POLYMER MEMS SYSTEM FOR MEASURING THE

MECHANICAL MODULUS OF A BIOLOGICAL CELL

Wenyue Zhang

1

, Markus Gnerlich

1

, Yaohua Sun

1

, Gaoshan Jing

1

, Jonathan J. Paly

2

Arkady Voloshin

2,3

and Svetlana Tatic-Lucic

*1,2

1

Sherman Fairchild Center, Electrical & Computer Engineering Department

2

Bioengineering Program

3

Department of Mechanical Engineering & Mechanics, Lehigh University, Bethlehem, Pennsylvania 18015, USA

Keywords: Cell mechanics, mechanical modulus, MEMS, polymer, dielectrophoresis.

Abstract: The measurements of the mechanical modulus of biological cells are critical to studies of pathophysiology

and the research for an effective treatment. This research has developed a rapid and cost effective technique

in order to measure the Poisson’s ratio and mechanical modulus of a live biological cell by utilizing

microelectromechanical system (MEMS) techniques in a biological application. The design, fabrication,

and characterization of a polymer-based MEMS system that integrates a V-shaped electrothermal actuator

array and a cell-positioning system in a single microelectronics chip are presented here. This BioMEMS

device compressed a NIH3T3 fibroblasts cell and caused up to 25% mechanical strain.

1 INTRODUCTION

Osteoporosis is a pubic health problem that affected

more than 44 million Americans in 2004, most of

them are women and/or seniors (U.S. Department of

Health and Human Services, 2007). This age-related

disease results in bones that lack the ability to

respond to dynamic mechanical stimulus, which is

required for the bones in the human musculoskeletal

system to maintain proper osteogenesis (Fritton,

McLeod, and Rubin, 2000). Since several properties

of bone cells, such as adaptation (Caillot-Augusseau,

Lafage-Reoust, Soler, Pernod, Dubois, and

Alexander, 1998) and the cytosolic calcium response

to fluid flow (Donahue, Zhou, Li, and McCauley,

1997), have been proven to decrease as a function of

age, biologists hypothesize that the biomechanical

properties of osteoblasts (bone-formation cells)

change as a function of age, and this change could

be a contributing factor to the pathogenesis of

osteoporosis (You, Yellowley, Donahue, Jacobs,

1999).

However, this hypothesis has not been carefully

examined due to the limitations of current

measurement techniques, such as atomic force

microscopy (AFM), which tests the mechanical

properties of one small portion of the cell, and can

only test one cell at a time. Testing cells one-by-one

is too time-consuming and expensive to be

commonly practiced in biological research, which

relies on statistical studies that require surveying a

large number of cells. As a result, the mechanism

underlying the pathophysiology of osteoporosis is

still unknown.

To improve the public health condition, it is

absolutely necessary to develop efficient techniques

to measure cell’s mechanical properties. Recently,

several MEMS devices have been applied to

biological researches, such as a MEMS-based force

sensor (Yang and Saif, 2006), and a frequency

depedent electrostatic actuator (Scuor, Gallina,

Panchawagh, Mahajan, and Sbaizero, 2006).

Compared to these single crystal silicon and

polysilicon devices, polymer devices have several

advantages, such as: less possibility of damaging

live cells when making physical contact due to the

low Young’s modulus of polymers; lower cost

(Elderstig and Larsson, 1997); and lastly, the ability

to operate in liquids if an electrothermal actuation

mechanism is used (the heat is insulated due to the

low thermal conductance of polymers). This paper

reports a polymer-based MEMS system for

measuring the mechanical properties of a live cell.

146

Zhang W., Gnerlich M., Sun Y., Jing G., J. Paly J., Voloshin A. and Tatic-Lucic S. (2008).

