TOWARDS ENTERPRISE APPLICATIONS USING

WIRELESS SENSOR NETWORKS

Stamatis Karnouskos and Patrik Spiess

SAP Research, Vincenz-Priessnitz-Strasse 1, D-76131 Karlsruhe, Germany

Keywords: Wireless sensor networks, service-oriented architecture, enterprise services.

Abstract: Wireless Sensor Networks (WSN) have become a hot issue in research, and significant progress has been

achieved in the past few years. Recently, the topic has gained lot of momentum and has become increas-

ingly attractive for industry paving the way for new applications of sensor networks which go well beyond

traditional sensor applications. Sensor Networks is seen as one of the most promising technologies that will

bridge the physical and virtual worlds enabling them to interact. Expectations go beyond the research vi-

sions, towards deployment in real-world applications that would empower business processes and future

business cases. In this paper we look at WSNs from the business software perspective, including business

model, service-oriented architecture, integration with enterprise software systems as well as benefits and

lessons learned. As an example use-case we demonstrate the use of WSNs for hazardous goods management

in the chemical industry. Finally, based on our experiences we depict some directions that can be followed

in order to pave the road to real business applications for WSNs.

1 INTRODUCTION

A “smart item” is a device that is able to provide

data about itself or the object it is associated with

and can communicate this information to other

devices. An example of an enhanced smart item is

an environmental sensor that provides a complete

picture of a tracked object and its physical

environment. Through automatic, real-time object

tracking, smart-item technology can provide

accurate data about business operations in a timely

fashion, as well as help streamline and automate

operations. However, bridging the gap between the

physical and digital worlds requires a flexible and

scalable system architecture to integrate automatic

data acquisition with existing business processes and

to make ubiquitous computing a reality.

Wireless Sensor Networks (WSN) constitute

communities of advanced smart items and although

visions have been laid out and significant progress

has been done in the research domain (theory,

algorithms, protocols, implementations, trials etc.), a

vast number of questions still remains to be

answered: what steps need to be taken so that this

technology will not remain forever at the labs and

that it will be more than just hi-tech toys for

scientists? How can a wide economic and positive

social impact be achieved? Where are the markets?

Which will be the major drivers? How will we

progress towards a successful, secure, and open

infrastructure?

Taking into account the above challenges, our

motivation comes from real-world enterprise needs.

Our aim is to develop a novel service-oriented

approach to support business processes that involve

physical entities (goods, tools, etc.) in large-scale

enterprise environments. Software systems that

provide various services for the enterprise are

usually based on highly decentralized, manual and

thus often error-prone data collection. On the other

hand, data storage and business logic execution is

performed centrally in so called “back-end” systems.

An important intention is to apply recent advances in

the area of sensor networks, in order to distribute

not only data gathering tasks but also business logic

functionality to “smart” physical entities. In this

way, the status of enterprises, as it is represented in

business processes and in the supporting enterprise

software systems, can reflect more closely what is

actually happening in the real world.

It is state of the art to augment physical entities

in enterprise environments with embedded

230

Karnouskos S. and Spiess P. (2007).

TOWARDS ENTERPRISE APPLICATIONS USING WIRELESS SENSOR NETWORKS.

In Proceedings of the Ninth International Conference on Enterprise Information Systems - ISAS, pages 230-236

DOI: 10.5220/0002389702300236

Copyright

c

SciTePress

technology to build automated item identification

and tracking systems. These systems can support

different processes related, for instance, to supply

chain management in intra- and/or inter-enterprise

business scenarios. Real world objects with sensors

attached reveal their identity or other dynamic/static

data for a communicating entity, e.g. another sensor.

Information gained that way can be basically used to

monitor the execution of business process tasks that

are implemented by back-end systems. In the CoBIs

project (www.cobis-online.de) our research focuses

on the development and the integrated application-

driven usage of so-called ‘Collaborative Business

Items’ (short CoBIs) that utilize a wide spectrum of

sensor networks technology.

