IDENTIFICATION OF THE DYNAMIC PARAMETERS OF THE C5

PARALLEL ROBOT

B. Achili

∗+

, B. Daachi

∗

, Y. Amirat

∗

and A. Ali-Cherif

+

+

Laboratoire d’Informatique Avanc´ee de Saint Denis, 2 rue de la libert´e, 93526 Saint Denis Cedex, France

∗

Laboratoire Images, Signaux et Syst`emes intelligents, 122-124 rue Paul Armangot, 94400 Vitry/seine, France

Keywords:

Identification, Parallel Robot, Least Squares Method, Cross validation.

Abstract:

This paper deals with the experimental identification of the dynamic parameters of the C5 parallel robot.

The inverse dynamic model of the robot is formulated under the form of linear equation with respect to the

dynamic parameters. Moreover, a heuristic procedure for finding the exciting trajectory has been conducted.

This trajectory is based on Fourier series whose coefficients are determined by using a heuristic method.

The least squares method has been applied to solve an over-determined linear system which is obtained by

sampling the dynamic model along the exciting trajectory. The experimental results show the effectiveness of

the identification procedure.

1 INTRODUCTION

A parallel architecture is a closed-loop mechanism

in which the end-effector (mobile platform) is con-

nected to the base by at least two independent kine-

matic chains. The pioneering works in this field are

those of Stewart who proposed in 1965 a parallel plat-

form with 6 DOF. Since then, several authors have

proposed a large variety of designs and studies. Paral-

lel architectures were first used for buildingflight sim-

ulators and tire testers. Since then, they were used in

other applications like the handling of heavy objects

with great accelerations, or the assembly of parts re-

quiring high precision. More recently, parallel robots

appeared in the medical field . The latter requires the

design of very precise parallel machines performing

in a limited workspace

Because of their structure, serial robots have lim-

ited dynamic performances. In the other hand, due to

their reducted inertia, parallel robots allow for the re-

duction of coupling dynamic effects and consequently

to better dynamic performance.

In the literature, several techniques were proposed

for the identification of dynamic parameters of robot.

A CAD method based on identifying inertia param-

eters is proposed in (An et al, 85). Usually these

methods lead to an unsufficientprecision of inertia pa-

rameters estimation and do not allow for the determi-

nation of other dynamic parameters (viscous friction,

coulomb friction). For better results, an estimation of

the whole dynamic parameters of the assembled robot

is required.

The identification procedure consists usually of

four main steps: (1) Calculation of an identifiable dy-

namic model, (2) Generation of the optimized excita-

tion trajectory, (3) Estimation of the dynamic parame-

ters, and finally (4) Validation of the obtained model.

The first step consists of calculating the minimal

set of dynamic parameters to be identified ( set of base

parameters). This set can be computed by using the

QR decomposition of observation matrix (Gautier,

91). In the second step, the optimal exciting trajec-

tory is calculated in order to guarantee the relevance

of the measured data. This step includes the choice of

an optimization criterion.

The third step consists of estimating the dy-

namic parameters from the measured data. Least

squares method is one of the most widely used es-

timation method. It consists of solving an over-

determined linear system (Janot, 07). An improve-

ment over the classical LS method is the use of a

Weighted Least Squares (WLS) estimator, (Renaud et

al, 06). Another approach is the Maximum Likeli-

hood Estimator(MLE) whose principle assumes that

the true parametric model is known exactly (Swevers

et al, 97). Other estimators like the ellipsoidal algo-

rithm or the interval analysis (Poignet et al, 03) have

been proposed in the literature.

The fourth step of identification procedure con-

sists of validating the identified dynamic model. In

67

Achili B., Daachi B., Amirat Y. and Ali-Cherif A. (2008).

IDENTIFICATION OF THE DYNAMIC PARAMETERS OF THE C5 PARALLEL ROBOT.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 67-70

DOI: 10.5220/0001487300670070

Copyright

c

SciTePress

most cases, this is realized by comparing the predicted

and the measured torques for a trajectory which is dif-

ferent from the exciting trajectory.

In this paper we present the identification of dy-

namic parameters of the 6 DOF parallel robot with C5

joints. First, the dynamic model is expressed as a lin-

ear relation with respect to the dynamic parameters.

The parameters are estimated by the classical tech-

nique of least squares solving an overdetermined lin-

ear system obtained from a sampling of the dynamic

model, along the exciting trajectory.

