SCREEN-PRINTED SENSOR FOR CHLORIDE

QUANTIFICATION IN SWEAT FOR

EARLY DETERMINATION OF CYSTIC FIBROSIS

Javier Gonzalo-Ruiz*, Roser Mas, F. Javier Muñoz

Centro Nacional de Microelectronica (CNM-IMB-CSIC), Campus UAB,08193 Bellaterra, Barcelona, Spain

Rafael Camero

Técnicas Científicas para Laboratorio (TECIL), C\Lope de Vega, 99-101,08005 Barcelona, Spain

Keywords: Screen-printed electrodes, choride detection, potentiometric sensor, sweat test, cystic fibrosis.

Abstract One-use screen-printed sensor capable to generate sweat and measure the chloride concentration is

presented. Sweat is induced by iontophoresis, pilocarpine is forced to get into de skin and stimulate the

sweat glands. Chloride concentration is measured by potentiometry. The performance of the devices has

been tested by means of reproducibility studies. Finally, the application of these sensors in several

volunteers has been carried out. Errors less than 10% have been obtained in real samples.

1 INTRODUCTION

Cystic fibrosis (CF) is a inherited chronic disease

that affects the lungs and digestive system(Davis,

1993). Life expectancy of people with cystic fibrosis

is between 30 and 40 years (Doering et al., 2007).

Early diagnosis of CF is important, newborn

screening can lead to fewer hospitalizations;

minimized the symptoms, nutritional benefits

(Rosenstein, 1998) and potentially better lung

function throughout early childhood (Wang et al.,

2002).

There is a close correlation between increased

concentration of chloride and sodium in sweat and

the presences of the disease (Rockville, 1974).

Chloride concentration in sweat less than 40 mmol

dm-3 is defined as normal but over 60 mmol dm-3 is

indicative of CF. People showing values between 40

– 60 mmol dm-3 are considered as population in risk

of CF. The sweat test offers a rapid diagnosis and

permits a early CF determination (Warwick et al.,

1990, Warwick et al., 1986).

The Gibson-Cooke sweat test (Gibson and Cooke

1959) is accepted as the most discriminatory test for

diagnosis of CF. This method is based on

iontophoretic sweat test. Pilocarpine is a reagent

with the capacity to stimulate sweat glands (Katzung

2004). Sweat is collected either upon a gauze square

or filter paper, and then the chloride presents on the

sample is analyzed on a laboratory. This test

involves multiple steps for collection and analysis of

sweat sample, and requires prescribed procedures for

each step and high level of quality control.

In this work, the development and test of four

electrodes configuration sensor, fabricated by thick

film technology, with the capacity to generate sweat

and measure chloride ion is presented. Two

electrodes were used for sweat generation.

Pilocarpine is immobilised over the cathode

electrode using a hydrogel matrix, and applying a

small current (iontophoresis), this reagent is forced

to get into the skin in order to induce sweat (Davis,

Wilson et al. 2005; Ortuno, Rodenas et al. 2007).

The other electrodes, working as ISE format,

measure the chloride concentration in sweat by

potenciometry. Both electrodes were made of

Ag/AgCl ink. One acts as working electrode. The

other one was cover with KCl-containing membrane

in order to realise the miniaturized reference

electrode. The organic matrix consist of KCl-

containing poly(2-hydroxyethl methacrylate)

(pHEMA) membrane (Simonis, Dawgul et al. 2005).

103

Gonzalo-Ruiz J., Mas R. and Javier Muñoz F. (2008).

SCREEN-PRINTED SENSOR FOR CHLORIDE QUANTIFICATION IN SWEAT FOR EARLY DETERMINATION OF CYSTIC FIBROSIS.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 103-106

DOI: 10.5220/0001047601030106

Copyright

c

SciTePress

The performance of the reference electrode as well

as these sensors was checked by their reproducibility

and the response in different synthetic solutions of

chloride. Finally, these devices were tested in

several volunteers. The chloride concentrations

obtained were compared with the results achieved by

a common method used by the hospitals.

2 EXPERIMENTAL

2.1 Reagents, Equipment and Software

Analytical grade chemicals were used. All the

solutions were prepared from ultra pure deionised

water (DI) (18 MΩ cm).