POLYMER MEMS SYSTEM FOR MEASURING THE MECHANICAL MODULUS OF A BIOLOGICAL CELL.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 146-150

DOI: 10.5220/0001052201460150

Copyright

c

SciTePress

2 METHODOLOGY

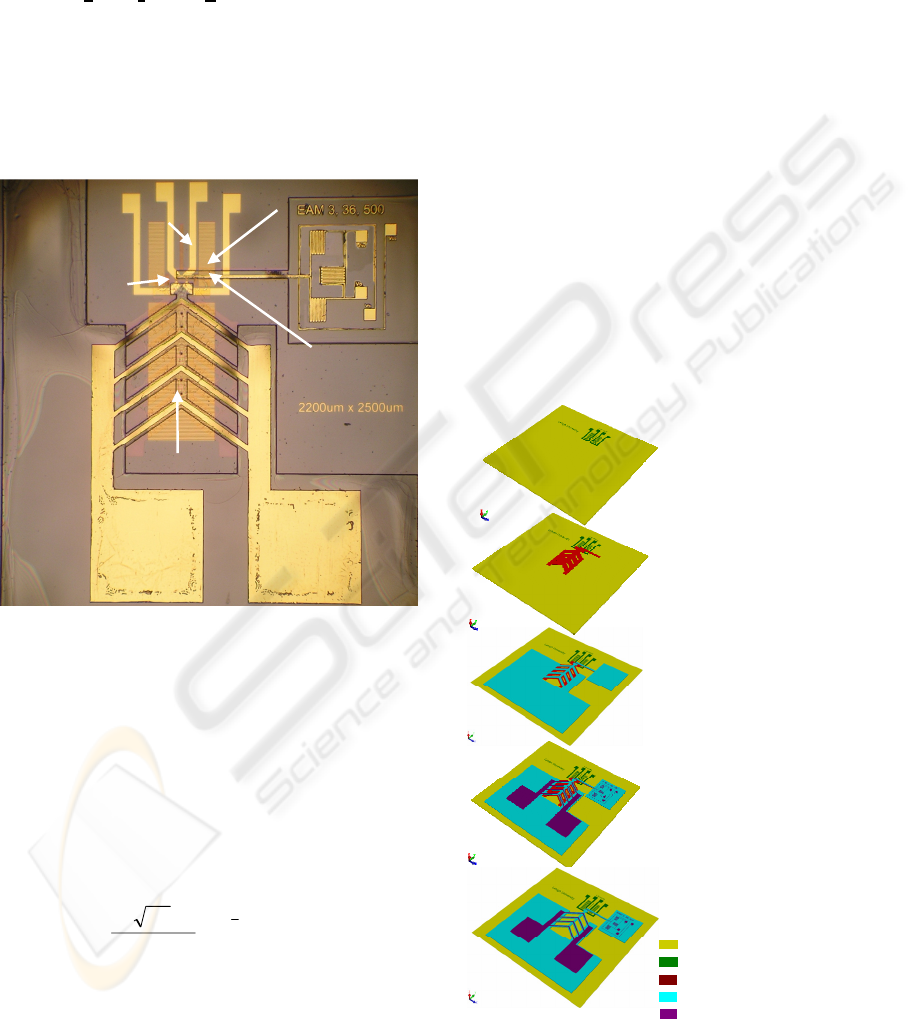

To measure the mechanical modulus of a biological

cell, a BioMEMS device was designed and

fabricated (Figure 1). In a 2.2 x 2.5 mm

2

single chip,

a polymer electrothermal actuator (ETA) array (1) is

to compress a live cell agaist a fixed wall (2), and

report associated forces and displacements during

the compression. In addtion, a cell positioning

system (dielectrophoresis quadrupole electrodes (3))

is used to trap a cell at a desired location, and a set

of scale bars (4) is used to calibrate the optical

measuring system.

Figure 1: Optical image of a fabricated BioMEMS device

for measuring the mechanical modulus of a biological cell.

Four experimental steps need to be done before

obtaining the mechanical properties of a cell: (a)

characterizing the actuator displacement as a

function of input electrical power; (b) determining

the reaction force between the actuator and the cell;

(c) recording the force versus deformation curve for

the cell; (d) fitting the curve with equation (1),

which which was based on the derived Hertz contact

model (Timoshenko and Goodier, 1970):

2

3

2

)1(3

22

d

Ed

F Δ

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−

=

νπ

(1)

where

F was the applied force to a cell, ∆d was cell

deformation,

E was compressive modulus of the cell,

d was the diameter of a cell, and ν was the Poisson’s

ratio of the cell. The fitted parameter reveals the

mechanical modulus of the cell.

