WISA

A Modular and Hybrid Expert System for Machine and Plant Diagnosis

Mario Thron, Thomas Bangemann and Nico Suchold

Institut f¨ur Automation und Kommunikation e.V. Magdeburg, Steinfeldstr 3, D-39179 Barleben, Germany

Keywords:

Industrial diagnosis, expert system, Fuzzy Logic, Bayesian Network, logic description, modularity.

Abstract:

Expert systems are well known tools for diagnosis purposes in medicine and industry. One problem is the

hard efford, to create the knowledge base. This article describes an expert system for industrial diagnosis and

shows an efficient approach for the creation of the rule base, which is based on the reusage of knowledge

modules. These knowledge modules are representants for assets like devices, machines and plants. The article

encourages manufacturers of such assets to provide diagnosis knowledge bases by using a proposed multi-

paradigm rule definition language called HLD (Hybrid Logic Description).

Rule based knowledge may be expressed by using various methodologies, which differ in expressiveness but

also in runtime performance. The HLD allowes rules to be defined as propositional logic with or without the

use of certainty factors, as Fuzzy Logic or as probabilistic rules as in Bayesian Networks. The most effective

rule type may be chosen to describe causal dependencies between symptoms and failures. An evaluation

prototype implementation has been developed in the research project WISA, which includes a sotftware tool

chain for handling HLD files.

1 INTRODUCTION

A fundamental goal of industrial companies is to op-

timize the use of their production equipment, which

consists of simple assets like devices (sensors, actua-

tors, etc.), assembled machines and even more com-

plex assets like production lines and plants. The term

‘optimization’ relates here to maximization of the as-

set performance and to minimization of production

down-times as effects of failures.

This article is dedicated to the maximization of the

equipment availability. Industrial companies prefer

the use of reliable equipment over managing failures.

Failure Mode and Effects Analysis (FMEA) or Fail-

ure Mode, Effects and Criticality Analysis (FMECA)

may be used for engineering of robust production sys-

tems. But the production equipment may fail even in

the case of a careful design. Thus different mainte-

nance strategies have been developed in order to in-

crease the availability of the assets:

• Predictive Maintenance. Assets are continuously

monitored to get information on the abrasion

state. The remaining asset life time is predicted

in order to schedule necessary maintenance activ-

ities like repairing or asset exchanges.

• Preventive Maintenance. Maintenance activities

are scheduled according to the machine run time

and absolute machine life time. Time based abra-

sion models are used.

• Reactive Maintenance. The equipment is repaired

in cases of failures according.

Traditionally a mixture of preventive and reactive

strategies is used. Predictive and preventive mainte-

nance may only be complementary elements to the

reactive maintenance, since they left a remaining risk.

This article emphases the optimization of reactive

maintenance by

• decreasing the diagnosis time to find the failure

causes and the repair information,

• integrate diagnosis results into the IT supported

planning workflows of the companies.

