HUNTER – HYBRID UNIFIED TRACKING ENVIRONMENT

Real-time Identification and Tracking System using RFID Technology

A. G. Foina and F. J. Ramirez Fernandez

Escola Politécnica - Universidade de São Paulo, São Paulo, SP, Brazil

Keywords: RFID, Middleware, Tracking, Real-time, Supervision, Wi-Fi, Wireless.

Abstract: This article presents a developed system that use RFID technology for trucks’ cargo real-time tracking.

RFID tags were settled at trucks’ dump-carts and readers were spread throughout warehouses entrances, at

the truck weighting scale and through unload platforms. The unload inspectors used robust PDA with

camera, along with Wi-Fi access points installed in warehouses, to confirm the truck information and take a

snapshot for future audits. A wireless broadband link was used to connect two weighting scale that are

distant from the unloading area. All technologies communicate with a web-based middleware that manages

all different devices. The system design is flexible enough to be used in very different applications like

product process control, automated manufactory lines control, supply chain applications and others.

1 INTRODUCTION

The unloading of bulk cargo is a great security

problem for companies that work with this product

modality, since the unloading process consists in

three tasks:

1. Full weight, which the truck is weighed with

full loaded dump-cart;

2. Unload, which the truck goes to a designated

site and unloads the product;

3. Empty weight, which the truck is once again

weighed unloaded.

The amount unloaded by the truck is the

difference between the second and first weight.

Thus, if a load theft occurs in the period between the

two weights, the company will not be able to know

if the theft had occurred or even how much was

stolen.

In some ports, the exporting companies' area is

open to access by anyone or any vehicle, and the

weight sites are approximately 2 kilometers far. This

scenario makes the cargo theft possible by the

following form: the truck is weighed fully loaded,

and then it goes to an area outside the unloading

zone; after that, it unloads the cargo at another truck,

or exchange dump-carts, and then return to be

weighed empty.

The estimated loss with cargo in bulk theft, at the

studied company, is approximately 7% of its annual

profit, which represents 750 thousand dollars. Based

on that scenario, it was projected a Radio Frequency

Identification (RFID) based solution to track the

vehicles and works as an electronic seal at the trucks'

dump-cart. So, the system control the sites where the

truck is passing by, time from one point to another,

and electronically detect a dump-cart seal violation.

All technologies used will be described to

follow, including the managing application.

2 ACTIVE RFID SYSTEM

Present RFID systems consist basically of four

components: an electronic tag, a reader, an antenna,

and application software to process the data. When a

tag approaches the antenna, the latter sends a signal

to the reader with the tag identification. The reader

receives the signal, and the information is sent to a

computer executing the software. This software is

normally a middleware application that processes

the data packets and sends them to an end-user

application or a database (Kim, 2006).

RFID tags can be active or passive. The active

ones are self fed by an intern battery and the passive

ones are fed with the energy from electromagnetic

waves sent by the reader. Regarding passive tags,

the reading ranges vary between 5 cm and 10 m. For

the active tags, since they have internal battery, the

reading range can reach distances in the order of 200

meters. Active tags can be connected to temperature,

322

G. Foina A. and J. Ramirez Fernandez F. (2008).

HUNTER – HYBRID UNIFIED TRACKING ENVIRONMENT - Real-time Identification and Tracking System using RFID Technology.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - ICSO, pages 322-325

DOI: 10.5220/0001493903220325

Copyright

c

SciTePress

tamper and movement sensors, among others. For

this reason, the active tags technology was chosen

here for truck access control in warehouses and

unloading area. In this case, the reader used operates

in the UHF frequency range, at 433MHz to transmit

data and at 915MHz to receive data from the tag,

with 80 meters reading range.

To work as an electronic seal, a tamper sensor

was attached to the tag. This sensor accuses “ok”

status if its terminal were placed in short circuit and

“violated” if the terminal were open circuit. This

feature allowed the development of a tag model that

could be fixed at a truck's dump-cart, seen in Figure

1. If occurs a tag removal attempt, the tamper sensor

would detect and send a violation signal to the

nearest reader.

The main difficulty found in the tag design was

towards the great difference between trucks used by

the company, which made difficult to develop a

single tag that could be fixed in each of them. To

solve this problem, the tag was designed be similar

to a padlock that can be fixed in any bar up to two

inches thick, common in all kinds of truck.

Therefore, it was possible to fix a tag in multiple

parts of the truck. The violation detection of a tag is

made throughout a small switch, that when the lock

is closed, this switch is pressed and when the lock is

opened, the switch is released. This switch was

connected from two wires to the tag's circuit

violation terminals sensor.

