AN APPROACH TO OBTAIN A PLC PROGRAM FROM A DEVS

MODEL

Hyeong T. Park, Kil Y. Seong, Suraj Dangol, Gi N. Wang and Sang C. Park

Department of Industrial Information & Systems Engineering, Ajou University, Korea

Keywords: Programmable Logic Controller(PLC), DEVS, Factory Automation, Simulation.

Abstract: Proposed in the paper is an approach to generate the PLC code from the Discrete Event System

Specification (DEVS) model. DEVS have been widely accepted to model the real system for the discrete

event system simulation. The objective of this paper is to generate PLC control code from the DEVS model.

To achieve it, this paper proposes two steps. First step is to convert the real system into the virtual model

using the ‘three-phase-modeling procedure’. In the second step, the obtained model is formalized with

DEVS formalism. The final model consists of different components, among them the State manager and the

Flow controller model plays vital role to generate PLC code. In this paper, proposed steps are described

with a work cell example.

1 INTRODUCTION

To survive and prosper in the modern manufacturing

era, a manufacturing company should be capable of

adapting reduced life cycle of products in a

continuously changing market place. Simulation is a

useful tool for manufacturers to adapt this kind of

rapidly changing market to design and analyze

complex systems that are difficult to model

analytically or mathematically (Choi, 2000).

Manufacturers who are using simulation can reduce

time to reach stable state of automated

manufacturing process by utilizing statistics, finding

bottlenecks, pointing out scheduling error etc... For

the simulation of manufacturing systems,

manufacturers have been using various simulation

languages, simulation software for example

ARENA, AutoMod. Most of traditional simulation

languages and softwares focus on the representation

of independent entity flows between processes; their

method is commonly referenced to as a transaction-

oriented approach. In this paper, we propose an

object-oriented approach that is based on the set of

object classes capable of modeling a behavior of

existing system components.

The object-oriented modeling (OOM) is a

modeling paradigm, that uses real world objects for

modeling and builds language independent design

organized around those objects (Rumbaugh, 1991).

Even though OOM has been widely known to be an

effective method for modeling complicated software

systems, very few researchers tried to apply the

OOM to design and simulate manufacturing system

software models. Based on the OOM paradigm,

different researchers have proposed various

modeling approaches despite the fact that they

express them in different ways with different

notations. For example, Choi et al. presented the JR-

net framework for modeling which is based on the

OOM paradigm of Rumbaugh et al., which is made

of three sub-models(an object model, functional

model, and dynamic model). Chen and Lu proposed

an object-oriented modeling methodology to model

production systems in terms of the Petri-nets, the

entity relationship diagram (ERD) and the IDEF0

(Chen, 1994). Virtual factory (VF) is also very

important concept to be considered in today’s

simulation environment. By using the OOM

paradigm, VF concept can be implemented

efficiently (Onosato, 1993).

Recently, Park (Park, 2005) proposed a ‘three-

phase-modeling framework’ for creating a virtual

model for an automated manufacturing system. This

paper employs the three-phase-modeling framework

of creating a virtual model, and the Discrete Event

System Specification(DEVS) (Zeigler, 1984) for

process modeling. The proposed virtual model

consists of four types of objects. The virtual device

model represents the static layout of devices. This

can be decomposed into the shell and core, which

87

T. Park H., Y. Seong K., Dangol S., N. Wang G. and C. Park S. (2008).

AN APPROACH TO OBTAIN A PLC PROGRAM FROM A DEVS MODEL.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 87-93

DOI: 10.5220/0001492400870093

Copyright

c

SciTePress

encourages the reusability making possible to adapt

different system configurations. For the fidelity of

the virtual model, The Transfer handler model

handles a set of device-level command that mimics

the physical mechanism of a transfer. The Flow

controller model decides the firable transfers based

on decision variables that are determined by the

State manager model. The State manager model and

Flow controller model can be converted to PLC part.

After finishing the process modeling by employing

the three-phase-modeling framework, those two

models will be the control information for the

converting to PLC.

The overall structure of the paper is as follows.

