DISTURBANCES ESTIMATION FOR MOLD LEVEL CONTROL

IN THE CONTINUOUS CASTING PROCESS

Karim Jabri

1,2

, Bertrand Bele

1

, Alain Mouchette

1

1

Measurement Control Engineering Department, ArcelorMittal Research, Maizières-Lès-Metz, France

Emmanuel Godoy

2

, Didier Dimur

2

2

Department of Automatic Control, Supélec,Gif sur Yvette, France

Keywords: Disturbance estimation, Luenberger observer, Harmonic disturbance, Continuous casting, Mold level

control.

Abstract: This paper addresses the problem of mold level fluctuations in the continuous casting process, which

strongly penalize the quality of the final product and lead to a costly machine downtime. Therefore, the

mold level is controlled using a stopper as the flow control actuator and a level sensor. Under normal

casting conditions, the current controllers provide suitable performances but abnormal conditions require

manual intervention, such as the decrease of the casting speed, in particular when undesired disturbances

like clogging/unclogging or bulging occur. These disturbances increase in severity for certain steel grades or

at high casting speeds. Therefore, this paper focuses on the on-line disturbances estimation in order to

introduce compensation actions. Starting with the presentation of the continuous casting process, the

description of the model of the machine, and highlighting the main control challenges, an observer

estimating clogging and bulging disturbances is then developed. This design may help future control

architectures based on disturbances estimation. The proposed observer is finally validated by extracting

disturbances from experimental signals measured on a continuous casting plant.

1 INTRODUCTION

Nowadays more than 96% of steel is produced by

means of a continuous casting process which has

significantly improved plant productivity in

comparison with other solidification processes.

Accurate control of the molten steel level in the

mold is an important task from both the operating

and quality points of view. Indeed, on the one hand,

it is important to control the mold level to avoid

molten steel overflows or mold emptying. On the

other hand, the mold level must be kept constant to

avoid alumina inclusions and slag being caught up in

the molten steel, leading to defects associated with

cracks in the slabs.

Under normal casting conditions, currently

implemented controllers provide suitable

performances. However, more severe operating

conditions still require manual intervention, such as

the decrease of the casting speed, in particular when

undesired clogging/unclogging or bulging

disturbances occur. These disturbances are in

particular extremely sensitive for certain steel grades

or at high casting speeds. Therefore, on-line

disturbance estimations become an important

challenge with a view to introducing feedforward

actions within the control law.

The paper is structured as follows. Section 2

describes the continuous casting process and the

model of the machine. The design of the observer is

presented in Section 3, successively estimating

clogging, bulging and both disturbances. The

proposed observer is finally validated in Section 4

by estimating disturbances from experimental

signals measured on a continuous casting plant.

119

Jabri K., Bele B., Mouchette A., Godoy E. and Dimur D. (2008).

DISTURBANCES ESTIMATION FOR MOLD LEVEL CONTROL IN THE CONTINUOUS CASTING PROCESS.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - SPSMC, pages 119-124

