DATA MINING AND KNOWLEDGE DISCOVERY FOR

MONITORING AND INTELLIGENT CONTROL OF A

WASTEWATER TREATMENT PLANT

S. Manesis, V. Deligiannis and M. Koutri

University of Patras,Electrical & Computer Engineering Department, Patras 26500, Greece

Keywords: Intelligent control, Knowledge-based systems, Data mining, Wastewater treatment, Expert-Fuzzy Logic.

Abstract: Intelligent control of medium-scale industrial processes has been applied with success but, as a method of

advanced control, can be further improved. Since intelligent control makes use of knowledge-based

techniques (such as expert systems, fuzzy logic, neural networks, etc.), a data mining and knowledge

discovery subsystem embedded in a control system can support an intelligent controller to achieve a more

reliable and robust operation of the controlled process. This paper proposes a combined intelligent control

and data mining scheme for monitoring and mainly for controlling a wastewater treatment plant. The

intelligent control system is implemented in a programmable logic controller, while the data mining and

knowledge discovery system in a personal computer. The entire control system is basically a knowledge-

based system which improves drastically the behavior of the wastewater treatment plant.

1 INTRODUCTION

Data mining is a fast growing research field aiming

at the extraction of valuable

knowledge from

massive databases. Due to the increasing use of

computing in the context of several applications,

data mining can actually be applied to various

problems related to the operation of man-made

systems and their interactions with other natural

ones. These interactions are becoming significantly

important as populations are growing and world’s

sensitivity for the environment is increasing. An

area of particular success has been in data mining

for wastewater treatment systems and surface water

systems (streams, lakes and rivers), where complex

problems can be solved that are unsolvable by any

other means (Condras et al. 2002; Condras and

Roehl 1999). Data mining tools have been adapted

for unsteady continuous systems, as wastewater

treatment plants where the hydro-dynamical,

biological and physical phenomena are highly

coupled, in order to monitor the wastewater quality

and detect dangerous faults of the process (Victor

Ramos et al. 2004).

On the other hand, intelligent control (DeSilva

1995; Harris et al. 1993), the discipline that

performs human-like tasks in environments of

uncertainty and vagueness with minimal interaction

with human operators, has had a significant impact

in the process industry. The cement industry was, in

fact, the first process industry to apply intelligent

control techniques in the late 1970s in the form of

fuzzy control, and today hundreds of industrial

plants worldwide are controlled by such controllers

(Boverie et al. 1991; Jamshidi et al. 1993; King

1992).

A fundamental attribute of intelligent control is

its ability to work with symbolic, inexact and vague

data which human operators comprehend best.

Indeed, its ability to deal with incomplete and ill-

defined information, an inherent characteristic of

wastewater treatment plants, permits implementation

of human-like control strategies which have hitherto

defied solution by any of the conventional hard

control techniques. Fuzzy logic and artificial neural

networks (Harris et al. 1993) are two examples of

soft computing which have migrated into the realm

of industrial control over the last two decades.

Chronologically, fuzzy control was the first and its

application in the process industry has led to

significant improvements in product quality,

productivity and energy consumption. Fuzzy control

is now firmly established as one of the leading

advanced control techniques in use in industry. Over

86

Manesis S., Deligiannis V. and Koutri M. (2008).

DATA MINING AND KNOWLEDGE DISCOVERY FOR MONITORING AND INTELLIGENT CONTROL OF A WASTEWATER TREATMENT PLANT.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - ICSO, pages 86-93

DOI: 10.5220/0001478400860093

Copyright

c

SciTePress

the last two decades or so wastewater engineering

has undergone significant advances in both theory

and practice. Experience gained from the operation

of numerous wastewater plants, coupled with the

results of recent research in the field, has led to

improved plant design and wastewater management.

Today, effective control of wastewater treatment

plants (Rodriguez-Roda et al. 2002; Manesis et al.

1998; Katebi et al. 2000) is of critical importance

not only for economic reasons but also to satisfy

stringent environmental constraints.

Expert fuzzy control systems have been

developed based on human operators’ experience,

the knowledge of which is acquired by way of

extensive interviews. However, the heuristic

knowledge of an operator, although it can contain

some important consequences about the operational

behavior of a plant, can not be based on a large

number of measurements and trend diagrams. A data

mining and knowledge discovery system can be

used to improve or optimize, as well as to evaluate

the behavior of the controller. Such a research and

development project, called TELEMAC (Lambert

2004; Dixon et al. 2007), within the European IST

program is now working on data mining which

opens up the prospect of learning from data in order

to manage wastewater treatment plants better.

Classification techniques for concept acquisition

have been also applied in order to build knowledge

bases that can help human experts to manage

wastewater treatment plants (Serra et al. 1994).

Usually, a Data Mining and Knowledge Discovery

(DMKD) system (Huang and Wang 1999; Sanguesa

et al. 1997; Dixon et al. 2004; Dixon et al. 2007) for

process monitoring and control is based on simple

measurements of the controlled variables from

which association rules may be found. As a valuable

addition, a DMKD system based on both

measurements and actions of a fuzzy controller is

the main idea presented in this work. Particularly,

the paper describes a new hybrid scheme in which

the induction rules are a priori given but modifiable

while the DMKD system searches on both inputs

and outputs of the fuzzy controller, records the

activity of rules and hence constitutes a part of the

overall controller. Experimental results from a four

months operation period of the treatment process are

presented in last section.

