DESIGN AND BALANCING CONTROL OF AIT LEG

EXOSKELETON-I (ALEX-I)

Narong Aphiratsakun, Kittipat Chirungsarpsook and Manukid Parnichkun

Asian Institute of Technology, P.O.Box 4, Klong Luang, Pathumthanee, 12120, Thailand

Keywords: ALEX-I, Exoskeleton, robot suit, balancing control, mechanical design.

Abstract: This paper is focused on the design of mechanical hardware, controller architectures, and analysis of

balancing control at the Asian Institute of Technology Leg EXoskeleton-I (ALEX-I). ALEX-I has 12 DOF

(6 DOF for each leg: 3 at the Hip, 1 at the knee and 2 at the ankle), controlled by 12 DC motors. The main

objective of the research is to assist patients who suffer from the paraplegia and immobility due to the loss

of lower limbs. ALEX-I’s parts and assembly are designed on CAD software, SolidWorks, exported to

MATLAB simulation environment, and observed using 3D VRML script interpreter to investigate balancing

postures of the exoskeleton. The simulation model is proven to be accurate by comparing the resulting

kinematics characteristics with the results from Corke’s MATLAB Robotics Toolbox (Corke, 1996). PC104

is employed as the main (master) processing unit for calculation of the balanced gait motion corresponding

to feedback signals from the force sensors mounted at the two feet plates, whereas ARM7’s are used for the

low-level (slave) control of the angular position of all joints. The balanced posture set-points (joint

trajectories) under the Center of Mass (CM) Criterion are generated in the simulation before testing on the

real mechanical parts is implemented to avoid damaging the system.

1 INTRODUCTION

Our society nowadays has many elders and patients

that have difficulties in their locomotion. All of

these patients need to sit, stand, walk, and perform

other activities to fulfil their daily tasks. These

people need assistance from either the nursing

personnel or assistive devices such as walkers or

wheelchairs. Our exoskeleton is intended to work as

an intelligent assistive device that would help

eliminating the difficulties and risks during the

locomotion of the wearer. For this purpose, the

exoskeleton has to be able to balance itself, carry the

wearer, and walk even if the lower part of the patient

is completely paralyzed. In addition to improving

the quality of many lives, the developed exoskeleton

can also serve as a tool used to imitate and integrate

human natural blueprints.

Exoskeleton systems also find their applications

in other various fields that draw a lot of interests

from many robotics researchers who want to imitate

the perfectly-designed and sophisticated

biomechanics and human anthropometries. Some of

the successful stories are HAL (Kawamoto, Kanbe,

Lee and Sankai, 2002 and 2003), BLEEX (Chu,

Kazerooni, Zoss, Racine, Huang and Steger, 2005),

and Sarcos (Guizzo and Goldstein, 2005)

exoskeletons, which are designed for power

enhancing and military missions respectively. HAL-

3 was developed by the research team of Tsukuba in

Japan. It was designed to help the elders in

performing their daily activities such as walking,

sitting, and standing. The latest model, HAL-5, is

the whole-body suit unit, which is suitable for either

the left or the right side paraplegic patient. BLEEX

developed by the University of California, Berkeley,

and Sarcos developed at Sarcos Research Corp. in

Salt Lake City implemented the hydraulic-actuated

exoskeletons as they are focusing on the power-

enhanced legs for the application of carrying heavy

loads in the difficult terrains.

Asian Institute of Technology Leg EXoskeleton-

I or known as ALEX-I is developed with the aim to

carry with it both the external loads and the pilot (or

the wearer). The exoskeleton has to be able to walk

on its own. Building up the robot and physically

testing it by means of trial-and-error could result in

damaging the robot links and fragile electronics

devices. Hence, we have to model the exoskeleton

robot to conduct the experiments in the both real

world and simulated environments. The simulation

model of ALEX-I has shown promising results

151

Aphiratsakun N., Chirungsarpsook K. and Parnichkun M. (2008).

DESIGN AND BALANCING CONTROL OF AIT LEG EXOSKELETON-I (ALEX-I).

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 151-158

DOI: 10.5220/0001480401510158

Copyright

c

SciTePress

through the modelling with MATLAB’s

SimMechanics library. Consequently, precise gait

pattern generation can be investigated based on the

kinematics information of all moving bodies. This

simulation model can serve as the framework for

development of the whole-body exoskeleton and all

types of biped robots, which will be developed in the

future at AIT.

This paper describes the analysis of the

architecture layout of the ALEX-I system in both

software and mechanical hardware. The mechanical

properties and controllers layout of the ALEX-I will

be explained in the next 2 sections. The simulation

model of the exoskeleton, its the interpretation of

experimental result in 3D virtual reality (VR)

environment, as well as the example of gait pattern

generation of one-step gait motion will be discussed

in section 4.

2 MECHANICAL DESIGN

Our previous work (Aphiratsakun and Parnichkun,

2007) reveals the required specification of the 12

actuators through the required torque calculations of

all the joints. The range of motion of the joints

determined in the previous work is refined to

disregard the range that will never be employed in

the real physical implementation, and the resulting

range of motion of all DOF is shown in Table 1.

The ALEX-I has 12 DOF (6 DOF for each leg: 3

at the Hip, 1 at the knee and 2 at the ankle),

controlled by 12 DC motors. Each motor is coupled

with a 1:100 gearhead and equipped with a 1024-

pulse incremental encoder as a feedback sensor. The

Scooter DC motors and Bonfiglioli Gearhead model

VF44P63B14 are selected in this work to conform to

the required flexibility in the mounting structures,

shapes, and weights. Table 2 gives specification of

the motors and the gearheads mounted on each joint.