Polyvinyl alcohol (PVA) powder (Mowiol 28-99,

Flucka, Steinheim, Germany), pilocarpine

(Advanced instruments Inc., Norwood, USA) and

sodium nitrate (Advanced instruments Inc.,

Norwood, USA) solutions were used to develop the

hydrogel matrix for iontophoresis process.

To fabricate pHEMA solution the adequate amount

of 2-hydroxyethl methacrylate (Aldrich, Steinheim,

Germany), ethilenglicol (Flucka, Steinheim,

Germany) Tripropylene glycol diacrylate (TPGDA)

(Aldrich, Steinheim, Germany) and Benzyldimethyl-

ketal (irgacure 651) (Ciba, Basel, Switzeland) were

mixed.

Potassium chloride (KCl) (Flucka, Steinheim,

Germany) solutions were used on the fabrication,

storage and test of the fabricated sensors.

Homemade equipment was developed in order to

integrate current application and chloride

measurement. Sweat chloride analyzer (Advanced

instruments Inc., Norwood, USA) was used to

contrast the measurements achieve with the

homemade electrodes.

2.2 Electrode Preparation

2.2.1 Screen-printed Electrode Fabrication

A DEK 248 screen-printing system (DEK, UK),

screen polyester mesh and polyurethane squeegees

were used to fabricate the electrodes. Sequential

layer deposition has been performed on a polyester

substrate (0.15mm thickness). First, a layer of silver

ink (Electrodag 418 SS) was deposited to define the

conductive paths. Over these paths, a layer of

Ag/AgCl ink (Electrodag 6037SS) was deposited to

form the electrodes. A drying cycle (80º/30 min +

120º/5 min) was subsequently applied (Gonzalo-

Ruiz et al., 2007). Finally, a piece of polyester

substrate was used to prevent the conducting paths

form the solution.

These designs are made up of two parts, sweat

generator made up of the two external electrodes

(28.2 mm

2

) and potentiometric sensor composes of

both internal electrodes (7.0 mm

2

) (Fig.1).

cathode

anode

Reference

electrode

Working

electrode

cathode

anode

Reference

electrode

Working

electrode

Figure 1: Picture of screen-printed sensor.

2.2.2 Electrode Modification Procedure

In order to fabricate the sweat generator, a hydrogel

formulation containing polyvinyl alcohol (PVA) and

pilocarpine was developed to entrap this drug over

the cathode surface.

Aqueous solution of 17% by weight of PVA was

prepared by adding a calculated amount of dry PVA

powder into a mixing vessel and slowly dissolving it

in water. The temperature of the solution was raised

to 98 – 100 ºC during 15 minutes with continuous

stirring of the mixture. It was then transferred to

pattern and frozen at -10 ºC during 24h. Each pattern

had a diameter of 6.2 mm, bit bigger than the

electrode, and a thickness of 2 mm. The cured

hydrogel samples were immersed, overnight, in a

solution of 0.5% by weight of pilocarpine. These

pieces were stuck on the cathode surface.

Hydrogel sample saturated with sodium nitrate

solution (1% by weight), fabricated in the same way

described above, was adhered onto the anode

surface.

Sensing part is composed by two electrodes

fabricated with Ag/AgCl ink. The surface of the

electrode which acts as working one were not

modified because of the high selectivity of this

material to chloride ion activity (Ives and Janz,

1961).

In the case of reference electrode, it is necessary

keep constant the chloride activity over the

electrode. In order to do this, the surface was

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

104

modified with KCl containing matrix based on

photocurable hydrogel. 80% of HEMA, 1,4% of

ethilenglicol, 14,6% of TPGDA and 4% of irgacure

solution (0.11gr l

-1

in EtOH)were mixed. 25% of 1

mol dm-3 of KCl solution was added to the mixture.

Using an O ring seal, a drop of HEMA-containing

solution was deposited on top of AgCl layer, which

will act as reference electrode, and it was irradiated

with UV light for 4.30 min to polymerise HEMA to

pHEMA.

The electrode was stored over night and a glassy

pHEMA layer was obtained. Before measuring, the

sensor was immersed in 3 mol dm

-3

of KCl solution.