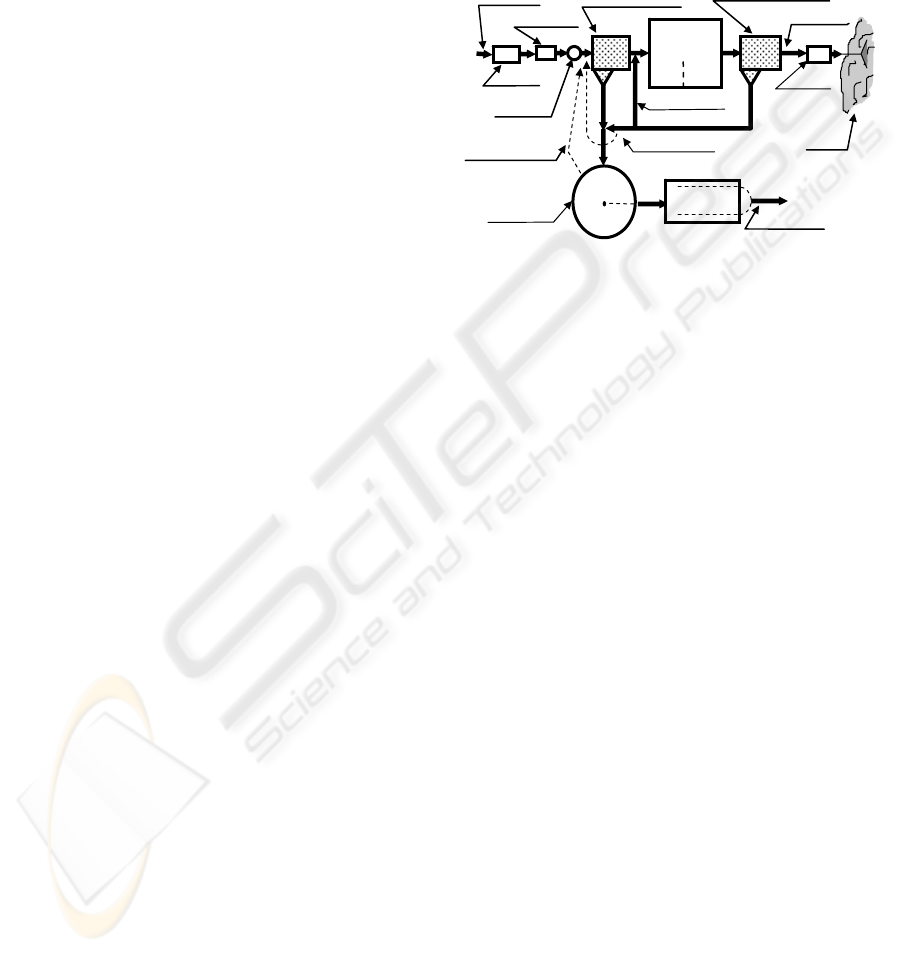

2 WASTEWATER TREATMENT

Wastewater treatment plants typically have two

principal stages as shown in Fig.1, the primary stage

which includes the bar racks, grit chamber and

primary settling tank whose objective is the removal

of the organic load and solids in the wastewater to a

degree of 30-50% and the secondary stage whose

objective is the biological treatment of the organic

load.

Figure 1: Schematic of a typical wastewater treatment

plant.

The removal of organic load (biochemical oxygen

demand or BOD, mixed liquid suspended solids or

MLSS) in conjunction with secondary treatment

performed in the final stage, leads to an overall

treatment level of the order of 80-90%. In all

wastewater treatment plants it is necessary the

oxygen content in the aerated zone to be also

subjected to close control. This is achieved by a

suitable control strategy involving the following

three manipulated variables:

(1) the oxygen supply to the aerated zone (O

2

Feed)

(2) the mixed liquid returns rate from aerated zone

to the anoxic one (R_ml)

(3) the sludge returns rate from settling tank to the

biological reactor (R_Sludge).

The quantities which are appropriately measured by

suitable instrumentation and constitute the

controlled variables of the plant are:

(1) the ammonia concentration in the reactor (N-

NH

3

)

(2) the nitrate concentration in the reactor (N-NO

3

)

(3) the dissolved oxygen in the reactor (DO)

(4) the temperature in the reactor (TEMP)

(5) the mixed liquid suspended solids concentration

in the reactor (MLSS)

(6) the difference in biochemical oxygen demand

between the entrance and exit of the secondary

settling tank (D(BOD))

These six variables constitute therefore the inputs to

Biological

treatment

Primar

y

settlin

g

Secondar

y

settlin

g

tank

Chloring

Sludge

Di

Sludge

Fusion

Sludge returns

Remaining

sludge

Slud

g

e

feed

Bar racks

Grit

Skimming

tank

Fields

Irrigation

Suspended liquids

Solids stora

g

e

Cl

DATA MINING AND KNOWLEDGE DISCOVERY FOR MONITORING AND INTELLIGENT CONTROL OF A

WASTEWATER TREATMENT PLANT

87

the intelligent controller. By the nature of the

process and the interaction of the controlled

variables it is obvious that effective control can only

be achieved by means of a multivariable controller

behind of which complex knowledge must exist.

