MICROCOMPUTERIZED SYSTEM TO ASSESS THE

PERFORMANCE OF INFANT INCUBATORS

Mário Anderson de Oliveira, Maurício Campelo Tavares

Institute of Biomedical Engineering, Federal University of Santa Catarina, campus trindade

88040 – 970, Florianópolis, SC, Brazil

Laboratory of Biomedical Engineering, Catholic University of Pelotas, campus I, number: 412

Félix da Cunha 109C, 96010-000, Pelotas, RS, Brazil

Raimes Moraes

Department of Electrical Engineering, Federal University of Santa Catarina, 88040 – 900, Florianópolis, SC, Brazil

Keywords: NBR IEC 601.2-19 (1999), Bluetooth, neonate incubators, clinical engineering, assessment.

Abstract: This work presents a system based on a microcomputer to assess the performance of infant incubators in a

semi-automatic manner. It carries out the tests described by the section 8 of the NBR IEC 601- 2-19 (1999).

The developed electronic circuit acquires data from the sensors using a microcontroller. A set of sensors are

used: five for temperature, one for humidity and one for air flow. The sampled data is sent to the PC via

Bluetooth. The software running on the PC manages the data sampling, as well as guides the user through

the test procedure by means of messages and sound alerts at the end of each stage. The sampled data is

shown on the screen and also stored in a database that can be remotely accessed. The results are presented

on a graph where the measurements (temperature, humidity and air flow) performed during the whole test

can be seen. The procedure to calibrate the sensors and an infant incubator assessment carried out with the

developed system is presented.

1 INTRODUCTION

There is a high percentage of mortality associated to

low birth weight newborns (Ministério da Saúde,

2002). These neonates have an immature thermal

control mechanism, preventing them to keep

constant their body temperature (Gonzáles, 2001).

The infant incubator (InI) aims to provide a thermo-

neutral environment where the infant does not

exchange heat, consuming a minimum amount of

oxygen. This environment is obtained by controling

the temperature, humidity and air flow. Inside the

InI, the infant has a reduced metabolism that helps

its healthier and faster growth (Ministério da Saúde,

2002). Therefore, InIs shall be periodically checked

to assure that they offer a suitable environment to

the neonate.

This work describes a system developed to

assess the InI performance according to the Section

8 of the NBR IEC 601-2-19 (1999).