Our vision is to delegate well-defined parts of

business logic functionality, i.e. process execution

from resource intensive back-end systems to

relatively low cost networked embedded systems

that run “at the point of activity”. These tiny systems

in our case build on sensor network technology that

enables them building collaborating ‘teams’ to work

together for a certain business relevant result

(Strohbach et al., 2004). The approach to handle

certain situations locally can lead to reduced process

execution and transactional costs, to improved

response times in business- and/or safety-critical

situations, and also to enhanced quality of process

results within a given operational environment. In

addition to improvements on existing business

processes, there is also a chance to identify new

business cases and develop corresponding useful

services based on this technology (Decker et al.,

2006). From a more technical point of view, flexible

handling of distributed process based on services

that run on CoBIs nodes can help saving back-end

systems’ resources, such as CPU-time, memory,

network bandwidth, etc., and can thus lead to

enhanced reliability, responsiveness and scalability

of the overall system.

2 BUSINESS MODEL

If WSNs are to be an integral part of commercial

applications, it is expected that the different compo-

nents that constitute a WSN infrastructure will be

driven by key players in that domain. Figure 1

depicts on the left side the service-oriented architec-

ture we used in CoBIs and on the right side a general

abstract model of the parties involved in the design,

implementation, deployment, and operation of such

an application. The business model depicted is

general enough and several other WSN approaches

can also be mapped to it.

Figure 1: Architecture and Business Model.

In detail, the following roles have been identified:

Consumer (C): The end-user of the services

offered by the Business Service Provider. The

Consumer can be located at the edge of the ser-

vice infrastructure (and be a classical end user)

or it may be an application or other service, a

service management system etc.

Business Service Provider (BSP): Composes

services delivered by various Sensor Network

Service Providers and Service Component Pro-

viders, and offers the resulting service to the

Consumers. A BSP may federate with other

BSPs in order to build services that are more

complex.

Sensor Network Service Provider (SNSP):

Provides sensor network based services. It of-

fers facilities for the deployment and operation

of the respective code into the sensor network

and provides possibly generic services that run

in the sensor network nodes.

Service Component Provider (SCP): Builds

service components and offers them (usually to

SNSP or BSP) in the appropriate form (e.g., as

binary or as source code). These components

usually run on middleware platforms delivered

by Middleware Providers.

Middleware Provider (MP): Provides specia-

lized middleware platforms that integrate sensor

network based services

Sensor Infrastructure Provider (SIP):

Provides managed sensor network infrastructure

and resources (bandwidth, memory, and proc-

essing power) to SNSPs. It offers a sensor

network platform over which services from

SNSP can be deployed. How a SIP offers the

underlying infrastructure depends on the ser-

vice-level-agreements (SLA) it has with the

respective partners.

Hardware Software Provider (HSP): Sup-

plies the software to realize the basic general

Service Injector

SMART ITEMS

MODEL-DRIVEN APPLICATION

DEVELOPMENT

Application Model

Middleware

Service

Repository

System Model

System Monitor

Development

Tools

Service Mapper

Deployment

Description

RFID

Embedded

Platform

Sensor

Network

Emerging

Technology

Hardware Provider

Hardware Provider

Hardware Software Provider

Hardware Software Provider

Middleware

Provider

Middleware

Provider

Consumer

Consumer

Sensor Infrastructure Provider

Sensor Infrastructure Provider

Business Service Provider

Business Service Provider

Sensor

Network

Service

Provider

Sensor

Network

Service

Provider

Service

Component

Provider

Service

Component

Provider

TOWARDS ENTERPRISE APPLICATIONS USING WIRELESS SENSOR NETWORKS

231

execution environment capabilities including

tools for executing code in the sensor nodes is

provided by the HSP. It is usual nowadays that

the Hardware Provider also slips in this role.

This might not be always the case in the future

for commoditized hardware.

Hardware Provider (HP): Manufactures the

hardware components of the sensor nodes e.g.

Motes, Particles, μ-Nodes etc.

It is still very early to clearly see such a model in

the market. Current market players at the moment

deliver almost all of the services depicted above,

trying to serve one-stop, turn-key solutions. How-

ever as the market matures it is expected that in the

mid-term the above roles will gradually be separated

and different players will compete at each level.

3 Service-Oriented ApproachesEnterprises are

moving towards service-oriented infrastructures.

Applications and business processes are modeled on

top of and using an institution-wide or even cross-

institutional service landscape. For any WSN

solution to be easily integrated in this environment,

it must feature a service-based approach. The overall

system architecture of the CoBIs project involves a

service-oriented architecture (Anke et al., 2006),

dividing the functionality of supported business

applications into different classes of services. The

core services include the basic, enabling capabilities

of a typical node, such as processing, storage,

sensing, actuating and communication. The base

services constitute primary functionality, mainly

focused on exchanging information within the

network reliably and efficiently. By combining base

services, more sophisticated ones can be realized.

