assigning objects to a technology. The non-

applicable objects are greyed out, as this is a

common way to show that they’re currently not

interactive or selectable. The objects surrounded by

a red line have already been selected.

Attributes of relationships or corresponding

objects can be entered in a properties panel which is

placed besides the display. Furthermore, the

interface supports use of a text editor to facilitate

direct editing of text. Hence the user is able to

modify any item attributes directly, without the need

to move his attention away from the object. In the

OOPUS-DESIGNER this feature is used to edit the

most common attributes for an item. This approach

ensures that the context is preserved, regardless of

the actual working progress of the user. In fact,

additional information or tasks can be arranged

around the main display. Thus, the user can

individually arrange the interface in such a way, that

all required information are avaible at one glance.

Figure 5: OOPUS-DESIGNER greys out non-applicable

items.

5 CONCLUSION

In this paper OOPUS-DESIGNER was introduced.

This application introduces a new user friendly

method of master data management to ERP and

PPC-Systems. Since the functionality of these

systems relies on valid master data, the avoidance of

faulty entries is an important task. OOPUS-

DESIGNER answers these challenges with an

intuitive representation of the master data and

relations between data sets. Since the process of

modelling and data input is not split into parts, an

extensive data validation becomes possible.

Therefore the concept behind OOPUS-DESIGNER

can help improve the utility of ERP and PPC

systems and shorten periods of vocational

adjustment for new users.

REFERENCES

Higgins, P., Le Roy, P., TIerney, L; 1996; Manufacturing

Planning and Control: Beyond MRP II. Springer

Verlag, Berlin, Heidelberg, New York

Balla, J.;2006; Production Planning with SAP APO-

PP/DS, SAP PRESS

Wallace, T.F., Kremzar, M.H.;2001; ERP:Making It

Happen: The Implementers’ Guide to to Success with

Enterprise Resource Planning, Wiley & Son,

Chichester

Diffenderfer, P.M., El-Assai, S.; 2005; Microsoft Navision

4.0: Jump Start to Optimisation, GWV-Vieweg,

Wiesbaden

Connolly, T.M. C. Begg, C.; 2001; Database Systems: A

Practical Approach to Design, Implementation, and

Management, Addison-Wesley, Boston

Dangelmaier, W., Klöpper, B., Timm, T. Brüggemann, D.;

A Modelling Approach for Dynamic and Complex

Capacities in Production Control Systems, BIS 2007,

Lecture Notes of Computer Science 4439, pp. 626-

637, Springer Verlag, Berlin, Heidelberg

Bauer, Christian; King, Gavin; 2005; Hibernate in Action

– A guide to concepts and practice of object/relational

mapping; Manning; Greenwich

Ship, Howard M. Lewis; 2004; Tapestry in Action – The

definitive guide to web application development with

Tapestry; Manning; Greenwich

Krasner, Glenn E.; Pope, Stephen T.; 1988; A cookbook

for using the model-vew controller interface paradigm

in Smalltalk-80; In: Journal of Object-Oriented

Programming, Volume 1 (3)

Heer, Jeffrey; 2004; prefuse: a software framework for

interactive information visualization; University of

California, Berkeley; 2004

Rickayzen, Allen; Dart; Jocelyn, Brennecke, Carsten;

Schneider, Markus ; 2002; Practical Workflow for

SAP - Effective Business Processes using SAP's

WebFlow Engine; Galileo Press; Bonn

Card, Stuart K.; Mackinlay, Jock D.; Shneiderman, Ben;

1999; Readings in Information Visualization: Using

Vision to Think; Morgan Kaufmann ; San Francisco

Heer, Jeffrey; Card, Stuart K.; Landay, James A.; 2005;

prefuse: toolkit for interactive information

visualization; CHI 2005

OOPUS-DESIGNER - User-friendly Master Data Maintenance through Intuitive and Interactive Visualization

297