The paper is organized in four sections. First one

describes the mechanical architecture of the C5 par-

allel robot. Second section presents the inverse dy-

namic model of the robot. Section 3 presents an esti-

mation of the dynamic parameters of the robot. Cal-

culation of the exciting trajectory along with the data

filtering procedure are developed in section 4. Fifth

section is dedicated to the presentation and analysis

of the experimental results including the cross valida-

tion procedure. Finally, a conclusion and some per-

spectives are given in the last section.

2 DESCRIPTION OF THE C5

PARALLEL ROBOT

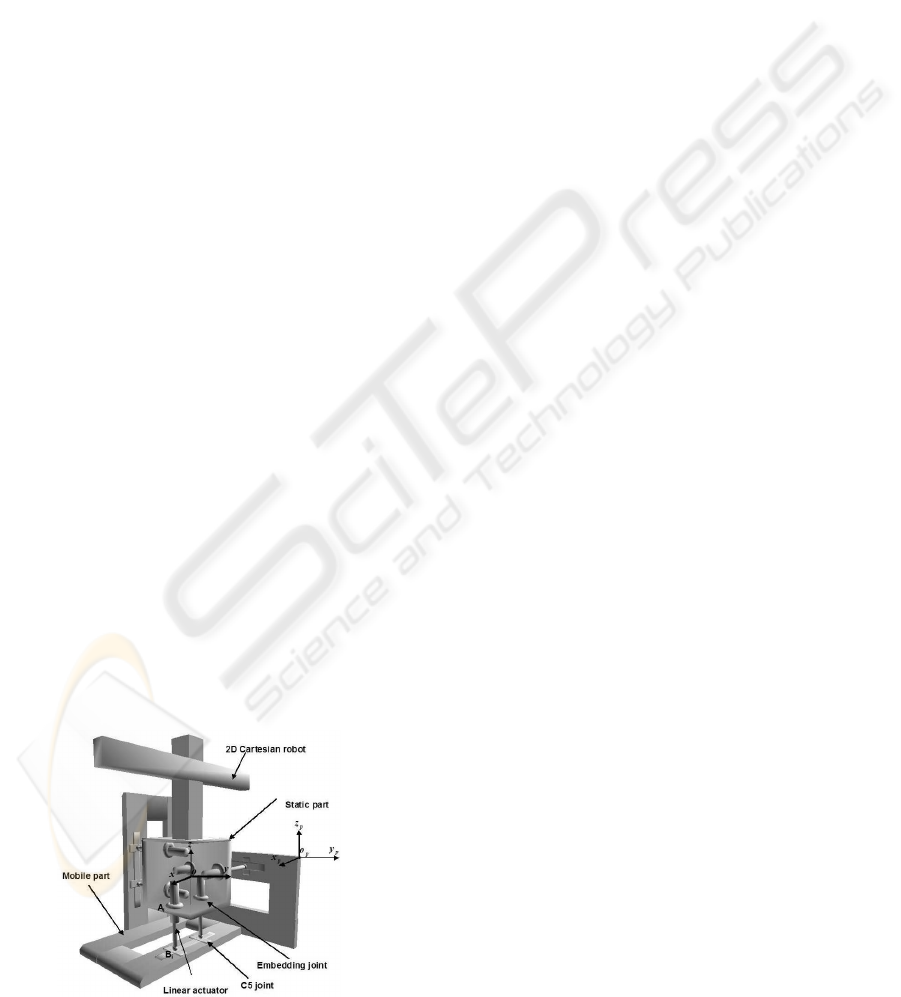

The C5 parallel robot consists of a static part and a

mobile part connected together by six actuated links.

Each segment is embedded to the static part at point

A

i

and linked to the mobile part through a spherical

joint attached to two crossed sliding plates at point B

i

(Fig. 1).

Theoretical study concerning this architecture has

been presented in the literature. The C5 links paral-

lel robot is equipped with six linear actuators; each of

them is driven by a DC motor. Each motor drives a

ball and screw arrangement. The position measure-

ments are obtained from six incremental encoders,

which are tied to the DC motors.

Figure 1: Parallel robot.

