STUDY OF DENTAL GYPSUM USING FIBRE SENSORS

Analysis of Different Water/Powder Ratios of High Strength Dental Stone

Nélia Alberto

1

, Rogério Nogueira

2

, Lídia Carvalho

3

, Ilda Abe

1

Hypolito Kalinowski

4

and João L. Pinto

1,2

1

Physics Department, University of Aveiro, Campus Universitário de Santiago, Aveiro, Portugal

2

Institute of Telecommunications, Campus Universitário de Santiago, Aveiro, Portugal

3

Dental Prosthesis IPSN, Paredes, Portugal

4

Federal University of Paraná, Curitiba, Brazil

Keywords: Fibre optic sensors, Bragg grating, dental gypsum, water/powder ratio.

Abstract: In this work, we present a device to measure strain and temperature, based on fibre Bragg grating (FBG)

sensors. The performance of these sensors was assessed in the study of a type of dental gypsum, namely

high strength dental stone. It was intended to know the influence of the water/powder (W/P) ratios in the

setting time and expansion. The results show that, a change in the W/P ratio influences the setting time as

well as maximum strain values. The data was compared with the values foreseen in ANSI/ADA

specification nº 25. The information that can be obtained with these sensors is quite important to dental

prosthesis technicians, in order to achieve more accurate dental prosthesis and these sensors can be a good

substitute to the actually device that is used to evaluate the setting expansion: extensometer.

1 INTRODUCTION

Optic sensors based on fibre Bragg grating (FBG)

have attracted much attention in the past few years

due to many advantages such as high sensitivity,

immunity to electromagnetic interference,

wavelength multiplexing, lightweight, low cost and

easiness handling, which allows to be embedded into

different materials. These characteristics have

opened wide fields of applications, from optical

communications to biomedicine. Thus, we can find

FBGs in civil structures monitoring (Lima, 2007);

sensing systems in vehicles, airplanes and ships

(Castelli, 2002), in the detection of virus/antibodies

(Petrosova, 2007) or even, in linear polymerization

shrinkage monitoring of dental materials (Arenas,

2007).

In its simplest form, an FBG consists of a

periodic modulation of the refractive index along the

fibre length, which is formed by exposure of the

core to an intense optical interference pattern of

ultraviolet light. The sensing principle of a FBG-

sensor is based on the monitoring of the wavelength

shift of the reflected Bragg wavelength when it is

subjected to strain and/or temperature changes.

The Bragg wavelength is given by the following

expression:

λ

Β

= 2 n

eff

Λ (1)

where n

eff

is the effective index of the core and Λ is

the refractive index modulation period (Kersey,

1997).

Among the dental materials, gypsum is one of

most used in dental prosthesis because of its ability

to change properties by the addition of different

chemical components. When powder particles of the

gypsum are mixed with water, a chemical reaction

occurs, according with the following equation

(Phillips, 1991):

(CaSO

4

)

2

.H

2

O + 3H

2

O CaSO

4

.2H

2

O + heat (2)

All manufacturers of gypsum products have its

own recommendations, concerning proper

water/powder (W/P) ratio to be used, to obtain the

best performance. However, if the W/P ratio is not

correctly followed, accordingly to the

manufacturer’s recommendations, the gypsum might

have different properties, namely the setting

expansion.

232

Alberto N., Nogueira R., Carvalho L., Abe I., Kalinowski H. and L. Pinto J. (2008).

STUDY OF DENTAL GYPSUM USING FIBRE SENSORS - Analysis of Different Water/Powder Ratios of High Strength Dental Stone.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 232-235

DOI: 10.5220/0001055302320235

Copyright

c

SciTePress

In this work the influence of the W/P ratios of a

high strength dental gypsum stone (type IV) was

experimentally studied, namely the setting time and

expansion, using devices based on FBG. The setting

expansion values obtained were compared with

values foreseen in ANSI/ADA specification nº 25,

which were measured using an extensometer.

