USING STEREO VISION AND TACTILE SENSOR FEATURES

For Grasp Planning Control

Madjid Boudaba

1

, Nicolas Gorges

2

, Heinz Woern

2

and Alicia Casals

3

1

TES Electonic Solution GmbH, Zettachring 8, 70567 Stuttgart, Germany

2

Institute of Process Control and Robotics, University of Karlsruhe

Engle-Bunte-Ring 8-Gebaeude 40.28, 76131 Karlsruhe, Germany

3

GRINS: Research Group on Intelligent Robots and Systems

Technical University of Catalonia, Pau Gargallo 5, 08028 Barcelona, Spain

Keywords:

Stereo vision, Tactile sensors, Grasp planning, Features matching.

Abstract:

Planning the grasp positions either from vision or tactile sensors one can expect various uncertainties. This

paper describes a scheme that match visual stereo and tactile data based on stereo vision and tactile sensors.

For grasp planning, initially, the grasping positions are generated from stereo features, then the feedback of

tactile features is used to match these positions. The result of the matching algorithm is used to control the

grasping positions. The grasping process proposed is experimented with an anthropomorphic robotic system.

1 INTRODUCTION

In recent years, considerable research in robotic

grasping systems has been published. The pro-

posed system works by using the principle of

sensing-planning-action. To place our approach in

perspective, we review existing methods for sensor

based planning for grasping. The existing literature

can be broadly classified into three categories; vision

based, tactile based and both vision-tactile based. For

all categories, the extracted image features are key

factors, they can range from geometric primitives

such as edges, lines, vertices and circles to optical

flow estimates. The first category uses visual image

features to estimate the grasping points and from

them define the robot’s motion with respect to the

object position and orientation before performing a

grasp (Yoshimi and Allen, 1994), (Maekawa et al.,

1995), (Smith and Papanikolopoulos, 1996), (Sanz

et al., 1998), (Kragic et al., 2001), and (Morales

et al., 2002). The second category uses tactile image

features to estimate the characteristics of the area in

contact with the object (Berger and Khosla, 1991),

(Chen et al., 1995), (Perrin et al., 2000), and (Lee

and Nicholls, 2000). The last category uses data

fusion from both vision and tactile sensors in order

to control grasping tasks efficiently (Namiki and

Ishikawa, 1999), and (Allen et al., 1999).

This paper is an extension of our previous work

(Boudaba and Casals, 2006) and (Boudaba and

Casals, 2007) on grasp planning using visual features.

In this work, we demonstrate the utility of matching

both visual and tactile image features in the context

of grasping, or fingers position controlling. In our

approach, we avoid using any object model, and in-

stead, we work directly from image features to plan

the grasping points. In order to avoid finger position-

ing errors, matching, by back projecting these tactile

features into visual features is required to compute the

similarity transformation that relates the grasping re-

gion with the sensitive touching area. To achieve a

high level of grasping position matching efficiency,

two matching schemes are considered in this paper.

The first establishes grasp points correspondences be-

tween the left and right images of the stereo head. In

this scheme, only the grasp positions are back pro-

jected into one side of the stereo image. A second

scheme is a region matching where the whole sensi-

tive touching area with the object is used in the back

projection into the visual image. All the points be-

longing to the sensitive area of a tactile sensor are

back-projected into the grasp region of visual fea-

tures. The processing in each match is completely

independent and can be performed at its own rate.

Our approach based on features matching can play the

214

Boudaba M., Gorges N., Woern H. and Casals A. (2008).

USING STEREO VISION AND TACTILE SENSOR FEATURES - For Grasp Planning Control.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 214-221

DOI: 10.5220/0001492902140221

Copyright

c

SciTePress

critical role of forcing the fingertips to move towards

the desired positions before the grasping is executed.

2 GRASPING SYSTEM

DESCRIPTION

In robotic grasping tasks, when data from several

sensors are available simultaneously, it is generally

necessary to precisely analyze all of them along the

entire grasping process (see Figure 1). The object

being extracted from a video sequence requires

encoding its contour individually in a layered manner

and provide at the receiver’s side some enhanced

visual information. In the same way, from the data

being extracted from a tactile sensor, the tactile layer

processes and provides the tactile information at

its receiver’s side. The architecture of the whole

grasping system is organized into several modules,

which are embedded in a distributed MCA2 (Mod-

ular Controller Architecture Version 2) software

framework (Scholl et al., 2001). There are mainly

three modules involved in this development; the

stereo vision, tactile sensors, and grasp planning.