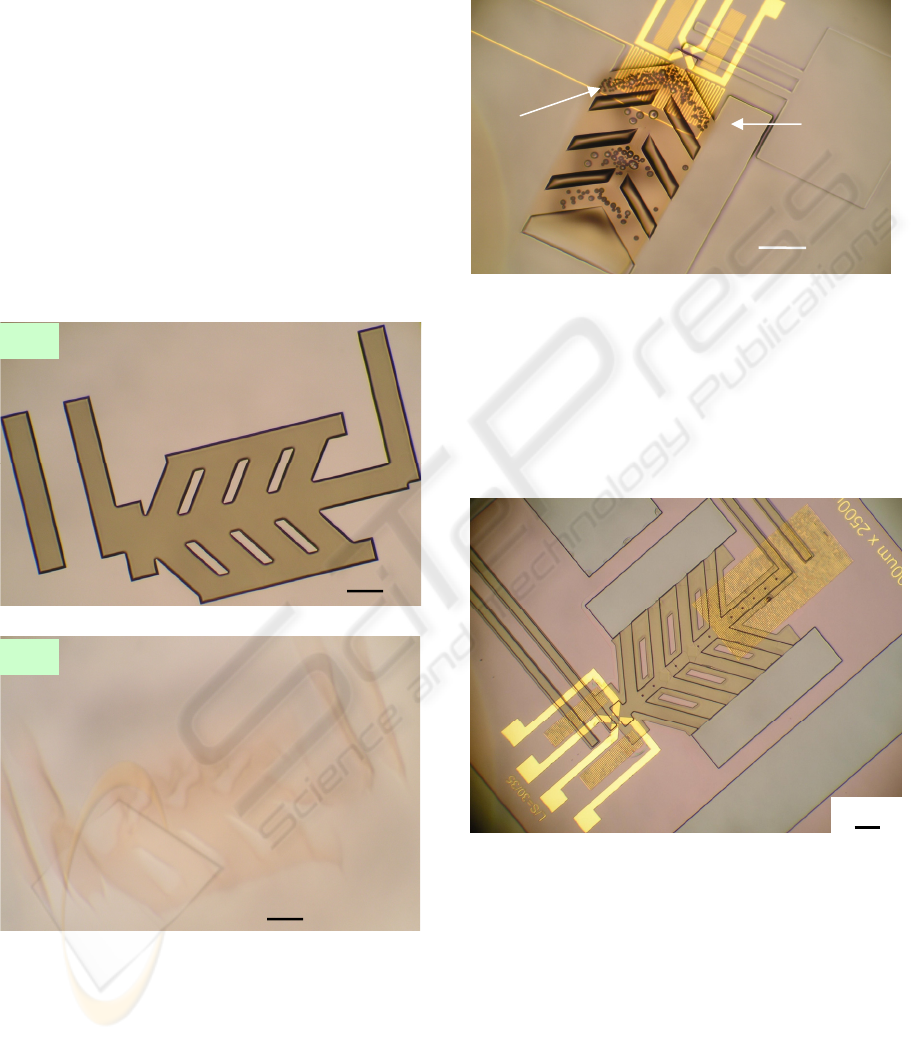

3 MEMS DEVICE FABRICATION

Fabrication of the MEMS devices utilized surface

micromachining techniques. The processing flow

has been described in detail previously (Zhang,

2007), and will be briefly summarized here (Figure

2). The starting materials are oxidized 3-inch

diameter silicon wafers. First, a metal layer of

80 nm platinum was patterned using lift-off process

(Figure 2a). A 20 nm titanium layer preceding this

conductive layer was used to increase the adhesion

wherever metallization was present. Second, a 5 µm

thick sacrificial photoresist (AZ P4620, Clariant,

New Jersey) was applied to create an air gap (Figure

2b). Third, a thick negative tone photoresist (SU-8,

product #: 2015, Microchem, MA) was used for a

structural layer (Figure 2c). Next, the second metal

layer of 80 nm gold (with the same adhesion layer)

was patterned on top of the structural polymer

(Figure 2d). Finally, the whole structure was

immersed in AZ 400T photoresist stripper (Clariant,

New Jersey) at room temperature to release the

polymer device (Figure 2e).