Similar to the core services, the base services are

generally platform dependent. In order to describe

these services we have developed a service descrip-

tion language that we refer to as CoBIs Language

(CoBIL). CoBIL documents are created and edited

by service developers when they develop or com-

pose a new service. A CoBIL document will be used

to describe exactly one service. Typically, the

service description will be stored together with the

corresponding service executable(s) in the CoBIs

Service Repository.

The general architecture is depicted in the left

part of Figure 1. We can clearly distinguish three

different levels. At the bottom there are the smart

items such as the sensor networks or similar

systems. A middleware level couples them with the

services offered by enterprise systems. The platform

abstraction layer developed in this provides the

enabling technology to access all CoBIs services in a

uniform manner. It describes an open architecture

providing a service-oriented interface to the business

logic that can be adapted to different business

standards. At the same time it provides means to

integrate sensor node communication by supporting

web service proxies for services integrated on CoBIs

nodes. Therefore it constitutes a middleware layer,

which is commonly transparent for both the business

application and the underlying WSN systems. It

even allows the direct use of WSN services in

executable business process descriptions like the

Business Process Execution Language (BPEL).

The applications or business processes using the

WSN systems are based on several services running

either on the back-end enterprise system or on the

nodes themselves. This is one of the strong points of

service-oriented architecture: new services can now

be composed using generic ones as modular building

blocks. Collaboration among sensor nodes should

provide a number of substantial benefits over the

existing centralized schemes:

Efficiency and low cost. The sensed data will be

processed within the network, communicating

only the relevant information among each other

and to the enterprise system. This only requires

modest communication bandwidth, and low en-

ergy needs.

Scalability. Sensor data is processed locally

within the network, and those computations (if

designed accordingly) are dependent only on other

nodes nearby. Adding more nodes to the network

will not degrade the performance, since additional

processing is made available besides the increase

of sensor data. Local processing also avoids a

bandwidth bottleneck between sensor network and

back-end that would occur if all data was proc-

essed centrally.

Fault tolerance and reliability. Nodes in the

network are in contact with each other processing

each others data and cross-verifying each other’s

results. Incorrect data samples or results will be

noticed by other nodes, and corrected if possible.

Therefore, we can avoid having a single point of

failure.

Autonomous systems. Nodes are almost com-

pletely autonomous and require hardly any

Figure 2: Management of Hazardous Goods.

CoBIs Nodes

Enterprise Portal

Enterprise Portal

Hazardous Goods

Management System

Hazardous Goods

Management System

Environment, Health

and Safety System

Environment, Health

and Safety System

Web Browser

iView

ICEIS 2007 - International Conference on Enterprise Information Systems

232

infrastructure. No cables are needed, no installa-

tion and maintenance activity. Each node can act

autonomously or in cooperation with others based

on its internal goals.

Enhanced accuracy. Through local cooperation,

sensor nodes can collect data more accurately.

These data can also be communicating with

neighboring nodes and deviations or errors are

easy to be pinpointed and corrected.

Local intelligence: The decisions that need to be

made locally are needed for a multitude of rea-

sons. On the one hand, in order to provide

business logic, the nodes are to make decisions

and conversions on the information they gather.

On the other hand, in order to efficiently provide

the requested functionality, nodes need to share

information with each other. This has a tremen-

dous effect on an enterprise system since now the

intelligence does not rely on a central point but

can be distributed in the infrastructure and in

places that is really needed.

4 USE-CASE: HAZARDOUS

GOODS MANAGEMENT

Taking into account the business model and the

trends in modern enterprise systems, our motivation

was to apply WSN concepts to real world problems.

In that sense we have identified the management of

hazardous goods (Kubach et al., 2004) as a common

problem in the chemical industry. Human error

during storage and transportation of such substances

can have fatal consequences for the working

personnel as well as long-lasting effects on the

environment, not to mention the financial issues.

Although several paper-based risk management

procedures exist, all of them rely mostly on label-

ling, inventory and the worker’s experience.

However by using wireless sensor networks, we can

offer a more active and fine-grained approach. Such

a solution can provide in real time services like

conflict detection and warn the personnel about

possible safety dangers would be indispensable.