3 INTELLIGENT CONTROL

OF A WASTEWATER

TREATMENT PLANT

Having established the principal controlled and

manipulated variables, the next task in developing

an intelligent controller for a wastewater treatment

plant, using linguistic techniques, is to establish a set

of linguistic descriptors for each manipulated

variable. These are expressions of the type Very

high, High, Low, OK etc. which are commonly used

by plant operators. The integrity of an intelligent

controller is directly related to the number of such

descriptors, bur practical limitations place a limit on

this number. The granularity of the controller is

inversely proportional to the number of linguistic

descriptors. Three descriptors are generally

sufficient to describe the controller input variables,

the HI (High), OK and LO (Low) descriptors all

with trapezoidal membership functions. The

locations of the centroids of the membership

functions can be considered as the modal points of

the fuzzy resolution while the number of such modal

points corresponds to the number of fuzzy states of

the variable. Also, the intermodal spacing of the

membership functions is a measure of the resolution

of the variable. It is obvious that the overall

accuracy of the intelligent control system is directly

related to this resolution. In a similar manner, the

manipulated variables or controller outputs are

allocated by five descriptors VH (VeryHigh), HI

(High), OK, LO (Low) and VL (VeryLow) which

provide sufficient fineness of control. For

computational simplicity, singletons provide a

convenient way to describe the membership

functions of the controller outputs where high

accuracy is not of paramount importance and also

lead to a particularly simple arithmetic procedure for

defuzzification.

The inference engine of the intelligent controller

manipulates linguistic control rules of the form:

R: if ((D(BOD) is Y

1

) and (MLSS is

Y

2

) and (TEMP is Y

3

and (DO is

Y

4

) and (N-NH

3

is Y

5

) and (N-NO

3

is Y

6

)) then ((O

2

Feed is U

1

) and

(R_Sludge is U

2

) and (R_ml is

U

3

))

where Y

m

and U

n

are the linguistic descriptors of the

m controller inputs and n outputs respectively,

where m ∈ {1,2,3,4,5,6} and n ∈ {1, 2, 3}. For the

kth linguistic rule, the values of the membership

functions corresponding to the process outputs (i.e.

the controller inputs) are computed to form the array

)(...)()),((

3621

NONMLSSBODD

kkk

−

μμμ

the minimum element of which is the degree of

fulfillment of that rule and is a measure of the

contribution of that rule to the final control action,

i.e.

{

}

1263

min ( ( )), ( )... ( ) [0,1]

kkk

k

DBOD MLSS N NO

σμ μ μ

=−∈

The union of the weighted products of the

corresponding membership functions of the

controller output fuzzy sets

{}

)(⋅v is subsequently

computed to form the resultant output membership

functions. The membership function of the jth

controller output is thus the result of the max

operator:

{

}

11 2 2 2 33

max ( ), ( _ ), ( _ )

jj j

v O Feed v R Sludge v R ml

σσ σ

The engineering values of the controller outputs,

necessary to drive the actuators of the plant under

control are obtained following the defuzzification

controller outputs are described by p singletons the

centre of gravity (COG) of the jth controller output

is simply the inner product procedure. When the

membership functions of the:

jjj

zy ,

ϕ

=

where the coefficients

[]

1,0

1

∈=

∑

=

p

l

l

j

j

σ

σ

ϕ

are the fractional degrees of fulfillment while the

array

{

}

j

z

contains the locations of the singletons

of the membership functions of the outputs.

A fuzzy system shell (FuzzyControl++ S7 ® by

Siemens) was used to develop the intelligent

controller of the wastewater treatment plant for a

city of 120.000 PE in Greece. The shell uses

trapezoidal membership functions, Mamdani max-

min inference and COG defuzzification (Mamdani

1974; Patyra and Mylnak 1996). A Simatic S7-300

programmable logic controller equipped with digital

and analogue input-output cards, to which the plant

sensors and actuators are directly connected, has

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

88

been selected. This actual controller is linked to a

host computer necessary not only for the fuzzy

system shell implementation but also for the data

mining and knowledge discovery procedure which is

described in next section.

4 DATA MINING AND

KNOWLEDGE DISCOVERY

FOR INTELLIGENT CONTROL

With intelligent controller being operated as

described above, the controller accepts a stream of

data and decides about the actions on the

manipulated variables. The generated continuously

over time actions, together with the operational

conditions constitute a kind of knowledge,

remarkably accepted or not, which nobody exploits.

Hence, a DMKD system should be introduced in

order to acquire and evaluate this knowledge. It is

known that the operational data of any industrial

process are used by plant operators and supervisors

to develop an understanding of a plant operation

through interpretation and analysis. In a first level,

there are methodologies and tools that automate data

interpretation and analysis derived by a large

number of measurements. In industrial processes

which already operate with an expert-fuzzy rule-

based controller the requirements of this first level

have been realized. Human operators are more

concerned with the current status of the process and

possible future behavior rather than the current

values of individual variables. Apart from simple

measurements, we need in a second level a

furthermore analysis of the dataset consisting of the

combined output actions and input measurements,

which only the expert fuzzy controller can give us

during its operation. Therefore, we propose the

analysis of the set of the fuzzy control states with

the use of DMKD techniques. Data mining refers to

the extraction of interesting patterns from large

amounts of data, while involves the use of

techniques from multiple disciplines such as

database technology, statistics, machine learning,

neural networks, information retrieval, etc.