The adopted rule to install readers was: at each

entrance and exit was installed a reader. For

example, at the weighting scale platform were

installed two readers, one at the entrance and another

at the exit. At the unloading warehouses, one reader

was put at each entrance/exit gate. All readers were

connected by Unshielded Twisted Pair (UTP) cables

Cat 5e. Warehouses and weighting scales were

connected by multimode optical fiber cables due the

long distance between readers’ installation point and

the server. The optical fiber and the UTP Cat 5a

cables create a local area network between all

devices and the server which executes managing

application. So, each truck's passage through a

reader generates a data packet to the server with

information containing the tag's identification,

electronic seal status, timestamp and the

identification of the reader that received the packet.

3 DIRECTIVE ANTENNA

The place where the tag is attached on each truck

may vary depending on the truck’s dump-cart, and

the material of it can vary between wood and steel as

well. These variations can influence in the

sensitivity of the tags, causing undesired tag

readings outside the calibrated reader reading range.

These readings happen when the truck is crossing in

front of the warehouse entrance, causing unexpected

alarms and making the system calls the security

team unnecessary. To solve this problem, two

resources were used: a directive antenna and the

Received Signal Strength Indication (RSSI) feature

of the reader (Foina, 2006).

This antenna will amplify the signal received in

its directive lobule, sending a stronger signal to the

reader in this case. But, if the signal is received

outside its directive lobule, the reader will receive a

weak signal (Balanis, 1997). The antenna used has

an E-Plane and H-Plane beamwidth of 65 degrees at

3dB, circular polarization and 7 dBi of gain.

The RSSI feature of the active readers allows the

measurement of the signal strength received by the

reader. In the chosen equipment, the RSSI is an

index from 0 to 255, where a higher value means a

stronger signal.

With the RSSI and the directive antenna, the

software can analyse the RSSI to check if the tag is

behind or in front of the antenna. The directive

antenna was installed behind the reader, facing to the

warehouse door, approximately 1 meter away

according to the Figure 2.

Figure 2: Aerial representation of the reading zone of both

approaches, a) using the omnidirectional antenna and b)

using the directive antenna.

Figure 1: Active tag in a padlock shape with opening

detector disassembled.

HUNTER – HYBRID UNIFIED TRACKING ENVIRONMENT - Real-time Identification and Tracking System using

RFID Technology

323

When the tag is close to the door, but behind the

antenna, the RSSI index will be very low because

the tag is not in the main lobule of the antenna.

When the tag is positioned between the door and the

antenna, the RSSI index will be much higher than if

measured in the same position with an

omnidirectional antenna. This enables the

middleware to make the decision of whether or not

granting access into the warehouse.

4 MANAGING APPLICATION

The managing application developed, called Hybrid

Unified Trekking Environment (Hunter), controls

the unloading process information over the

monitored vehicle. Every truck is treated by the

system as an event queue to be executed. Inside the

system, every truck's passage through an

entrance/exit is an event. Full weight, unload and

empty weight are examples of events to be executed

by the truck. Thus, in the system, each truck has a

state within a finite state's machine. Through

received events by that truck, it registers exactly in

which stage of unloading flow the truck is in real-

time. In other words, the trucks in movement inside

the area are treated as independent threads in the

system, which is initiated when its tag passes by the

weighting scale to capture the full weight,

generating the first event. When these threads are

created, a task queue at the data base is created as

well, with all the tasks the truck must accomplish

along the process, such as: weighting scale entrance

for full weight, full weight capture, weighting scale

exit, unloading area entrance, etc. While the truck

moves and generates the events, these are interpreted

by the system and converted into its respective tasks,

and thus they are removed from the task queue and

inserted in the journal table. In case the tasks orders

are not obeyed, an alarm is generated on the system

operator's screen.