Section 2 represents the brief explanation about the

PLC, and Section 3 is about the DEVS. The overall

approach to create manufacturing system model for

generation PLC code is described in Section 4.

Section 5 gives as example cell, which is observed

to find correlation between the PLC code and the

DEVS model in Section 6. Finally, Conclusion and

discussion is addressed in Section 7.

2 PROGRAMMABLE LOGIC

CONTROLLER (PLC)

The Programmable Logic Controller (PLC) is an

industrial computer used to control automated

processes in manufacturing (Parr, 1999). PLC is

designed for multiple inputs and outputs

arrangements, it detects process state data through

the sensing devices such as limit sensors, proximity

sensors or signals from the robots executes logics in

its memory and triggers the next command through

the actuator such as motor, solenoid valve or

command signal for the robots etc. PLC executes the

control logic programmed in different types of

languages. IEC published IEC 61131-3 to

standardize PLC languages including Ladder

diagram, Sequential Function Chart, Structured Text

and Function Block Diagram (Maslar, 1996).

Figure 1: The PLC code in the form of Ladder diagram.

3 DISCRETE EVENT SYSTEM

SPECIFICATION (DEVS)

DEVS formalism is introduced by Zeigler, which is

a theoretic formalism and it supplies a means of

modeling discrete event system in a modular,

hierarchical way. With this DEVS formalism, we

can perform modeling more easily and correctly by

dividing large system into segment models and

define the coupling between them. Formally, an

atomic model M is specified by a 7-tuple:

M = < X, S, Y,

δ

int,

δ

ext,

λ

,

t

a

>

X : input events set;

S : sequential states set;

Y : output events set;

δ

int

: SÆS : internal transition function;

δ

ext

: Q x X Æ S : external transition function

Q = { (s, e)|s ∈ S, 0 ≤

e

≤

t

a

(

s

)}

: total

state of M;

λ

: S->Y : output function;

t

a

: S

Æ

Real : time advance function:

The second form of the model, called a coupled

model, indicates how to couple several element

models together to form a new and bigger model.

Formally, a coupled model DN is defined as:

DN = < X, Y, M, EIC, EOC, IC, SELECT >

X : input events set;

Y : output events set;

M: set of all component models in DEVS;

EIC ∈ DN.IN x M.IN : external input coupling

relation;

EOC ∈ M.OUT x DN.OUT : external output

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

88

coupling relation;

IC ∈ M.OUT x M.IN : internal coupling relation;

SELECT : 2

M

- ø-> M : tie-breaking selector,

Where the extension .IN and .OUT represent the

input ports set and the output ports set of each

DEVS models.

4 APPROACH TO CREATE

MANUFACTURING SYSTEM

MODEL TO GENERATE PLC

CODE

To construct the automated process, the factory

designers have to consider the overall process

layout. After deciding skeletal layout, the process

cycle time is simulated by the discrete event system

software like ARENA or AutoMod. In this stage,

including the process cycle time and production

capability, the physical validity and efficiency of co-

working machines are also described. Simulation

and modeling software QUEST or IGRIP are used

for this purpose (Breuss, 2005).

Figure 2: Automated Factory construction procedure.

On the next step, the PLC code programming for

logical functioning is done without utilizing

information from previous discrete event systems

modeling. The gap between the high level

simulation of discrete event system and the low level

physical process control logic need to be bridged for

the utilization of process modeling and practical

simulation in terms of physical automated device

movement. This paper tries to find the bridge

between these two different simulation levels and

further describes automatic generation of PLC code

from the DEVS model.

In developing the DEVS model, the first thing

we have to do is to model the manufacturing system

by the three-phase-modeling framework (Park,

2005). The framework describes manufacturing

system modeling with 4 components; the Virtual

device model, the Transfer handler model, the State

manager model and the Flow controller model as

shown in Figure 3.

Figure 3: Outline of the virtual manufacturing model.

