TELECONTROL PLATFORM

Telecontrol Platform for Industrial Installations

Eduardo J. Moya, Oscar Calvo, José María Pérez, José Ramón Janeiro and David García

Fundación CARTIF, Parque Tecnológico de Boecillo, Parcela 205, 47151 Boecillo, Valladolid, Spain

Keywords: GSM modem, analogical modem, PLC, SCADA, monitoring, Industrial Process.

Abstract: This article explains the telecontrol platform for industrial installations developed by CARTIF Foundation.

Using this system it will be able to send control orders and receive notification of alarms from the PLC

thanks to SMS (Short Messages System) messages which use GSM technology. In case of requiring a

greater flow of data it will use telephone line combined with MODBUS protocol. All this will enable us to

monitor and control any industrial installation with a very low cost. Copyright © 2007.

1 INTRODUCTION

The possibility of remote connections with industrial

processes can represent significant savings of time

and money for companies. In fact, you can control

and monitor equipments, update the software or

locate faults regardless of equipment location with a

simple remote connection.

These monitoring tasks can be carried out with

conventional technologies, as GSM network or

switched telephone network, (International

Engineering Consortium, 2007) which have been

installed for many years. These systems are

reappearing in industrial applications thanks to its

low cost and the broad range of possibilities offered

By using of these technologies (GeneralLynx,

2007), CARTIF Foundation has developed a

monitoring system based on GSM modems and

analogical ones that allow us to monitor and modify

variables of processes controlled by SIEMENS S7-

200 automatisms.

The article is organized as follows. In Section 2

we explain the first part of this project that consisted

in creating a system capable of controlling and

monitoring a process through SMS messaging. In

Section 3 we expose the second part of this project.

In this case we use an analogical modem to link PLC

and SCADA. In Section 4 we will explain a practical

case of the combined use of the library SMS and

communication via RTC modem. Finally

conclusions and open issues for future research are

discussed in Section 5.

2 MONITORING OF PROCESSES

USING GSM TECHNOLOGY

In the case we're dealing with we’ll use the GSM

network, which will allow us to send simple control

commands between a cellular and a PLC from any

place as long as we have enough coverage; this

system requires only a GSM modem and a SIM card

which are very cheap.

In this section we’ll explain the library called

SMS developed by CARTIF Foundation. This

library has been developed to be used with a

programmable Siemens PLC although similar

developments can be performed to be used with

other brands as Telemecanique, Omron or Allen-

Bradley.

2.1 Elements of the System

CARTIF Foundation uses mainly programmable

PLCs of Siemens or Telemecanique. We decided to

develop SMS library to be used with a low-mid

range Siemens PLC. In this way, the automatism

that has been selected is a S7-200. Developing this

library for the S7-200, subsequent developments in

other PLC´s will be able to be conducted in a very

similar way.

Besides that it will be needed a RS 232/PPI

Multi-Master cable because the ports of Siemens S7-

200 series are RS-485 and GSM modems usually

have RS-232.

The third item of the system is a GSM modem.

81

J. Moya E., Calvo O., María Pérez J., Ramón Janeiro J. and García D. (2008).

TELECONTROL PLATFORM - Telecontrol Platform for Industrial Installations.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 81-86

DOI: 10.5220/0001491300810086

Copyright

c

SciTePress

At first it was wanted to develop a library that would

be independent of the brand and model of GSM

modem, but it wasn’t possible because each brand

have different responses to the commands that are

sent to it. In order to simplify the design of the

library it will be used a generic one, GSM/GPRS

Wavecom Fastrack (Fastrack Modem M1306B,

2007).

Figure 1: PLC & GSM modem.

2.2 Characteristics of SMS Library

SMS library has as basic functions the reception and

sending SMS messages, always besides their

treatment. The great advantage is that

communication with modems is standardized

through the use of AT commands (AT Commands

Interface Guide, 2007). AT commands are just

coded instructions for communication between a

device and a modem. As we said before although the

instructions that are sent to modems are standardized

through the AT commands, the modems responses

are not. This causes the library not to be valid for all

GSM modems, although its adaptation to other

models is very simple.

