A Multi Agent Decision Support System for Real Time

Scheduling

N. Taghezout

1

and P. Zarate

2

1

Computer Science Department, University of Es-Senia Oran,

BP 1524, El-M' Naouer, 31000, Oran, Algeria

2

IRIT – INPT – ENSIACET, 118 route de Narbonne 31062 Toulouse Cedex 9, France

Abstract. The environment of firms and market requirements necessitates a

performance increased by the product flux management in the course of their

manufacture. This management plays a certain number of functions among

which the scheduling of workshop is taking more and more importance. This

article presents an approach which takes into account robustness and flexibility

of a real time scheduling, by defining and undertaking an interactive decision

support system. We develop a structure of piloting and supervising of distrib-

uted and integrated, as well as reactive workshop. Independent modules of pi-

loting in the latter allow organizing resource tasks and adapting generated plans

according to disturbances. As support to modelling and decisional system im-

plantation, we propose a multi-agent system. The agent actions of the same hi-

erarchical level become concrete across the analysis and reaction procedures.

The decision centres negotiate compromises to solve conflicts, under the con-

trol of a supervisor entity.

1 Introduction

Planning and control for manufacturing problems are the most common manufactur-

ing application. Design process, and information integration are the other two main

domains of applications. Scheduling is one of the crucial tasks guaranteeing the

smooth execution of activities that is defined as the temporal assignment of activities

to resources where a number of goals and constraints have to be considered [3]. It is a

difficult and complex problem solving, particularly when it takes place in an open,

dynamic environment.

Dynamic scheduling (also known as reactive scheduling), which can react to a

dynamic environment and adjust the planning as fast as possible, is growing rapidly

in importance, and close attention has been paid to it by many researchers in recent

decades. In this paper, we use dynamic scheduling mechanism to indicate that a real-

time manufacturing scheduling can update its schedule to adapt to changing situations

such as new order insertion, machine failure, and job tardiness.

The approach introduced in this article tries to exploit the advantages of static and

dynamic techniques of scheduling; it is based on three (3) proposals:

Taghezout N. and Zarate P. (2007).

A Multi Agent Decision Support System for Real Time Scheduling.

In Proceedings of the 4th International Workshop on Computer Supported Activity Coordination, pages 55-65

DOI: 10.5220/0002420300550065

Copyright

c

SciTePress

1. The first one consists in generating a set of acceptable solutions in the

scheduling phase from the initial plan of production.

2. The second one consists in exploiting this set of real-time solutions by an in-

teractive decision support system.

3. The third one tries to take advantage of entity modelling thanks to the agent

formalism in order to exploit the following two characteristics.

The first one attempts to establish a correspondence between the distribution as-

pect of the agents system and the physical dynamic distribution of resources in PS

(production system).

The second one defines the high degree of flexibility which characterizes the

multi agent model. This makes the adaptation of the piloting structure easier to the

changes of PS configuration.

We argue that the agent-based technology has emerged as a new paradigm for

conceptualizing, designing, and implementing software systems. Multi-agent systems

(MAS) enhance overall system performance, in particular along such dimensions as

computational efficiency, reliability, extensibility, and flexibility. They are also capa-

ble of solving the problem of matching supply to demand and allocating resources

dynamically in real time, by recognizing opportunities, trends and potentials, as well

as carrying out negotiations and coordination [5].

Because of its highly combinatorial aspects and its practical interest for manufac-

turing systems, the scheduling problem has been widely studied in the literature

through various alternative methods and techniques [7]: Heuristics, constraints propa-

gation techniques, simulated annealing, genetic algorithms, etc.

Agent technology has recently been considered as a successful attempt to treat the

distributed aspect of those methods. Agent approach replaces the central framework

with a network of agents, each endowed with a local view of its environment and the

ability to respond locally to that environment [13]. Then the overall system perform-

ance is not globally planned, but emerges through the dynamic interaction of agents

in real time.

ADDYMS developed a dynamic scheduling mechanism for local resource alloca-

tion at the local work cell level [9]. [10] proposed a holonic architecture for the dy-

namic scheduling of manufacturing systems. It also presented a negotiation protocol

based on the contract net protocol and suitable for the dynamic scheduling of manu-

facturing tasks [10].