In MCA2, every module is structured in a data

vector that allows the module to receive and send

the data from/to other modules, or to take any part

of an output data and permute and copy it to other

modules. In order to control its current functionality,

every module has fully or partially access to the input

data of the other modules depending on the tasks

involved. For instance, the grasp planning module

has full access to the input data of the sensory system

and has partially access to the robot hand. Because

the architecture of the system has a global planning

to access to all the data available to the system, the

grasp planning module can locally plan the grasping

positions without having a global view of the robot’s

environment. For instance, the robot hand needs

some information supplied by the global planning

module such as grasp configurations for the object to

be grasped.

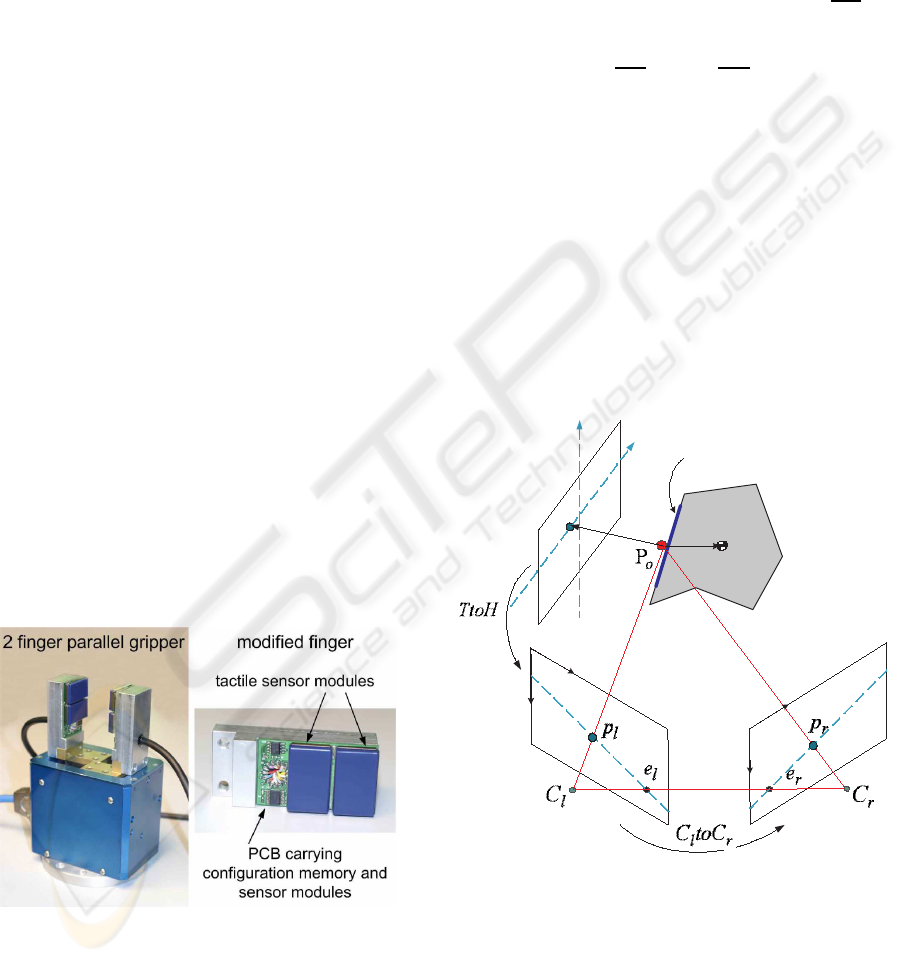

2.1 Visual Layer: Feature Extraction

We consider visual features extraction in the context

of a stereo head (see Figure 2). First, however,

we recall the epipolar geometry technique which is

motivated by considering the search of corresponding

points in the stereo image pair. Since we are dealing

with a stereo head, we need to extract features well

suited for determining the grasp points on the first

image either from the left or right side of a stereo

Figure 1: Grasping system description.

pair and then computing their correspondences in

the second image. Given the estimated object pose,

placed on the table, the full observability of the

object is then projected into the left and right image

planes. The visual layer takes these images and

calibration data as input (see Figure 1) and provides

as output a set of visual features. Segmentation is

used to separate the object from the background

and other objects in the environment by determining

the coordinates of a closed rectangular bounding

box. After segmenting the region corresponding to

the object, features belonging to the object contour

are extracted. A function is then constructed for

parameters regrouping object features together.

Stereo

camera

system

Pan-tilt

unit

Figure 2: Stereo camera system and a Pan-tilt unit.

We denote by V a function regrouping visual pa-

rameters that is defined by

V = {glist, g

param

, com} (1)

where glist, g

param

and com are the visual features.