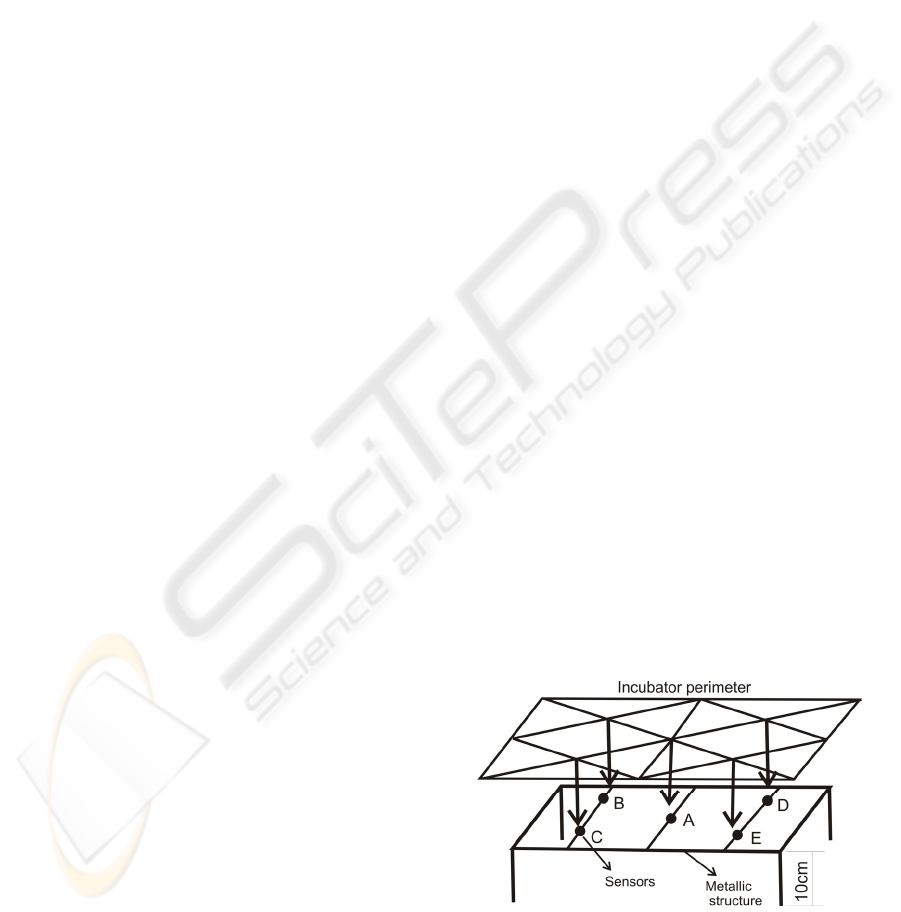

To evaluate the InI performance, the standard

demands measurements of the following parameters:

air temperature at five different points, relative

humidity and air velocity. The temperature sensors

are placed at five points 10 cm above the mattress

surface (A, B, C, D and E) as shown in Figure 1.

Figure 1: The NBR IEC 601-2-19 demands temperature

measurements at 5 different points (10 cm above the

mattress surface): A, B, C, D and E. A metallic structure is

used to hold the sensors at the required positions.

119

Anderson de Oliveira M., Campelo Tavares M. and Moraes R. (2008).

MICROCOMPUTERIZED SYSTEM TO ASSESS THE PERFORMANCE OF INFANT INCUBATORS.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 119-122