The Virtual device model shows the manufacturing

devices. It has input port to receive the action signal

and output port to send the work done signal. The

Transfer handler model handles the parts stream and

assisting resources (tools and pallets) between

devices. This approach focused on the physical

mechanism enabling the transfer than conventional

approaches. In reality, a transfer happens by the

combination of device-level command between co-

working devices (giving and taking devices). The

State manager model collects the state data of every

device. Whenever there is a state change of devices,

it will update the device states. Then, this

information will be delivered to the Flow controller

model as a decision variable. After getting the state

information from the State manager model, the Flow

controller model will decide firable transfer based on

the system state (decision variables).

AN APPROACH TO OBTAIN A PLC PROGRAM FROM A DEVS MODEL

89

For the implementation of the virtual

manufacturing system model, this paper employs the

Discrete Event Systems Specification (DEVS)

formalism, which supports the specification of

discrete event models in a hierarchical modular

manner. The formalism is highly compatible with

OOM for simulation. Under the DEVS formalism,

we need to specify two types of sub-models: (1) the

atomic model, the basic models, from which larger

ones are built and (2) the coupled model, how

atomic models are related in a hierarchical manner.

When the DEVS model is developed, both the

State manager atomic model for the process

monitoring and the Flow controller atomic model for

the actual control can be replaced the PLC part.

Namely, control part for the manufacturing cell.

Here is the goal of this paper.

5 DEVS MODELING OF A

SIMPLE CELL BASED ON THE

THREE-PHASE-MODELING

FRAMEWORK

In this Chapter, we will observe a small work cell

example. The work cell is modeled according to the

three-phase-modeling framework and converted to

the DEVS model like mentioned above. Finally, we

will compare the DEVS model and the PLC code to

find some meaningful bridge.

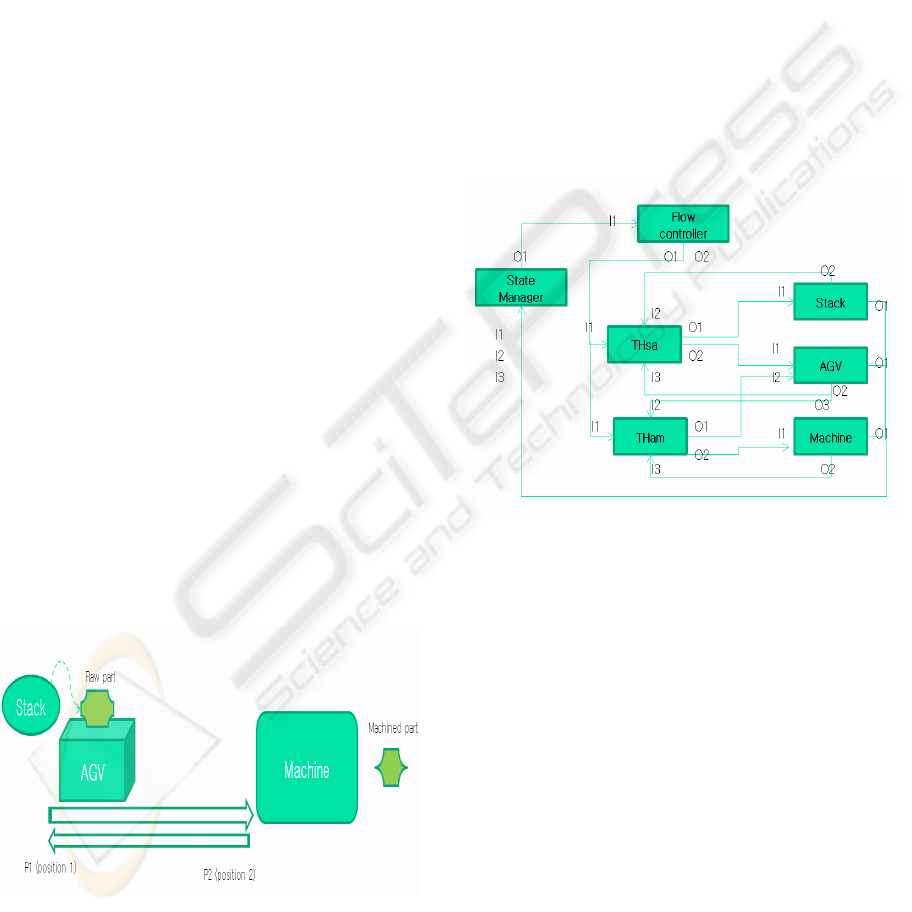

Figure 4 shows the small cell example. At first,

an entity is generated from the Stack, which will lay

on the AGV machine in P1, then AGV senses this

raw part and moves to the P2 for machining. When

machine detects the part arrival by the AGV, the

machine starts to operate.