During image processing, V is maintained as a dou-

bly linked list of grasping region and intervening their

USING STEREO VISION AND TACTILE SENSOR FEATURES - For Grasp Planning Control

215

parameters as g

1

g

param

1

, ··· , g

m

g

param

m

. A grasping

region g

i

is defined by its ending points g

ui

and g

vi+1

,

and its orientation φ with respect to the object’s center

of mass com. The resulting parameters of V fully de-

scribe the two-dimensional location of features with

respect to the image plane The visual features ob-

tained can be used as input data for both, grasp plan-

ning and grasp position matching. For more details

about this topic, we refer the reader to our previous

work (Boudaba and Casals, 2007).

2.2 Tactile Layer: Feature Extraction

Unlike vision which provides global features of the

object, tactile sensor provides local features when

the fingertip is in contact with the object. The tactile

layer shown in Figure 1 takes as input the data ex-

tracted from a set of tactile sensor (or so called Group

Of Tactile sensor (GOT)) and the configuration of

the robot hand and provides as output a set of tactile

features. To simplify the problem, tactile features

are treated as visual features using the basic results

from different approaches. For the purpose of sensor

features matching, extracting edge features are of

interest and will be discussed in section 4. Figure

3 illustrates the PCB tactile sensor module with its

memory and data control units. The sensor module

(from Weiss Robotics, (K.Weiss and Woern, 2005))

consists of a sensitive area organized in matrix of 4x7

sensor cells with a spacial resolution of 3.8 mm. By

using four modules, (two in each gripper finger), the

parallel gripper shown in Figure 3 is equipped with a

total number of 112 sensor cells.

Figure 3: Gripper equipped with tactile sensor modules.

The data of the tactile sensor matrix corresponds

to a two-dimensional planar image. We analyze this

image using moments up to the 2

nd

order (Hu, 1962).

The two-dimensional (p+ q)

th

order moment m

p,q

of

an image is defined as the following double sum over

all image pixels (x, y) and their values f(x, y):

m

pq

=

∑

x

∑

y

f(x, y)x

p

y

p

p, q ≥ 0 . (2)

The moment m

0,0

constitutes the resulting force ex-

erted on the sensor. The center of gravity cog =

(x

c

, y

c

)

T

of this force can be computed as follows:

x

c

=

m

10

m

00

, y

c

=

m

01

m

00

. (3)

The center of gravity of each tactile sensor matrix

determines a contact point of the gripper.

3 GRASP POSITION MATCHING

The Grasping system can be explained in more

detail through a set of tasks. In order to complete

the grasp matching process, it is necessary to find

the relationship between their Cartesian coordinate

frames (see Figure 4).

v

t

T

a

c

t

i

l

e

P

l

a

n

e

I

m

a

g

e

P

l

a

n

e

r

i

g

h

t

t

d

u

t

l

u

l

v

r

u

r

v

o

d

Grasping region

OCS

Object

I

m

a

g

e

P

l

a

n

e

l

e

f

t

t

p

Figure 4: Sensor frames relationship for grasping.

We define these frames as follows:

• HCS. Head Coordinate System has a stand

alone configuration of stereo head. The fixation

of the head is assured by controlling the pan-tilt

angle. The offset to the object coordinate system

(OCS) is constant.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

216

• GCS. Gripper Coordinate System (also known

as the end effector frame) is determinated by con-

trolling the angular configuration of the robot arm.

The robot arm moves over itself and the measure-

ments given by all joints enable the system to de-

termine the Tool-Center-Point (TCP) relative to

the robot coordinate system.

• OCS. Object Coordinate System is fixed on the

table and does not change its position and orienta-

tion during calibration. Once the object pose rela-

tive to the stereo head (HCS) is determinated, the

GCS relative to the object pose is determinated by

using robot hand - stereo head calibration.

• TCS. Tactile Coordinate System. The location

of TCS is terminated by controlling the GCS con-

figuration.

• WCS. World Coordinate System. The location

of the object position and orientation OCS, HCS

and the robot base station are determinated rela-

tive to the WCS.

In the remaining of this work, the kinematics of

the robot arm and robot hand are ignored. So far,

for grasping using features matching, we have es-

tablished two mapping relationships between feature

frames. The first mapping implies finding the grasp

points correspondence between left and right image

of the stereo head (C

l

toC

r

). The second mapping

implies matching the two apparent features into the

tactile and stereo frames (TtoH).

3.1 Stereo Images Matching: C

l

toC

r

We adopt some notations similar, but not identical

to the work of (Hartley and Zisserman, 2000) on

multiple view geometry (see Figure 4). Considering

a point P

o

in contact with the object, its distance to

the center of mass, d

o

is measured and its projection

into the stereo head and tactile frames is given by

(p

l

, p

r

) and p

t

, respectively. The subscripts, o, c, l,

r, and t are referred to object, contact point, left and

right frames, and tactile frame, respectively.