2 EXPERIMENTAL SETUP

The FBGs were written into photosensitive optical

fibre (Fibercore PS1250/1500), by illuminating it

with ultraviolet light, using an automated phase-

mask interferometer system (Nogueira, 2002).

Two sensors were used in this work. One of them

was protected mechanically, in order to be only

sensitive to temperature variations. For that, the

sensor was placed inside a double needle (figure 1).

Figure 1: Temperature sensor.

The other sensor consisted in a free FBG, which was

in close contact with gypsum, and is sensitive to

strain and temperature variations. In the first

analysis it was verified that there was sliding of the

gypsum along the free FBG. In order to overcome

this situation, two plastic spheres were glued to the

fibre, down and above the sensor (figure 2),

allowing a better response of the fibre to the gypsum

expansion/contraction.

Figure 2: Schematic representation of the experimental

setup.

The free sensor was put inside a hard metallic

container (diameter = 3.5 cm and height = 7 cm)

with a hole in the bottom, through which the fibre is

pulled through. The fibre is then bonded to a support

and slightly tensioned (about 700 με) allowing

measuring both expansion and shrinkage.

Relatively to the W/P ratio, three different values

were considered. One corresponds to the value

recommended by the manufacturer, which is 0.22,

one corresponding to a 15% decrease of the water

quantity (W/P = 0.19) and another corresponding to

a 15% increase of the water quantity (W/P = 0.26).

These values were chosen, according with the

reaction’ stoichimetry and the W/P ratio

recommended by manufacturer. Through reaction’

stoichimetry we verified that a 15% decrease of

water quantity relatively to W/P ratio recommended

by manufacturer is the minimum value requested to

occur reaction thus. With a decrease of water below

15% it is impossible to have a full reaction of

gypsum. The choice of the other W/P ratio is related

to the fact that we consider that usually there is a

tendency to add a larger amount of water than the

one recommended, facilitating the handling of

gypsum.

For each case, the water was added to powder

and spatulated, during 45 seconds. Then, the mixture

was flowed into the metallic container and finally,

the temperature sensor was inserted into the mixture.

The Bragg wavelength measurement was made

every 5 seconds, during 3 hours, simultaneously for

the two sensors. The resolution of the system

(sensor+interrogation system) allows measurements

of displacement and temperature with a precision of

about 1 με and 0.1 ºC respectively.

The measurements were repeated several times

for each W/P ratio, being the results presented in this

work a result of an average.