We have equipped a set of drums containing

different chemicals with wireless sensors (Particles)

and set-up the necessary infrastructure for commu-

nication with a back-end system, allowing for

remote monitoring and configuration. The back-end

system is SAP's Environment, Health and Safety

Application (EH&S), a standard enterprise applica-

tion for managing hazardous goods installed and

used by several chemical companies worldwide. The

data stored in the EH&S incorporates safety-relevant

substance information, such as chemical features,

handling and storage constraints for compliance with

international or corporate standards, etc. The sensor

nodes attached to the drums can communicate both

peer-to-peer and via a Platform Gateway with the

SAP EH&S. As this communication is real-time, we

are able to have a real-time model of the warehouse

status in the back-end IT systems.

In this way, Smart Drums act autonomously.

When the storage regulations are changed in SAP

EH&S, the new rules are automatically pushed to all

warehouses and all sensor nodes in the company. All

nodes that are currently not connected to fixed

infrastructure (e.g. during transportation) are

updated as they reconnect. We focused in the

following use-cases:

Ensure that only a safe volume limit of a sub-

stance is stored in a storage location

Prevent storage of incompatible chemicals in the

same storage location or at non-safe distance

Prevent storage of chemicals in unsuitable storage

areas

In case of a violation of the above rules, alert

warehouse staff and offer advice on how to re-

solve the situation

Automatic suggestion of safe storage location for

each new drum arriving at a warehouse

Within this context, Smart Drums are able to

respond to dynamically changing context conditions.

Such changes can occur in their local environment,

but can also be caused by administrative changes

within the EH&S system. An overview of the system

prototype used in this lab trial is depicted in Fig-

ure 2. We can distinguish:

Web Browser: the user connects via the browser

to the Enterprise Portal.

Enterprise Portal (EP): The main entry point to

the CoBIs infrastructure for users. This SAP

product gives the user access to all the informa-

tion needed based on the role that has been

assigned to him/her. The prototype development

included the production of CoBIs-specific so

called iViews and the building blocks for the

portal’s role-based user interface.

Hazardous Goods Management System (HGM):

This is an application developed in Apache’s

Tomcat that is used for managing hazardous

goods, e.g. like a simple warehouse management

system.

Environment Health and Safety System (EH&S):

This is a standard SAP product. Via EH&S rules

for handling and storage of hazardous goods

including storage limit and incompatibilities are

managed for each substance.

CoBIs Nodes: these are the infrastructure nodes

where CoBIs services are running on. For this

trial, we used Particle nodes.

The HGM portal monitors the warehouse status

based on the information sent by the particles nodes

attached to the drums. The hazardous goods business

TOWARDS ENTERPRISE APPLICATIONS USING WIRELESS SENSOR NETWORKS

233

Figure 3: Management GUI.

service that runs on the items continuously checks

whether the current storage conditions are compliant

with the storage rules defined in the EH&S system.

If the storage limit of one type of chemical is

modified in the EH&S system (e.g. because of

changes in official or corporate policies) this is

propagated to the particles, who store the new value

and start to verify the rules based on the new data.

The bridges located in the warehouse periodically

(with a moderate period) broadcast the current

storage limit for each chemical. This ensures that

even drums that have been out of communication

range, e.g. during transport on a truck, receive the

updated regulations as soon as they are stored in the

warehouse. Instead of using periodic rule broadcasts,

a more advanced, energy-aware protocol could be

used to disseminate rule changes.

A system management console, allows for a

uniform way of managing the CoBIs nodes. It

provides an abstraction layer for management

related tasks that hides the heterogeneity in nodes

and their services, by providing a common manage-

ment GUI. A monitoring tab provides real-time

information about the CoBIs network. As we can see

in Figure 3, the underlying network topology is

depicted. One can select a platform via the respec-

tive tabs e.g. the platform of Sindrion (Gsottberger

et al., 2004) nodes, Particle nodes (Decker et al.,

2005) or μNodes. By moving the mouse pointer over

the respective node, the user is able to acquire info

about that specific node according to the available

services e.g. battery, CPU, free memory, location,

temperature, light, acceleration, and field strength.

When a node is selected, additional info about the

node available in the Monitoring Service (if de-

ployed) is displayed, such as a complete list of

services running on the node etc.