Let p

r

= (u

r

, v

r

, 1)

T

and p

l

= (u

l

, v

l

, 1)

T

denote

the projection of P

o

on the right and left images, re-

spectively. The epipolar plane defined by the three

points P

o

, C

l

and C

r

intersects the two image planes

in two epipolar lines ep

r

and ep

l

. The line connect-

ing the two centers of projection [C

l

,C

r

] intersects the

image planes at the conjugate points e

r

and e

l

which

are called epipoles. Using the projective coordinates,

the epipolar constraints can be written:

p

T

l

Fp

r

= 0 (4)

where F is the so-called fundamental matrix

which consists of a 3x3 unknown entries and can be

expressed as follows:

F =

f

11

f

12

f

13

f

21

f

22

f

23

f

31

f

32

f

33

(5)

In the calibrated environment, the 9 unknown entries

of F can be captured in an algebraic representation as

defined by

F = C

−T

r

EC

−1

l

(6)

where the fundamental matrix F encapsulates both

the intrinsic and the extrinsic parameters of the stereo

head, while the essential matrix E = [T]

×

R which

compactly encodes the extrinsic parameters of the

stereo head can be composed of the baseline vector

t = [C

r

−Cl] = (t

x

, 0, t

z

)

T

and the angular rotation β

about the y-axis that renders the left image parallel to

the right one, then we have:

E =

0 −t

z

0

t

z

0 −t

x

0 t

x

0

cos(β) 0 −sin(β)

0 1 0

sin(β) 0 cos(β)

(7)

C

l

and C

r

are the intrinsic parameter matrices of

the left and right cameras defined by

C

l

=

f

u

l

0 C

ul

0 f

v

l

C

vl

0 0 1

, C

r

=

f

u

r

0 C

ur

0 f

v

r

C

vr

0 0 1

(8)

where u

0l

and v

0l

(resp. u

0r

and v

0r

) are the coor-

dinates of the principle point (in pixels) of the left

(resp. right) camera. ( f

x

, f

y

) are the focal length in x

and y direction.

For more details about camera calibration and re-

lated topics, we refer to the work of (Faugeras and

Toscani, 1986) and (Tsai and Lenz, 1989).

3.2 Tactile and Stereo Matching: TtoH

By dealing with the contact constraint, the minimum

distance between a fingertip (tactile) and the object

can be expressed by a parameter d

t

. So keeping a fin-

gertip in touch with the object, the condition d

t

= 0

must be maintained, and tactile features are extracted

and measured into the tactile frames. Matching these

tactile features with visual features implies the com-

putation of a similarity transformation relating the

USING STEREO VISION AND TACTILE SENSOR FEATURES - For Grasp Planning Control

217

grasping region to actual sensitive touching area. Tac-

tile and visual features are then related by the follow-

ing transformation

s

i

= TtoHv

i

(9)

where s

i

and v

i

are points on the tactile and visual

image features, respectively. TtoH is the similarity

transformation given by

TtoH =

scosα −sinα t

x

sinα scosα t

y

0 0 1

(10)

where s , α, and [t

x

, t

y

, 1] are scaling, rotation angle

and translation vector of the tactile image with

respect to the visual image, respectively.

In the calibration cases, the parameters of (10) can

be computed directly using homogeneoustransforma-

tion matrices between frames as shown in Figure 4.

4 IMPLEMENTATION

The implementation of our algorithm for grasping

position matching using stereo vision and tactile

sensor can be divided into two parts. First is related

to the grasp planning using stereo vision. The

second part of this implementation is related features

matching between stereo vision and tactile sensor.

4.1 Grasp Planning using a Stereo Head

As stated before, the first implementation con-

sists of computing the grasp points correspon-

dence in the stereo vision. More formally, let

G =

G

v

1

, G

v

2

, · ·· , G

v

k

be a set of valid grasps and

G

l

v

i

= (g

l

u

i

, g

l

v

i

, 1)

T

be its ith− determinated grasp

point on the left image, next step is to compute its cor-

respondence on the right image, G

r

v

i

= (g

r

u

i

, g

r

v

i

, 1)

T

.

To do this, we first need to establish a mapping

relationship between a line and point by exploiting

the epipolar constraint defined by (4).

Let

L

r

i

= FG

l

v

i

, L

l

i

= F

T

G

r

v

i

(11)

be the mapping equations where F

T

is the transpose

of F and i := 1, 2, ..., k is the number of grasping

points. G

l

v

i

(resp. G

r

v

i

) is the determinated grasp point

on the left (resp. right) image and L

r

i

(resp. L

l

i

) is

its corresponding epipolar line on the right (resp.

left) image. By exploiting the epipolar constraint (4),

the grasping points are constrained to lie along the

epipolar lines L

r

i

and L

l

i

, respectively.