[13] presents a multi agent system that is an implementation of a distributed pro-

ject management tool, activities, resources, and important functions are represented as

agents in a network. Methods to schedule activities and resolve resource conflicts by

message exchanging and negotiation among agents are presented [13].

The proposed system has for objectives:

1. to develop in real-time the set of solutions offered by the projected scheduling by

updating it according to the decisions taken and (unpredictable) significant events.

2. to help choosing decision on the basis of updated set of solutions.

3. to offer local modifications on the set of solutions

This paper describes a tool structure for resolving real time scheduling problem

and shows how it can be applied to solve the real time scheduling problem. Section 2

presents a DSS architecture and specification of a compositional agent. The concepts

used are defined, and the state of the workshop is introduced in the third section.

56

Section 4 details the specific agents involved (ISP agent and supervisor agent) in

terms of their specific tasks, while section 5 deals with interaction between agents

(negotiation form). Finally, Section 6 discusses the results of the DSS and highlights

those aspects which require further work (multicriteria methodologies).

2 Description of the DSS Architecture

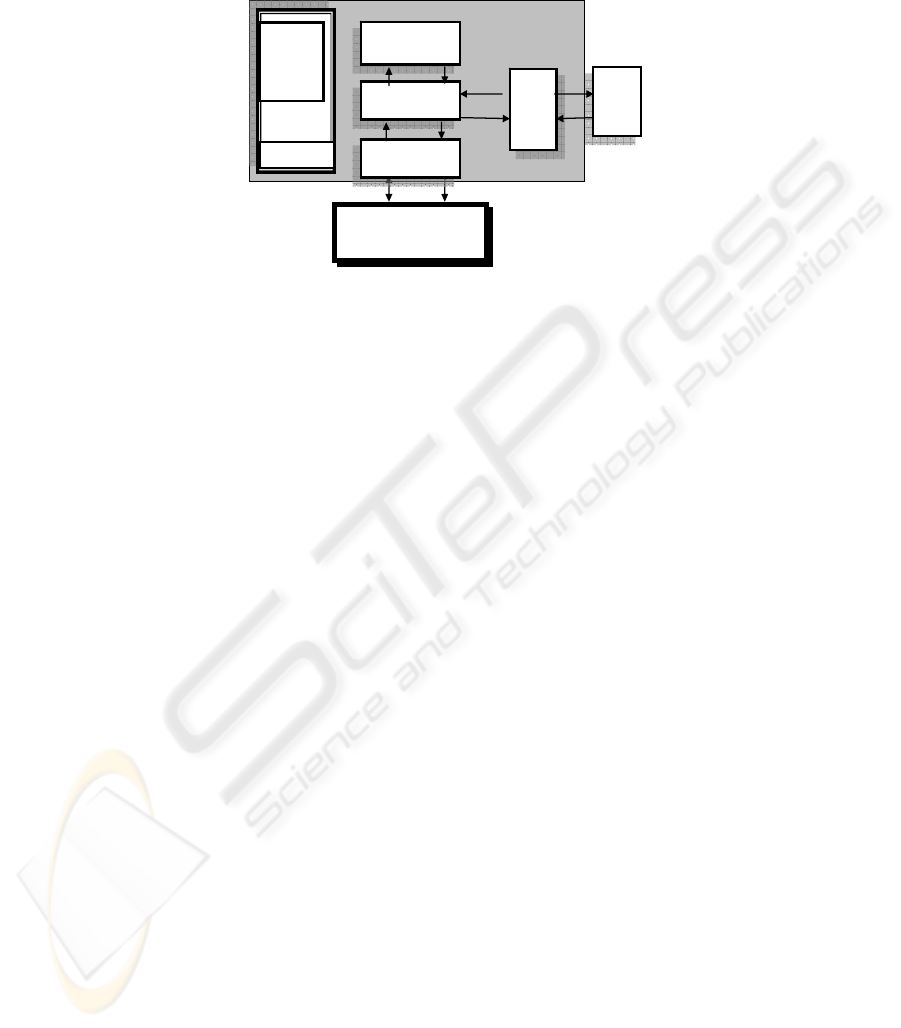

The DSS architecture is composed of several modules. Each module has its own

functionalities and objectives. The DSS architecture is described in the figure 1. The

module of analysis and reaction is developed thanks to a multi-agent technology. The

agent based system is decomposed into a supervisor agent and several ISP agents.