Figure 2: Fabrication process flow for the BioMEMS

device for measuring the mechanical modulus of a

biological cell.

a) Deposit and

pattern the first metal

layer (Pt/Ti) on a

glass (or oxidized

silicon) wafer

b) Deposit and

pattern the sacrificial

la

y

er

(

AZ P4620

)

c) Deposit and

pattern the structural

la

y

er

(

SU-8

)

d) Deposit and

pattern the second

metal la

y

er

(

Au/Ti

)

e) Release the structural

layer by removing the

sacrificial layer

Substrate (Oxidized Silicon)

1

st

Metal Layers (Pt/Ti)

Sacrificial Layer (AZ P4620)

Structural Layer (SU-8)

2

nd

Metal La

y

e

r

s

(

Au/Ti

)

(2) Fixed wall

Oxidized Silicon

substrate

(1) Polymer ETA

array

(4) Scale bars

Cell location

(3) dielectrophoresis

quadrupole electrodes

POLYMER MEMS SYSTEM FOR MEASURING THE MECHANICAL MODULUS OF A BIOLOGICAL CELL

147

3.1 Effects of UV/Ozone Treatment

A UV/Ozone cleaner was used to clean the

substrates and harden the sacrificial pattern (AZ

P4620). Without this step, the sacrificial pattern was

destroyed during the spin-coating of the structural

SU-8 polymer (Figure

3) by centrifugal forces and/or

solvent diffusion. During the UV/Ozone treatment,

the deep UV light (in ranges of 185 nm to 254 nm

wavelength) hardened the thick sacrificial

photoresist (Allen, Foster, and Yen, 1982) while the

heat generated by the UV lamps added additional

cross-linking. Therefore, the sacrificial patterns can

maintain their shapes after SU-8 patterning. We

used polymer sacrificial materials because it was too

difficult to selectively remove a metal sacrificial

layer with the pre-patterned Pt/Ti layer on the

substrate.

Figure 3: Optical images of the sacrificial patterns (a)

before and (b) after spin-coating a transparent structural

layer. These sacrificial patterns did not have UV/Ozone

treatment and were destroyed.

One more benefit of an UV/Ozone treatment was

reduction of gas bubbles in the resist. During the

UV exposure of SU-8, the underlying AZ P4620 that

had not been previously exposed also absorbed UV

radiation. Then, gases due to photoresist outgassing

in UV light (Kunz, 2004) were trapped by the SU-8

layer, which causes gas bubbles formation (Figure

4).

Figure 4: Optical image of gas bubbles that appeared the

post exposure baking after UV exposure of the structural

layer (SU-8).

Short UV/Ozone treatment (3 to 4 minutes) was

applied to solve the gas bubbles problem and

resulted in a sacrificial pattern hard enough to resist

physical and chemical damage (Figure 5), but still

able to be removed at the end of processing.

Figure 5: Optical image of a fabricated device. After

selecting the proper UV/Ozone treatment time, the

sacrificial patterns keep their shapes after SU-8 patterning.

(This image was taken after developing the SU-8 layer but

before the second metal layer formation).

4 RESULT & DISCUSSION

High frequency (800 KHz, sinusoidal) AC voltages

were applied to these BioMEMS devices to avoid

electrolysis, which generates a large amount of gas

in liquids (Selvaganapathy,

Leung Ki, Renaud, and

100 µm

Gas

bubbles

SU-8

Pattern

100 µm

The AZ P4620 pattern

was destroyed during

s

p

in-coatin

g

of the SU-8

(

b

)

The AZ P4620

pattern before spin-

coating of the SU-8

(

a

)