Obviously, the torques offered by the gearheads in

each joint are in comply with the torque

requirements revealed in (Chu, Kazerooni and Zoss,

2005).

Table 1: Range of motion of each joint.

Joint Axis Range of rotation

(degree)

X (pitch) -90<θ<90

Y (yaw) -35<θ<35

Hip

Z (roll) -15<θ<15

Knee X (pitch) 0<θ<90

X (pitch) -45<θ<45 Ankle

Z (roll) -20<θ<20

Table 2: Specification of the motors coupled with 1:100

gearhead at each joint.

Motors

Joints the motors

mounted on

RPM ;

Rad/s

Torque

[Nm]

250 W Hip (yaw) 95

350 W

Hip (roll),

Ankle (roll)

134

500 W

Hip (pitch),

Knee (pitch),

Ankle (pitch)

25 ; 2.62

191

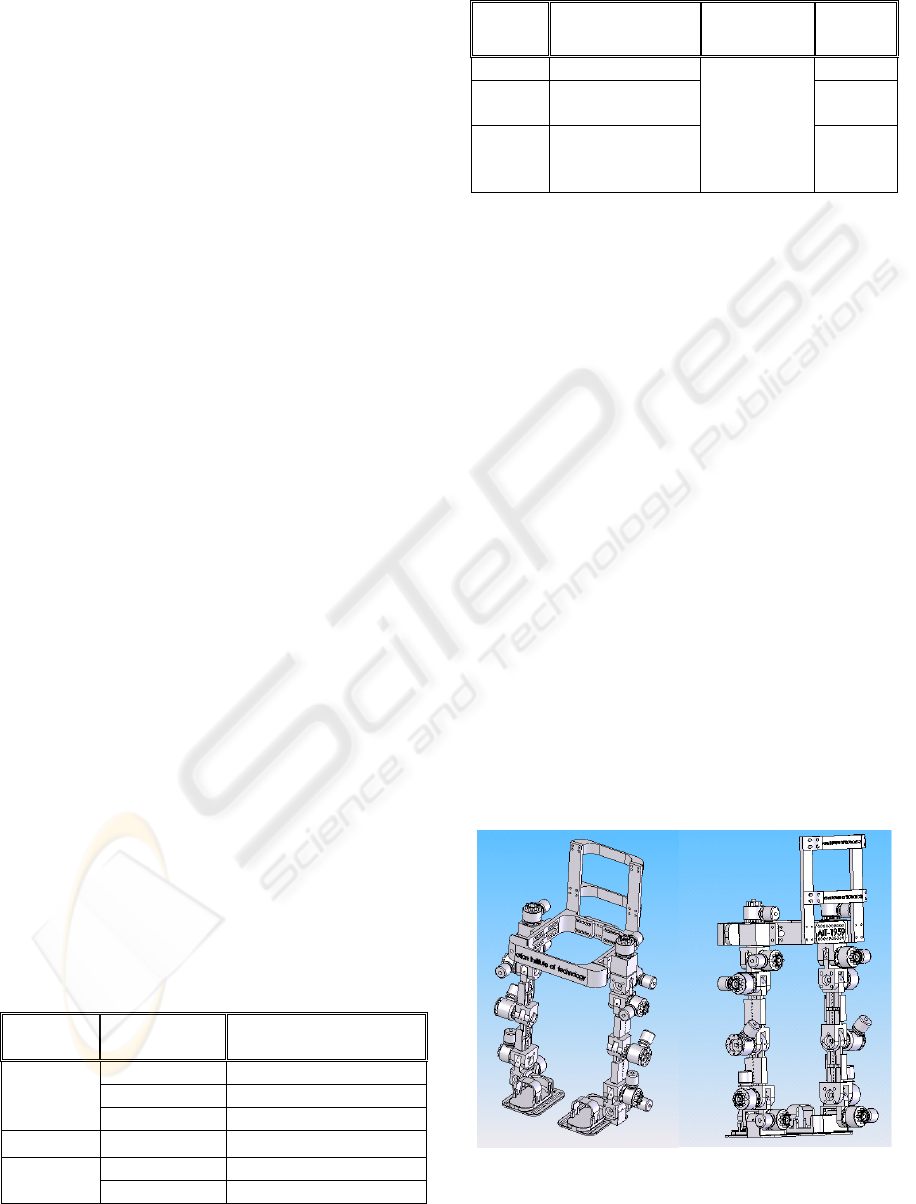

The lower limb exoskeleton mechanical parts are

designed with a CAD Application, SolidWorks, as

shown in Figure 1. The anthropometric

considerations and other design parameters are

discussed in (Aphiratsakun and Parnichkun, 2007).

This CAD assembly can be imported to MATLAB

development environment, which will be used to

analyze for the balanced gait motion through the

simulation model. The simulation model will be

revisited in section 4.

With the CAD design, aluminum 5083 with the

density of 2657.27 Kg/m

3

is mainly used for the

frame structure. The front and back views of the

fabricated prototype is shown in Figure 2. The

weight of the ALEX-I is measured to be 117.5 Kg

excluding the weight of the bag pack.