Knowledge Discovery in Databases (KDD) concerns

a systematic process consisting of a set of well-

defined steps. Data mining constitutes a step in the

whole knowledge discovery process (Comas et al.

2001; Gibert et al. 2005). The processes controlled

by expert-fuzzy controllers are usually slow

procedures and hence the DMKD process can

operate off-line allowing the human confirmation.

The data mining algorithmic procedure will operate

as a computational component at the control center

and will run periodically to discover knowledge and

update the knowledge base.

4.1 Problem Ddefinition and

Rrepresentation

Given a wastewater treatment plant along with the

corresponding intelligent controller, we define the

fuzzy control state as the vector

((m

1

, m

2

, m

3

, m

4

, m

5

, m

6

), (u

1

, u

2

, u

3

), t

k

)

where m

i

, i=1,…,6 are the measurements of the

inputs for which the fuzzy controller decides the

actions u

j

, j=1,…,3 for the corresponding outputs at

the time stamp t

k

, k= 1, 2 …,

∞

. According to this

description, a set of fuzzy control states could be

stored in a relational database on which data mining

could be performed. A relational database is a

collection of tables, each of which is properly

named. In our case there is one table representing

the set of fuzzy states (see Table 1). As an example,

the fuzzy state s

1

is defined as

s

1:

((HI, OK, OK, LO, OK, OK), (VH, OK, LO), 2)

The table of fuzzy control states results after

removing the erroneous data and integrating

information from various data sources, in particular

from the measurements and actions, as well as from

the set of fuzzy rules. Particularly, the rule activity

and the degree of rule fulfillment are also stored in

database. This process constitutes the first step of

the overall knowledge discovery process. The

second step concerns the data selection and

transformation into meaningful representations. In

our case, the time stamp may partially eliminated,

because we are interesting in the behavior of the

system during a period of time rather than a

particular time instance. For example, weather

conditions for certain periods of time may affect the

plant operation. Changes in rainfall, temperature and

humidity must be recorded with time stamp and

correlated with the rest of mined data.

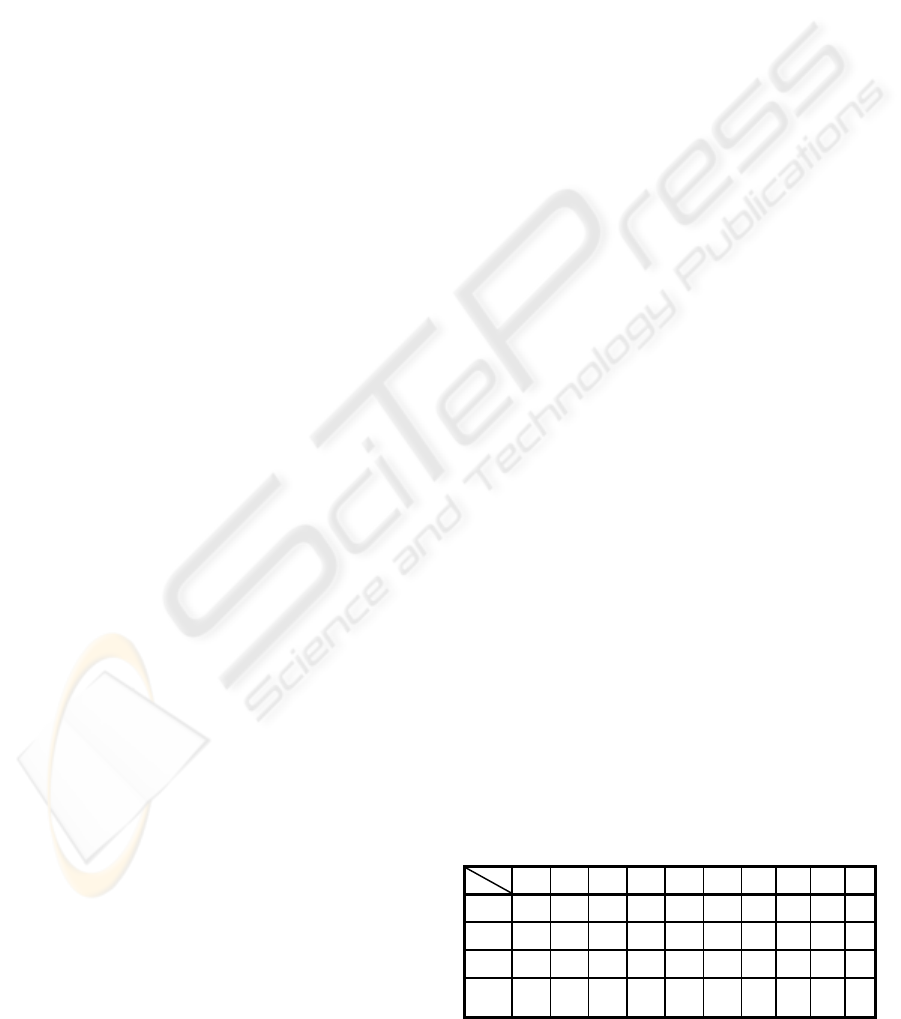

Table 1: Fragment of records from the database for fuzzy

control states

m

1

m

2

m

3

m

4

m

5

m

6

u

1

u

2

u

3

t

s

1

HI

OK

OK

LO

OK

OK

VH

OK

LO

2

s

2

HI

OK

HI

LO

OK

LO

VH

LO

LO

3

s

3

…

DATA MINING AND KNOWLEDGE DISCOVERY FOR MONITORING AND INTELLIGENT CONTROL OF A

WASTEWATER TREATMENT PLANT

89

4.2 Mining Interesting Patterns

Data mining methods and techniques could be

applied into the set of cleaned records, in order to

discovering interesting patterns. Association rule

mining, clustering, and classification seem to better

serve the needs of the particular problem of

controlling a plant. Association rule mining aims at

finding frequent patterns, associations, correlations,

or causal structures among sets of items or objects in

transaction databases, relational databases, and other

information repositories (Vazirgiannis et al. 2000).