2.2.1 AT Commands

The commands AT used in the library are: ATE0,

AT+CPIN ?, AT+CPIN = "Nº PIN", AT+CMGF =

1, AT+CSMP = 17,167,0,0, AT+CREG ?,

AT+CPMS = "SM", AT+CMGS = "PHONE

NUMBER", AT+CMGR = X, AT+CMGD = X.

2.2.2 Library Functions

The library functions are:

Sending SMS.

Periodical control of coverage.

Output of error.

Automatic blocking in case of entering a

wrong PIN.

Reception of SMS

Elimination SPAM.

Automatic Clearing of the read SMS.

Permits of access.

Treatment automatic SMS.

Treatment of SMS by the user.

Size in program memory: 4.5Kb

Size in data memory: 490 bytes.

2.3 Compatible SMS

For the use of library SMS is only necessary to have

a mobile phone (Moya, 2007). You can send SMS of

two types:

2.3.1 SPECIFIC Messages

These messages are customized for an installation in

concrete. In this case, the library SMS returns the

text message received and is the programmer of PLC

who is responsible to deal with it. These messages

have the following format:

“PERS” “STOP MOTOR 1”

In addition, the programmer of PLC can send

SMS of notification of alarms or as a response or

acknowledgement to an SMS received, being the

format of these messages to choice of the controller.

2.3.2 STANDARD Messages

These messages are called standard because they are

not specific of an installation. They are treated

directly by the library SMS and in the event that it

will have configured, send an acknowledgement of

receipt.

This kind of message has the following format in

the case of messages of modification of variables:

“ESTA”“SYMBOL”“ADDRESS”“OPERATION”

or in case of messages of consultation

“ESTA” “SYMBOL” “ADDRESS” “?”

Once received a message of consultation, the

response is sent automatically, and in the case of

modifications of variables is sent an

acknowledgement if it has been configured.

In this kind of messages, “SYMBOL”

corresponds with the type of variable (V, VB, VW,

VD and VR). The “ADDRESS” corresponds with

the memory address (1000.1). The “OPERATION”

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

82

field corresponds with the value to write in the

direction of memory and in the case of "?" means

that it is a consultation of the value of the data

located in this address.

Table 1: Operations performed by SMS.

DATA OPERATION DESCRIPTION

1 Force a bit to be ON

0 Force a bit to be OFF

V

?

Ask about a bit status

VALUE Change a byte

VB

?