Force sensors or load cells are used to measure

the forces exerted by the body. Futek LLB400 load

cell, which can measure up to 500 lb (2224 N) of

force, is chosen in the implementation. Four of these

sensors are placed between two plates of the ALEX-

I’s feet. INA126 micro power instrumentation

amplifier is used as the amplifier for the load cell.

The designed layout of the load cell and its amplifier

circuit is shown in Figure 3. From the force reading

from the load cells, the center of mass (CM) position

could be calculated.

Figure 1: Prototype design of exoskeleton frame (lower

part) (a) front view and (b) back view.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

152

Figure 2: Front and back views of the ALEX-I mechanical

frame.

Amplifier

Circuit

Load Cell

ALEX-I’s feet

Figure 3: Load cells arrangement.

3 CONTROLLER

ARCHITECTURE

16

8

74LS373

(1)

D

1-8

Q

1-8

O/P

Control

G

8

8

74LS373

(2)

D

1-8

Q

1-8

O/P

Control

G

8

16

ARM (1)

16

74LS154 (1)

System 1

ARM (12)

System 12

12

4

74LS373

(1), (2)…..(12)

5

Buffer

1A

2A

1Y

2Y

74LS244

4

4

8 8

1G 2G

PC104

1A

2A

1Y

2Y

74LS244

4

4

8 8

1G 2G

16

74LS154

4IN

ABCD

OUT

74LS244

1A

1Y

2A

2Y G

2

G

1

1G

2G

Chip Select

8

74LS373

(1)

D

1-8

Q

1-8

O/P

Control

G

8

8

74LS373

(2)

D

1-8

Q

1-8

O/P

Control

G

8

16

16

74LS154 (12)

Latch

Latch

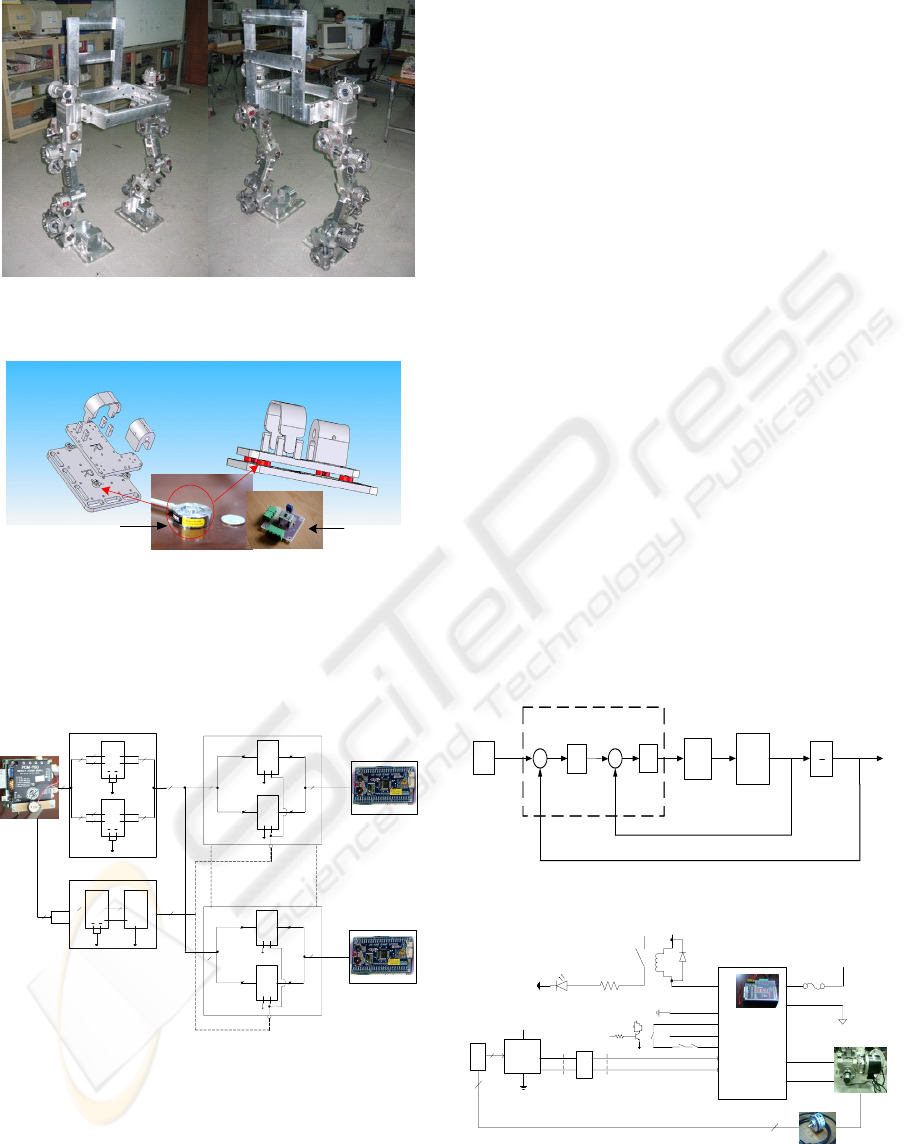

Figure 4: Overview of High and Low level controllers’

architecture.

The data of gait analysis from the simulation is used

as the input for positional control of the motors,

which will eventually make ALEX-I walk in the

desired motion. In this work PC104 and ARM7

LPC2138 are used as the high and low level

controllers respectively. The overview of the

controllers’ layout is shown in Figure 4. The twelve

set-points data for the joints’ trajectories, which are

sent from PC104, are stored in the latching circuit to

eliminate the lag time that might be incurred from

serial communication. Chip selecting circuit is then

used to address each slave-controller with its proper

set point. Putting these set-points data in parallel

manner allows low-level controller to acquire the

data without delay.