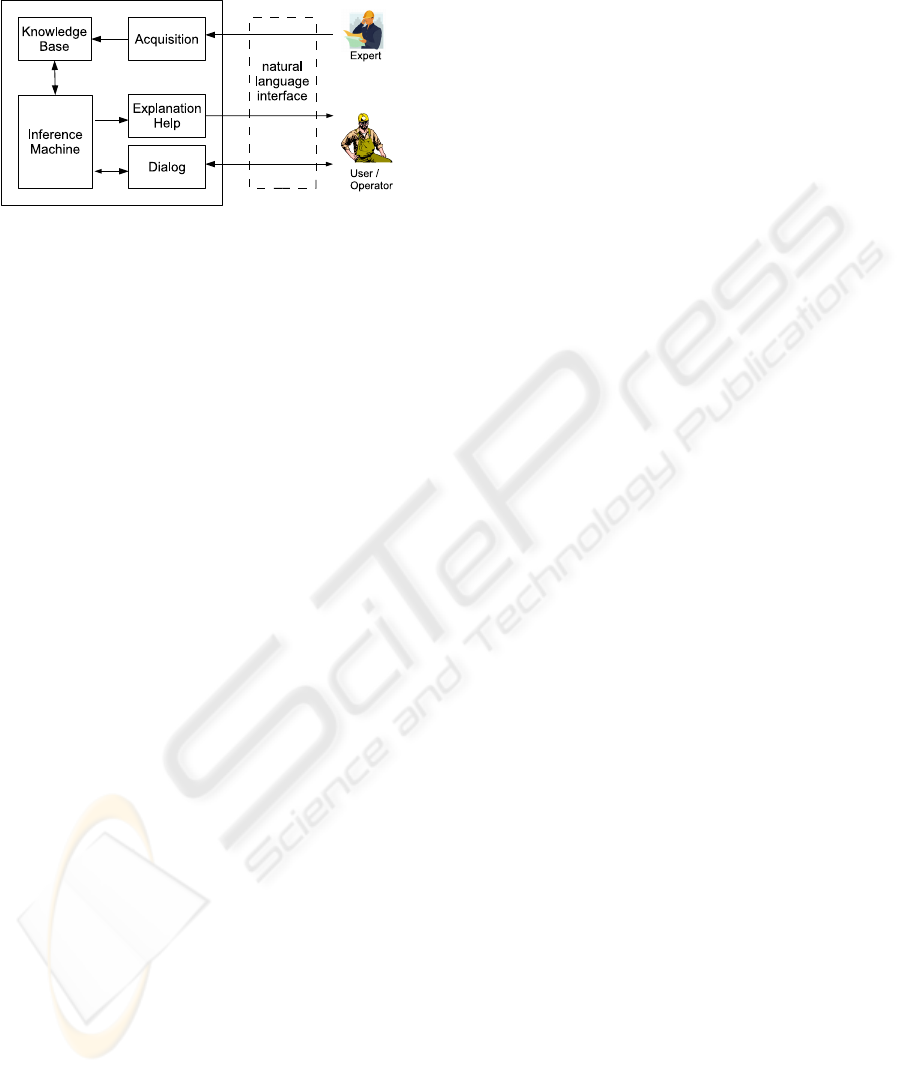

An approved approach to increase diagnosis effi-

ciency is the use of expert systems as shown in

figure1. It contains a knowledge acquisition compo-

nent, which is the interface for the expert. He may

input new information about the respective knowl-

edge domain into the knowledge base. Expert sys-

tems guide the user with questions to input only most

338

Thron M., Bangemann T. and Suchold N. (2008).

WISA - A Modular and Hybrid Expert System for Machine and Plant Diagnosis.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - ICSO, pages 338-341

DOI: 10.5220/0001497003380341

Copyright

c

SciTePress

relevant symptom information for determine failure

causes.

Figure 1: Structure of an expert system.

According to Moore’s Law and its derivatives com-

puter performance and memory availability doubles

roughly every two years. Thus some handicaps of ex-

pert systems, regarding space and time complexity of

applied algorithms, are reduced by time.

The WISA project focuses one of the remaining

problems, which is the reduction of necessary effort

of the experts to establish and maintain the knowledge

base. This problem avoids the broad assignment of

knowledge based systems in the industry.

The WISA project is funded by the German Min-

istry of Economy and Employment. It is registered

under reg.-no. IW060215.

2 WISA SYSTEM DESCRIPTION

2.1 Standards based Knowledge

Integration

Key factors of decreasing the effort for the creation

and maintenance of knowledge bases are to reuse for-

malized knowledge and to spread the work among dif-

ferent experts. Another one is the formalization of

the knowledge by the creators of the equipment, since

they already own the necessary expertise.

Thus there is a need for a language, which makes

it possible to describe knowledge bases. The com-

plexity of this language should be small and reflect

the needs of the application context (diagnosis) only.

In any case it should be a standardized language to

become relevant for the industry.

There are different approaches to establish a stan-

dard. The WISA project aims to be part of the follow-

ing approach: problem definition → finding solution

ideas → proof of concept → publication → founda-

tion of a standardization consortium → redefinition

of the proposals → reference implementation → fi-

nalization of the standard. The project leads up to

the publications, which are necessary to involve can-

didates for a standardization consortium.