If both grasping points satisfy the relation

G

l

v

i

FG

r

v

i

= 0 then the lines defined by these points are

coplanar. This is a necessary condition for the grasp

points to correspond.

Given the parameters of a line and a grasp point

in one image, the maximum deviation of a point from

the line can be computed as follows:

d

2

l

i

= norm(L

l

i

, G

l

v

i

), d

2

r

i

= norm(L

r

i

, G

r

v

i

) (12)

where d

2

l

i

(resp. d

2

r

i

) is the maximum deviation of a

grasp point on the left (resp. right) image.

We can estimate a cost function with respect to a

parameter t as follows:

C(t) = d

2

l

i

+ d

2

r

i

(13)

The minimum threshold (t

min

) corresponds to the t

i

where the cost function is minimum.

4.2 Features Matching

The second implementation consists of computing

the similarity between the stereo and the tactile

images features. To compare image features, the

Hausdorff metric based on static features matching is

used (Huttenlocher et al., 1993).

Given two feature sets: S =

s

1

, s

2

, ..., s

q

and

V =

v

1

, v

2

, ..., v

q

, the Hausdorff distance from the

point set S to point set V is defined as

h(S, V) = maxmin

s∈Sv∈V

s

i

− v

j

(14)

where

s

i

− v

j

corresponds to the sum of the pixel

difference and indices i and j correspond to the size

of a searching window.

The matching process is evaluated according to

the output of the function (14). The matching that

results in the lowest cost is the one that matches the

closest grasp planning. Since we want to guide the

gripper toward the grasping points previously gener-

ated by the grasp planning, the solution consists of re-

ducing the cost function (or so called grasp error) by

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

218

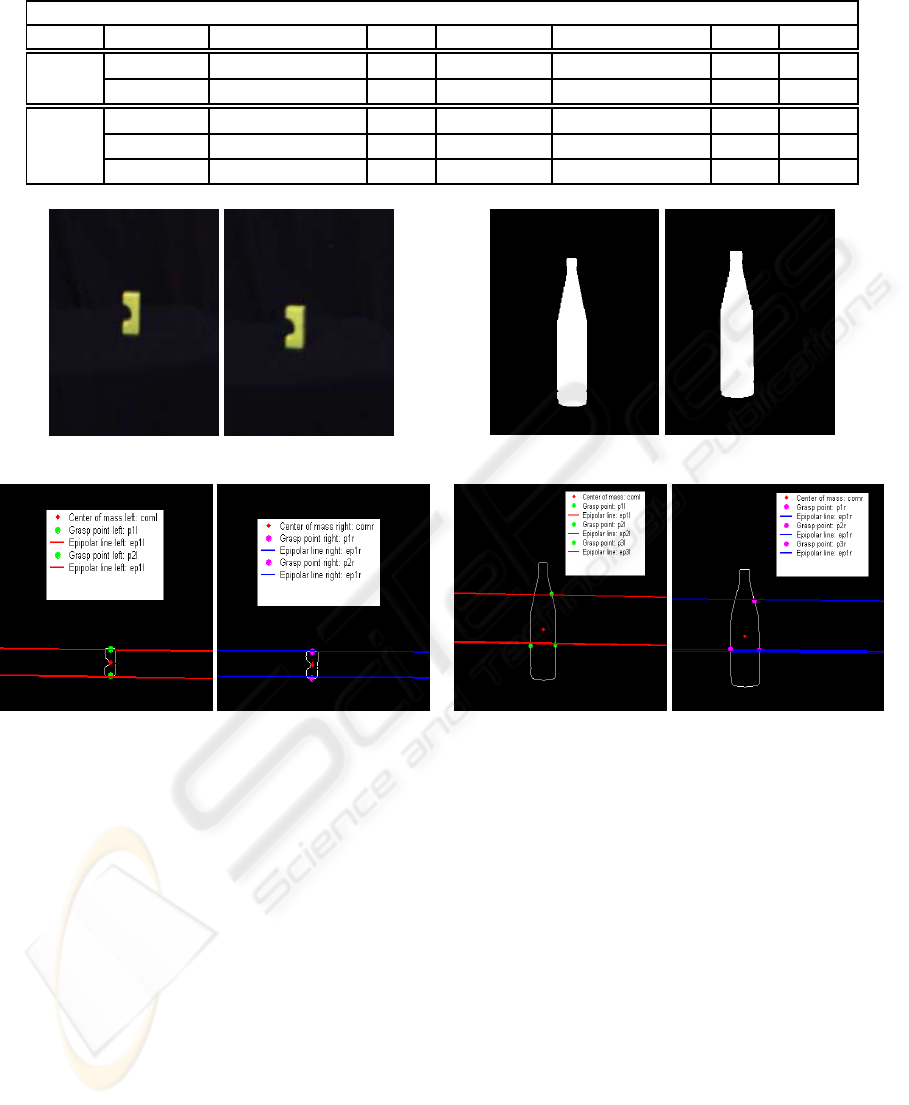

Table 1: Parameters measure of grasping positions and cost function: obj1, obj2.