3.1 Joint Controller: ARM7 LPC2138

Microcontroller

The joint controller block set is shown in Figure 5.

The twelve sets of 16-bits set points command are

sent from PC104, which configures the required

motion balancing tasks for the whole system, as the

input to the low-level close-loops that comprise 2

closed loops (P and PD) for each control block:

speed and position loops. 10 Bits, 1024 pulses/rev

Koyo TRD-S1024V series incremental encoder is

used as a feedback sensor at each joint. LS7366 by

LSI, is used to obtain the quadrature A/B of the

incremental encoder signal. This IC communicates

through SPI with ARM7 processor and increases the

quadrature counting up to four times. It increases the

resolution of the encoders to 4096 pulses/rev. Axor

MicrospeedPlus is chosen as the servo driver and

interfaced between ARM7 as shown in Figure 6.

Mo t o r

+

Gearhead

1

s

-

+

-

+

Mot or

Dr i v er

PC10 4

Set point

joint di stance

P

PD

ARM7 Controller

Figure 5: Joint controller.

1 OK

3 GND

24 V

4 +10 V

5 -10 V

6 Enable

5 V

7 PWM

8 Dir

ARM7

Controll er

3.3 V

From

control ler

+AT

-AT

36 V

+M

-M

Motor 24 VDC + Gear head

Encoder

1024 pulses/rev

3

A, B , Z

3 A, B, Z

Microspeed

Plus

NO

5 V

2.2 K

2 K

0-9V

MC14504

PWM

1: ccw /0: cw

LPC2138

0-3.3 V

DIR

LS7366

NC

limit2

NC

limit1

SPI

4

Figure 6: Servo interfacing circuit.

DESIGN AND BALANCING CONTROL OF AIT LEG EXOSKELETON-I (ALEX-I)

153

4 SIMULATION MODEL

This section shows the model of ALEX-I in its

simulation environment and the gait pattern

generation. All links and joints are modelled with

their real inertia matrices, links’ location of centers

of gravity (CG), and location of joints as calculated

automatically in Solidworks’s mass properties

command. Our simulation approach allows the

researcher to keep track of all joints’ and links’

kinematics and dynamics properties very precisely

through virtual sensors. Firstly, the ALEX-I

SimMechanics model is verified with simple

Denavit-Hartenberg (DH) matrix for analysis of

manipulator’s end-effector to verify the correctness

of our simulation model. The balanced gait motion is

also performed and shown in latter part of the

section.