An association rule is a statement of the form A⇒B,

where A and B are disjoint subsets of a set of items.

The rule is accompanied by two meaningful

measures, confidence and support. Confidence

measures the percentage of transactions containing

A that also contain B (i.e. confidence (A⇒B) =

P(B\A)). Similarly, support measures the percentage

of transactions that contain A or B (i.e. support

(A⇒B) = P(B∪A)) (Han and Kamber 2001).

The application of association rule mining

algorithms in the relational database of the control

states of the wastewater treatment plant could

produce interesting results. If the derived set of

association rules contains some rules not already

encountered into the input data set, then these new

rules could be embedded into the inference

mechanism of the expert-fuzzy controller.

Techniques of rule induction are also being applied

to estimate values of sensors readings based on more

easily obtained values, and to determine how

reliable the models remain over time. Rules may be

generated in forms such as the following,

Variable (DO) falls in a

particular range of low values

if variable D(BOD) falls

within a particular range of

high values

accompanied by an indication of the degree of

satisfaction of the rule.

Subsequently, the clustering concerns the process

of grouping a set of physical or abstract objects into

classes of similar objects. So, a cluster is a collection

of data objects that are similar to one another within

the same cluster and are dissimilar to the objects in

other clusters (Han and Kamber 2001; Gibert et al.

2005). The application of clustering into a set of

data objects requires that the data objects are not

class-labeled. In our specific problem a state,

consider for example s

1

(see Table 1), constitutes a

data object. This data object is labeled by the values

of the three output variables, u

1

, u

2

, and u

3

. The

unlabeled data object corresponding to s

1

is:

s

1

: (HI, OK, OK, LO, OK, OK)

The application of clustering algorithms to the set of

unlabeled states could conduct to the identification

of states of similar behavior and, thus, to the

derivation of theoretical and more general rules.

Lastly, classification could be considered as a

function that maps (classifies) a data object into one

of the several predefined classes (Vazirgiannis et al.

2000). That means (i) a well-defined set of classes,

and (ii) a set of pre-classified data objects are

required. Consequently, classification is a two-step

process: learning and classification. During the

learning sub-process, the set of labeled data objects

is analyzed using a classification algorithm and a

classification model is derived. Next, during the

classification sub-process, the model can be applied

to the new unlabeled data objects for inferring their

classes. To be clearer, in our case, a classification

algorithm is firstly applied on the set of cleaned

control states in order to find a classification model.

Next, whenever a new unlabeled state appears, the

model is applied for classifying this new state; in

other words for deciding the actions u

1

, u

2

, and u

3

.

Classification is, thus, another way for creating new

rules, for testing and modifying the existing ones.

4.3 Data Mining Tools

The selection of a commercial data mining tool

depends on various similar parameters, such as:

• system issues (like operating system, client-

server architecture, etc.)

• support of different types of data sources

(ASCII files, relational databases, ODBC

connections)

• support of various data mining algorithms

• visualization of the resulted patterns

• price

• ease of learning to use

For the wastewater treatment plant application

described above and particularly for a plant of

medium size we need a stand-alone PC architecture

with windows operating system, to support only flat

files with numerical data and various mining

algorithms while visualization in not necessary.

Some examples of data mining tools are IBM

Intelligent Miner, SGI MineSet, Clementine (SPSS)