100 µm

100 µm

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

148

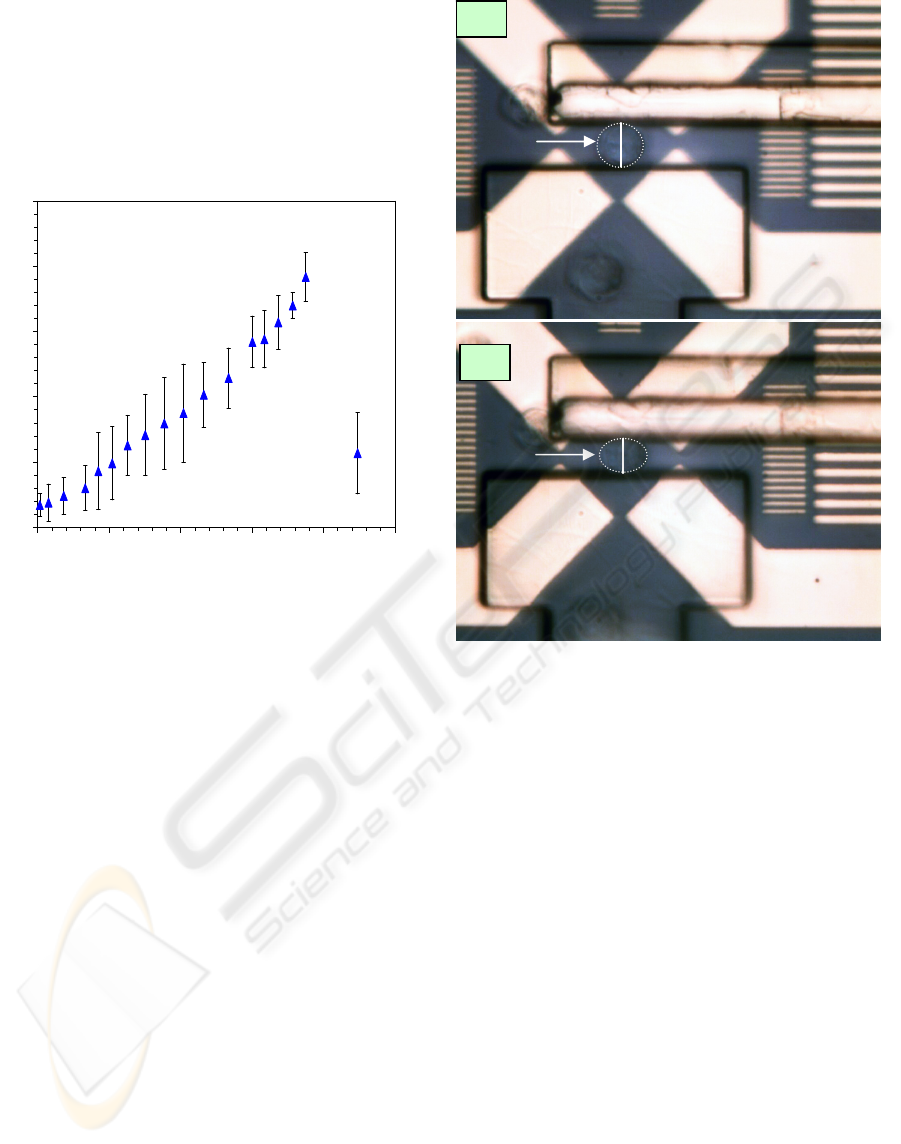

Mastrangelo, 2002). The actuator displacement as a

function of input electrical power was recorded

(Figure 6) when operation in NIH3T3 fibroblasts

cell medium. The maximum displacement was

4 µm when power was RMS 750 mW. After

exceeding the maximum value, the displacement

decreased due to the out-of-plane deformation of the

polymer V-shaped electrothermal actuator array.

Figure 6: Experimental data of the BioMEMS ETA arrays’

displacement as a function of input AC power.

The lab experiments started with immersion of the

BioMEMS device into the cell medium. Cells were

transferred to the device using a micropipette. First,

a cell was trapped at the centre of the

dielectrophoresic quadrupole electrodes after

applying an AC voltage (10 V

p-p

, 1 MHz, sinusoidal)

to them (Figure 7a). Next, the actuator was moved

towards the cell, and it compressed the cell up to

4 µm (Figure 7b). The diameter of the cell under

test was measured to be 16 µm. This means that the

BioMEMS devices can mechanically stimulate the

cell in 25% strain, which is double the minimum

requirement (10% strain) of mechanical stimulation

to a cell (You, Cowin, Schaffler, and Weinbaum,

2001).

When the cell was under compression,

orthogonal extension was observed as well.

Currently, the displacement resolution was ±0.5 µm.

Next, the spring constant of the polymer ETA was

calibrated using a nanoindenter (TriboScope,

Hysitron Inc.). Finally, the compressive modulus of

the NIH3T3 fibroblast cell can be extracted from

these measurements. In order to extract reliable

mechanical modulus, we are currently working on

improving the resolution of this method.

Figure 7: Optical images of: (a) a cell being trapped at the

centre of dielectrophoresic quadrupole electrodes, and (b)

the cell being compressed by the actuator after being

powered up. (Outline of the cell is for better visibility.).