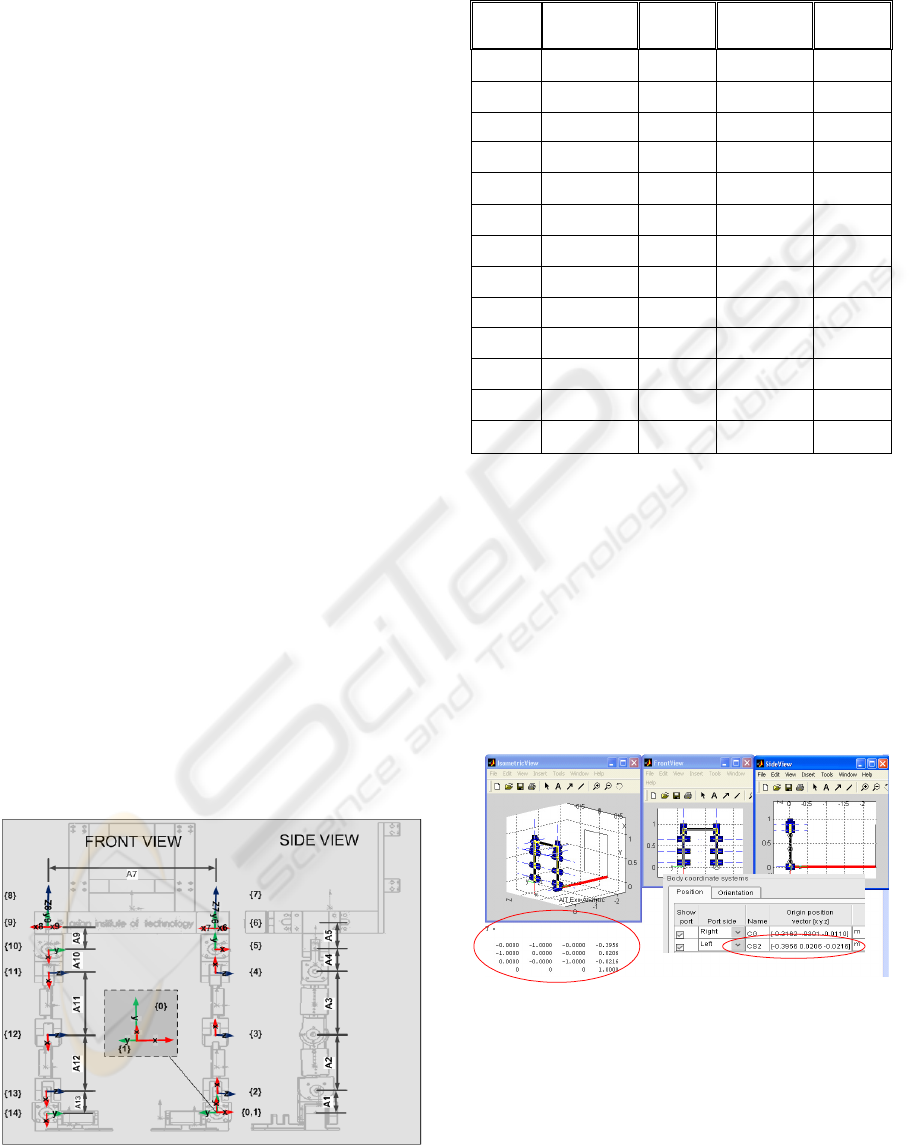

4.1 Model Verification with

Denavit-Hartenberg Matrix and

P. I. Corke’s MATLAB Robotics

Toolbox

To verify the correctness of the simulation

modelling, the authors use the DH matrix in

describing the 12-DOF ALEX-I assuming that the

left ankle is fixed to the ground as if the whole robot

is a 12-DOF manipulator with the right ankle being

the end-effector. Obviously, the dynamics behavior

of the robot with this assumption does not match the

real situation. However, the position and velocity

obtained from the DH and Jacobian matrix

consideration proves our simulation model to be

quite accurate in terms of kinematics characteristics.

Figure 7 and Table 3 conclude the properties of links

as defined by DH (Craig, 2005).

Figure 7: Assignment of coordinate systems in accordance

to DH.

Table 3: Links’ properties required for the calculation of

DH transformation matrixes and Jacobian matrices.

Link

α

[degree]

a

[m]

θ

[degree]

d

(m)

1 90 0.1 90 0

2 0 0.26 0 0

3 0 0.28 0 0

4 90 0.11 0 0

5 0 0.12 0 0

6 -90 0 90 0

7 0 0.594 0 0

8 -90 0 0 0

9 0 0.12 -90 0

10 -90 0.11 0 0

11 0 0.28 0 0

12 0 0.26 0 0

13 90 0.1 0 0

Applying the links’ properties in Table 3 with

the Robotics Toolbox written (Corke, 1996), we

obtain another version of stick diagram as shown in

Figure 8. The toolbox calculates transformation

matrix referred from the end-effector (right ankle) to

the world coordinate (left ankle) as similar to that of

our simulation model with accuracy of 1 millimeter

as shown in the highlighted numerical data. The left

circle highlights the transformation matrix resulted

from the Corke’s procedures whereas the right circle

is the data from our developed simulation model

.

Figure 8: Simulation result from P. I. Corke Robotics

Toolbox (Corke, 1996).