3 MODELING OF THE C5 ROBOT

3.1 Inverse Dynamic Model

The inverse dynamic model of the C5 parallel robot is

given in (Khalil et al, 04):

To solve our identification problem, we rewrite the

inverse dynamic model to make it linear with respect

to dynamic parameters (Poignet et al, 02). The dy-

namic model is rewritten then as follows:

Γ = D(ω

p

,

˙

ω

p

,

˙

V

p

,q, ˙q, ¨q) X

s

(1)

with

• Γ : (6× 1) torque vector

• D : (6× 34) observation matrix

• X

s

: (34× 1) standard parameters vector:

X

s

= (X

s1

X

s2

X

s3

X

s4

X

s5

)

T

X

s1

= (M

1

M

2

M

3

M

4

M

5

M

6

M

p

)

X

s2

= (XX XY XZ YY YZ ZZ MX MY MZ)

X

s3

= (I

a1

I

a2

I

a3

I

a4

I

a5

I

a6

)

X

s4

= (F

v1

F

v2

F

v3

F

v4

F

v5

F

v6

)

X

s5

= (F

s1

F

s2

F

s3

F

s4

F

s5

F

s6

)

4 DYNAMIC PARAMETERS

IDENTIFICATION

For the purpose of dynamic parameters identification,

we use the formulation given in (Janot et al, 07). The

principle of identification consists in sampling the in-

verse dynamic model of the robot with respect to

the base parameters, obtained by QR decomposition

(Gautier, 91) along the exciting trajectory. A filtering

process is applied to the measured data in order to ob-

tain a good estimation of dynamic parameters. This

technique allows us to obtain an over-determined lin-

ear system of full rank.

5 EXCITING TRAJECTORY

CALCULATION

The quality of the exciting trajectory can be evaluated

through a good condition number of the regressor

matrix. The calculation of this trajectory can be

done by nonlinear optimization. In our case, we

used an exciting trajectory based on Fourier series

(Swevers et al, 91). For each segment j ( j = 1, 2, ...6),

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

68

the position q

j

can be written as follows:

q

j

(t) = q

j,0

+

M

∑

k=1

(a

j,k

sin(kω

f

t) + (b

j,k

cos(kω

f

t))

(2)

with

• ω

f

the fundamental pulsation of the finite Fourier

series.

• t the time.

• a

j,k

and b

j,k

(k = 1,...5) the amplitudes of sine

and cosine functions

• q

j,0

is the initial value of the position trajectory.

In order to excite the robot in the bandwidth of the

position closed loop, f

dyn

< 2 Hz , we have chosen the

fundamental frequency of trajectories equal to 0.1Hz

and the number of harmonics k = 5.

As the number of Fourier series coefficients is

high, it is difficult to determine them by a nonlinear

optimization. For this reason, we calculate these co-

efficients in a heuristic way. The calculation of these

parameters is based on the motion constraints which

are imposed by physical limitations of robot. These

constraints can be expressed as follows:

−0.05m < q

j

(α) < +0.05m (3)

−0.1m/s < ˙q

j

(α) < +0.1m/s (4)

−0.5m/s

2

< ¨q

j

(α) < +0.5m/s

2

(5)

Where:

Vector α includes the trajectory parameters q

j,0

,

a

j,k

and b

j,k

.

The heuristic approach allows us to find the excit-

ing trajectories shown in Fig. 2.

0 2000 4000 6000 8000 10000

−0.04

−0.02

0

0.02

0.04

Time [ms]

joint q1 [m]

0 2000 4000 6000 8000 10000

−0.02

0

0.02

Time [ms]

joint q2 [m]

0 2000 4000 6000 8000 10000

−0.04

−0.02

0

0.02

0.04

Time [ms]

joint q3 [m]

0 2000 4000 6000 8000 10000

−0.02

0

0.02

Time [ms]

joint q4 [m]

0 2000 4000 6000 8000 10000

−0.04

−0.02

0

0.02

0.04

Time [ms]

joint q5 [m]

0 2000 4000 6000 8000 10000

−0.04

−0.02

0

0.02

0.04

Time [ms]

joint q6 [m]

Figure 2: Exciting trajectories.

5.1 Data Filtering

For a good estimation of the dynamic parameters, the

measurementssignals need to be filtered . So the posi-

tion is filtered by the 4

th

order Butterworth filter. The

vector Y and each column of matrix W are filtered by

the 8

th

order Tchebychev filter and are resampled at

lower rate in order to reject the high frequency ripples

of the measured torques. The computation of joint ve-

locities and accelerations is made by using the central

difference algorithm in order to avoid any distortion

of phase and amplitude.