DOI: 10.5220/0001053501190122

Copyright

c

SciTePress

2 MATERIALS AND METHODS

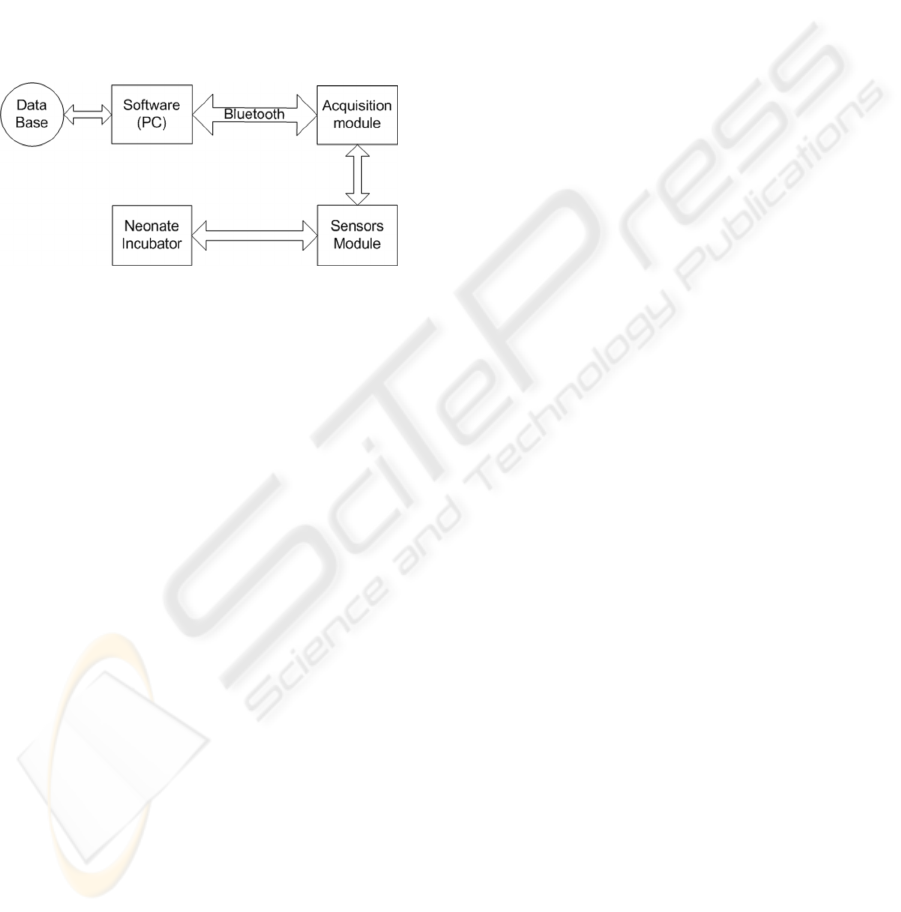

The performance testing required by the standard is

relatively difficult to be carried out manually, being

desirable to automate it. Thus, a microcontrolled

system was developed to automatically sample InI

data that are sent to a microcomputer (Figure 2).

The developed system consists of 5 modules:

sensors, acquisition, communication, control

software and database.

The remote control software running on a PC

communicates with the acquisition module to

require samples from the sensors placed into the InI.

Figure 2: The developed system has five modules: sensor,

acquisition, communication (Bluetooth), control software

and database.

2.1 Sensors Module

The sensors are placed into the InI as shown by the

Figure 1.

The sensor SHT75 (Sensirion Inc) is used to

measure the Incubator Temperature (temperature at

the point A of Figure 1) and the relative humidity

(RH). It measures temperature in a range from -40 to

123.8°C and RH from 0 to 100%RH. For

temperature, the SHT75 has a typical accuracy of

±0.5°C and resolution of 0.01°C. For humidity,

typical accuracy of ±1.8%RH and resolution of

0.03%RH.

The measurements executed by the SHT75 are

available in digital format via the 2-wire protocol.

This is a bi-directional protocol, allowing the sensor

to receive commands as well.

To measure the temperature at the other points

(B, C, D and E), 4 TMP05 (Analog Devices) sensors

are used. The TMP05 measures temperature in a

range from -40 to 123.8°C with a typical accuracy of

±0.5°C and resolution of 0.01 °C.

The TMP05 sensors can be connected in

cascade, establishing a net. Thus, only two

microcontroller pins are needed to acquire the

temperature measurements from the sensors: one

generates a start pulse and the other receives the

PWM signal.

The sensor F900 (Degree Controls Inc.) is used

to measure the air velocity in the InI. It has a linear

output voltage for a range from 0.15 to 2m/s with a

typical accuracy of ±0.05m/s and resolution of

0.05m/s.

2.2 Acquisition Module

The acquisition module contains the microcontroller

ADuC841 (Analog Devices) that has the following

characteristics: 8052 core, 20 MIPS, 8 ADC

channels (12 bits), 2 DAC channels (12 bits), 3

timers/counters (16 bits) and serial communication

interfaces (UART, I2C and SPI).

The ADuC establishes serial communication

with the SHT75 and TMP05 to get the humidity and

temperature measurements. Its ADC samples the

F900 voltage output to figure the air velocity out.

These measurements are sent to the PC when

demanded by the control software.

2.3 Communication Module

The Bluetooth module implements wireless link

between the acquisition module and the PC. To

provide a communication range up to 100 meters, a

KC-11 unit (KCWirefree) is connected to the

acquisition module and a KC-210 is inserted into the

PC USB port.

A virtual serial port driver is used by the

control software to communicate with the KC-210.

2.4 Control Software Module

About 6 hours are necessary to carry out the

measurements required by the NBR IEC 601-2-19

(1999). To simplify the task, a control software was

developed for WindowsOS® in Borland C++

Builder.

At 20 second intervals, the software demands

a new set of measurements. For that, an ASCII

command is sent to the acquisition module. After

receiving the command, the microcontroller

communicates with the sensors to get the

measurements that are sent back to the PC. The

received data are presented on the PC screen and

stored into a database.