3 RESULTS AND DISCUSSION

3.1 Potentiometric Sensor Test

First, the performance of the potentiometric sensor

in synthetic samples was tested by its

reproducibility. The potentiometric response of six

different electrodes was checked. Calibration curves

in the concentration range 0.01–0.1 mol dm

-3

of KCl

were carried out (Fig. 2). The slopes of these

calibrations were used to evaluate the sensor

reproducibility. The residual standard deviation

(RSD) was 8.02 % (n=6 α= 0.05).

y = -67.345x - 67.251

R

2

= 0.9995

y = -65.447x - 66.53

R

2

= 1

y = -60.819x - 61.628

R

2

= 0.9999

y = -60.243x - 67.536

R

2

= 0.9918

y = -57.926x - 60.747

R

2

= 0.9999

y = -53.972x - 59.546

R

2

= 0.9982

-10

0

10

20

30

40

50

60

70

80

-2.1 -1.9 -1.7 -1.5 -1.3 -1.1 -0.9 -0.7 -0.5

log ([Cl-])

E( mV)

.

Figure 2: Calibration curves recorded to estimate the

sensor reproducibility.

3.2 Application in Real Samples

These devices were used to chloride determination

in sweat.

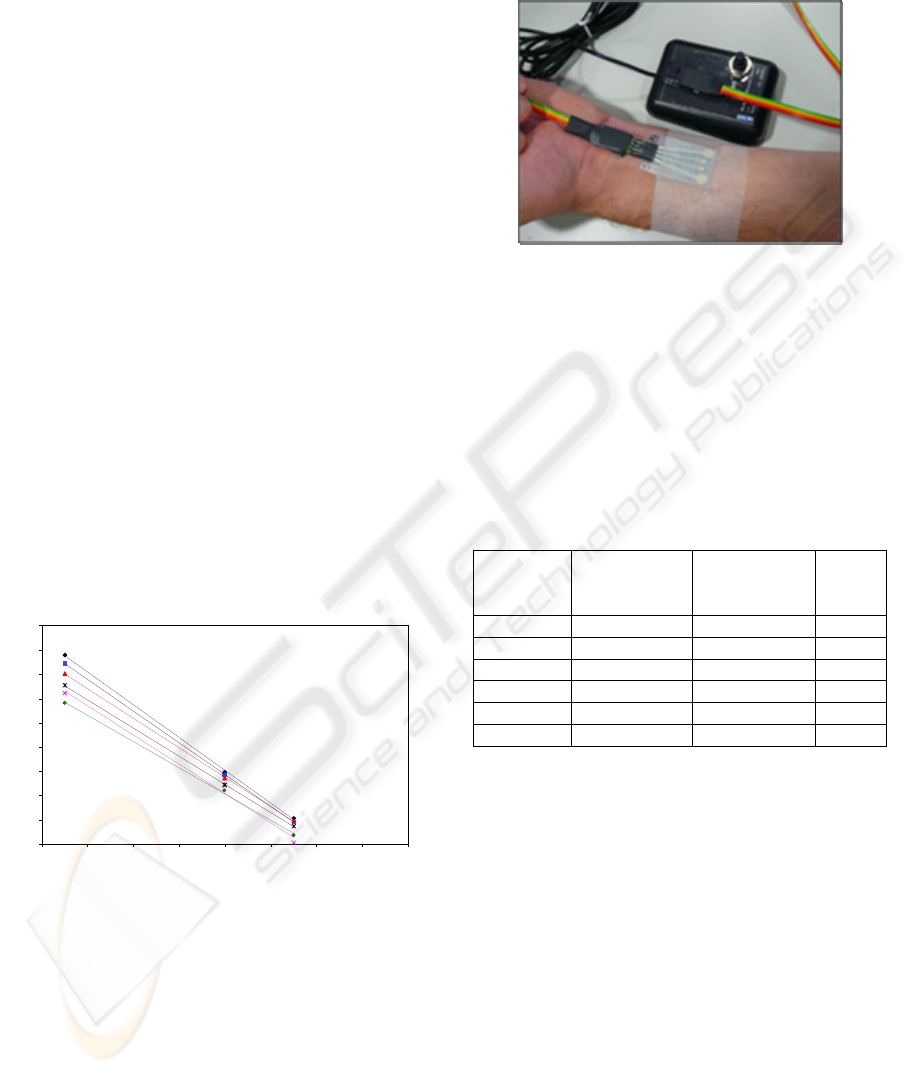

First, the sensor was stuck over the skin (Fig. 3),

and then a current between 1 and 1.2 mA was

applied during 10 min between the cathode and the

anode to force the pilocarpine to get into the skin.