6 EXPERIMENTAL RESULTS

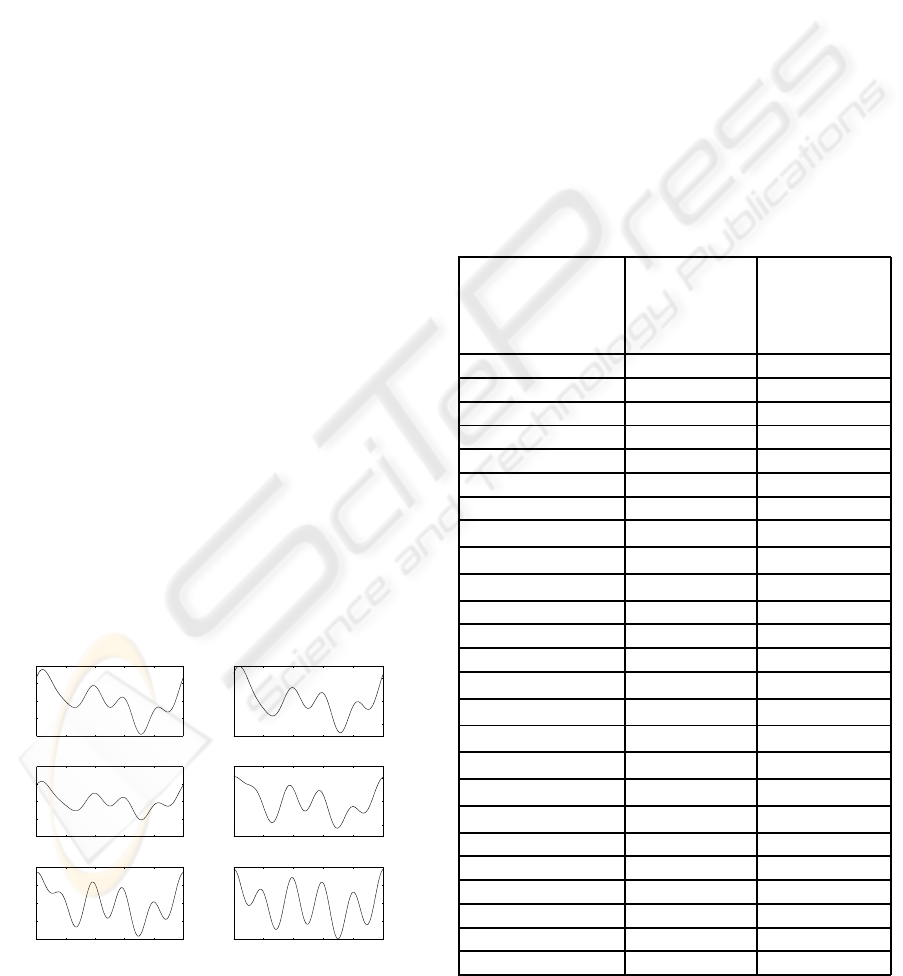

The table given in Fig. 3 shows the estimated base

parameters. The relative standard deviations are also

given.

parameters

identified

values

ˆ

X

relative

standard

deviations

%σ

ˆ

X jr

M

1

+ I

a1

(kg) 0.5435 7.0629

M

2

+ I

a2

(kg) 0.4075 11.3082

M

3

+ I

a3

(kg) 0.5436 7.0617

M

4

+ I

a4

(kg) 0.5909 6.7516

M

5

+ I

a5

(kg) 0.4909 8.8692

M

6

+ I

a6

(kg) 0.5718 6.7108

M

p

(kg) 8.2652 9.6980

XX(kg.m

2

) 0.1035 1.7892

YY(kg.m

2

) 0.2124 5.8701

ZZ(kg.m

2

) 0.0178 7.0021

MX(kg.m) 7.5925 2.0799

MY(kg.m) -1.8212 8.6681

MZ(kg.m) 21.2650 16.1002

F

v1

(N.m.s.rad

−1

) 8.8464 2.0209

F

v2

(N.m.s.rad

−1

) 7.9940 2.2183

F

v3

(N.m.s.rad

−1

) 8.7253 2.1198

F

v4

(N.m.s.rad

−1

) 7.5517 2.2366

F

v5

(N.m.s.rad

−1

) 8.1706 2.2777

F

v6

(N.m.s.rad

−1

) 8.7312 2.1182

F

s1

(N.m) 0.5034 5.1484

F

s2

(N.m) 0.3424 7.4246

F

s3

(N.m) 0.2344 9.3723

F

s4

(N.m) 0.2705 8.3329

F

s5

(N.m) 0.1753 13.1492

F

s6

(N.m) 0.2335 9.4081

Figure 3: Identified parameters.