Ask about a byte value

VALUE Change a word

VW

? Ask about a word value

VALUE Change a integer

VD

? Ask about a integer value

VALUE Change a real

VR

? Ask about a real value

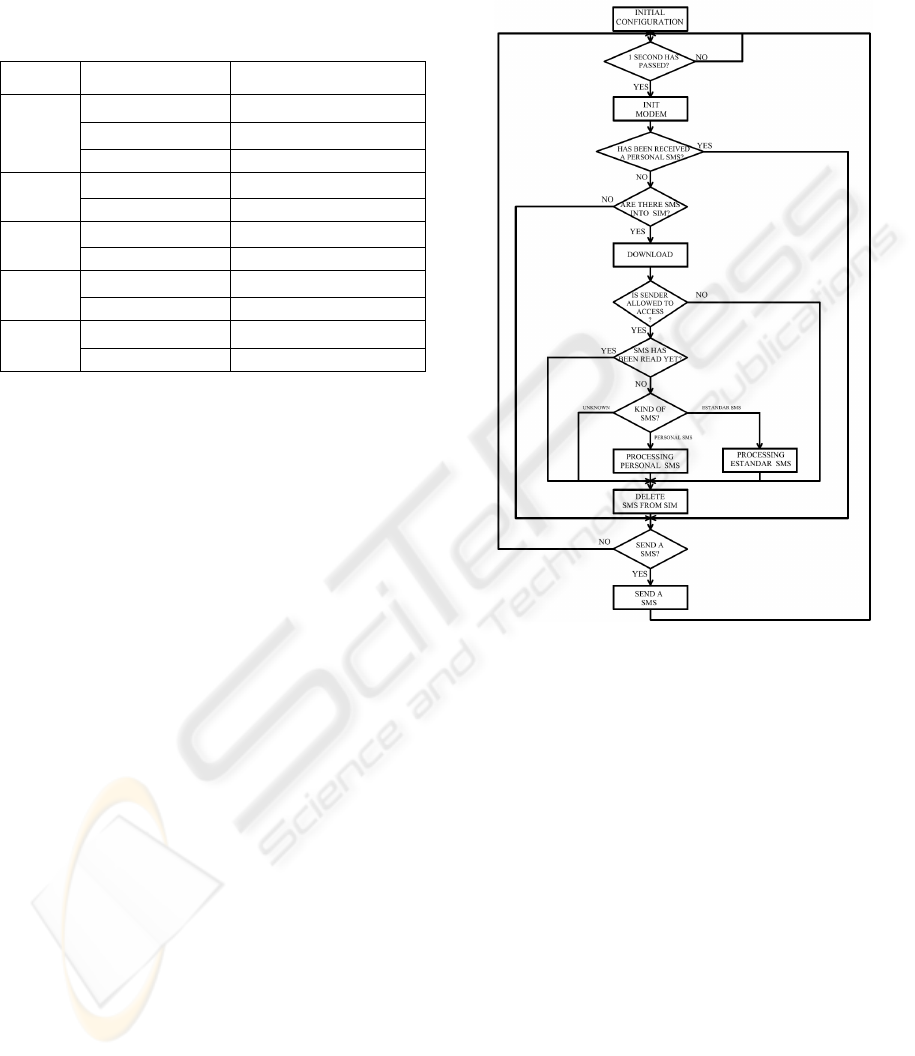

2.4 Program Flow

As is shown in the flow diagram (figure 2), firstly a

start stage is done in which, among other things, it’s

checked whether the PIN code is entered (if it’s not,

it will be entered) and the existence of coverage is

verified.

The following step is to check if there are

messages in the SIM card. In the case that there are

any, the message is downloaded from the SIM card

to a reserved area in the PLC. In the case that there

are not, it would go to the stage for sending SMS

from which it would send a message in the case that

the user program required so. In the next step it’s

checked whether the SMS sender’s telephone has

permission to access to the control and modification

of variables. This eliminates directly SPAM and

telephones without access permission.

In the next step it’s verified that the text message

has not been read in previous cycles. In the case that

the telephone does not have permission to access or

the SMS has been read, the message is deleted. In

the case that the SMS has not been deleted in the

previous stage, it is checked whether the type of

message is: “ESTANDAR”, “SPECIFIC” or none of

the two types. In the last case it is removed.

When it is received a “ESTA” SMS, it is dealed

by the library SMS whether it is a monitoring

message or if it is a control message.

If it’s a message "PERS" type it is returned by

the subroutine SMS to the main programme and it is

the programmer the responsible for its dealing.

Then, once dealed, the SMS is removed from the

GSM modem’s SIM memory. In the next step

SMS’s are sent both of the acknowledgement,

responses to consultations or notification of alarms.

Figure 2: SMS program flow.

3 SUPERVISION & CONTROL

OF PROCESS THROUGH

ANALOGICAL MODEMS

In recent decades, the improvement of

communication systems has caused a change in the

form that the society sees the world. These

improvements have narrowed the gap between the

different points of the planet so any event can be

known anywhere almost instantaneously.

Communications via telephone line and its

application to computer systems through the

modems have largely contributed to this.

The great coverage of the conventional telephone

network enables an almost immediate connection

between two computers if modems are used, and if

it’s extended to the industrial area it will provide us

a cheap and effective method of controlling a

process without the need for large disbursements.