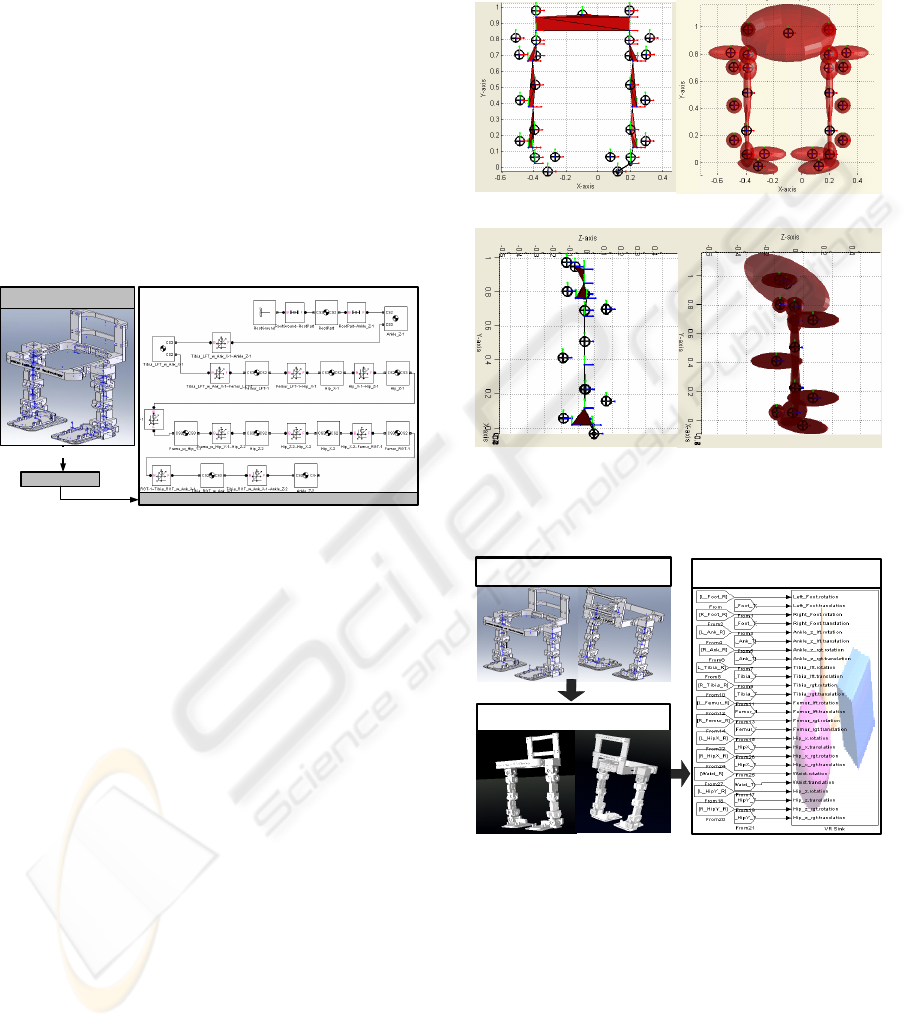

4.2 MATLAB Physical Model

The simulation modelling of the 12-DOF ALEX-I

has to be started with the transformation of CAD

data from the CAD application, SolidWorks, to the

physical model format in MATLAB’s

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

154

SimMechanics. The mating functions and mass

properties are automatically translated into the joints

and links with precise inertia matrices and joint

coordinate systems location as referred from the

grounded position. Figure 9 shows the flow of how

the precise simulation model can be created from

CAD assembly file format. Apparently, this

simulation model is very accurate in resembling the

real physical exoskeleton as it is created from the

exact sizes, mass and inertia properties, and joint

locations of the real fabricated links and assembled

robot. In the figure, the block diagrams with the

signs of the CGs and the signs of 5-DOF represent

the robot links and joints as defined in the mating

function respectively. Figure 10 shows the imported

frontal and lateral views of the ALEX-I model.

Filename.xml

Assembly File from

SolidWorks

MATLAB: Filename.mdl

Save as ...

Import_physmod(‘Filename.xml’)

Figure 9: Importing the physical model from SolidWorks

assembly file.

4.3 SimMechanics Virtual Sensors

Development of the simulation model on the

MATLAB environment offers great advantages

since the SimMechanics Library offers virtual

sensors that allow monitoring of kinematics and

dynamics properties of all moving bodies and joints,

including the monitoring of position, velocity,

acceleration, angular displacement, angular velocity,

angular acceleration, reaction force, and reaction

torque. More importantly, the SimMechanics also

offers virtual actuators that allow the actuation of

both the joints and the bodies by the Source toolbox

in the Simulink Library. With the virtual tools

offered by SimMechanics Library, the manipulation

of all kinematics and dynamics parameters could be

done and monitored so as to study the motion

behaviour and gait generation of the ALEX-I in

virtual environment.

Nevertheless, the numerical data observed from

the virtual sensors does not give understandable

interpretation unless applied with the graphical

visualization. The authors create the graphical

interpretation of results both in the forms of 2D

MATLAB graphics and in the 3D Virtual Reality

(VR) environment. Figure 11 shows how the motion

signals could be used as input to the 3D VR

graphics.

(a)

(b)

Figure 10: (a) Frontal and (b) Lateral views of transformed

diagram.

V-Realm Builder:

Part.VRML

SolidWorks:

Part.SLDPRT

VR Sink inputs from virtual

sensors

Figure 11: Procedures for the 3D Virtual Reality Graphical

Interpretation.

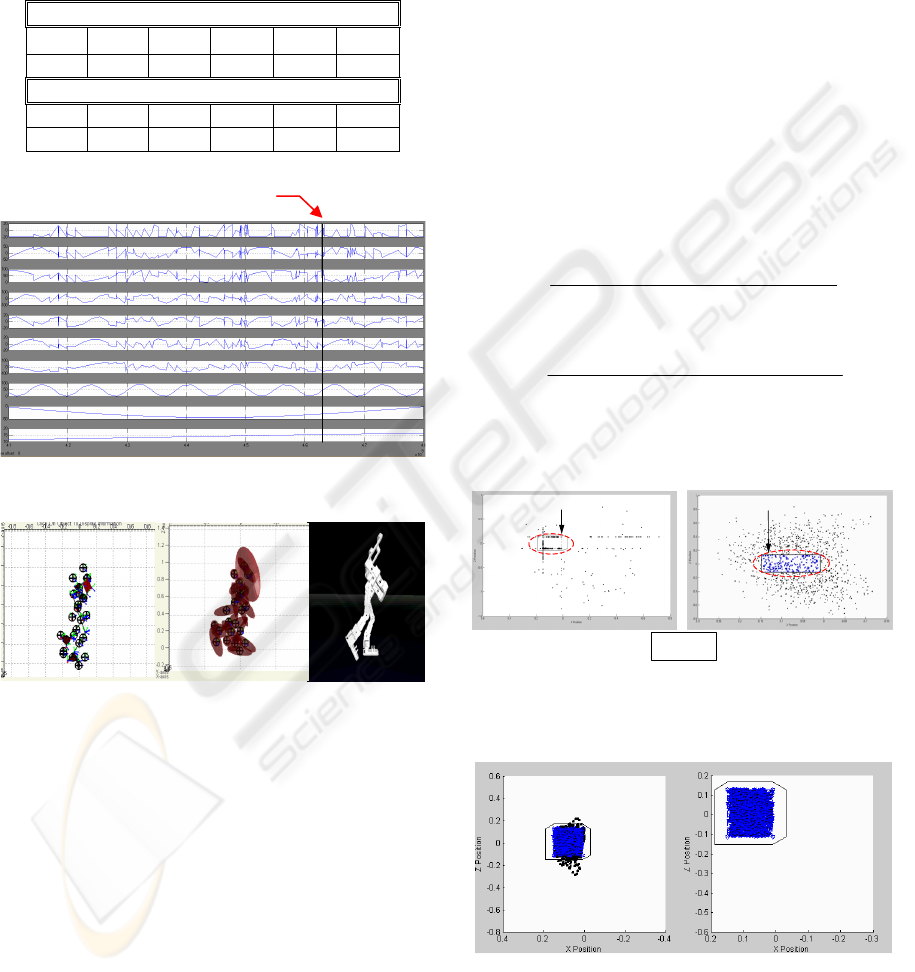

Figure 13 shows the illustrated stick diagram,

ellipsoidal mass-represented diagram, and 3D VR

animation respectively. The input signals captured

from the virtual sensors are fed to each joint for the

angular position of all joints. The signals inputted to

create the corresponding posture in Figure 13 are

shown in Table 4 and Figure 12.