IDENTIFICATION OF THE DYNAMIC PARAMETERS OF THE C5 PARALLEL ROBOT

69

Note that the dynamic parameters present in most

cases a relative standard deviation lower than 10%,

which represents a good estimation. However the rel-

ative standard deviation of the parameters MZ, and

F

S5

is higher than 10%. This deviation is due to me-

chanical constraints, consequently, we conclude that

the obtained results are encouraging and we can state

that these identification results are globally accept-

able.

In order to validate the estimated dynamic param-

eters, we proceed to a cross validation which con-

sists in comparing the measured torques with those

obtained by the inverse dynamic model with the iden-

tified parameters. The trajectory which is usedfor this

validation has not been used previously for the iden-

tification. Figure 4 show the results of this validation.

For the others axis, we have also obtained the same

ting than figure 4

0 1000 2000 3000 4000

−8

−6

−4

−2

0

2

4

6

8

10

Time [ms]

Torque 1 [N.m]

0 1000 2000 3000 4000

−4

−3

−2

−1

0

1

2

3

4

Time [ms]

Torque 2 [N.m]

Estimated torque 2

Measured torque 2

Estimated torque 1

Measured torque 1

Figure 4: Estimated and measured torque for the joints 1

and 2.

Note that the calculated torques using the inverse

dynamic model with the estimated parameters are

close to those measured on the robot. Consequently,

one can conclude that the estimation of the dynamic

parameters, using the least squares method is valid.

7 CONCLUSIONS

In this paper, we identified the physical parameters

of the C5 parallel robot. The identification is based

on the least squares method. The application of this

identification method uses an exciting trajectory cal-

culated from a heuristic approach. To validate the

identified parameters, we considered another trajec-

tory different from that used in identification. The

cross validation enables us to conclude with the ef-

fectiveness of the considered identification. In short

term of our project, we propose to include the joint

elasticity, which is the major source of flexibility in

many practical applications.

REFERENCES

Swevers J., Ganseman C., Bilgin D., De Schutter J., Van

Brussel H., 1997. Optimal robot excitation and identi-

fication. IEEE Transactions on Robotics and Automa-

tion, 13(5):730–740.

Renaud, P., Vivas, A., Andreff, A., Poignet, P., 2006. Mar-

tinet, P., Pierrot, F., Company, O., Kinematic and dy-

namic identification of parallel mechanisms, In Con-

rol Engineering Practice 14, pp1099 - 1109.

Poignet, P., Ramdani, N., Vivas, A., 2003. Robust estima-

tion of parallel robot dynamic parameters with inter-

val analysis, Proceedings of the 42nd IEEE Confer-

ence on Decision and Control, pp. 6503-6508, Maui,

Hawaii, USA.

Khalil, W., Ibrahim, O., 2004. General Solution for the Dy-

namic Modeling of Parallel Robots, lnternational Con-

ference on Robotics & Automation, New Orleans, LA.

Gautier, M., Poignet, P., 2002. Identification en boucle

ferm´ee par mod`ele inverse des param`etres physiques

de syst`emes m´ecatroniques, Journal Eurepeen des

Syst`emes Automatis´es,36:465-480.

Gautier M., 1991. Numerical calculation of the base inertial

parameters, Journal of Robotics Systems, Vol. 8, No.

4, pp. 485-506.

An, C. H., Atkenson, C. G., Hollerbach, J. H., 1985. Es-

timation of inertial parameters of rigid body links of

manipulators, Proceedings of the 24th Conference on

Decision and control, pp. 990-995.

Janot, A., Bidard, C., Gosselin, F., Gautier, M., Keller, D.,

Perrot, Y., 2007. Modeling and Identification of a 3

DOF Haptic Interface,IEEE International Conference

on Robotics and Automation Roma, Italy, pp 4949-

4955

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

70