TELECONTROL PLATFORM - Telecontrol Platform for Industrial Installations

83

3.1 Items of the System

3.1.1 PLC

Like for communication via GSM the PLC that we’ll

use will be a S7-200, although once set the

foundations of the system, it can be carried out in

other brands’s PLC by introducing small changes.

3.1.2 Analogical MODEM

The Modem chosen is a module for expansion of S7-

200. It does not need any library and its

configuration is very simple, thanks to the assistant

of the PLC’s programming tool. It works in slave

mode, and it uses MODBUS protocol to

communicate with the PC, which will play a master

role in our supervision system (Jiménez, 2007).

3.1.3 Personal Computer

The master of the system is a PC. This has a Modem

to communicate with the Modem EM241 via the

telephone line. To treat the data being received, a

software application in Visual Basic has been

scheduled, which transforms the MODBUS strings

characters in data that can be displayed in a SCADA

also scheduled in Visual Basic (Janeiro, 2006).

3.2 System Characteristics

3.2.1 Description of Modbus RTU Protocol

Once the connection between the modem local

modem and remote modem connected to the PLC is

established, we must choose a protocol that helps us

to exchange data between the PC (MASTER) and

the PLC that controls our process (SLAVE).

In our case the protocol which we’ll use will be

MODBUS RTU, very used in the industry for

communications via modem.

The controllers communicate by means of a

master-slave technique, in which only one device

(master) may start transactions. The other devices

(slaves) respond by supplying the master the data

requested, or carrying out the action requested in the

petition. Among the master devices typical central

processors and programming panels are included.

Typical slaves are the PLC’s.

3.2.2 The Query-Response Cycle

Query: The function code in the petition indicates

the slave device directing the type of action to

perform. The bytes of data contain any additional

information that the slave will need to carry out the

function. The data field must contain the information

to indicate the slave in what registration it should

begin and how many has to read. The error

verification field provides a method for the slave to

validate the integrity of the contents of the received

message.

Response: If the slave develops a normal response,

the function code content in the response is a replica

of the function code sent in the petition. The bytes of

data contain data collected by the slave, such as

values of registers or states. If an error occurs, the

function code content in the answer is different from

the function code sent in the petition, to indicate that

the answer is a response of error and the bytes of

data contain a code that describes the error. The

verification of error field allows the master to

confirm that the contents of the message are valid.

3.2.3 Queries Implemented by the

Application

Modbus is a protocol developed by Modicon for its

range of PLCs. Siemens, particularly S7-200, has

implemented libraries, which introduced in the

program code, allow to use it. In our case, the

EM241 module has them included, for what it’s not

necessary to modify anything in the PLC’s

programme.

Table 2: Modbus operations implemented by SIEMENS.

FUNCTION DESCRIPTION

1

Read coil status

2

Read input status

3

Read holding registers

4

Read input registers

5

Force single coil

6

Preset single register

15

Force multiple coils

16

Preset multiple registers

Despite that Modbus incorporates a wide variety

of functions, SIEMENS only has 8 implemented

which are those indicated in the table 2.

These operations act on bits in the case of inputs

and outputs, or in words if it is variables in PLC

memory. In the case of desiring to use different

variable sizes, as double words, bits of PLC

memory, etc, it must be done from these functions.

The application which has been developed, has

taken into account this problem and has been

programmed to allow the following requests:

Read and write digital outputs.

Read analogical inputs.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

84

Read and write integers.

Read and write double integers.

Read and write real numbers.

Read and write bits from V memory.

The PLC responds by strings MODBUS RTU in

hexadecimal that must be decoded.

3.2.4 AT Commands used

As in the case of communication using a GSM link,

it has been needed AT commandsm: AT, ATE0,

ATS30=time (s), ATDnumber, ATH.