θ

1-12

in the Table 4

are left ankle [z,x], left knee [x], left hip [x,z,y],

right hip [y,z,x], right knee [x], right ankle [x,z]

DESIGN AND BALANCING CONTROL OF AIT LEG EXOSKELETON-I (ALEX-I)

155

respectively. On the other hand, the input signals

observed from virtual scope in Figure 13 are listed

as the right ankle [z,x], right knee[x], right hip [x,z],

left hip [z,x], left knee [x], and left ankle [x,z] in the

order from the top to the bottom.

Table 4: 12 set-points angles.

Angles (degree)

θ

1

θ

2

θ

3

θ

4

θ

5

θ

6

0.294 36.88 58.95 -66.58 -14.98 0

Angles (degree)

θ

7

θ

8

θ

9

θ

10

θ

11

θ

12

0 -7.61 -65.15 53.73 -31.47 15.48

Figure 12: Sampled set-point signals.

(a)

(b)

(c)

Figure 13: Example of the (a) stick diagram, (b) ellipsoidal

mass-represented diagram and (c) 3D Virtual Reality

Graphical Interpretation at following set-point.

4.4 One Step Gait Motion

The generation of all geometrically feasible postures

of the exoskeleton is done using sine curves to

characterize the changes in the joint trajectories by

assuming that the left and right feet are supporting

and swinging feet respectively. The CM equations as

given in (1), (2) and (3) refer to well known zero

moment point (ZMP) equations where all

acceleration are equal to zero except g ≈ 9.81 m/s

2

.

With random sampling from all postures (6.1 x10

9

postures) while arranging them from time 0 second

to 6.1x10

9

seconds, the range of time (searching

domain) that returns stable leg-swinging postures

could be found from Figure 14 (a) between

4.18x10

9

-5.91x10

9

seconds. From the sampled

experiment, the authors could reduce size of the

searching domain from 6.1x10

9

solutions to

approximately 2x10

9

solutions. However, from the

visual interpretation in VR environment, the

postures that result from the solution numbered

4.7x10

9

to 5.91 x10

9

show the waist orientation that

would be difficult for the wearer of the exoskeleton

to move along with the exoskeleton. Therefore,

another detail simulation is performed to determine

the CM-feasible postures (joint angles) within the

searching domain 4.18 x10

9

to 4.7 x10

9

. The result is

shown in Figure 14 (b).

()

()

i i i i ix ix

iii

ZMP

i

i

my gz mzy I

z

myg

θ

+− −

=

+

∑

∑∑

∑

&&

&&

&&

&&

(1)

()

()

iiiiiziz

iii

ZMP

i

i

my gx mxy I

x

my g

θ

+− −

=

+

∑

∑∑

∑

&&

&& &&

&&

(2)

0

ZMP

y

=

(3)

ALEX-I’s Supporting Feet

* : Safe Location

. Unstable Region

(a) (b)

ALEX-I’s Supporting Feet

Figure 14: (a) Location of CM sampled over the entire

searching domain, (b) Location of CM sampled over the

reduced searching domain.

Figure 15: Filter and interpolated feasible posture CM-

save joints.

Only the postures (joints angles) that return the

balanced gait are saved into the database so that the

12 Set-Points values

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

156

interpolation of all feasible joints angles could be

interpolated. The filtered postures are again

interpolated to obtain very detailed joint trajectories

and filtered to get only the balanced CM joints

angles. The resulting filtered CM locations are

shown Figure 15.

0 10 20 30 40 50 60 70 80 90 100

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

Comparison Between Real and Ideal Position of Swing Foot

Cycle (%)

Position (m)

Real X

Real Y

Real Z

Ideal X

Ideal Y

Ideal Z

Figure 16: Comparison between ideal and CM-save gait

pattern.

initial

final

(a)

initial

final

(b)

Figure 17: (a) Right-Swing step, (b) Left-Swing step.