Within our infrastructure, the sensor nodes detect

possibly dangerous situations, and inform workers

and warehouse managers via alarms. Having

business logic directly on the items allows for a

quick detection of any dangerous situation, even if

there is no network connection. Such properties

were requested by corporate end-users like BP who

want to prevent accidents on drilling platforms in the

North Sea, where a network link is not always

available. This approach also makes the complete

system more scalable, since decisions can be taken

locally, at the point of activity and the back-end is

only subsequently informed about the decision-

result. The business logic is encapsulated in services

that can be deployed to the nodes. The use of

service-oriented architecture (SOA) makes the

management of such complex systems more

responsive and brings it closer to real-world situa-

tion where they can be applied.

The direct business benefits of using WSNs as

illustrated by this trial are:

Automatic compliance with legal or corporate

regulations concerning the storage of hazardous

goods

Warning of security and management staff about

potentially dangerous situations

Increased efficiency / safety of handling by

suggesting a safe storage location for each new

drum arriving in the warehouse and advice for

resolution of alert situations

Introduction of smartness within the on-site items

increasing reliability, scalability, and autonomy of

the approach

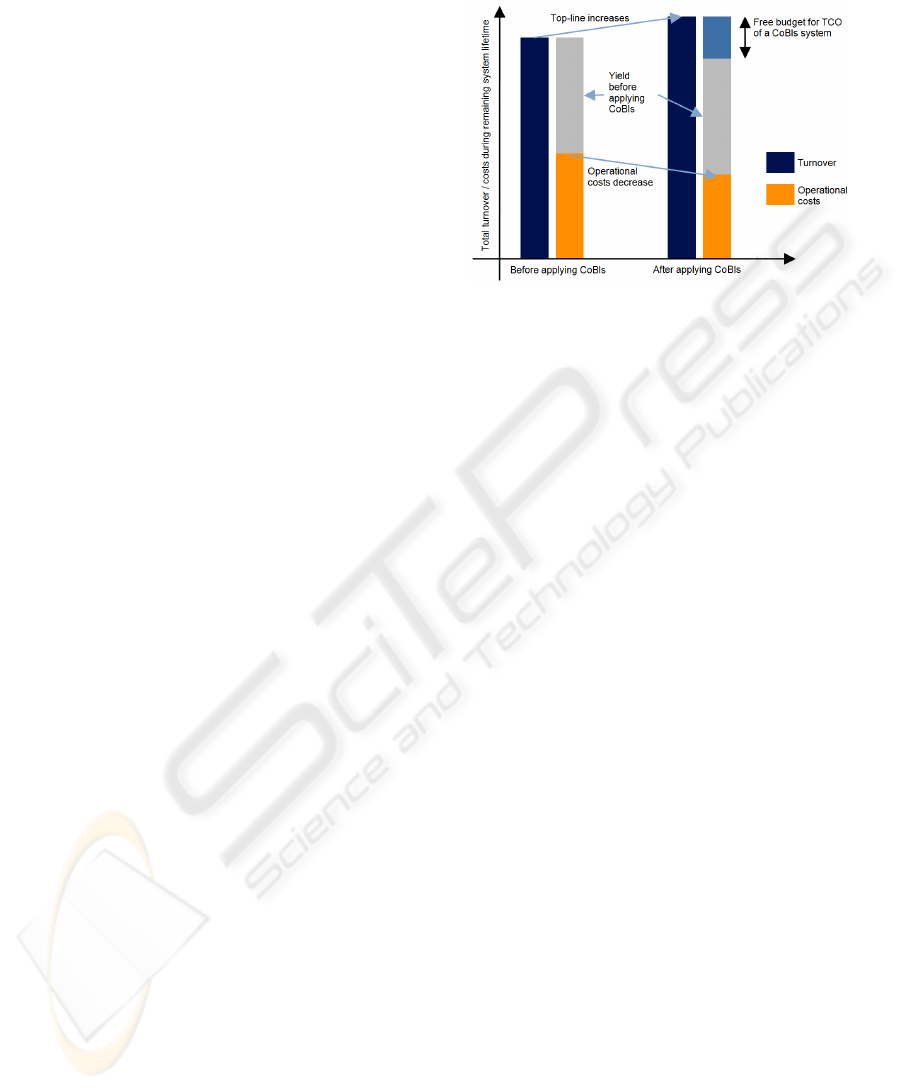

5 THE PERSPECTIVE OF WSN

IN ENTERPRISE SERVICES

A CoBIs system, just like any other wireless sensor

or ubiquitous system will not be set up and run for

the sake of its own. It is designed to support a

business process by either providing real time data,

executing business logic on the items, or providing

decisions for the further process flow. WSNs or

ubiquitous systems will only be deployed in the

future, if the costs for setting up and maintaining it

are less than the costs that are saved (bottom-line

growth) plus the additional top-line revenue that is

generated. This fact is depicted in Figure 4.