Threshold: t = 2 corresponds to the maximum deviation.

Object Left grasp (x

l

, y

l

) d

l

Right grasp (x

r

, y

r

) d

r

C

G

l

v

1

358.500 365.500 2.934 G

r

v

1

313.500 377.000 2.940 17.252

obj1 G

l

v

2

359.000 400.000 5.008 G

r

v

1

312.500 411.500 5.018 50.261

G

l

v

1

355.000 226.000 1.726 G

r

v

1

299.500 237.500 1.731 5.9768

obj2 G

l

v

2

363.000 314.500 0.922 G

r

v

1

309.000 323.500 0.926 1.7028

G

l

v

3

309.500 316.500 5.251 G

r

v

1

255.000 321.500 5.259 55.234

(a) obj1: Left image (b) obj1: Right image (c) obj2: Left image (d) obj2: Right image

(e) Left image features (f) Right image features (g) Left image features (h) Right image features

Figure 5: Result of two and three-fingered grasp planning algorithms using stereo images.

moving the tactile sensors toward these points. The

cost of a solution is expressed as the total sum of con-

tact displacements over the surface of the object from

an initial contact configuration. If the result of match-

ing is outside a givenmargin, then the grasp controller

should launch a new measurement via joint angle and

position sensors.

4.3 Matching Algorithm

• Input: images: im

1

, im

2

. features: V

1

, V

2

. Num-

ber of fingers: k. Fundamental matrix: F. Thresh-

old t. Size of window: 7x7 pixel.

• Output: Grasping points: (G

l

v

i

, G

r

v

i

), with i :=

1, ..., k. Matching: h(S, V)

Process:

1. Perform the features extraction tasks

• for i := 1 to 2 do

• extract features: V

i

:= im

i

.

2. Perform the grasp planning tasks

• select V

1

on which the grasp will be performed.

• Get valid grasps point G

v

from (1)

3. Perform the grasping point correspondences

• select V

2

on which the grasping correspon-

dences will be performed

• for i := 1 to k do

• Compute G

l

v

i

:= G

v

i

• Compute L

r

i

and G

r

v

i

using (11)

4. Perform the matching function

• for i, j := 1 to 7, 7 do

• Compute h(S, V) ≤ r and h(S, V) ≥ r

• Compute pixel difference h(S, V) from (14)