Figure 4: Example cell.

When we consider this example cell in terms of

the three-phase-modeling framework, there are three

virtual device models; the stack model, the AGV

model and the machine model. The stack model

generates the raw part entity and places it on the

AGV for transfer. Until this point, the entity transfer

process is between the stack and the AGV virtual

device model as a result the transfer handler model

is created between the stack the AGV model.

Similarly, entity transferring between the AGV

model and the Machine happens. This transfer

handling model can be represented as THam. If there

is any state change among the virtual devices, the

changes are supposed to be reported to the State

manager model. The State manager model maintains

the decision variables in compliance with the

reported state changes of the virtual devices and the

Flow controller model will make a decision on

firable transfer based on the decision variables.

Figure 5 represents the constructed model about the

example cell.

Figure 5: Modeling of the example cell in the Park’s

methodology.

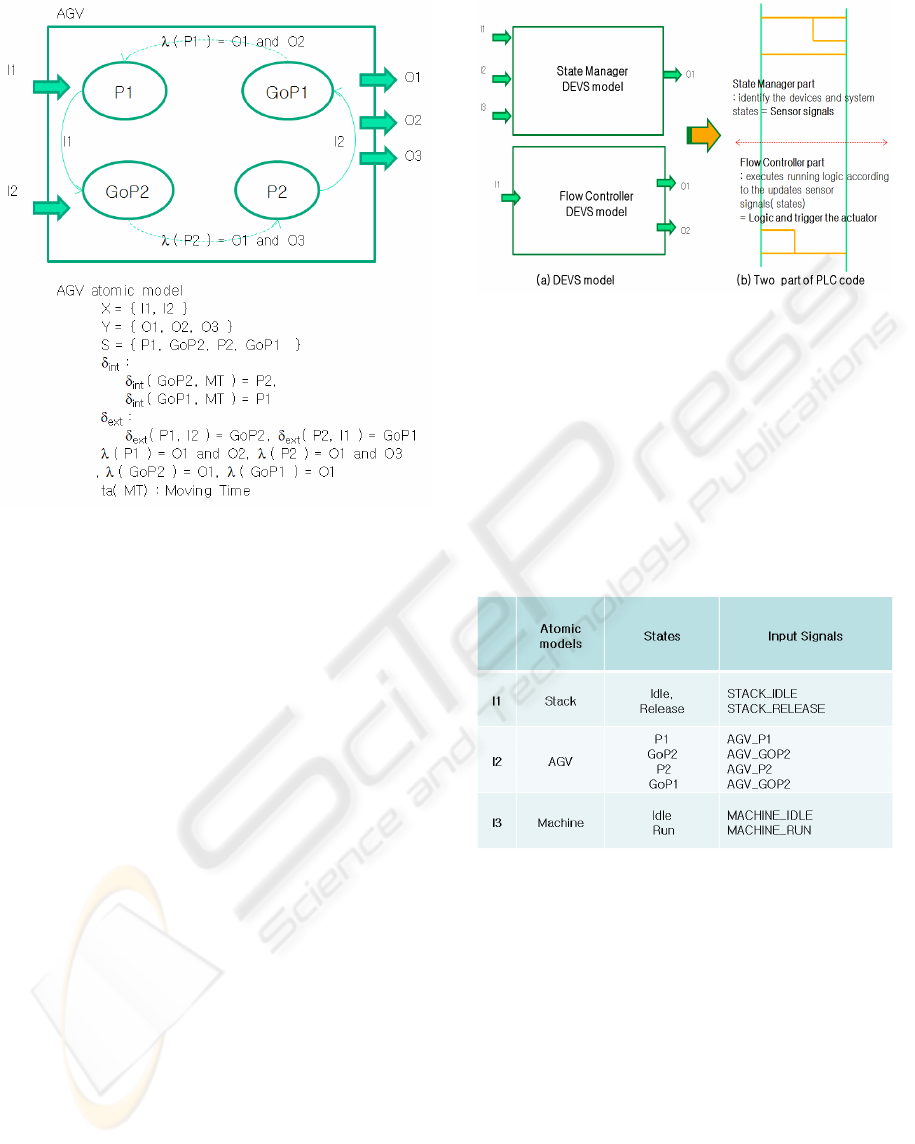

Once the modeling by means of the three-phase-

modeling framework is finished, second step is to

convert the model to the DEVS formalism. In this

example, every model is converted to the atomic

model and entire cell will be the coupled model that

is consist of all atomic models. Figure 6 is the

converted DEVS model example of AGV. In the

traditional implementation of discrete event system

simulation using DEVS, DEVSIM++ is a simulation

framework which realizes the DEVS formalism for

modeling and related abstract simulator concepts for

simulation, all in C++ (Kim, 1994). Through this

open source frame, we can develop the discrete

event system simulation engine easily. Once, both

the DEVS implementation and the simulation with

PLC control logic is done, we can achieve the

overall physical control simulator for automated

process.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

90

Figure 6: DEVS model of the AGV.

6 CORRELATION BETWEEN

THE PLC CODE AND THE

DEVS MODELS

For the auto generation of PLC code from the DEVS

model, we need to examine the PLC code of

example cell and the DEVS models, especially the

State manager and the Flow controller model.

In the manufacturing unit, PLC collects the

process state information through the sensors. These

sensor signals are referenced to decide next