Current over 1.2 mV may cause burns. After 10 min

waiting, the skin started sweating. The sensing part

recorded potential values which can be related to

chloride concentration by a calibration curve.

Figure 3: Picture of a sensor during measurement.

Chloride concentration was measured in six

volunteers using 1-use screen-printed sensors (SPS).

The results were compared with the values achieved

by a common method (CM) used by the hospitals.

Table 1 shows the results obtained, as it can be seen,

good agreement with the common method was

obtained.

Table 1: Chloride concentrations obtained by two different

methods in 6 volunteers.

Volunteer

[Cl] (SPS)

(mmol dm

-3

)

[Cl] (CM)

(mmol dm

-3

)

Error

(%)

1 55.5 58 4.3

2 52.7 50 -5.4

3 60.1 56 -7.4

4 60.2 58 -3.9

5 56.8 58 1.9

6 74.5 70 -6.4

4 CONCLUSIONS

We have demonstrated that it is possible to develop

a device capable to induce sweat and measure

chloride concentration. The potentiometric sensor

reaches acceptable values of reproducibility (8.02%)

These sensors were applied in 6 volunteers with

satisfactory results, using a rapid and low cost

methodology for cystic fibrosis detection.

ACKNOWLEDGEMENTS

The authors would like to acknowledge funding

from the Spanish Ministry of Science & Education

via the MICROFIBROSIS (PET2005-0849) project.

SCREEN-PRINTED SENSOR FOR CHLORIDE QUANTIFICATION IN SWEAT FOR EARLY DETERMINATION OF

CYSTIC FIBROSIS

105

REFERENCES

Davis, P. B. (Ed.) (1993) Cystic fibrosis, Marcel Dekker,

cop., New York.

Davis, S. L., Wilson, T. E., Vener, J. M., Crandall, C. G.,

Petajan, J. H. and White, A. T. (2005) Journal of

Applied Physiology, 98, 1740-1744.

Doering, G., Elborn, J. S., Johannesson, M., de Jonge, H.,

Griese, M., Smyth, A., Heijerman, H. and Grp, C. S.

(2007) Journal of Cystic Fibrosis, 6, 85-99.

Gonzalo-Ruiz, J., Alonso-Lomillo, M. A. and Munoz, F. J.

(2007) Biosensors & Bioelectronics, 22, 1517-1521.

Ives, D. J. and Janz, G. J. (1961) Reference Electrodes,

Theory and Practice, New York.

Katzung, B. G. (Ed.) (2004) Basic and Clinical

Pharmacology, 9th ed.

Ortuno, J. A., Rodenas, V., Garcia, M. S., Albero, M. I.

and Sanchez-Pedreno, C. (2007) Sensors, 7, 400-409.

Rockville (Ed.) (1974) Guide to Diagnosis and

Management of Cystic Fibrosis, Cystic Fibrosis

Foundation.

Rosenstein, B. J. (1998) Clinical in Chest Medicine, 19,

423-441.

Simonis, A., Dawgul, M., Luth, H. and Schoning, M. J.

(2005) Electrochimica Acta, 51, 930-937.

Wang, S. S., O'Leary, L. A., FitzSimmons, S. C. and

Khoury, M. J. (2002) The Journal of Pediatrics 141,

804-810.

Warwick, W. J., Hansen, L. G. and Werness, M. E. (1990)

Clinical Chemistry, 36, 96-98.

Warwick, W. J., Huang, N. N., Waring, W. W., Cherian,

A. G., Brown, I., Stejskallorenz, E., Yeung, W. H.,

Duhon, G., Hill, J. G. and Strominger, D. (1986)

Clinical Chemistry, 32, 850-853.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

106