DOI: 10.5220/0001486601190124

Copyright

c

SciTePress

2 CONTINUOUS CASTING

PLANT MODEL

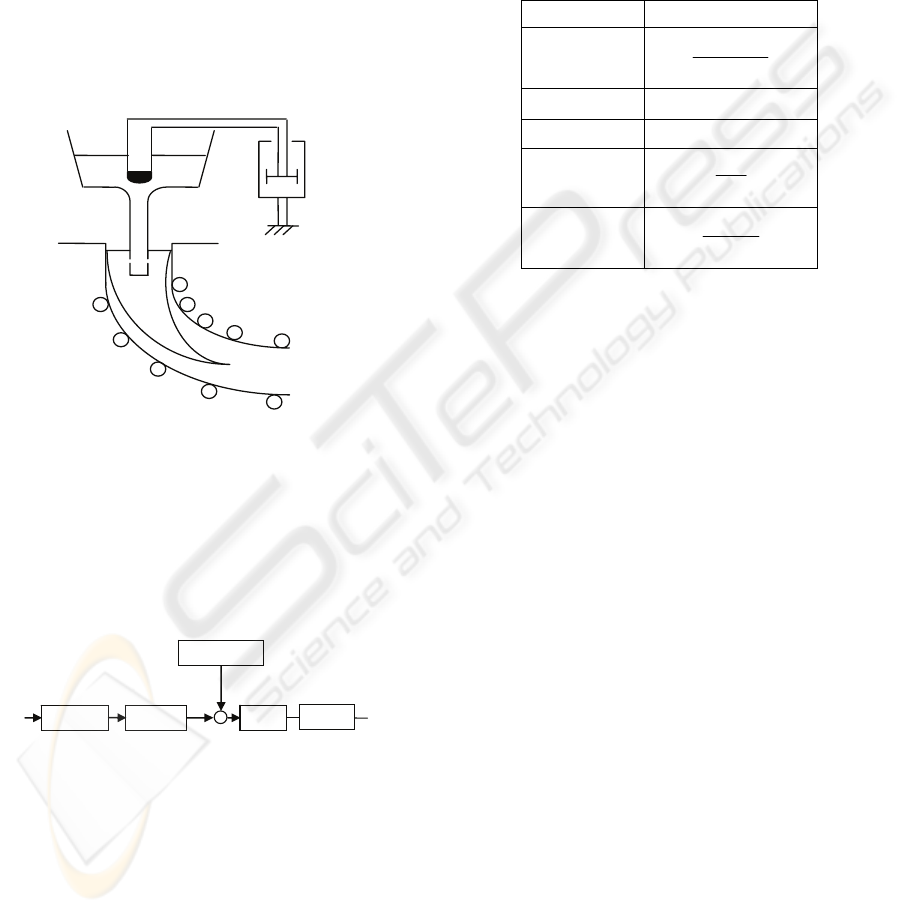

In the continuous casting process, as shown in

Figure 1, molten steel flows from the tundish into

the mold through the nozzle where it freezes against

water-cooled mold walls to form a solid shell. There

are several rolls below the mold to withdraw the

solidified steel continuously from the bottom of the

mold. The mold has an oscillatory movement with a

magnitude of a few millimetres and a frequency of

about 2 Hz that makes shell extraction easier. At the

outlet of the machine, the steel is fully solidified and

is cut into slabs.

Mold

Nozzle

Stopper

Tundish

Rolls

Solid

Liquid

Actuator

Figure 1: Continuous casting machine.

Usually, the casting speed is kept constant. The

flow out of the mold is thus constant and only the

inflow is controlled.

Figure 2 shows the major components of the

mold level control model without any disturbance

that is usually considered in the plants for the design

of the control law,

-

Mold

out

Q

in

Q

Withdrawal

Sensor

Actuator

Nozzle

P

N

u

+

Figure 2: Plant model.

where

u

is the control input,

P

the stopper

position,

N the mold level,

in

Q and

out

Q the steel

flow-rate into and out of the mold.

This behavioral model shows that the flow into

the mold

in

Q is regulated by the stopper position

P

by acting on the control input u of a hydraulic

actuator. The nozzle is usually modelled in most

cases by a simple gain. The flow out of the mold

out

Q is imposed by the casting speed. The mold

level

N is thus given by the integration of the

difference between

in

Q and

out

Q divided by the

cross section of the mold. This level is measured by

a sensor which can be either an eddy current or a

floating one, returning only local level and not the

whole free surface feature. Transfer functions appea-

ring in the plant model are summarized in Table 1,

Table 1: Transfer functions of the plant model.

Block Transfer function

Actuator

)1(

1

ss

G

a

τ

+

Nozzle

s

G

Withdrawal

vS

Mold

sS

1

Level sensor

s

G

ss

2

1

τ

+

where

s

G is the stopper gain,

ss

G the level sensor

gain,

a

G the actuator gain, S the mold section,

n

τ

the nozzle delay,

1

τ

the actuator time constant,

2

τ

the time constant of the level sensor, v the casting

speed and

s

the Laplace variable.