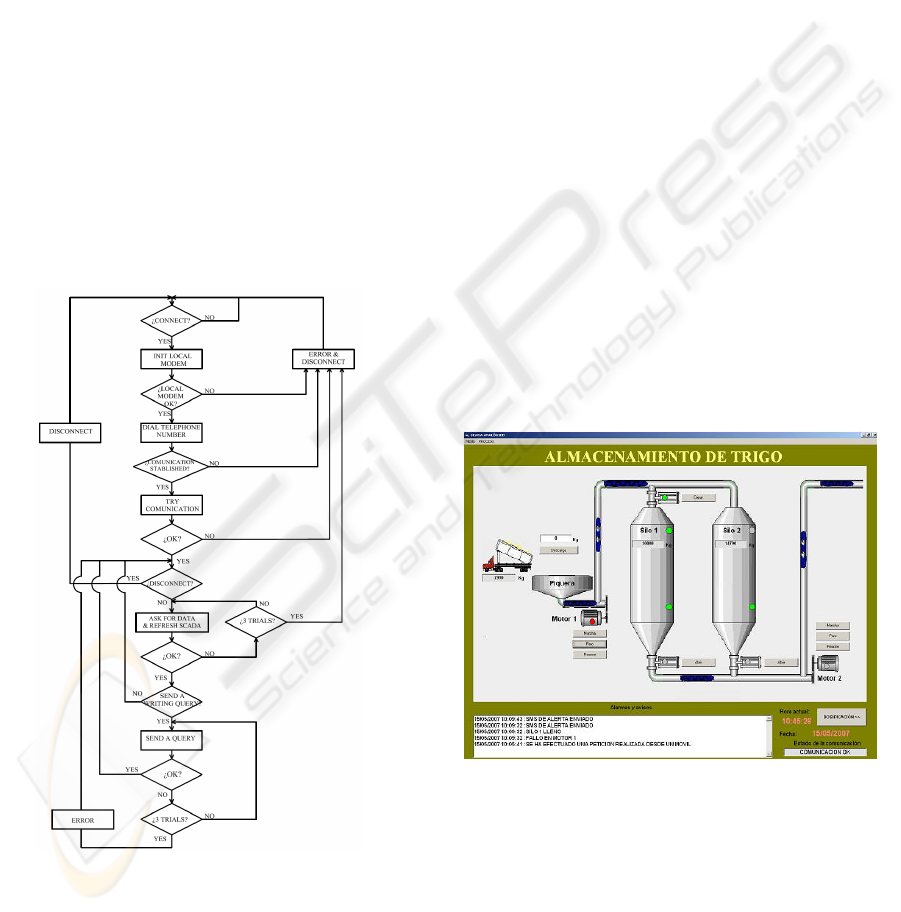

3.2.5 Application Flow

Before establishing any communication it must be

verified that the configuration of PC-Modem is

correct. If this is so it can proceed to dial the

telephone number of the modem connected to the

PLC. In the case of being the line occupied or not to

establish the connection it will generate a message

informing about what is happening.

Figure 3: Program flow.

After connecting with the PLC test strings will

be sent to see check that the communication is good.

If everything is OK application will send petitions to

the PLC with the frequency of refresh assigned by

the user. The times of refresh can vary, from 2

seconds. Application must send petitions to the PLC,

receive the responses from it, decode them and

display in a screen through the SCADA. In addition

to this, it will have to detect the communication

errors that may occur.

On the other hand, it also takes into account the

possible delays that may result from a wrong

function of the modem, temporary disconnections of

the line, etc. If these failure times are excessive, as

in the previous case, the Modem gets disconnect and

the cause is notified. In the case of wanting to

change a variable of the PLC, the SCADA

refreshing cycle is interrupted and the petition sent.

If the operation is carried out successfully it returns

to the routine of variable reading.

4 PRACTICAL APPLICATION

Now we will explain a practical case of the

combined use of the library SMS and

communication via RTC modem.

The case that we explain is a wheat storage and

dosage plan. The process is divided into two parts:

the part storage of wheat (Figure 4) consists of the

bunghole and the first of two silos, while the part

dosage of wheat (Figure 5) includes the last five

silos and a weight scale.