Each ISP agent has the possibility to use resources.

Fig. 1. Structure of the DSS.

2.1 Multi agent Structure of Hybrid Piloting

We consider a production system made up of several Integrated Stations of Produc-

tion ISP. They are called agents ISP. Each agent (ISP) is specialized in the operations

of production; it is of a cognitive type.

Supervisor Agent

ISP

ISP

ISP

R

R

R

R

R

R: resource

Fig. 2. Modelling of the distributed and supervised piloting structure by the multi agent model.

It has sufficient knowledge to make decisions. Its role is then:

a. To manage locally in real time the processes of allocation of tasks, queues, etc

b. To manage the availability of the necessary elements to the realization of operat-

Human Operator

Behaviours

Configuration of

resources

Data Base

Total

Information Subsystem

Inter

face

Subs

y

s

te

Communication

Subsystem

Module of

Analysis

and

Decision Subsystem

Control Subsystem

Expert Interface

57

ing tasks. The system then consists of a set of co-operative agents under the control of

a supervisor (Figure1). This structure has been used in many projects and its effec-

tiveness has been showed [8] [12].

Subs

y

stem of

Subsystem of

communication

Subsystem of

information

Analysis and

reaction

module

Behaviou

Subsystem of

Interface

Human

Operator

Subsystem of

control

Fig. 3. Architecture of ISP Agent.

2.2 The Agent Structure (ISP)

An agent is composed of five subsystems [11] (as shown in Figure3.):

• Information subsystem: allows ensuring communication between the subsystems

and managing local information.

• Communication subsystem: ensures the connection between the ISP and the other

agents, the production system components.

• Interface subsystem: allows the information exchange between the human opera-

tor and the agent.

• Control/Order subsystem: ensures the order of production resources and transmits

the follow-up information to the information subsystem.

• Decision subsystem: is responsible of the set of decisions made during the prob-

lem realization process.

The decomposition into subsystems has been adopted, but in order to test several

multicriteria decision-making processes, the decision subsystem has undergone some

modifications which consist in adding [11]:

a) A module of analysis and reaction in order to take into account the state of

workshop at any moment.

b) A set of behaviours associated with each ISP.

3 Description of the Production System

3.1 State of the Workshop

The reactive stage of the proposed approach corresponds to the implementation of

group scheduling. It is treated by an interactive decision support system. The latter

works in the following way:

Piloted System

piloté

58

- The state of workshop, defined by the states of resources and operations is regu-

larly updated.

- State changes are due to the occurrence of events or to decision making.

- The decision making is guided by information provided by DSS and is based on

communication between the entity supervisor and agents ISP.

The support decision proposed consists in the basis of indicators to assess the pos-

sible choices regarding admissibility; that is, to meet the deadline.

3.2 States of Resources

- Free (FR): if it is useful and if no operation is appointed to it.

- Active (AC): when it carries out an operation.

- Failure (FA): if it cannot work due to an incident.

- Non active (NAC): The operation is stopped due to a blockage in the order of

manufacture. The resource remains appointed to the current operation.

3.3 States of Operations

During its execution, an operation could be in one of the following states:

- White (WH): When at least a previous operation in the sense of the range is not

in the current state.

- In approach (AP): when all the operations in the sense of the range are passed in

the current state.

- In transport (TP): when all the previous operations in the sense of the range are

ended and the operation discussed is in transport on its way to place of execution.

- Available (AV): Once the transport is ended, the operation is ready to be carried

out.

- Current (EC): the operation is under execution on a resource.

- Stopped (ST): The execution is stopped because the resource which carried it out

was subject to a breakdown on one or many of its lines of load.

- Blocked (BK): an operation passes to the blocked state due to the occurrence of

an incident linked to the order of manufacture or anything else.