The technology will lead to increased turnover

(because of higher process efficiency or quality or

reduced loss) and / or lower operational costs

(because of increased automation). Both effects

increase the yield. That increase caused by CoBIs

sets the upper boundary for additional money a

company would be willing to invest into the new

technology. Of course, some properties like in-

creased workplace safety or faster time to market do

not easily fit into that scheme. However, one can try

ICEIS 2007 - International Conference on Enterprise Information Systems

234

Figure 4: Budget for installing and maintaining a SOA

WSN solution e.g. CoBIs.

to monetarize these benefits over the whole system

lifetime and treat them as saved costs.

When a company sets up a CoBIs network to

increase efficiency of its current business processes,

the dominant share of costs will not be hardware

costs (since it is expected to become very cheap in

the future) but the development of embedded

software for the embedded processors and secondary

components as well as for the integration logic to

integrate the sensors into the current enterprise

systems. The CoBIs framework already covers many

aspects of device integration like platform abstrac-

tion so that application developers can deploy their

services in a WSN-agnostic way i.e. without writing

WSN-platform specific code etc. However, it must

be ensured that the costs for the remaining develop-

ment that is needed to deploy supported hardware in

a scenario are minimal.

Having analyzed, designed, implemented and

trialed a WSN based enterprise service, we have

often come to conflicts between market needs and

technology, and we have identified some directions

which we think need to be successfully tackled

before WSNs empower future enterprise services.

Some key results include:

The concept of collaborative smart items that can

execute business logic is worthwhile and truly

innovative solutions for real world needs can be

realized. For SMEs there is room to invent and

innovate at hardware and software level. The

industry is making some attempts to test the new

technology, however most of the projects remain

simple trials and no wide-spread real-world com-

mercial platform/solution exists; something that is

however understandable taking into consideration

the challenges that remain to be solved.

As we move towards the “Internet of Things”, the

CoBIs approach represents a sophisticated imple-

mentation of it. The things are not passive objects

of sensors and actuators, but actually can host

intelligence and take part in collaborative scenar-

ios. The idea of distributing logic within the

network (back-end-gateway-nodes) and not only

at end-nodes enables the implementation of a fine-

grained open service infrastructure and is a prom-

ising approach that may effectively deal with

robustness, scalability, adaptability and interop-

erability.

Openness of the infrastructure should be the

focus. We need to agree on common, open, exten-

sible interfaces at different levels, so that the

underlying parts can evolve independently. This

should be invisible to upper layers which only see

a common web-service enabled interface to any

sensor network platform. In that case we can

expect innovation at all levels in parallel and

better integration of the whole infrastructure.

The WSN market and its economic prospects are

not clear to the wide public contrary to simple

forms like RFID tags. There is still a lot of “hype”

in the community and WSNs are still seen by

many commercial companies at the moment as

toys for scientists rather than real business oppor-

tunities. However, this might change in the mid-

/long- term especially if real world scenarios are

demonstrated successfully. For the last to happen,

the research community should not try to simply

tackle general problems in WSNs, but primarily

focus on real-world industrial problems and take

into account their requirements. In other words,

the solutions developed by the WSN community

should be built to satisfy real-world requirements

rather than building solutions first and trying to

identify problems later. We do not foresee a “one-

size-fits-all” WSN platform, but rather clusters

solving domain-dependent problems.

Regulators and policy makers have to be consid-

ered more intensively in the WSN community

since at this early stage they provide guidelines

for interoperability, consumer protection. Adher-

ence to standards could be is still rather the

exception and not the rule and can still be a strong

value proposition. The impact of wide-spread

WSNs on traditional regulated infrastructure has

to be assessed. For instance issues like roaming,

billing, network access, radio spectrum manage-

ment etc will probably arise.