5 CONCLUSIONS

The measurements of the mechanical properties of

biological cells are critical to improve the public

health condition. This research focuses on the

design, fabrication, and characterization of a MEMS

system to measure the compressive modulus of a

live biological cell. This MEMS-based system has

realized three basic functions: (1) trapping a cell to a

designed area before testing; (2) applying forces to a

cell, and (3) sensing the forces and displacements

during the compressing. The device was able to

compress a cell up to 25% mechanical strain in a cell

medium. The measurements of mechanical

properties are limited by the current displacement

resolution and the improvements are under

investigation.

Fixed wall

(a)

A

c

t

ua

t

or

Cell

DEP

Electrodes

16 μm

Cell

A

c

t

ua

t

or

Fixed wall

DEP

Electrodes

(b)

12 μm

0

1

2

3

4

5

0 200 400 600 800 1000

AC Power RMS [mW]

Displacement [

μ

m]

POLYMER MEMS SYSTEM FOR MEASURING THE MECHANICAL MODULUS OF A BIOLOGICAL CELL

149

REFERENCES

Allen, R., Foster, M., Yen, Y.-T., 1982. Deep U.V.

Hardening of positive photoresist patterns. J

Electrochem. Soc., 128, 1379.

Caillot-Augusseau, A., Lafage-Reoust, M.-H., Soler, C.,

Pernod, J., Dubois, F., Alexander, C., 1998. Bone

formation and resorption biological markers in

cosmonauts during and after a 180-day space flight

(Euromir 95). Clin. Chem. 44(3), 578-585.

Donahue, H. J., Zhou, Z., Li, Z., McCauley, L. K., 1997.

Age-related decreases in stimulatory G protein-

coupled adenylate cyclase activity in osteoblastic cells.

Am. J. Physiol. 273, E776-E781.

Elderstig, H., Larsson, O., 1997. Polymeric MST-high

precision at low cost. J. Micromech. Microeng., 7, 89-

92.

Fritton, S. P., McLeod, K. J., Rubin, C.T., 2000.

Quantifying the strain history of bone: spatial

uniformity and self-similarity of low-magnitude

strains. J. Biomechanics. 33 (3), 317-325.

Kunz, R. R., 2004. Photoresist outgassing: a potential

Achilles heel for short wave-length optical lithography?

in Proc. of SPIE, 5376, 1-15.

Scuor, N., Gallina, P., Panchawagh, H. V., Mahajan, R.

L., Sbaizero, O., 2006. Design of a novel MEMS

platform for the biaxial stimulation of living cells.

Biomed. Microdevices, 8, 239-246.

Selvaganapathy, P., Leung Ki, Y.-S., Renaud, P.,

Mastrangelo, C. H., 2002. Bubble –free electrokinetic

pumping. J. Microelectromech. Syst., 11(5), 448-453.

Timoshenko, S.P. and Goodier, J.N., 1970. Theory of

Elasticity. 3rd ed. New York: McGraw-Hill Publishing

Company. 409-415.

U.S. Department of Health and Human Services, (2007).

Bone Health and Osteoporosis: A Report of the

Surgeon General. Retrieved July 9, 2007, from

http://www.surgeongeneral.gov/library/bonehealth/fac

tsheet2.html

Yang, S., Saif, T., 2006. MEMS based sensors for the

study of indentation response of single cells. in Tech.

Dig. of MEMS 2006, Istanbul, Turkey, 20-23.

You, J., Yellowley, C. E., Donahue, H. J., Jacobs, C. R.,

1999. Physiological levels of substrate deformation are

less stimulatory to bone cells compared to fluid flow,

In American Society of Mechanical Engineers,

Bioengineering Division (Publication) BED, 43, 161-

162.

You, L., Cowin, S. C., Schaffler, M. B., Weinbaum, S.,

2001. A model for strain amplification in the actin

cytoskeleton of osteocytes due to fluid drag on

pericellular matrix. J. Biomechanics. 34 (11), 1375-

1386.

Zhang, W.-Y., 2007. Design, Modeling, Fabrication and

Characterization of a MEMS Device for Measuring

the Mechanical Compliance of a Biological Cell. Ph.D.

Dissertation, Lehigh University, 2007.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

150