- Finished (FH): When the execution of operation is ended.

3.4 Events

Events correspond to situations determined in the workshop supported by its manu-

facture monitoring system, causing changes of states, they can list:

- At the End of execution of an operation (FE):

Once the operation is ended, the resource which carried it out becomes free. The

following operation in the range passes the transport state.

- At the End of transport of an operation (ETp): The operation is ready to be car-

ried out.

- Breakdown (B) of a resource: The statement of breakdown is accompanied by

the name of resource and stopped operation.

- At the End of Breakdown (EB): After the end of breakdown, the resource can

carry out a planned operation.

59

- Blockage of an operation: The blockage of an operation covers all the problems

related to the operation which prevent its execution.

- At the End of blockage: The operation will be ready to be carried out after this

event.

Events can be classified into two categories according to their mode of occurrence:

1. The expected events, of which the occurrence is obligatory as soon as the work-

shop is in a certain state.

2. The unexpected events, corresponding to disturbances which appear during pro-

duction.

3.5 Decisions

Increasing the total reactivity of the decision structures in production control requires

to give a greater autonomy to the actors. It also poses the problem of total coherence:

this autonomy can put in danger. Regulations are necessary so that each decision

maker can ensure at the same time the treatment of disturbances which fall on to it

and meet the coherence of its decisions. Those pass by negotiations which can inter-

vene especially in reaction to the impossibility of carrying out decisions which are

already made. This is by taking into account the extent of the disturbances to be ab-

sorbed [2], [4].

Decisions aim to organize the use of resource to carry out the operations according

to delays defined by the plan of production.

Every decision therefore concerns the relation between an operation and the re-

source used for its execution, we distinguish:

- Decision of type E: to couple an operation with a resource to undertake its execu-

tion.

- Decision of type R: to take back the execution of an operation on a loading line

after its repairing (breakdown).

- Decision of type I: Liberate the resource due to the break of execution of operation.

- Decision of type C: to change the allocation of an operation.

A decision –making centre can consist of a single resource or a set of grouped re-

sources under the same decision maker. The messages sent of a decision making

centre toward the DSS are filtered by the entity supervisor and are treated according

to their priority. This is by starting from a queue managed by the supervisor. Once the

requests treated by DSS, the supervisor establishes (figure 4) the correspondence

between entities ISP in difficulty and transmits to this entity the response to its re-

quest.

4 Principle of Negotiation between the Agents ISP

4.1 Introduction

We outline in this part the specifications at the level of every ISP and the addition of

a supervision level.

60

The system is composed of a set of cooperative ISP under control of a supervisor.

We detect two types of cooperation [12]:

1. between the operator and the agent: The human operator is responsible for local

decisions. This type of cooperation is specified to study the influence on the auto-

adaptation and on the integration of objectives of production of a possible integration

via an interactive multicriterion decision making system.

2. Which represents the interaction between agents? It is at this level that the struc-

ture of robust communication interferes. The integration of a resistance to dysfunc-

tions obliges to spread the protocol of allocation of tasks to insert a minimum level of

robustness.

Six primitives have been developed to describe generically the steps of any com-

munication protocol. We outline here their use.

The sequence of different actions leading to a contract of data exchange (service)

between a transmitter (applicant of service) and a receiver is represented by the first

five primitives. In case where, following the approval of exchange contract, transmit-

ted data are not sufficient, the transfer primitive can be called.

We outline them below:

REQUEST

: a request is issued when it is necessary to acquire a service from the

resource called.

ACCEPTANCE

: an acceptance stipulates a potential agreement of service. The

receiver can or not receive a request of effective service (activated service but not

active).

RESERVATION

: a reservation corresponds to service exclusive. The latter is then

active.

RELAXATION

: a relaxation corresponds to the cancellation of request.

LIBERATION

: a liberation is sent to end a service.

To these five primitives we link a sixth particular one:

TRANSFER

: this primitive is used to assure the transit of any information inde-

pendently of the five primitive above. It is used when a service is active (a reserva-

tion has been sent) or is activated (an acceptance has been received), or even in a

completely asynchronous way (case where the transmitter does not check the con-

nection). It can be also linked to a message of physical transfer of the room.