Security, trust and privacy needs to be investi-

gated. CoBIs assumes a closed infrastructure and

at the moment the trials were conducted simply to

prove the concept. However if similar scenarios

are to be commercialized, a solution to the secu-

rity related challenges needs to be found.

TOWARDS ENTERPRISE APPLICATIONS USING WIRELESS SENSOR NETWORKS

235

New tools that help with (also wireless) mass-

deployment of services as well as with design of

models and business process adaptation for WSN

based infrastructures need to be developed. WSN

networks are expected to be too complex and

therefore abstraction layers and tools to manage

this complexity are needed at several levels.

One new class of tools could analyze business

processes, expressed e.g. in BPEL that make use

of sensor network services and automatically

identify sub-processes that can be processed

autonomously by the WSN. The sensor network

could be augmented with execution capabilities

for efficiently encoded business process descrip-

tions.

The hardware used needs to be reduced in size,

cost and energy consumption, increased in com-

puting power and able to act reliably. This is

expected to be solved in the mid- / long-term.

Both industry and academia should work towards

developing appropriate business models, stan-

dards for several levels in WSNs, and tackle the

security issues. Integration of the semantic web

and a service based infrastructure (as followed by

CoBIs) provide a really promising approach.

The WiSeNts Research roadmap (Marron et al.,

2006) provides an excellent source for a more

general view of the challenges, trends and roadmap

for WSNs.

CONCLUSIONS

We have presented our opinions and experiences

from the design, analysis and realization of a WSN

based service solution for the management of

hazardous goods. We have investigated from the

business perspective focusing on aspects such as

service-oriented architecture, better support for

business processes etc and laid out the motivation

behind our decisions. We have also presented a

business model for WSNs while in parallel we have

provided some directions that from the business

perspective need to be tackled if WSN technology

should transform from a mere toy for scientists to a

powerful tool, enabling real-world business applica-

tions. There is still a long way to go, however initial

efforts are promising and we expect that the whole

area will be radically reshaped within the next years.

REFERENCES

Anke, J., Müller, J., Spiess, P., Weiss Ferreira Chaves, L.,

2006. A Service-Oriented Middleware for Integration

and Management of Heterogeneous Smart Items Envi-

ronments, proceedings of the 4th MiNEMA workshop

in Sintra, July 2006.

Decker, C., Krohn, A., Beigl, M., Zimmer, T., 2005. The

Particle Computer System, IPSN Track on Sensor

Platform, Tools and Design Methods for Networked

Embedded Systems (SPOTS), Proceedings of the

ACM/IEEE Fourth International Conference on In-

formation Processing in Sensor Networks (IPSN05),

pp 443-448, Los Angeles, 25-27 April 2005.

Decker, C., Spiess, P., Moreira sa de Souza, L., Beigl, M.,

Nochta, Z. 2006. Coupling Enterprise Systems with

Wireless Sensor Nodes: Analysis, Implementation,

Experiences and Guidelines, Pervasive Technology

Applied @ PERVASIVE, May 7, 2006.

Gsottberger, Y.; Shi, X.; Stromberg, G.; Weber, W.;

Sturm, T.F.; Linde, H.; Naroska, E.; Schramm, P.,

2004. Sindrion: A Prototype System for Low-Power

Wireless Control Networks. IEEE Conf. on Mobile Ad

hoc and Sensor Systems, 25-27 Oct. 2004.

Kubach, U., Decker, C., Douglas, K. 2004. Collaborative

control and coordination of hazardous chemicals,

Proceedings of the 2

nd

international conference on

Embedded networked sensor systems 2004 (SenSys

2004), Baltimore, MD, USA, November 03 - 05, 2004.

Marron, P.J., Minder, D., 2006. Embedded WiSeNTs

Research Roadmap, Logos Verlag Berlin, ISBN: 3-

8325-1424-4, www.embedded-wisents.org

Spiess, P., Vogt, H., Jütting, H. 2006. Integrating Sensor

Networks with Business Processes, Real-World Sen-

sor Networks Workshop at ACM MobiSys, Uppsala,

Sweden, June 19, 2006.

Strohbach, M., Gellersen, H., Kortuem, G., Kray, C. 2004.

Cooperative Artefacts: Assessing Real World Situa-

tions with Embedded Technology, Proceedings of the

6th International Conference on Ubiquitous Comput-

ing, Nottingham, UK, September 7-10, 2004.

ICEIS 2007 - International Conference on Enterprise Information Systems

236