command or operation. This task is done by the state

manager model in the modeled frame. The State

manager model detects every change in state of the

virtual device and then updates the decision

variables. Similar to PLC code, the Flow controller

model is supposed to have running logic that is kind

of combination of decision variables. As a result,

PLC code from the DEVS model can be divided into

two parts. One part is for updating the decision

variable from the signal of input port in the State

manager model. Another is for actual logic

composed of decision variables to fulfill the

intended process control.

Figure 7: Two part of PLC code.

In the front part, the State manager model

collects every state changes through the input port.

The one input port of example cell has different kind

of signal depend on the state. For example, the input

port I2 is the signal from the AGV and it has 4

different kinds of state signals. With the same way,

each input port of the State manager model has

multiple input signals like shown in Table 1.

Table 1: The States of Atomic models.

The memory structure in the PLC code can be

classified into three groups. The first group is input

memory which consists of input signal names and

the second group is the output memory consisting

output signal names and the last is the internal

memory which is used to maintain the signal

information of input or output and for temporary

numerical calculation. The name of input signal can

be determined with combination between the input

port and its state name. In this way, we can give a

name to all input signals.

As mentioned before, the flow controller model

reads the decision variables to execute next

command. Thus, we have to make decision variables

representing the process state as the internal

memory. As we did in the input variable for naming,

we can give decision variables’ name by putting the

AN APPROACH TO OBTAIN A PLC PROGRAM FROM A DEVS MODEL

91

‘On’ between the port name and the state name.

Then, this decision variable shows the port’s current

state is active condition. Once decision variables are

set, the Flow controller detects the firable output

signals from the set variables. Figure 8 show the

decision variables of each input of AGV model and

moving condition. To the AGV, the possible

condition to move from P1 to P2 is when the raw

part is on the AGV, AGV’s state is ‘GoP2’, and the

machine state is ‘Idle’ at the same time.

Figure 8: The triggering condition for AGV move.