and GESCONDA (Gibert et al. 2005), from which

the first one has been selected to implement the

current project.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

90

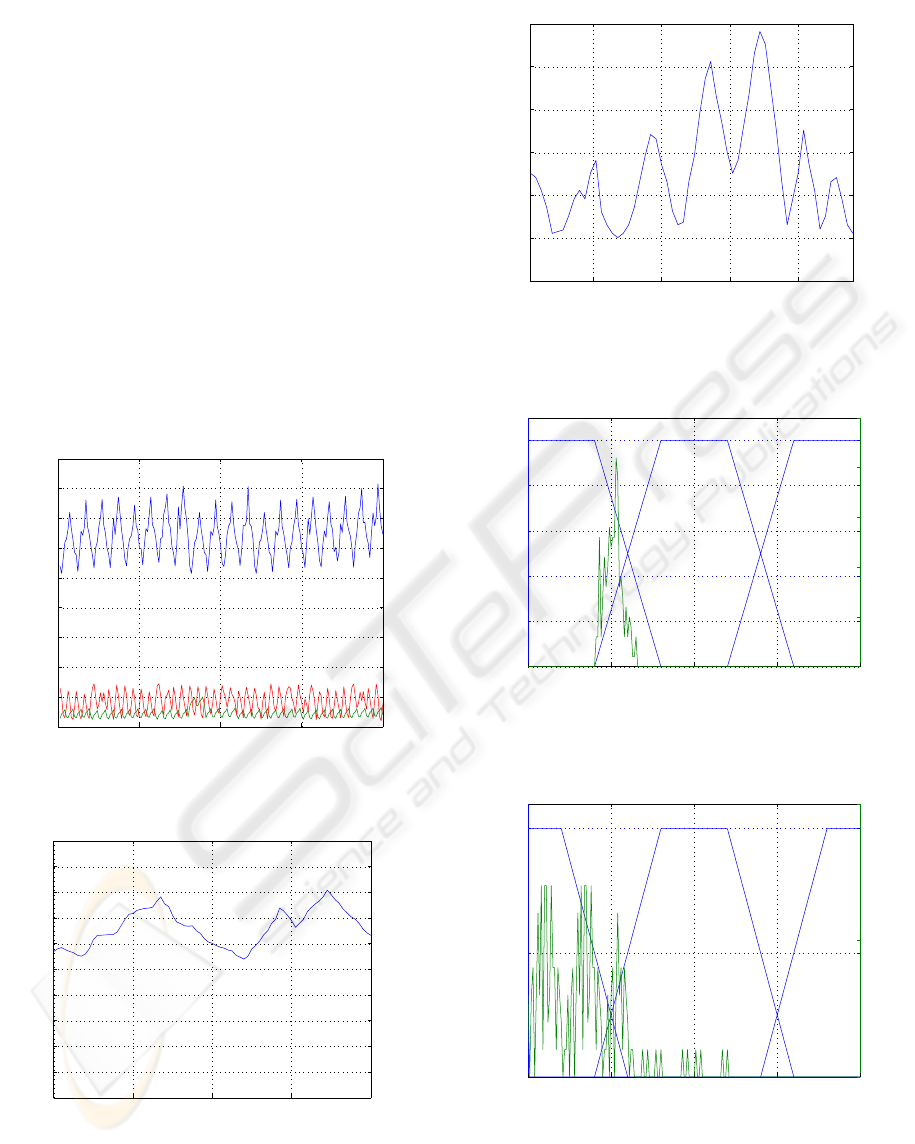

5 EXPERIMENTAL RESULTS

In this work, we used the time series data of four

months (April 2006 to July 2006) measured or

recorded at the medium-size wastewater treatment

plant mentioned above. As one example for all of

these data records the measurements in the influent

D(BOD), N-NO

3

and DO are shown in Fig.2.

Zooming into this plant’s monitoring in order to

achieve better resolution the corresponding

measurements are shown in Fig.3 and Fig.4 in a

two-day and one-day section for D(BOD) and N-

NO

3

concentrations respectively. The set of acquired

data includes also the actions of the fuzzy controller

which are recorded in the database by means of

rules activity. Figs.5, 6, 7 show the membership

functions and the input value appearance frequency

for the D(BOD), N-NO

3

and DO respectively. The

10 15 20 25 30

0

2

4

6

8

10

12

14

16

18

Time [days]

[mg/l]

D(BOD) (blue), N−NO3 (red), DO (green)

Figure 2: Measured D(BOD), N-NO3 and DO

concentrations during the period 10/6 – 30/6 2006.

16 16.5 17 17.5 18

0

2

4

6

8

10

12

14

16

18

20

Time [days]

D(BOD) [mg/l]

Figure 3: Two-day section of D(BOD) concentration from

the four months data (16/6-18/6 2006).

5 10 15 20

0

0.5

1

1.5

2

2.5

3

Time [hours]

N−NO3 [mg/l]

Figure 4: One-day section of N-NO

3

concentration from

the four months data.

−100 −50 0 50 100

0

0.2

0.4

0.6

0.8

1

Normalised values

ì[D(BOD)]

−100 −50 0 50 100

0

5

10

15

20

25

Input value appearance frequence

Figure 5: Membership functions and sampled

measurements for D(BOD).

−100 −50 0 50 100

0

0.5

1

Normalised values

ì[DO]

−100 −50 0 50 100

0

5

10

Input value appearance frequence

Figure 6: Membership functions and sampled

measurements for DO.

DATA MINING AND KNOWLEDGE DISCOVERY FOR MONITORING AND INTELLIGENT CONTROL OF A

WASTEWATER TREATMENT PLANT

91

−100 −50 0 50 100

0

0.5

1

Normalised values

ì[N−NO3]

−100 −50 0 50 100

0

5

10

Input value appearance frequence

Figure 7: Membership functions and sampled

measurements for N-NO

3

.

The values in these three figures are normalized into

the domain [-100, 100] since the six inputs variables

get values in different domains and hence

uniformity is needed. By inspection of Fig.5 one can

deduce that the most of the reformatted

measurements belong partially in both LO and OK

membership functions. This means that a

reconfiguration of the defined membership

functions is required in order to have a set of

membership functions which will cover effectively

the actual values of D(BOD) in the real process. The

narrow distribution of the sampled measurements

into the heuristically predefined membership

functions indicates furthermore that reconfiguration

is necessary. Another conclusion concerns the small

variation of D(BOD) measurements in comparison

to the corresponding predefined range of D(BOD)

values and therefore has to be reconsidered. Fig.6

shows a more uniform distribution of the sampled

measurements of DO, while the best distribution of

the obtained measurements is depicted in Fig.7

concerning the N-NO

3

variation.