4.2 General Description

Stage 1: When an operation on a product has just been performed by an agent, the

latter checks if there remains an operation to be accomplished on this product (or lot

of products). If yes, a request is sent to the entire linked ISP.

Stage 2: The ISP able of executing the operation goes back to ISP which sent the

request an acceptance as well as a data set on its own characteristics (state of queue,

etc). They turn then into a state of waiting of reservation / relaxation. An ISP which

accepts a message of the type request checks the concordance between the constraints

imposed by the operation and its own possibilities. This concordance is developed for

instance in term of compatibility "type of realisable operation by the system of pro-

duction linked to ISP "versus" type of operation requested for the task to be realised".

61

Stage 3: The sender ISP chooses the best adapted ISP and sends it a reservation. It

informs the other ISP of their non-selection by sending them a relaxation. The sender

ISP turns then into the state of waiting of liberation.

The set of ISP candidates is assessed an algorithm able to consider the classical

rules of allocation. The objective function can then be defined according to the total

objectives of production.

Stage 4: The ISP chosen sends back to the sender ISP a message of the end of com-

munication (liberation) to inform it about the reception of reservation and is in the

state of waiting of transfer. The transfer of product and the order of manufacture

between the two ISP can take place.

4.3 The Supervisor Agent

The Module of Analysis and Reaction

This module performs a continuous analysis of messages which the agent supervisor

accepts, across its interface of communication. And, it activates the behaviours which

correspond to them. It also updates the states of operations in the total agenda due to

the messages sent by the agents ISP.

The Behaviours

The entity supervisor has a set of behaviours to fulfil its task:

• The behaviour CPA: aims at searching for the resource satisfying best the objec-

tives to be attained for production.

• The behaviour CPR: attempts to search for the agent (the best) of substitution for

an operation of re-affectation (in case of failure of a local re-affectation).

The Total Agenda

This agenda allows the supervisor to represent and follow the evolution of all the

tasks in the system. This agenda also allows reconstructing information of any local

agenda in an ISP.

The Interface of Communication

This module manages the messages in transit between the agent supervisor and all the

other agents of the system.

The Real Time Clock

It generates the time.

4.4 The ISP Agent

The Module of Analysis and Reaction

It constantly analyses the messages received by the ISP agent, across its interface of

communication, and activates the behaviours corresponding to the events received.

So, the state of operations is updated.

The Behaviours

• The behaviour CPF: aims at managing the queue of the ISP Agent and chooses

the next operation to be carried out.

62

• The behaviour CPS: corresponds to the process of allocation and aims for the

research of the next ISP (the best) to treat the following operation of current pro-

duction.

• The behaviour CPR: allows searching for a machine of substitution among those

that it controls (the best) for operating re-affectation due to a breakdown.

The Local Agenda

The agenda, a form of representation of engagements of any ISP, obeys the following

rules:

• At each beginning of execution of an operation, the ISP agent registers in its

agenda the beginning of this operation which it signals to the supervisor.

• At each end of an operation, the ISP agent registers in its agenda the end of this

operation which it signals to the supervisor.

Interface Expert

Allows to the human operator to consult and modify the configuration of ISP

agent, to know the present state of resources and to follow the evolution of activity of

production.

The Interface of Communication

This module allows the management of messages in transit between ISP agent and

the other entities of the system.

The Real Time Clock

It generates the real time factor in the ISP agent.