The control objective is to maintain the mold

level at a specified constant setpoint while limiting

the level fluctuations as much as possible.

Implemented controllers use both the level and

stopper signals as available measurements and

elaborate the actuator input

u acting as the

manipulated variable. Classic control structures

currently working on real plants are of two types: a

first structure considers regulation of the mold level

with a PID controller; a second one includes two

cascaded loops, regulating the stopper position in an

inner loop through a proportional gain and the mold

level in an external loop by means of a PI controller.

However, the control becomes more complex

when disturbances occur on the plant or when the

operating conditions change, leading to an unstable

behavior. In fact, several phenomena disturb the

balance between the flow into and out of the mold,

causing fluctuations over the meniscus surface or an

abrupt increase of the mold level. The standard

controllers are not designed for such casting

conditions. Therefore, new control strategies should

be designed, for example those based on

disturbances rejection. For this purpose, the

disturbances must first be estimated on-line so that

the control structure can compensate their influence

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

120

(Furtmueller and Gruenbacher, 2006). Section 3 will

thus consider the design of observers able to

estimate the two most important disturbances

occurring during continuous casting: the

clogging/unclogging and the bulging.

3 DISTURBANCE ESTIMATION

This Section will successively consider observers for

clogging/unclogging disturbance, then bulging

disturbance and finally for both types.

3.1 Clogging

The clogging event is one of the most serious

phenomena faced by the operators in the continuous

casting machine. It increases operating cost and

decreases productivity. Clogging takes place essen-

tially at the nozzle wall even if in principle it can

occur anywhere inside the nozzle. Nozzle clogging

takes many different forms. The first one is the

sediment of solid inclusions already present in the

steel entering the nozzle. The second form is related

to air aspiration into the nozzle through joints which

leads to reoxidation. The third type of clogging is

attributed to reactions between aluminum in the steel

and an oxygen source in the refractory. In practice, a

given nozzle clog is often a combination of several

of these types (Thomas and Bai, 2001). The

clogging effect is not an instantaneous phenomenon

but develops over time. Its cycle consists of a phase

of slow clogging, followed by a sudden unclogging

that raises considerably the mold level. Its period is

random (Dussud et al., 1998).