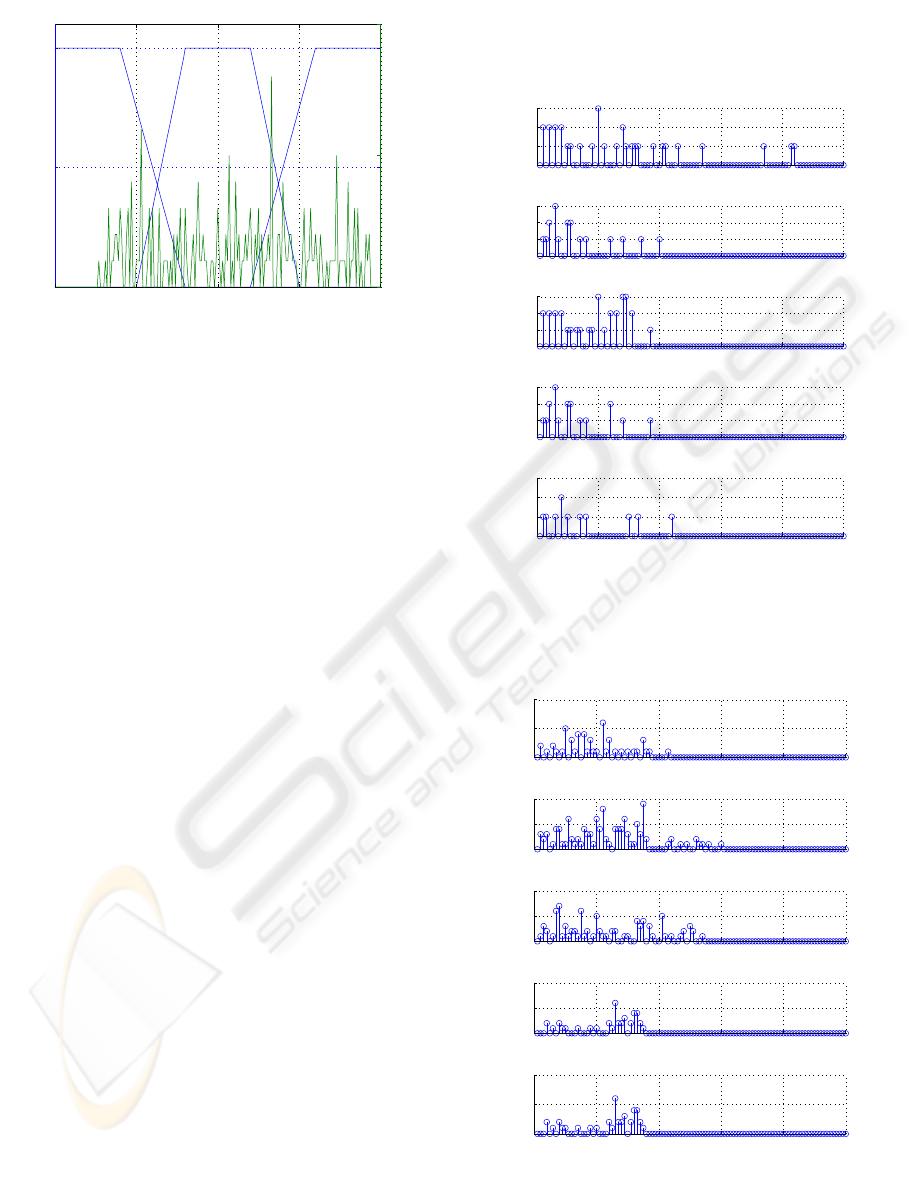

5.1 Rule Activity-Modification

As mentioned above, the second step of the overall

knowledge discovery process concerns the data

selection based on statistical criteria and the

transformation of them into meaningful

representations. As a first approach to obtain

cleaned data for knowledge creation, the rule

activity has been recorded in DMKD off-line

module and some results are shown in Fig.8 and

Fig.9. Each figure has five subplots for equal

number of rules. For each rule, the number of

appearances is shown as a function of the degree

fulfillment. For example, rule No.5 was satisfied

three times with a 20% degree of fulfillment. Fig.8

indicates the least active rules while Fig.9 shows the

corresponding most active ones.

0 20 40 60 80 100

0

1

2

3

Rule 5

Degree of fulfilment

# of appear.

0 20 40 60 80 100

0

1

2

3

Rule 6

Degree of fulfilment

# of appear.

0 20 40 60 80 100

0

1

2

3

Rule 14

Degree of fulfilment

# of appear.

0 20 40 60 80 100

0

1

2

3

Rule 15

Degree of fulfilment

# of appear.

0 20 40 60 80 100

0

1

2

3

Rule 41

Degree of fulfilment

# of appear.

Figure 8: Statistical analysis of the least-active rules

behavior.

0 20 40 60 80 100

0

5

10

Rule 31

Degree of fulfilment

# of appear.

0 20 40 60 80 100

0

5

10

Rule 32

Degree of fulfilment

# of appear.

0 20 40 60 80 100

0

5

10

Rule 33

Degree of fulfilment

# of appear.

0 20 40 60 80 100

0

5

10

Rule 40

Degree of fulfilment

# of appear.

0 20 40 60 80 100

0

5

10

Rule 42

Degree of fulfilment

# of appear.

Figure 9: Statistical analysis of the most-active rules

behavior.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

92

6 CONCLUSIONS

Although wastewater treatment plants are

implemented with properly functioning control

loops concerning the biological process, in practice,

this type of plant requires a major time investment

on the side of the operator, involving many manual

operations. These difficulties can be overcome by an

intelligent controller which incorporates the human

experience. The mined data, characterized as

multivariate and interrelated, constitutes a

combination of measurements of the process’s

variables and actions of the controller. The

consequences of the mining and knowledge

discovery procedure are used to adapt the soft

structure of the intelligent controller through a semi-

automatic scheme that provides deeper

understanding and better operation of the controlled

plant. The experimental results give us basic

directions to improve the operation of the control

system but it is obvious that a longer validation

period of data monitoring and processing is needed.