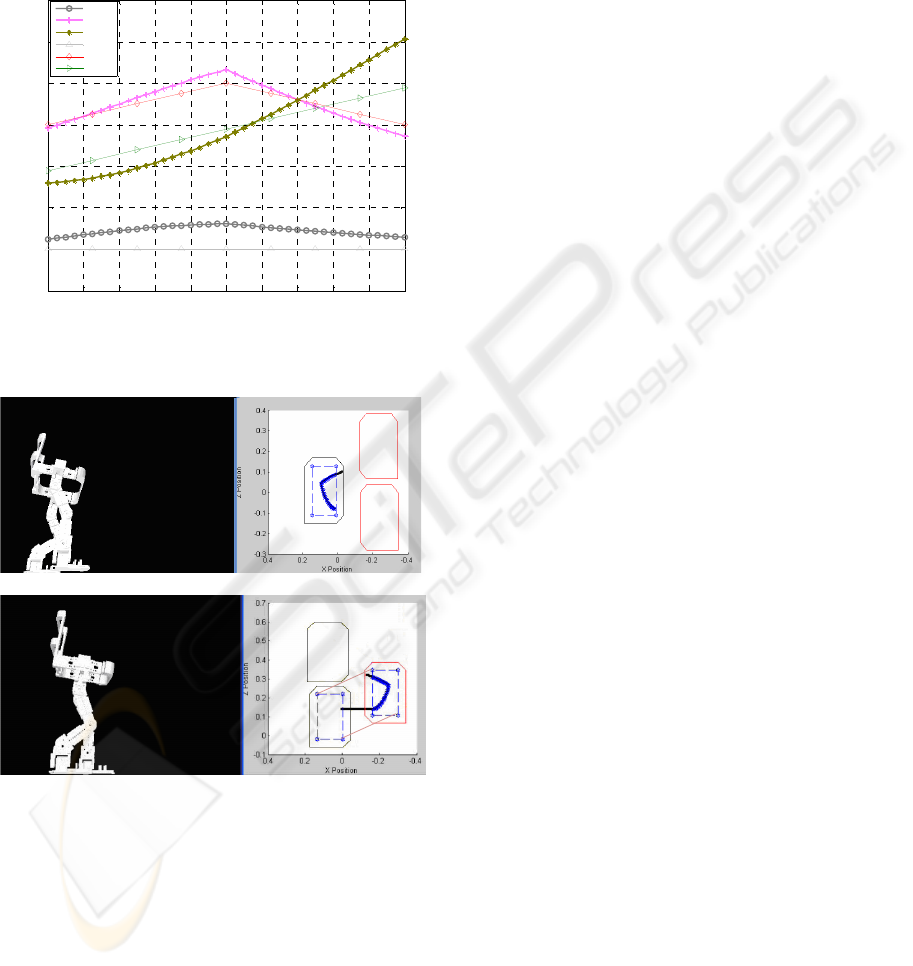

With the feasible joint trajectories, the step

parameters, which comprise the swinging height,

step length, and step time, are obtained. After having

all joints angles in the database together with the

location of the swing foot and orientation of the

ALEX-I from the virtual sensors in the simulation

model, the one-step gait pattern is generated from

the CM-feasible joint trajectories.

In Figure 16, the ideal walking pattern and

balanced CM walking pattern are compared.

Apparently, the obtained step parameters could only

be partially achieved since the ALEX-I has to

balance itself and could not be in some particular

postures. The successful right-swing and left-swing

step are shown in the Figure 17 with the outlined

initial and final locations of the swung feet.

5 CONCLUSIONS

This paper has revealed the balancing control

analysis and design of the architecture layout of the

ALEX-I. The ALEX-I was initially controlled to

walk in open-loop manner. Position control for each

joint is operated with 32-Bits processor ARM7

controller, which senses position feedback from

1024 pulses/rev encoder. PC104 is used as a main

controller to control the entire joints controller and

to calculate all the set-points for the gait motion of

the ALEX-I. The ALEX-I simulation model has

been verified with DH matrix Robotics Toolbox and

the accurate results are observed. The model has

been further integrated to perform gait motion

analysis. The motion is captured in the form of 12

set-points observed with virtual sensors offered by

SimMechanics library. The CM-feasible balance gait

data are filtered and interpolated. One gait cycle has

been shown in the simulation and in this study. With

the obtained balanced gait motion, the data could be

set and calculated by PC104. The future works

would emphasize on the ZMP-feasible gait pattern

generation, implementation with the real wearer, and

disturbance-tolerating control system.

ACKNOWLEDGEMENTS

This research is financially supported by National

Electronics and Computer Technology Center

(NECTEC), Thailand.

REFERENCES

Aphiratsakun, N., Parnichkun, M., 2007. Preliminary

Study and Design of an Exoskeleton. Proceeding of

the CRIT 2007, Nakon Pathom, Thailand.

Chu, A., Kazerooni, H., Zoss, A., 2005. On the

Biomimetic Design of the Berkeley Lower Extremity

Exoskeleton (BLEEX). Proceeding of the 2005 IEEE

International Conference on Robotics and Automation,

Barcelona, Spain, pp. 4345-4352.

DESIGN AND BALANCING CONTROL OF AIT LEG EXOSKELETON-I (ALEX-I)

157

Corke, P. I., 1996. A Robotics Toolbox for MATLAB, IEEE

Robotics and Automation Magazine, no.1, vol.3, pp.24-

32.

Craig, J. J., 2005. Introduction to Robotics: Mechanics

and Control, Pearson Prentice Hall. 3

rd

edition.

Guizzo, E., Goldstein, H., 2005. The rise of Body Bots.

Spectrum, IEEE.

Kawamoto, Sankai, Y., 2002. Comfortable Power Assist

Control Method for Walking Aid by HAL-3.

Proceeding of the 2002 IEEE/SMC International

Conference.

Kawamoto, H., Kanbe, S., Sankai, Y., 2003. Power Assist

Method for HAL-3 Estimating Operator’s Intention

Based on Motion Information. Proceeding of the 2003

IEEE International Workshop on Robot and Human

Interactive Communication, California, USA, pp. 67-72.

Kazerooni, H., Racine, J. L., Huang, L., Steger R., 2005.

On the Control of the Berkeley Lower Extremity

Exoskeleton (BLEEX). Proceeding of the 2005 IEEE

International Conference on Robotics and Automation,

Barcelona, Spain, pp. 4353-4360.

Lee, S., Sankai, Y., 2002. Power Assist Control for Leg

with HAL-3 Based on Virtual Torque and Impedance

Adjustment. Proceedings of the 2002 IEEE/SMC

International Conference.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

158