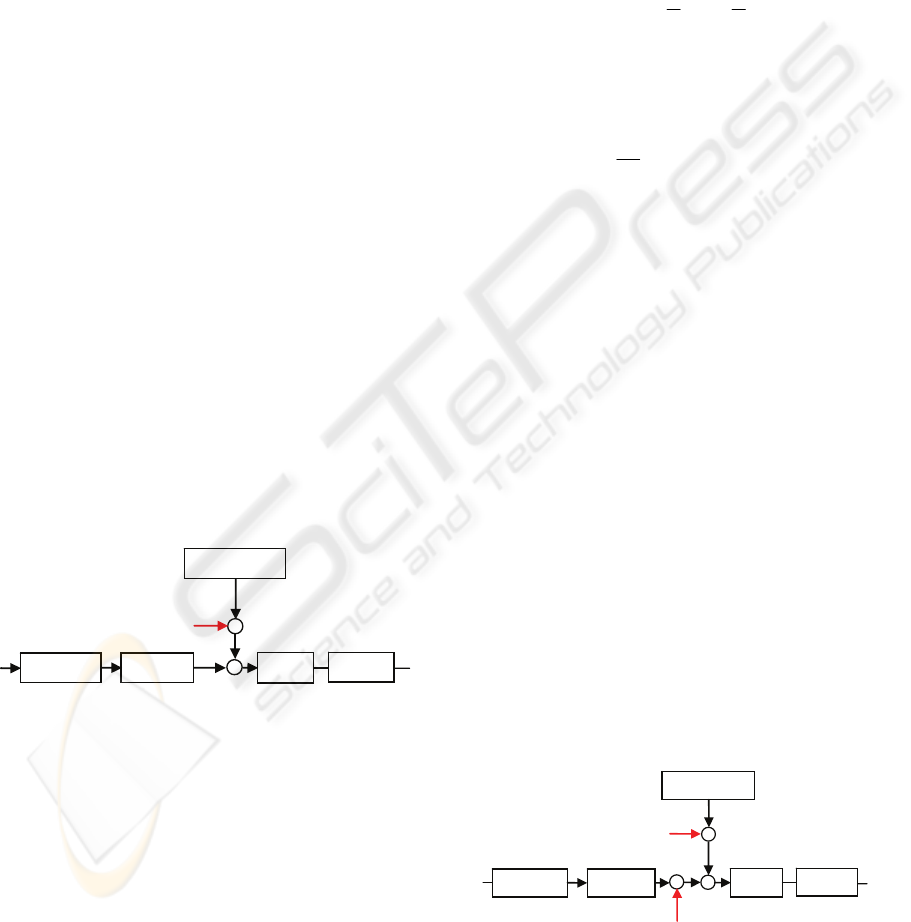

This part sets out to propose a clogging

estimation procedure assuming that this is the only

disturbance to arise during the casting operations.

Currently, when the clogging occurs, the controller

forces the stopper to move to maintain a constant

casting speed and a constant level inside the mold.

When the unclogging occurs, the flow passage

inside the nozzle becomes larger. The stopper

position decreases suddenly to reduce the control

zone (opening surface) in order to maintain a

constant flow rate into the mold. During the

clogging/unclogging cycle, the stopper position is

thus a succession of ramps. Therefore, a possible

model of the clogging/unclogging phenomenon can

be the inclusion of an additional flow

clog

d

to

idealin

Q

_

(which is the real inflow without

clogging), as in Figure 3.

clog

d

is also a succession

of ramps because the flow-rate out of the mold

out

Q

and the level

N are generally constant.

clog

d

has

thus the same behavior as the stopper position

P

.

-

+

out

Q

in

Q

Actuator Nozzle

Mold

Sensor

clog

d

-

-

P

N

Withdrawal

+

Figure 3: Plant model taking clogging into account.

The observer is designed considering the stopper

position P and the casting speed v as inputs, and the

mold level N as output. In the following modelling

phase, the time constant of the level sensor is

ignored, since it influences frequencies out of the

bandwidth of the regulation. Without loss of

generality,

ss

G is assumed to be equal to 1.

According to the previous figure:

{

0with

clog

clog

_

=

−−=

d

dvSPGNS

out

idealin

Q

Q

s

&&

321

&

(1)

Thus, the clogging model under the state space

formalism is given by:

⎪

⎩

⎪

⎨

⎧

=

+=

clogclog

logclogclogclogclog

XCN

UBXAX

c

&

(2)

with:

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎝

⎛

=

clog

clogclog

d

d

N

X

&

,

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

=

v

P

U

clog

,

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎝

⎛

=

0

0

1

clog

T

C

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎝

⎛

−

=

000

100

00

1

clog

S

A ,

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎝

⎛

−

=

00

00

1

clog

S

G

s

B

(3)

The observability matrix

clog

O

has full rank 3.

The system is therefore completely observable.

Based on the model Eq. 2, the Luenberger observer

(Sontag, 1998) is given as follows:

NKUB

XCKAX

clogclogclog

clogclogclogclogclog

ˆ

)(

ˆ

++

+−=

&

(4)

where

clog

K is the observer gain chosen so that the

observer is stable and achieves a desired dynamic.

The observer converges if the eigenvalues of the

square matrix

clogclogclog

CKA −

are strictly nega-

tive.

clog

K

is in a first step chosen to satisfy this

condition. The observer is afterwards adjusted with

DISTURBANCES ESTIMATION FOR MOLD LEVEL CONTROL IN THE CONTINUOUS CASTING PROCESS

121

dynamics as fast as possible, the compromise being

that its stability decreases with increasing dynamics.