Figure 4: Storage of wheat.

The download of wheat from the truck is carried

out in the bunghole. To transfer the burden of wheat

from the entry deposit to one of the two storage silos

(Silo 1 or 2) the engine on the left must be on to

activate the endless screw and the buckets elevators

(horizontal and vertical displacement of wheat).

The wheat shall be deposited in Silo 1 or Silo 2,

depending on whether the upper chopping block in

Silo 1, is open or not. The wheat flow considered

TELECONTROL PLATFORM - Telecontrol Platform for Industrial Installations

85

when this transfer performed is 10 kg/s.

The process of dosage consists on four silos

(Silo 3, 4, 5 or 6) where different types of wheat are

stored and on silo 7, where the mixture composed by

wheats form Silos 3, 4, 5 or 6 is obtained. The

maximum capacity of all these silos is 10.000 Kg.

The flow of endless screws and the buckets elevators

is as maximum 50 kg/s. The wheat supply in Silos 3,

4, 5 or 6 comes from storage Silos 1 and 2 of. The

operator will be responsible for selecting the

destination of wheat from Silos 1 and 2 by

opening/closing the different upper chopping blocks

of Silos 3, 4, 5 or 6.

Figure 5: Dosage of wheat.

Apart from "ESTANDAR" SMS configured for

this installation, the following "SPECIFIC"

messages have been programmed:

Control: It can activate the dosage and stop it.

Consultations: It can make consultations such as

the weight of different silos, of the bunghole or of

the dosage. It can ask about the state of the engines,

as well as the state of the chopping blocks.

Maintenance: The alarm notifications have been

programmed: unloading a truck in the bunghole,

failure of any of the engines, filling of silos, and

failure in the dosage and notices that the dosage has

been completed.

To display the status of the process and the

changes that we are doing via SMS we use the

SCADA scheduled in Visual Basic, which uses the

RTC line to establish the communication with the

PLC.

5 CONCLUSIONS

The aim of this project was to make a system for

supervising processes that allowed remote control of

any installation in a simple and safe way but without

incurring big costs.

This platform has been focused to be used in

mid-range automatons such as the S7-200, because

this PLC is the most indicated to control the

processes that can be supervised by this system.

It has been tried to deal with the issue from two

fronts, through a wireless communication by GSM

Modems and on the other hand, a communication

through telephone line. The choice of one or another

depends on different factors such as: the location

and accessibility of the plant, means of

communication, level of automation, process

complexity, etc.

In general, it can be said that for all activities that

require an important exchange of data or/and a

constant supervision, it would be advisable the

implementation of an analogical modem

communication system.

In the future is planned to develop this platform

with other PLC brands like Telemecanique and

Omron.

ACKNOWLEDGEMENTS

This work was supported in part by “Programa de

Fomento de la Investigación Técnica para los

Centros Tecnológicos”, (PROFIT grant FIT 330220-

2005-138) from the Spanish Education and Culture

Ministry.

REFERENCES

AT Commands Interface Guide, <http://

www.rfsolutions.co.uk>, (in June 6, 2007).

Fastrack Modem M1306B User Guide, <http://

www.omniinstruments.co.uk>, (in June 6, 2007)

GeneraLynx. Remote supervision and control by WAP,

<http://www.euroines.com/down/DemoDoc/WapScad

a%20DD.pdf>, (in January 10, 2007)

International Engineering Consortium. Global System for

Mobile Communication, <http:www.iec.org/online/tu

torials/gsm/>, (in January 10, 2007)

Janeiro, J. R., 2006. Supervisión remota de procesos

industriales controlados por Autómatas Programables,

University of Valladolid. Spain, 1

nd

edition.

Jiménez, M., Comunicaciones Industriales, Protocolo

Modbus, <http:www.dte.upct.es>, (in June 6, 2007).

Moya, E., 2007. Control y mantenimiento de instalaciones

remotas. Wireless. Automática e Instrumentación, 384,

pp. 44-47.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

86