5 A Case Study

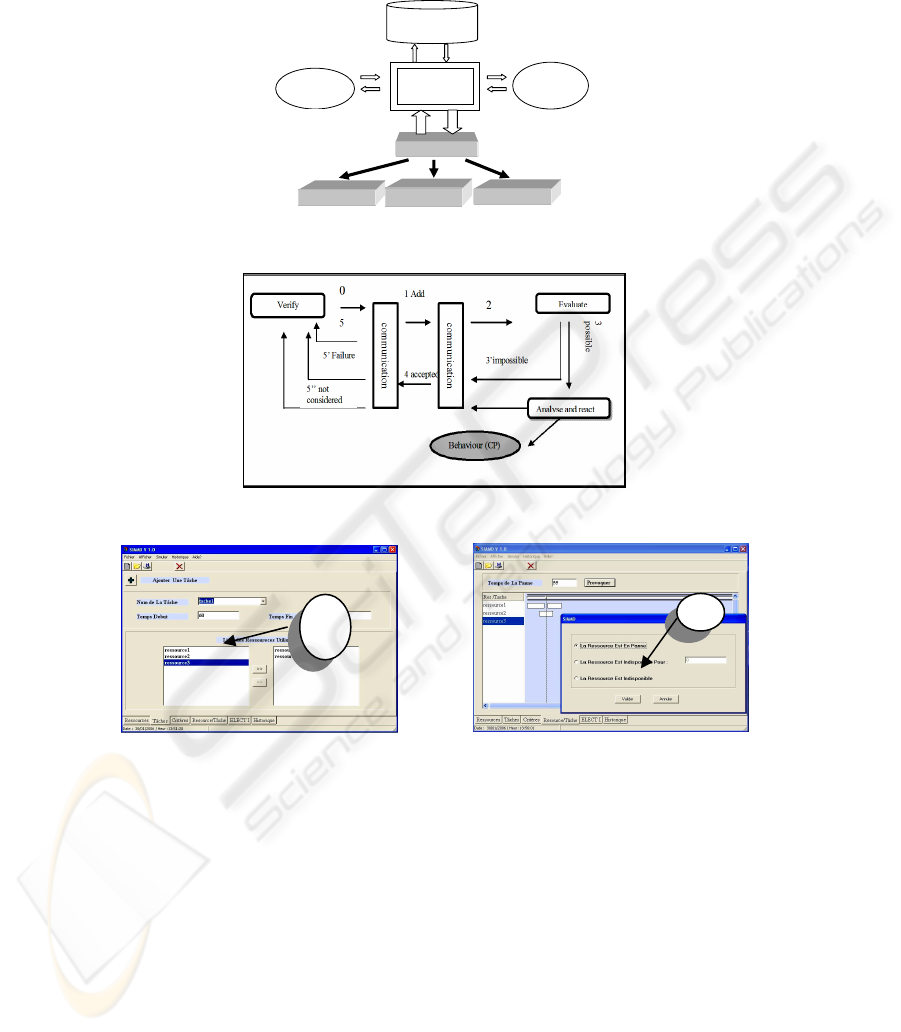

The conversations are built by the agents and are controlled by the entity supervisor:

for example, when Checking the coherence of a decision of ISP agent1 by an ISP

agent2 that should start the adequate behaviour. The ISP agent1 communicates infor-

mation to ISP agent2 (arcs 0 and 1on Figure 5). The ISP agent 2 evaluates if the addi-

tion of this information is possible or not (arcs 3, 3') and transmits the result to ISP

agent1 (arc4). The procedure succeeds if ISP1 answers favourably in time (arc5). It

fails if not (arcs5 and 5'). The ISP agent 2 starts the procedure of analysis and reac-

tion.

5.1 Breakdown of a Resource

1. The resource n°1 controlled by agent 3 is in the state breakdown. The module of

analysis and reaction discerns this event and triggers off the behaviour connected;

that is CPR, if the process fails ISP agent n°3 re-redirect the request of re-affectation

to the agent supervisor. This triggers off behaviour CPR at the supervisor level.

2. The agent supervisor transmits the request towards other agents ISP (ISP 1, ISP 2)

and treats the received answers accepted to choose the best machine of substitution.

3. The result will be announced to the ISP agent chosen as well as the ISP agent ap-

plicant.

We consider a structure of piloting made up of a supervisory agent and of 4-5

agents ISP. Let us suppose the arrival of a work order made up of several spots T1-

63

T7. In Figure 7, we can see a view of the simulation tool on tag1, the simulator tool

permits to animate the task model in concordance with the user interface as presented

in Figure 6 (tag2).

Decision

Support System

Current set of

Scheduling

Current State of

workshop

Supervisor Entity

Decision Centre 1

Decision Centre 2

Decision Centre n

Set of acceptable

Scheduling

Sending of information

and proposals

Consideration of events

and decisions

Fig. 4. Decision support system Functioning.