3 RESULTS AND DISCUSSION

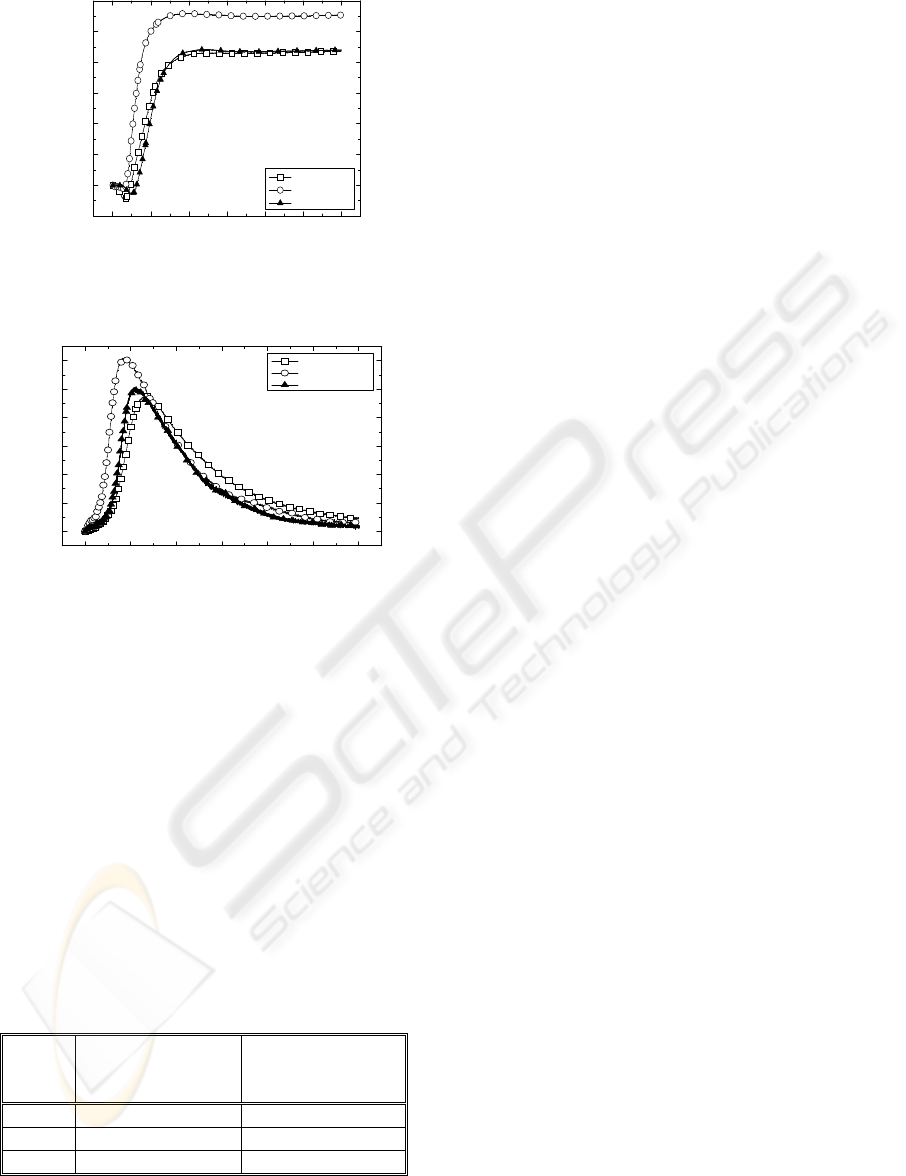

The evolution of strain and temperature with time,

for the two sensors used in the experiments are

showed in the graphs of figures 3 and 4,

respectively.

FBG

STUDY OF DENTAL GYPSUM USING FIBRE SENSORS - Analysis of Different Water/Powder Ratios of High Strength

Dental Stone

233

0 30 60 90 120 150 180

0

2

4

6

8

10

12

TEMPERATURE VARIATION (ºC)

TIME (min)

(W /P) = 0.19

(W /P) = 0.22

(W /P) = 0.26

Figure 3: Evolution of strain during setting reaction, for

gypsum type IV, for three different (W/P) ratios.

Figure 4: Evolution of temperature during setting reaction,

for gypsum type IV, for three different (W/P) ratios.

The strain curve was obtained by subtracting the

effect of temperature, obtained with the temperature

sensor, in the measurements accomplished by the

free FBG. The sensitivity coefficients of the FBG to

temperature and strain was 10.6 pm/ºC and

1.1 pm/με, respectively. These values were

previously measured.

According with the results obtained, we can

observe that when we change the W/P ratio

recommended by manufacturer, the maximum strain

value and maximum thermal amplitude, reached

during the setting reaction of dental gypsum are

different (table 1), although the behaviour is similar.

Table 1: Values of maximum strain and maximum thermal

amplitude for the W/P ratios analysed.

(W/P)

ratios

Maximum strain

(με)

Maximum thermal

amplitude

(ºC)

0.19 874 9.5

0.22 1120 12.3

0.26 884 10.1

Initially, we observe a shrinkage of dental

gypsum, being more accentuated in the case of the

W/P = 0.19, where it reaches about -90 με.

Following, there is an increase of strain, along with

an increased of temperature. After 55 min, for

W/P = 0.22 and after 65 min, for W/P of 0.19 and

0.26, the setting expansion stabilized and

temperature returned slowly to its initial value (room

temperature).