REFERENCES

Boverie, S, Demaya, B and Titli, A, 1991, Fuzzy logic

control compared with other automatic control

approaches, Proceedings of 30

th

CDC Conference,

Brighton.

Comas, J., Dzeroski, S., Gibert, K., Roda, I.R. and

Sanchez-Marre M., 2001. Knowledge discovery by

means of inductive methods in wastewater treatment

plant data”, AI Communications, Vol.14(1), pp.45-62.

Condras, P, Cook, J and Roehl E, 2002, “Estimation of

Tidal Marsh Loading Effects in a Complex Estuary”

American Water Resources Association Annual

Conference, New Orleans.

Condras, P and Roehl, E, 1999, Real-time control for

matching wastewater discharges to the assimilative

capacity of a complex tidally affected river basin

South Carolina Environmental Conference, Myrtle

Beach.

DeSilva, C W, 1995, Intelligent Control, Fuzzy Logic

Applications, CRC Press, Boca Raton.

Dixon, M., Gallop, J.R., Lambert, S.C., Lardon L., Steyer

P. and Healy J.V., 2004. Data mining to support

anaerobic WWT plant monitoring and control,

Proceedings of the IFAC Workshop on Modelling and

Control for Participatory Planning and Managing

Water Systems, Venice Italy,.

Dixon, M., Gallop, J.R., Lambert S.C. and Healy, J.V.,

2007. Experience with data mining for the anaerobic

wastewater treatment process, Environmental

Modelling & Software, Elsevier, , vl.22, pp.315-322.

Gibert, K., Sanchez-Marre, M. and Flores X., 2005.

Cluster discovery in environmental databases using

GESCONDA: The added value of comparisons, AI

Communications, Vol.18(4), pp.319-331.

Han, J and Kamber, M, 2001, Data Mining: Concepts and

Techniques, San Francisco, Morgan Kaufmann.

Harris, CJ, Moore, CG and Brown, M, 1993, Intelligent

control-aspects of fuzzy logic and neural nets, NJ,

World Scientific Publishers.

Huang, YC and Wang, XZ, 1999, Application of fuzzy

causal networks to wastewater treatment plants,

Chemical Engineering Science 54:2731-2738.

Jamshidi, M, Vadiee, N and Ross, TJ, 1993, Fuzzy Logic

and Control–Intelligentware and Hardware Applicati-

ons, NJ, Prentice Hall.

Katebi, R, Johnson, M and Wilkie, J, 2000, The future of

Advanced Control in Wastewater Treatment Plants,

Proceedings of the CIWEM Millennium Conference

Leeds UK.

King, R, 1992, Expert supervision and control of a large-

scale plant, Journal Intelligent and Robotic Systems,

2(3).

Lambert, S, 2004, (CCLRC-Data mining Resp.)

Telemonitoring and advanced tele-control of high

yield wastewater treatment plants, TELEMAC, R&D

project, No. IST-28156.

Mamdani, EH, 1974, An application of fuzzy algorithms

for the control of a dynamic plant, Proceedings IEE ,

121(12).

Manesis, S, Sapidis DJ and King RE, 1998, Intelligent

Control of Wastewater treatment Plants, Journal

Artificial Intelligence in Engineering (12):275-281.

Patyra, MJ and Mylnak, DM, 1996, Fuzzy Logic

Implementation and Application, NJ, J. Wiley-

Teubner.

Rodriguez-Roda, I, Sanchez-Marre, M, Comas, J, Baeza,

J, Colprim, J, Lafuente, J, Cortes, U and Poch M,

2002, A Hybrid Supervisory System to Support

WWTP Operation: Implementation and Validation,

Water Science and Technology Journal (45): 289-297.

Sanguesa, R, Cortés, U and Béjar, J, 1997, Causal

dependency discovery with posscause: an application

to wastewater treatment plants, Proceedings of the 1

st

International Conference on the practical application

of knowledge discovery and data mining, London.

Serra, P, Sànchez, M, Lafuente, J, Cortès, U and Poch, M,

1994, DEPUR: a knowledge-based tool for wastewater

treatment plants, Engineering Applications of

Artificial Intelligence, 7(1):23-30.

Vazirgiannis, M and Halkidi, M, 2000, Data Mining:

Concepts and Techniques, Athens University of

Economics and Business, TR HELDiNET 10.

Victor Ramos, J, Goncalves, C and Durado, A, 2004, On-

line Extraction of Fuzzy Rules in a Wastewater

Treatment Plant, Proceedings of the 1

st

International

Conference on Artificial Intelligence Applications and

Innovations, 1:87-102.

DATA MINING AND KNOWLEDGE DISCOVERY FOR MONITORING AND INTELLIGENT CONTROL OF A

WASTEWATER TREATMENT PLANT

93