Besides managing the measurements, the

developed software guides the user through the

testing procedure by means of messages and sound

alerts at the end of each stage. The software displays

messages on the PC screen asking the user to change

the InI settings or the mattress position. After doing

so, the user shall click the OK button of the message

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

120

box. Then, the software keeps executing the

measurements.

2.5 Database

The database (DB) was developed with PostgreSQL

8.0, a free software object-relational database

management system (Matthew and Stones, 2005).

The implemented DB has two entry tables, one

registers the equipment identification key; the other

stores the measurements carried out during the InI

testing.

3 SENSORS CALIBRATION

The F900 and SHT75 sensors are individually

calibrated. They both have calibration certificate.

The F900 is supplied with its calibration curve. The

SHT75 has calibration coefficients programmed into

its internal memory.

The TMP05 sensors were calibrated using the

SHT75 as reference since there was no other

traceable reference sensor with better accuracy and

resolution available in this laboratory.

To calibrate the four TMP05 sensors, they were

placed together with the reference sensor into a

container with low heat transmission walls. The air

inside the container was heated up to 60ºC and then,

the heat source was turned off. During the air

cooling, 17 sets of temperature measurements were

obtained for each sensor within the range from 25 to

41ºC. For each sensor, a third order polynomials was

fitted to the experimental data to correct the

systematic error observed with respect to the

reference sensor. These polynomials are used by the

software running on the PC to reduce the

measurement errors.