Although there is a modification on the setting

expansions values when the W/P ratio change, the

results obtained experimentally are within the range

established by ANSI/ADA specification nº 25, that,

in this case, is between 0% and 0.15 %. This range

was determined using an extensometer that allows

the measurement of length changes within 0.01 mm

resolution in a specimen with a length of 100 mm,

(100 με of resolution). The proposed device, based

on FBG, allows a real time measurement of the

evolution of the strain and temperature in the

material. Moreover, the resolution is around 1 με.

Thus, the use of this device can be an incentive to

the revision of actual ANSI/ADA specification

nº 25, where we suggest the measurement of the

setting expansion, using optic fibre sensors to the

detriment of the extensometer because this technique

present more resolution, with more reliable results.

When the gypsum is dry, it is also possible to

measure the linear thermal expansion coefficient.

This thermal property is other information quite

important to dental prosthesis technicians, which is

defined as the change in length per unit of length of

gypsum, when its temperature is raised or lowered

1ºC.

4 CONCLUSIONS

In this work we presented a device for strain and

temperature measurements, based on FBGs.

These sensors were applied in the study of the

influence of the W/P ratios of dental gypsum, in the

setting time and expansion. Also the sensor shows

applicability in the determination of thermal

expansion coefficient.

The sensors’ response showed that, a

modification of the amount of water influences the

value of maximum strain and, this difference might

interfere in the outcome of the technicians work. So,

it is advisable following the manufacturer’s

recommendations.

The present devices can also be a useful tool for

gypsum’ manufacturers, allowing a real time

monitoring of strain and temperature along the

production process, what can be very important in

0 30 60 90 120 150 180

-200

0

200

400

600

800

1000

1200

STRAIN (με)

TIME (min)

(W/P) = 0.19

(W/P) = 0.22

(W/P) = 0.26

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

234

the control and improvement of the gypsum’s

properties.

ACKNOWLEDGEMENTS

The authors acknowledge support received from

FCT SFRH/BD/30551 and SFRH/BPD/14513/2003

and project THRONE PTDC/EEA-TEL/66840/2006

(Portugal).

REFERENCES

Lima, H., Vicente, R., Nogueira, R., Abe, I., André, P.,

Fernandes, C., Rodrigues, H., Varum, H., Kalinowski,

H., Costa, A., Pinto, J. (2007), “Structural health

monitoring of the church of Santa Casa da

Misericórdia of Aveiro using FBG sensors”, Proc.

SPIE – Third European Workshop on Optical Fibre

Sensors, 6619, 661941.

Castelli, P., Falciai, R., Galli, R., Mattiucci, N., Pallaro,

N., Trono, C., (2002), “Aplications of FBG sensors for

the monitoring of critical components of vehicles”,

European Workshop on Smart Structures in

Enginnering and Technology, 4763, 252 - 258.

Petrosova, A., Konry, T., Cosnier, S., Trakht, I., Lutwama,

J., Rwaguma, E., Chepurnov, A., Mühlberger, Lobel,

L., Marks, R., (2007), “Development of a highly

sensitive, field operable biosensor for serological

studies of Ebola virus in central Africa”, Sens and

Actuators B, 122, 578 - 586.

Arenas, G., Noriega, S., Vallo, C., Duchowicz, R., (2007),

“Polymerization shrinkage of a dental resin composite

determined by a fiber optic Fizeau interferometer”,

Opt. Commun., 271, 581-586

Kersey, A., Davis, M., Patrick, H., LeBlanc, M., Koo, K.,

Askins, C., Putnam, M., Friebele, E., (1997), “Fiber

Bragg sensors”, J. Lightw. Technol., 15, 1442 - 1463.

Phillips, R., (1991), “Skinner’s Science of Dental

Materials”, W. B. Saunders Company, Philadelphia,

9

th

edition.

Nogueira, R., Abe, I., Kalinowski, H., Pinto, J., Rocha, J.,

(2002), “Sistema interferométrico autorizado para

gravação de redes de Bragg”, 13ª Conferência

Nacional de Física – Livros de Resumos, Évora,

Portugal, 592 - 594.

STUDY OF DENTAL GYPSUM USING FIBRE SENSORS - Analysis of Different Water/Powder Ratios of High Strength

Dental Stone

235