3.2 Bulging

During the continuous casting process of a slab, the

volume of liquid steel inside the solidified shell can

be changed by strand bulging in the secondary

cooling zone. The bulging occurs between rolls due

to increasing pressure inside the strand. It is divided

into static or dynamic bulging, according to the

strand movement, and steady or unsteady bulging

according to the variation with time (Yoon et al.,

2002). The most disruptive type is the unsteady

bulging generating level fluctuations in the mold.

This part sets out to propose a bulging estimation

procedure assuming that this is the only disturbance

to arise during the casting operations. It is supposed

that the bulging profile at each site between two rolls

is described by a sine function (Lee and Yim, 2000)

with a frequency between 0.05 and 0.15 Hz.

Therefore, this displacement induces changes in the

flow-rate out of the mold. The bulging phenomenon

can thus be modelled by an additional flow

bulge

d

to

idealout

Q

_

(which is the real outflow without

bulging).

bulge

d

is a sum of several sine waves. To

determine its frequencies, the level signal spectrum

must be calculated and the most significant

frequencies belonging to the frequency range

selected. In the following part of this subsection, and

without loss of generality, only two frequencies of

bulge

d

are considered (see Figure 4).

-

Mold

+

out

Q

in

Q

N

Withdrawal

Sensor

Actuator Nozzle

P

idealout

Q

_

+

bulge

d

+

u

Figure 4: Plant model taking bulging into account.

For the following modelling phase, the time

constant of the level sensor is again ignored.

According to Figure 4:

2,1)cos(with

)(

bulge

2bulge1bulge

_

=+=

++−=

itAd

ddvSPGNS

iiii

Q

Q

s

out

idealin

ϕω

44443444421

321

&

(5)

The bulging model under the state space

formalism is thus given by:

⎩

⎨

⎧

=

+=

bulgebulge

bulgebulgebulgebulgebulge

XCN

UBXAX

&

(6)

with

⎟

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎜

⎝

⎛

=

2bulge

2bulge

1bulge

1bulge

bulge

d

d

d

d

N

X

&

&

,

⎟

⎠

⎞

⎜

⎝

⎛

=

v

P

U

bulge

⎟

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎜

⎝

⎛

−

−

−−

=

0000

10000

0000

00100

000

2

2

2

1

11

bulge

ω

ω

SS

A

,

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎝

⎛

−

=

00

00

00

00

1

bulge

S

G

s

B

,

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎝

⎛

=

0

0

0

0

1

bulge

T

C

(7)

The observability

bulge

O has full rank 5. The

system is thus completely observable. Based on the

model Eq. 6, the Luenberger observer is given by the

following equation:

NKUB

XCKAX

bulgebulgebulge

bulgebulgebulgebulgebulge

ˆ

)(

ˆ

++

+−=

&

(8)

where

bulge

K

is the observer gain adjusted as in

Section 3.1.

3.3 Clogging and Bulging

The previous clogging and bulging observers were

designed separately to estimate respectively

clogging or bulging being the only disturbance

acting on the system. However, when clogging and

bulging occur simultaneously during the continuous

casting operation, these two observers must be

merged into a single global one that will be able to

estimate

clog

d

and

bulge

d

individually (Figure 5).

-

+

out

Q

in

Q

Actuator Nozzle

Mold

Sensor

clog

d

-

-

P

N

Withdrawal

+

bulge

d

Figure 5: Plant model with clogging and bulging effects.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

122

With this figure, merging Eqs. 1 and 5 leads to:

2,1)cos(

0with

)(

bulge

2bulge1bulgebulge

clog

bulgeclog

=+=

+=

=

+−−=

itAd

ddd

d

dvSdPGNS

iiii

QQ

s

outin

ϕω

&&

44344214434421

&

(9)

which results in the global clogging/bulging model

under the state space formalism:

⎪

⎩

⎪

⎨

⎧

=

+=

estest

estestestestest

XCN

UBXAX

&

(10)

with:

(

)

bulge2bulge2bulge1

bulge1clogclog

ddd

dddNX

T

est

&&

&

=

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎝

⎛

−

−

−−−

=

000000

1000000

000000

0010000

0000000

0000100

0000

2

2

2

1

111

ω

ω

SSS

est

A

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

=

v

P

U

est

,

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎝

⎛

−

=

00

00

00

00

00

00

1

S

G

est

s

B

,

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎟

⎠

⎞

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎜

⎝

⎛

=

0

0

0

0

0

0

1

T

est

C

(11)

The observability matrix

est

O has full rank 7.