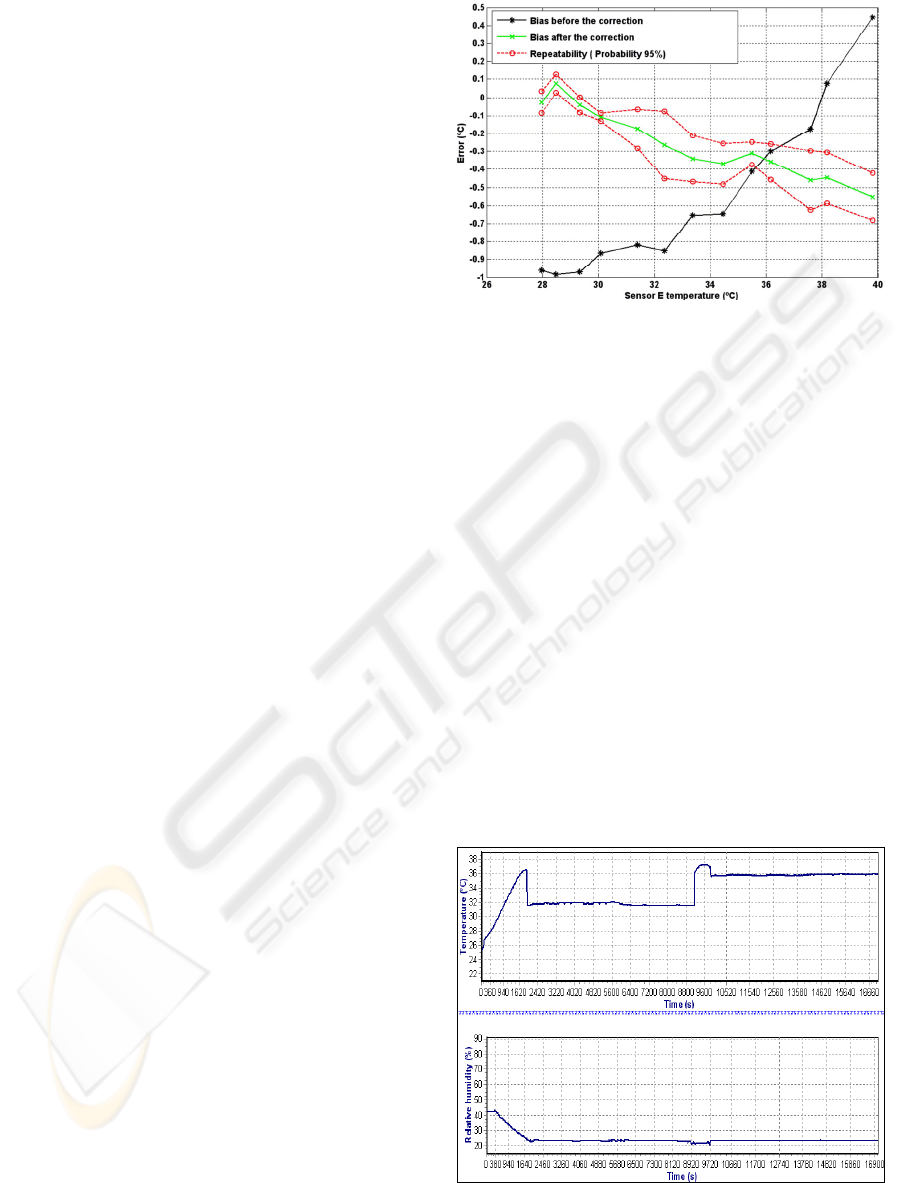

To evaluate the described calibration, 3

measurements were executed for 13 different

temperatures within the calibrated range to find out

the resultant errors. This procedure was repeated for

each sensor.

For each sensor, the systematic error (bias) and

the random error (repeatability) were surveyed.

As example of the result achieved with this

sensor calibration procedure, the Figure 3 shows the

curves obtained for the sensor to be placed at the

point E (Figure 1). This one presented the larger

errors (about ± 0.5ºC) within the InI operating range

(32 to 36ºC).

Figure 3: Measured error curve versus temperature is

plotted for the sensor E. It is also shown the systematic

error (before and after the application of the polynomial

adjustment) and the random error.