Fig. 5. SIP1 checks the coherence of its decision.

Fig. 6. Declaration of tasks. Fig. 7. Execution of simulation

6 Conclusion

The decision support approach allows, on the basis of deterministic model, to organ-

ize in real time the execution of tasks according to the real state of making workshop

and thus to take into account the unexpected situations. We have proposed in this

article a model of piloting which is based on a supervised distributed structure. The

multi agent system allows, by defining a set of states, events and decisions and in-

stalling of behaviours associated with the decision support processes of real time

2

1

64

scheduling of workshop, to bring a decision support and a help to the negotiation

between entities ISP and the entity supervisor. This modelling is centred on a module

of analysis and of reaction. The latter provides the function of identification of situa-

tions and starts the adequate behaviours. For the future, the research will be extended

according to three important directions. Firstly, given that robustness of a scheduling

characterizes its performance [1], we would like to extend the decision support given

by this approach to treat uncertainty. Secondly, in the case where the number of risks

is important, the feasibility of a method cannot be guaranteed [6], it will be necessary

to ensure flexibility by setting up a mechanism of choice in the group of acceptable

scheduling and ensure feasibility for the greatest number of possible scenarios of

execution. Finally, we intend to integrate the human operator in the decision support,

several co-operation modes have been defined with the decision support system. This

integration will be done by the use of a method of multicriterion assistance such as

AHP [12].

References

1. Billaut, J-C., Moukrim, A., 2005. Introduction à la flexibilité et à la robustesse en ordon-

nancement in Flexibilité et robustesse en ordonnancement (Billaut). Lavoisier Hermes

sciences publications. Paris.

2. Camalot, J-P., Esquirol, P., 1997. Aide à la décision et à la négociation dans un problème

de gestion de production distribuée in Deuxième congrès international franco-québécois de

Génie industriel- ALBI.

3. Chen, Y.-M., Wang, S.-C. 2005. Framework of agent-based intelligence system with two

stage decision making process for distributed dynamic scheduling in Applied Soft Comput-

ing 229-245

4. Huguet, M-J., Erschler, J., 1996. Negotiation based on constraints in cooperation. In Com-

puter supported cooperative work.

5. Jianxin, J., Xiao, Y., 2005. An agent-based framework for collaborative negotiation in the

global manufacturing supply chain network in Robotics and Computer-Integrated Manufac-

turing 22. 239-255. Elsevier.

6. Pomerol, J-C., 2006. La décision humaine : reconnaissance plus raisonnement in Concepts

et méthodes pour l’aide à la décision (Bouyssou, D.), Hermes sciences publications. Paris.

7. Reaidy, J., Massotte, P., Diep, D., 2005.Comparison of negotiation protocols in dynamic

agent-based manufacturing systems. In International Journal of Production economics. 117-

130.

8. Rouba, B., Taghezout, N., 2004. Un processus décisionnel multicritère basé sur l’approche

multi agent pour le contrôle de SAP. In MOAD’04.

9. Shen, W., Yoon, H.J., Norrie, D.H., 2006. Applications of agent-based systems in intelli-

gent manufacturing: An updated review in Advanced engineering INFORMATICS 415-431

10. Sousa, P., Ramos, C., 1999. A distributed architecture and negotiation protocol for schedul-

ing in manufacturing systems in Computers in Industry (38) 103-113

11. Taghezout, N., Beldjilali, B., 2006. Prise en Compte des Préférences de l’Opérateur Hu-

main dans un Processus Décisionnel Multicritère Basé sur AHP : Application à un système

de production. In MCSEAI’06. Maghrebian Conférence on information technologies.

12. Taghezout, N., 2006. Expérimentation et Intégration de la méthode Electre I dans système

d’aide à la décision appliqué aux SAP. In SNIB’06, 5eme Séminaire National en informati-

que de Biskra, Vol.1, pp 196-206.

13. Yan, Y., Kuphal, T., Bode, J., 2000. Application of multiagent systems in project manage-

ment in International Journal of Production economics (68) 185-197

65