The system is thus completely observable. Based on

the model Eq. 10, the global Luenberger observer is

given by the following equation, where

est

K is the

observer gain adjusted as previously:

NKUB

XCKAX

estestest

estestestestest

++

+−=

ˆ

)(

ˆ

&

(12)

The generalization to more than two frequencies

taken into account in the bulging disturbance is

performed by considering two additional state

variables per added frequency, with adequate rows

and columns in the state representation. It must be

noticed that, due to the observer structure, the ave-

rage of the

bulge

d signal is included in the estima-

tion of

clog

d . In short,

clog

d contains the average

of

bulge

d and a succession of ramps possibly.

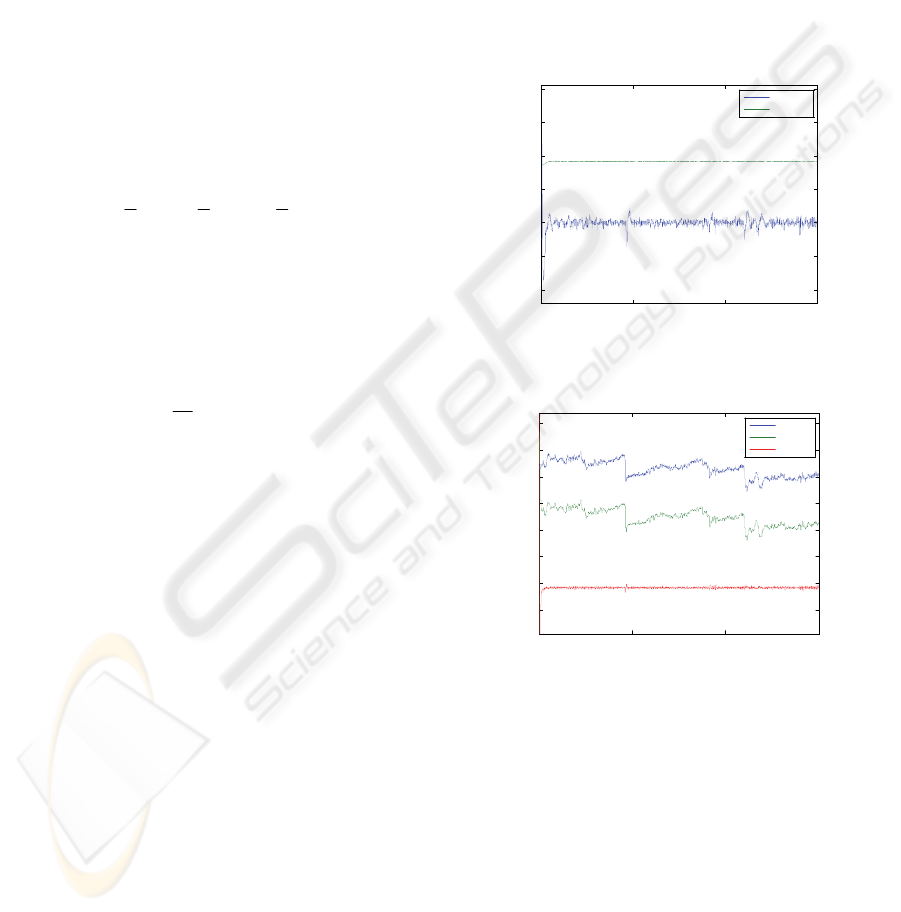

4 OBSERVER VALIDATION

The previous global observer is now applied on

experimental data registered during continuous

casting operations. A first experiment is considered

(record 1), for which the eigenvalues of the observer

have been tuned (according to bulging signal

frequencies) to −1.5, −1.57, −1.27, −1.42, −1.35,

−1.2 and −1.12. Results are given in Figures 6 and 7.