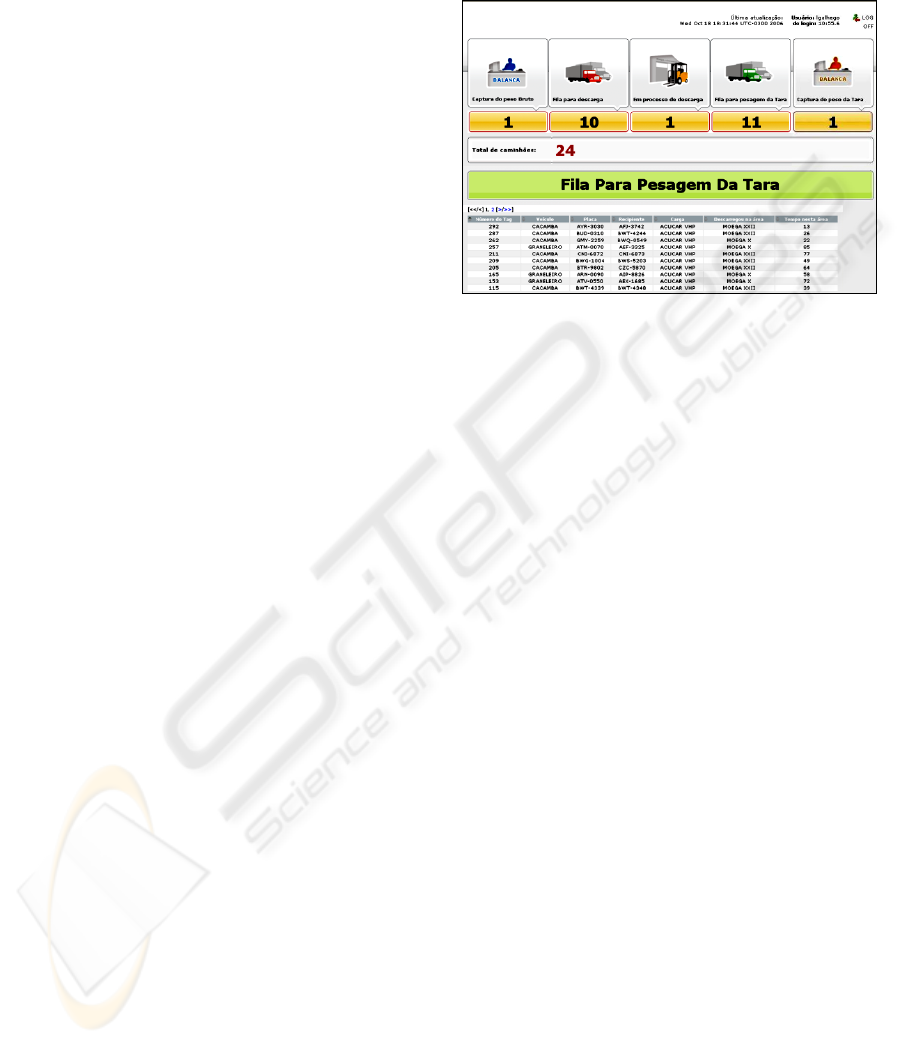

The system graphical interface shows the number

of trucks on each state of the unloading process,

seen in Figure 3. The numbers of trucks in the lines

between each state are showed as well. So, there are

five states presented in the interface: Full weight

capture, Unload line, Unloading process, Empty

weight line and Empty weight capture. Through the

graphical interface, it is possible to see the trucks

that are in this state and how long they are there.

The application was totally developed in Java,

being a part of it monolithic and a part in form of a

web-base application. It is executed by a Tomcat

application server and connected to an Oracle 9i data

base with features of advanced task queue. As

different technologies are used, the managing

application was developed with modules, divided in

three layers (Chen, 2003).

Figure 3: Hunter’s screenshot showing the number of

trucks in each state.

The first system layer, called Device

Management Subsystem (DMS) is the layer

responsible for the connection between the physical

device, in this case RFID readers, and the system

engine for process control, times and alarms, called

here as Core. The DMS stays waiting for a package

at the serial port or at the Ethernet connections, and

when it receives a data sent by any device, it

interprets the information and generates a message

in Extensible Markup Language (XML) with

information about the devices positioning, the name

of the place where the tag was read and details about

the truck which has read tag attached. to be sent to

Core. DMS is a middleware, connecting different

devices in the system at the same time, and allow

new devices to be connected to the system without

any change in the source code of the application.

The Core has a servlet that receives the XMLs

from DMS and inserts them into the data base.

When this insertion is made, the table where the

information is stored has a trigger that initiates all

the data analysis process, such as the alarms that can

be generated due to this event or updates on truck’s

state in the unloading process. Connected to Core,

there is the interface layer with two other modules,

the graphical interface and the legacy integration

systems. The first one is responsible for presenting

information on the screen, such as alarms,

navigation maps and reports. The second module is

responsible for sending information to the

company's legacy system, updating the warehouse

stock, linking timing information and alarms

generated to the company's Warehouse Management

System (WMS).

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

324

All communication between system modules is

made through XML messages and all system

graphical interfaces are web-based, allowing its

access from any computer without needing specific

application installation, just a conventional web

browser. The integration of the managing

application with the company's corporative systems

is made through recorded text files containing the

XML messages in a shared directory due limitations

of the company legacy system.