USING STEREO VISION AND TACTILE SENSOR FEATURES - For Grasp Planning Control

219

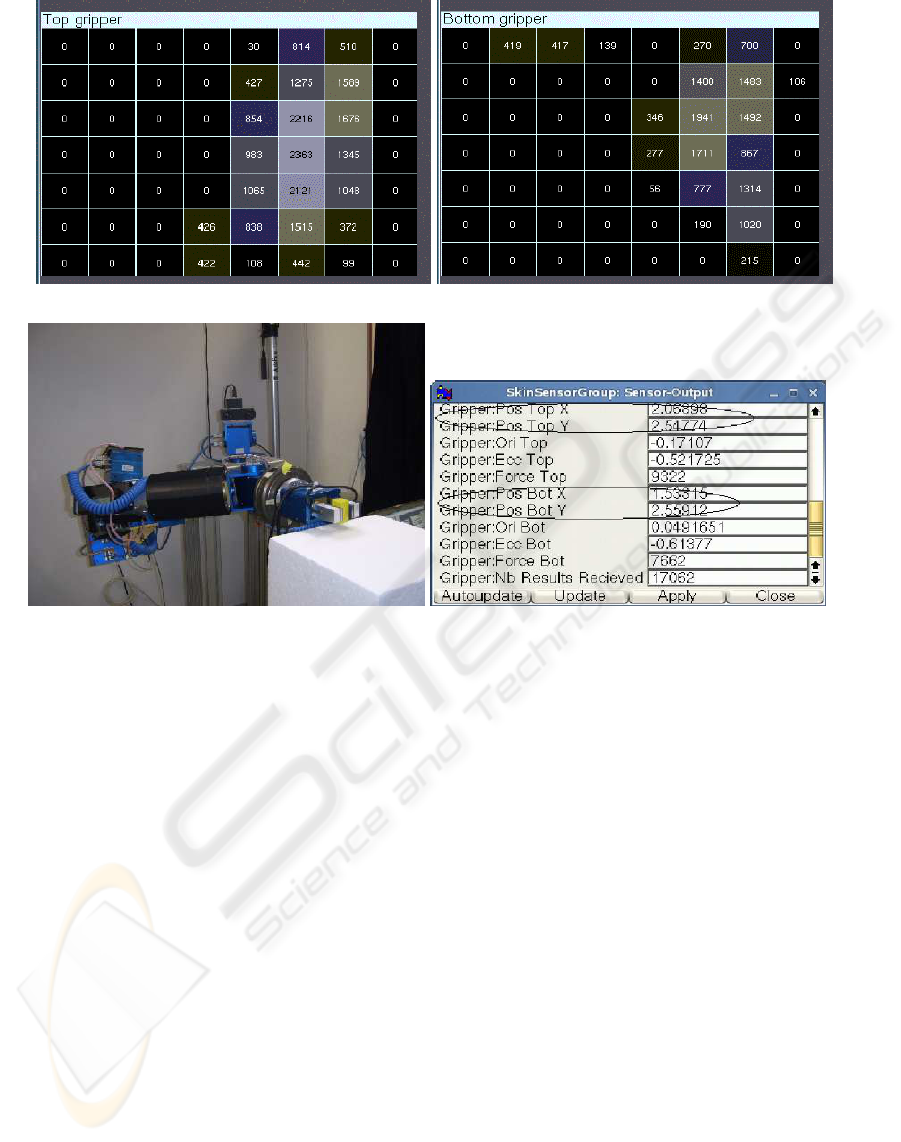

(a) Tactile sensor feedback: top gripper (b) Tactile sensor feedback: bottom gripper

(c) Gripper grasping an object (d) Fingers position

Figure 6: The Experiment setup. (a)-(b) Tactile sensor feedback giving the sensitive area in contact with the object. (c) Object

grasped with two fingers parallel gripper. (d) Tactile sensor output giving the top/bottom position of the gripper.

5. Perform the cost function

• Compute d

2

l

i

and d

2

r

i

using (12)

• Compute C(t) with (13)

6. End.

4.4 Experimental Results

The algorithm was implemented on our experimental

system, which consists of a 7 DOF manipulator arm,

a robot hand with two fingers, each one equipped with

a tactile sensor module mounted directly to the finger

tip, and a vision system (see Figure 6). This first pro-

totype of anthropomorphic robot system developed

by the German Research Foundation (see (Boudaba

et al., 2005)) is used as platform and demonstrator for

a coming generation of service robots. The grasping

configuration is based on a stand-alone stereo head

(MEGA-D from Videre Design) mounted on a pan-

tilt controller unit equipped with a pair of 4.8 mm

lenses and a fixed baseline of about 9cm. We have

experimented our approach with two different kind of

objects placed on a fixed table with a fixed position

and orientation (static object). Figure 5 illustrates the

results obtained from our matching algorithm using

stereo vision. The performance of our results (see Ta-

ble 1) is validated according to a cost function C de-

fined in the stereo images as the errors between grasp-

ing points. The cost that results in the lower value is

the one that matches the closest grasp planning. Fig-

ures 6(b)-(d) illustrate the feedback of tactile sensor

giving the top/bottom position of fingers with respect

to the tactile image plane in (b) while (c)-(d) showing

the top/bottom sensitive area in touch with the object.

5 CONCLUSIONS

The implementation of our algorithms for grasping

points matching using stereo vision and tactile sen-

sor have been detailed. Two schemes for grasping

points matching have been included in this work. In

the first scheme, stereo vision matching was used to

find the grasp points correspondence between left and

right images. It is shown that the quality of matching

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

220

depends strongly on the precise computation of the

intrinsic and extrinsic parameters of the stereo head

calibration. The performance of our results is evalu-

ated according to a cost function defined in the stereo

images as the errors between a pair of grasping points.

In the second scheme, the tactile sensor provides the

sensitive area of a fingertip in contact with an object

which was used with the grasp region to compute the

similarity between both features. Using these two

matching schemes, we were able to fuse the visual

grasp region with the tactile features and capabilities

of reducing or avoiding the grasp positioning errors

(or so called controlling the grasp planning) before

executing a grasps.

REFERENCES

Allen, P., Miller, A., Oh, P., and Leibowitz, B. (1999). Inte-

gration vision, force and tactile sensing for grasping.

Int. Journal of Intell. Mechatronics, 4(1):129–149.