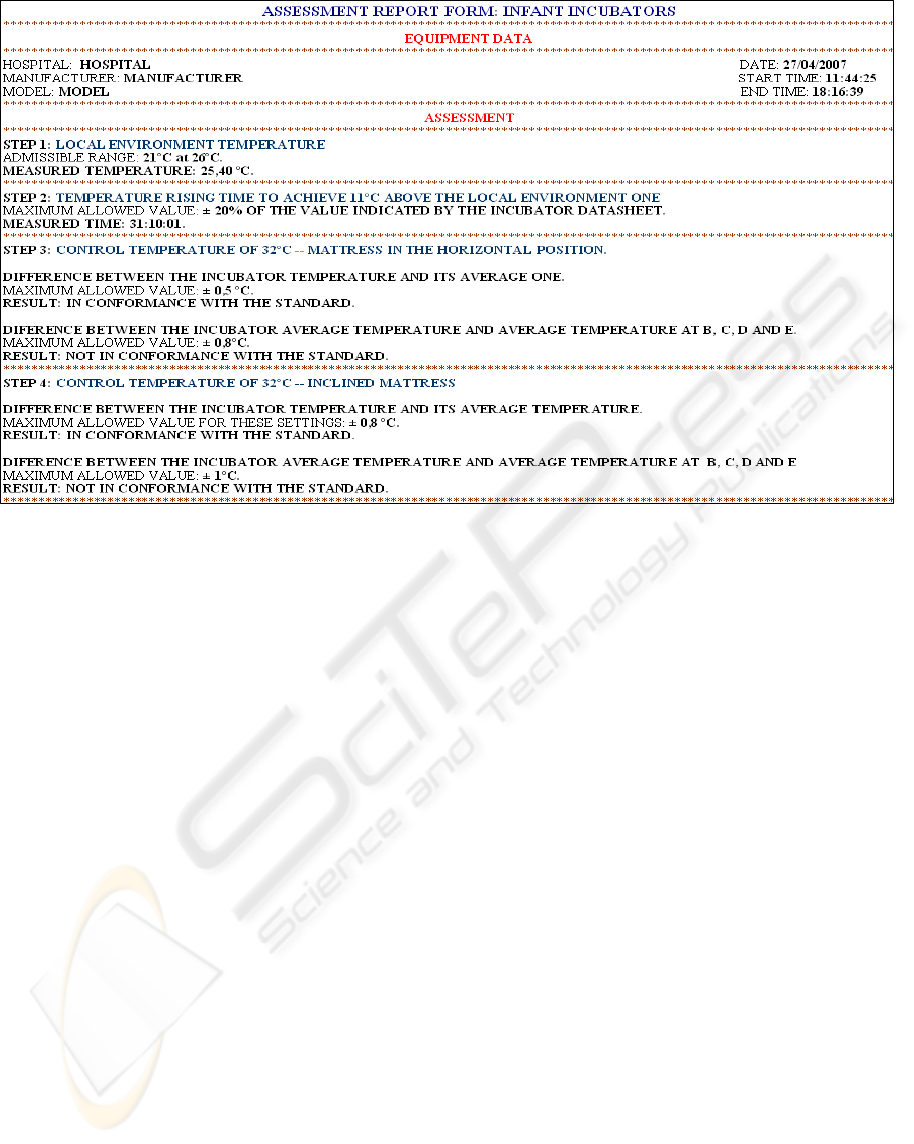

4 RESULTS

To evaluate the performance of the developed

system, assessment of an InI was carried out.

At the end of test, the results are stored in the

DB. The results can be consulted on text format or

graphically visualized. In text format, statements on

the standard conformance are presented as shown in

Figure 4.

For ethical reason, since the developed system

was not certificated by an accredited laboratory,

reference to the model and manufacturer of the InI

as well as the health institution to which it belongs

are omitted.

In the graph, the behaviour of the measured

parameters (Incubator Temperature, RH and the air

velocity) during the whole test can be observed.

Figure 4: Incubator temperature measured during the

assessment. Relative humidity and air flow curves are also

presented in the graphical report.

MICROCOMPUTERIZED SYSTEM TO ASSESS THE PERFORMANCE OF INFANT INCUBATORS

121

5 CONCLUSION

The developed system does not comprise a sound

level meter. The sound measurements required by

the standard are relatively simple to be made.

Equipments available in the market can be employed

to this end, having a layout that allows their use in

other applications.

The maximum uncertainties in the temperature

measurements (taking into account the propagation

of the reference sensor uncertainty: ±0.3ºC) obtained

with the sensors B, C, D and E are ±0.4 ºC, ±0.5 ºC,

±0.5 ºC and ± 0.61 ºC, respectively.

Assessment of InIs according to the NBR IEC

601-2-19 standard can be performed by the

developed system in a semi-automatic manner, since

the user has to change the InI operating settings

during the test. Throughout the procedure, the

control software beeps at the end of each stage and

shows messages on the PC screen. These messages

ask the operator to adjust the InI settings before

performing the next set of measurements.

The control software and the used

communication protocol have proven to be suitable

and robust during the InI assessment.

The report generated at the end of the assessment

points out the InI conformance with respect to the

NBR IEC 601-2-19 requirements.

It shall be noted that all the tests carried out with

an InI are stored in a same DB, allowing a better

follow-up of its performance along its lifetime.

For instance, the number of corrective

maintenance underwent by a given InI model can be

very useful to the managers when considering the

purchasing of new equipments.

ACKNOWLEDGEMENTS

The authors thank the CNPq for financial support

(507363/2004-3).

REFERENCES

Ministério da Saúde, 2002. Manual do curso de

humanização do recém – nascido de baixo peso.

Método Canguru - Série A: Normas e Manuais

Técnicos Nº 145. Brasília. 1

nd

edition.

Gonzaléz, L. H., 2001. Termoregulación em Recién

Nacido. In: Servicio Neonatalogia. Servicio

Neonatalogia. Hospital Clinico Universidad de Chile.

Chile. 1

nd

edition. p. 34-40.

NBR IEC 601-2-19, 1999. Equipamento Eletromédico

Parte2: prescrições particulares para segurança de

incubadoras para recém-nascidos RN, Rio de Janeiro.

ABNT.

Matthew N, Stones R., 2005. Beninning databases with

PostgreSQL. Aprress. 2

nd

edition.

Figure 5: Part of the report generated by the developed system.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

122