Figure 6 compares the estimated

bulge

d

to

idealout

Q

_

.

idealout

Q

_

appears to be ten times

greater than

bulge

d

. It can be concluded that there is

no bulging effect in this first record.

0 500 1000 1500

-10

-5

0

5

10

15

20

Flow out (l/s)

d-bulge

Qout-ideal

Figure 6: Comparison between the estimated

bulge

d and

idealout

Q

_

in the case of the first record.

0 500 1000 1500

5

10

15

20

25

30

35

40

Flow (l/s)

Qin-ideal

d-clog

Qin

Figure 7: Comparison between the estimated

clog

d , the

ideal and the real input into the mold for the first record.

Knowing this, Figure 7 now compares the

estimated

clog

d elaborated by the observer with the

ideal (

idealin

Q

_

) and the real (

in

Q ) input into the

mold in the case of this first record.

idealin

Q

_

is

recomputed by means of the measurement of the

stopper position

P

as mentioned in Eq. 5 and

in

Q

is recalculated by means of the relation in Eq. 9. It is

shown that the estimated clogging disturbance

follows the expected profile, i.e. ramp variations

during the clogging phase and a sudden decrease due

to unclogging. This figure also illustrates that

in

Q is

three times smaller than the ideal value

idealin

Q

_

Time (s)

Time (s)

DISTURBANCES ESTIMATION FOR MOLD LEVEL CONTROL IN THE CONTINUOUS CASTING PROCESS

123

expected without clogging. Thus this estimation by

means of an observer, which may be useful for

control purposes, also helps to quantify the intensity

of the clogging phenomenon.