Berger, A. D. and Khosla, P. K. (1991). Using tactile data

for real-time feedback. International Journal of of

Robotics Research (IJR’91), 2(10):88–102.

Boudaba, M. and Casals, A. (2006). Grasping of planar

obbjects using visual perception. In Proc. IEEE 6th

International Conference on Humanoid Robots (HU-

MANOIDS’06), pages 605–611, Genova, Italy.

Boudaba, M. and Casals, A. (2007). Grasp configuration

matching using tactile and visual information. In Proc.

IEEE 4th International Conference on Informatics in

Control, Automation and Robotics (ICINCO’07), vol-

ume Vol. II, pages 121–127, Angers, France.

Boudaba, M., Casals, A., Osswald, D., and Woern, H.

(2005). Vision-based grasping point determination

on objects grasping by multifingered hands. In Proc.

IEEE 6th International Conference on Field and Ser-

vice Robotics, pages 261–272, Australia.

Chen, N., Rink, R. E., and Zhang, H. (1995). Edge tracking

using tactile servo. In Proc. IEEE/RSJ International

Conference on Intelligent Robots and Systems, pages

84–99.

Faugeras, O. D. and Toscani, G. (1986). The calibration

problem for stereo. In In Proc. IEEE Conference on

Computer Vision and Pattern Recognition, CVPR’86,

pages 15–20, Miami Beach, FL, USA.

Hartley, R. and Zisserman, A. (2000). Multiple View Geom-

etry in Computer Vision. Cambridge University Press,

England, UK.

Hu, M.-K. (1962). Visual Pattern Recognition by Moment

Invariants. IEEE Transactions on Information Theory,

8(2):179–187.

Huttenlocher, D., Klanderman, D., and Rucklige, A. (1993).

Comparing images using the hausdorff distance. IEEE

Transaction on Pattern Analysis and Machine Intelli-

gence, 15(9):850–863.

Kragic, D., Miller, A., and Allen, P. (2001). Real-time

tracking meets online grasp planning. In Proc. IEEE

International Conference on Robotics and Automata-

tion (ICRA’2001), pages 2460–2465, Seoul, Korea.

K.Weiss and Woern, H. (2005). The working principle of re-

sistive tactile sensor cells. In Proceedings of the IEEE

Int. Conf. on Mechatronics and Automation, pages

471–476, Ontario, Canada.

Lee, M. H. and Nicholls, H. R. (2000). Tactile sensing for

mechatronics - a state of the art servey. Mechatronics,

9:1–31.

Maekawa, H., Tanie, K., and Komoriya, K. (1995). Tac-

tile sensor based manipulation of an unknown object

by a multifingered hand with rolling contact. In Proc.

IEEE International Conference on Robotics and Au-

tomatation, pages 743–750.

Morales, A., Sanz, P., and del Pobil, A. (2002). Heuris-

tic vision-based computation of three-finger grasps

on unknown planar objects. In Proceedings of the

IEEE/RST Int. Conf. on Intelligent Robots and Sys-

tems, pages 1693–1698, Lausanne, Switzerland.

Namiki, A. and Ishikawa, M. (1999). Optimal grasping us-

ing visual and tactile feedback. In Proceedings of the

IEEE/RST Int. Conf. on Intelligent Robots and Sys-

tems, pages 589–596.

Perrin, D., Smith, C., Masoud, O., and Papanikolopoulos,

N. (2000). Unknown object grasping using pressure

models. In Proceedings of the IEEE International

Conference on Multisensor Fusion and Integration for

Intelligent Systems, pages 575–582.

Sanz, P., del Pobil, A., Iesta, J., and Recatal, G. (1998).

Vision- guided grasping of unknown objects for ser-

vice robots. In ICRA’98, page 30183025, Leuven,

Belgium.

Scholl, K. U., Albiez, J., and Gassmann, B. (2001). MCA -

An Expandable Modular Controller Architecture. 3rd

Real-Time Linux Workshop.

Smith, C. and Papanikolopoulos (1996). Vision-guided

robotic grasping: Issues and experiments. In ICRA’96,

pages 3203–3208.

Tsai, R. Y. and Lenz, R. K. (1989). A new techniques for

fully autonomous and effecient 3d robot hand/eye cal-

ibration. IEEE Trans. on Robotics and Automation,

5(3):345–358.

Yoshimi, B. H. and Allen, P. K. (1994). Visual control of

grasping and manipulation tasks. In Proc. IEEE In-

ternational Conf. on Multisensor Fusion and Integra-

tion for Intelligent Systems, pages 575–582, Las Ve-

gas, USA.

USING STEREO VISION AND TACTILE SENSOR FEATURES - For Grasp Planning Control

221