As we have noticed for the case of the AGV

model, the other devices’ executing condition can be

derived. While the PLC code for the State manager

model part can be generated automatically with a

combination of decision variables, the flow

controller part is sometimes rather ambiguous. That

is because unlike the flow controller, DEVS model

is quite abstract and high level, the PLC part is very

specific control area. Even though, process system

designer can construct the DEVS model including

low level of PLC, normally DEVS modeling is not

fulfilled in this way. This aspect will be limitation or

designer’s choice in reference to PLC code auto

generation. The DEVS modeling here is done

specifically in mind of the PLC code generation of

the Flow Controller model part. Figure 9 illustrates

the two part of PLC code about the AGV from the

State manager and the Flow controller model. And

the Flow controller DEVS model for PLC code auto

generation with the simple work cell is shown in

Fig. 10.

7 DISSCUSSION AND

CONCLUSIONS

This paper presents the PLC code auto generation

methodology from the DEVS model. The PLC level

control logic is rather closed and unopened

engineering area while discrete event system

modeling and simulation is widely used to

Figure 9(a): PLC code from the State Manager model of

AGV model.

Figure 9(b): PLC code from the Flow Controller model of

AGV model

measure the process capacity. By using the discrete

event system simulation technique, the process or

overall cycle time and throughput can be calculated.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

92

Figure 10: The Flow Controller DEVS model.

However, there is a big gap between the PLC code

and the discrete event system simulation. This gap

causes the repetition of process analysis work for the

PLC programmer and the time delay to implement

automated processing system in a manufacturing

unit.

The overall procedure for proposed approach has

three steps. Modeling the real system according to

the three-phase-modeling framework is first step.

And this model is converted to the DEVS formalism

in second step. Among the 4 kind of models, the

State manger and the Flow controller model is going

to be replaced to the PLC part.

The generated PLC code from our approach can

be categorized into two parts, one is from the state

manager and another is from the flow controller. The

first part is created from the input signals and the

decision variable. And the latter part is from the

control part which is from combination of decision

variables.

The latter part generation is not achieved

perfectly because the DEVS modeling level is more

abstracted than the PLC level. However, this

approach offers the overall framework for the PLC

code generation from DEVS model. In the following

future, the direction mentioned above will be the

inevitable stream for the more physical process

simulation, for the time saving toward the mass

production condition and for better competitiveness

to the company.

REFERENCES

B. K. Choi, B. H. Kim, 2000. Paper templates, In Current

Advances in Mechanical Design and Production

Seventh Cairo University International MDP

Conference. New Trend in CIM: virtual manufacturing

systems for next generation manufacturing.

J. Rumbaugh, M. Blaha, W. Premerlani. 1991. Paper

templates, In Prentice Hall Inc. Object-Oriented

Modeling and Design.

B. K. Choi, H. Kwan, T. Y. Park, 1996. Paper templates,

In The International journal of Flexible

Manufacturing Systems. Object-Oriendted graphical

modelling of FMSs.

K. Y. Chen, S. S. Lu, 1997. Paper templates, In

International journal of Computer Integrated

Manufacturing. A Petri-net and entity-relationship

diagram based object oriented design method for

manufacturing systems control.

M. Onosato, K. Iwata, 1993. Paper templates, In CIRP.

Development of a virtual manufacturing system by

integrating product models and factory models.

Sang C. Park, 2005. Paper templates, In Computers in

Industry. A methodology for creating a virtual model

for a flexible manufacturing system.

B. P. Zeigler, 1984. Paper templates, In Academic Press.

Multifacetted Modeling and Discrete Event Simulation.

E. A. Parr, 1999. The book, Programmable Controllers :

An Engineer’s Guide 3

rd

ed.

M. Maslar, 1996. Paper templates, In IEEE Pulp and

Paper Industry Technical Conference. PLC standard

programming language: IEC61131-3

F. Breuss, W. Roeger, 2005. Paper templates, In Journal of

Policy Modeling. The SGP fiscal rule in the case of

sluggish growth: Simulations with the QUEST

T. G. Kim, 1994. The Book. DEVS++ User’s Manual

AN APPROACH TO OBTAIN A PLC PROGRAM FROM A DEVS MODEL

93