5 CONCLUSIONS

Despite the difficulties installing a wireless network

and an optical fiber network in old warehouses, and

placing sensible radio frequency equipment exposed

to weather hazards, it was possible to install

successfully all equipment and do their calibration.

The server applications behaved correctly when

were placed an amount of 200 trucks simultaneously

circulating around the area and unloading the cargo.

Some unexpected problems happened and they

were solved. The switch installed inside the padlock

tag changed the inductance of the 433MHz antenna,

so the internal organization of the tag was changed

to keep the antennas as far as possible from the

switch. Sometimes the truck parks in front of the

reader, generating many readings of the tag, but

sometimes the readings happed before the truck left

the place. For this reason, filtering controls were

implemented inside the DMS to avoid generation of

fake alarms.

The system helped the company management

and security. With the additional information

generated by the system for the logistic department

about the weight, unload time statistics, and the

number of trucks in real time in each stage of the

unloading process, it was possible to optimize the

trucks' line, reducing the wait in line and therefore,

reducing the average time of the unload process

from 50 minutes to 30 minutes. The installation of

RFID padlock tags in the trucks reduced in 60% the

load theft in the port area and allowed the security

team to find out points of vulnerability of the

previous system and to detect the majority of the

truck drivers corrupted by the theft group.

This same system showed flexible enough to be

used with other RFID technology and applications,

like passive tags to control automated manufacture

lines, supply chain pallets and forklifts. In this case

the application will control if the item pass through

all the phases in manufactory line, from the

beginning until the expedition. Can control who was

the forklift operator and how long he took to move

the products from one place to other. So the product

will be tracked, supplying information about the

storing and movement time, and the forklifts will be

tracked as well, supplying information about the

efficiency of the forklift operator and generating

alarms if he does something wrong.

REFERENCES

Almanza-Ojeda, D. L.; Hernandez-Gutierrez, A.; Ibarra-

Manzano, M. A.; 2006. Design and implementation of

a vehicular access control using RFID. In Electronics

and Photonics, 2006. MEP 2006. Multiconference on

2006, pp. 223 – 225.

Balanis, C. A.; 1997. Antenna Theory: Analysis and

Design. John Wiley & Sons, USA, second edition, pp.

86-88.

Blythe, P.; 1999. RFID for road tolling, road-use pricing

and vehicle access control. In RFID Technology (Ref.

No. 1999/123), IEE Colloquium on 25 Oct. 1999, pp.

8/1 – 816.

Chen, S.; Gulati, S.; Hamid, S.; Huang, X.; Luo, L.;

Morisseau-Leroy, N.; Powell, M. D.; Zhan, C.; Zhang,

C; 2003. A three-tier System Architecture Design and

Development for Hurricane Occurrence Simulation. In

Information Technology: Research and Education,

2003. Proceedings International Conference, pp. 113

– 117, 11-13 Aug. 2003.

Foster, P.R.; Burberry, R.A.; 1999. Antenna problems in

RFID systems. In RFID Technology (Ref. No.

1999/123), IEE Colloquium on 25 Oct. 1999, pp. 3/1 - 3/5.

Foina, A. G.; Barbin, S. E.; Ramirez Fernandez, F. J.;

2007. A New Approach for Vehicle Access Control

using Active RFID Tags. In IMOC - International

Microwave and Optoelectronics Conference, 2007.

Proceedings of the 2007 IMOC.

Kim, T.; Kim, H.; 2006. Access Control for Middleware in

RFID Systems. In Advanced Communication

Technology, 2006. ICACT 2006. The 8th International

Conference Vol. 2, 20-22 Feb. 2006, pp. 1020 – 1022.

Ni, L. M.; Liu, Y.; Lau, Y. C.; 2003. LANDMARC:

Indoor Location Sensing Using Active RFID. In IEEE

International Conference in Pervasive Computing and

Communications, 2003, pp. 407-415.

Raza, N.; Bradshaw, V.; Hague, M.; 1999. Applications of

RFID technology. In IEE Colloquium on, 25 October,

1999, pp. 1/1 - 1/5.

Tuttle, J.R.; 1997. Traditional and emerging technologies

and applications in the radio frequency identification

industry. In Radio Frequency Integrated Circuits

(RFIC) Symposium on, 8-11 Jun. 1997, pp. 5 – 8.

Zhao, J.; Zhang, Y.; Ye, M.; 2006. Research on the

Received Signal Strength Indication Location

Algorithm for RFID System. In Communications and

Information Technologies, 2006. ISCIT '06.

International Symposium on Oct. 2006, pp. 881 – 885.

HUNTER – HYBRID UNIFIED TRACKING ENVIRONMENT - Real-time Identification and Tracking System using

RFID Technology

325