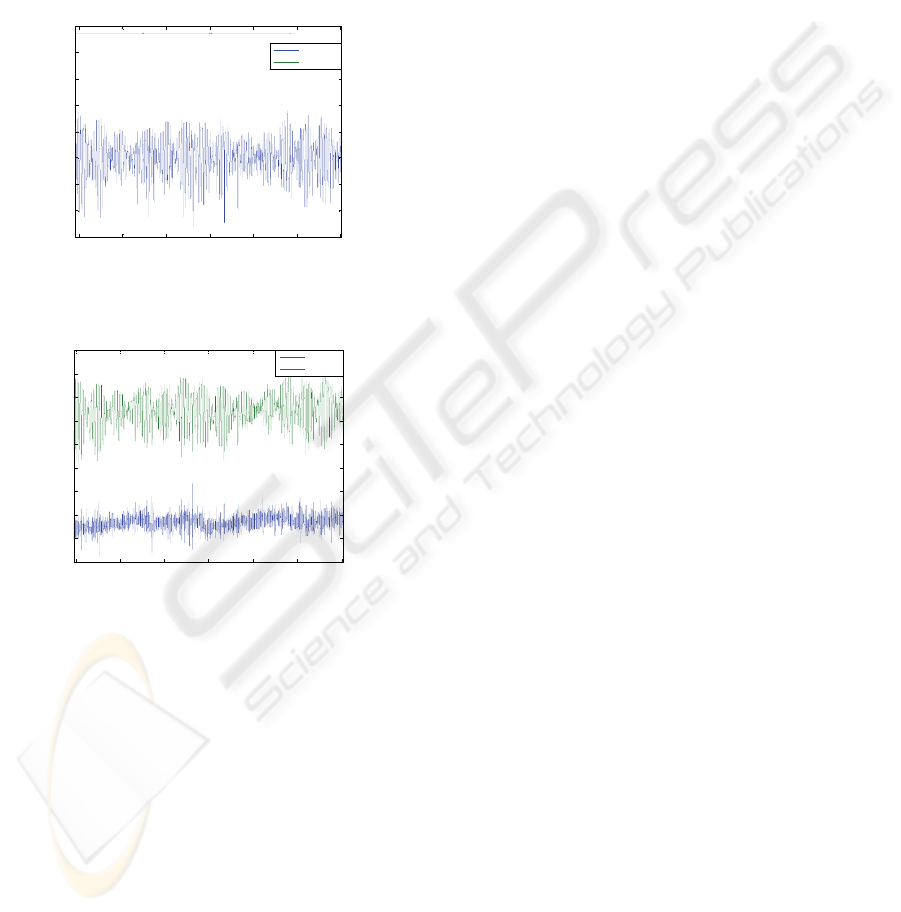

The observer, tuned as previously, is now

applied to a second experiment (record 2). In this

case, three frequencies of the signal

bulge

d

have to

be considered, respectively 0.084, 0.095 and

0.082 Hz as the most significant in the bulging

frequency range [0.05, 0.15] Hz.

400 600 800 1000 1200 1400 1600

-6

-4

-2

0

2

4

6

8

10

Flow out (l/s)

d-bulge

Qout-ideal

Figure 8: Comparison between the estimate

bulge

d and

idealout

Q

_

in the case of the second record.

400 600 800 1000 1200 1400 1600

10

12

14

16

18

20

22

24

26

28

Flow in (l/s)

d-clog

Qin-ideal

Figure 9: Comparison between the estimated

clog

d and

idealin

Q

_

in the case of the second record.

Figures 8 and 9 show the estimated disturbances

bulge

d and

clog

d . Figure 9 compares the estimation

of

clog

d to

idealin

Q

_

. Without ramp in

clog

d , it can

be concluded that

clog

d only represents the average

of the

bulge

d signal of Figure 8 which should be

added to it in order to estimate its correct value, and

that there is no clogging effect in this record. From a

control point of view as described in (Furtmueller

et

al

., 2005), to have the average of

bulge

d included in

clog

d is not problematic. In fact, the control

structure which compensates disturbances should

use the sum of

clog

d and

bulge

d as an input and not

the two disturbance estimations separately.

5 CONCLUSIONS

This paper presents the elaboration of a global

observer designed to estimate clogging and bulging

disturbances appearing in a continuous casting

process. These estimations may be further used as

inputs to compensation modules within mold level

control structures. This observer is built with

behavioral models of the physical process, assuming

that these disturbances can be modelled as

exogenous signals. Further research may consider a

nonlinear nozzle gain to model the clogging effect,

robustness analysis of the estimator, particularly

with respect to variations of the bulging signal

frequencies and model uncertainties.

REFERENCES

Thomas, B.G., Bai, H., 2001. Tundish nozzle clogging –

application of computational models. In

18

rd

PTD

Conf. Proc.

, Baltimore (US).

Sontag, E., 1998.

Mathematical Control Theory:

Deterministic Finite Dimensional Systems

, Springer.

2

nd

edition.

Yoon, U-S., Bang, I.-W., Rhee, J.H., Kim, S.-Y., Lee, J.-

D., Oh, K.H., 2002. Analysis of mold level hunching

by unsteady bulging during thin slab casting. ISIJ

International, 42(10):1103-1111.

Lee, J.D., Yim, C.H., 2000. The mechanism of unsteady

bulging and its analysis with the finite element method

for continuously cast steel. ISIJ International,

40(8):765-770.

Dussud, M., Galichet, S., Foulloy L.P., 1998. Application

of fuzzy logic control for continuous casting mold

level control.

IEEE Transactions on Control Systems

Technology

, 6(2).

Furtmueller, C., Gruenbacher, E., 2006. Suppression of

periodic disturbances in continuous casting using an

internal model predictor. In

Proc. IEEE Intl. Conf. on

Control Applications

, Munich, Germany.

Furtmueller, C., Del Re, L., Bramerdorfer, H., Moerwald,

K., 2005. Periodic disturbance suppression in a steel

plant with unstable internal feedback and delay. In

Proc. 5

th

Intl. Conf. on Tech. and Automation, Greece.

Time (s)

Time (s)

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

124