The subject for standardization is a language for

description of industrial equipment. It is called Hy-

brid Logic Description (HLD). Design goals coming

from the application domain of intelligent diagnosis

where:

• handling of logic and causal dependencies be-

tween failure symptoms and their causes,

• handling of uncertain assertions about these de-

pendencies,

• handling of vague information about the symp-

toms and their causes.

The HLD design includes propositional logic in com-

bination with certainty factors, Fuzzy Logic and

Bayesian networks.

2.2 Language Features of the HLD

2.2.1 Logical Description

A natural kind of causal reasoning is propositional

logic. A simple sentence for diagnosis purposes could

be

IF symptom1 AND symptom2 THEN cause1

The knowledge base of a propositional logic system

would consist of a bunch of such rules. Variables

contain truth values therein. Operators like NOT,

AND, OR, IMPLICATION, BICONDITIONAL may

be used in the rule sets.

Diagnosis for a broad variety of devices may be

done by using propositional logic. Even good cars

or TVs ship with a manual containing chapter for

first aid diagnosis in a kind of propositional logic de-

scriptions. A look into these documents shows that

there is seldom a need for operators of first-order or

higher-order logic like ALL- or EXISTENCE opera-

tors. Thus the WISA project focused on propositional

logic for handling binary variables.

Certainty Factors are extensions to propositional

logic. They were developed in the 1970s for medi-

cal diagnosis expert systems, see for example (Rus-

sell and Norvig, 2003) or (Norvig, 2004). The prin-

cipal idea is that the same observable symptomatic

may have different causes but with different certainty.

Thus the conclusion of a rule is weighted by using a

certainty factor (CF).

Certainty factors are born by empirical develop-

ment. The value range of a CF is part of the inter-

val [−1, +1], where selected meanings for the vari-

able value are:

WISA - A Modular and Hybrid Expert System for Machine and Plant Diagnosis

339

CF = +1 => true

CF = 0 => unknown

CF = -1 => false

Disjunctive and conjunctive combinations of condi-

tions are allowed in logic systems with certainty fac-

tors. A variable may be the conclusion in different

rules. Thus there exists a combination calculus for

merging different conclusion results.

One problem with certainty factors is that the

memory space, which is necessary for the computa-

tion of the conclusion, grows with complexity O(c

n

)

because of a necessary breadth-first search. Therein

c is an approximation of the average count of condi-

tions in the rules, whereas n is the number of rules,

which are involved in the recursive computation of

the conclusion. Another problem is the sloppy han-

dling of certainties for maximization of efficiency.

Bayesian Networks are additionally included into the

HLD, which avoid these problems but expect input

of probabilities from the expert, which are difficult to

estimate.

2.2.2 Fuzzy Logic

Propositional logic deals perfectly with truth values.

But in industrial plants there are symptoms and fail-

ures with continuous value domains, like tempera-

tures, pressures, speed and other physical and chemi-

cal phenomenon.

Fuzzy Logic is a better way to deal with this kind

of information than handling truth variables, which

represent special value ranges. Continuousvalue vari-

ables are handled as linguistic variables in Fuzzy

Logic. Attributes (with a representation as fuzzy

set) are spread over ranges of the full variable value

space. Attributes are characterized by membership

functions, which map a continuous space [0..1] over

the related value range. This allows a more accurate

reasoning in Fuzzy Logic than in propositional logic

with discretized values.

An interesting point is that the notations of rules

in Fuzzy Logic are very similar to the notations in

propositional logic. Thus experts have to rearrange

their thinking not too much when using both.

But the inference processes in Fuzzy Logic is

expensive. It is done in a fuzzyfication - inference

- defuzzyfication approach. While fuzzyfication is

a straight forward computation of the membership

value, inference and defuzzyfication are time consum-

ing operations. Thus Fuzzy Logic should only be used

in diagnosis scenarios where really necessary.

Figure 2: High level elements of the HLD specification.

2.2.3 Bayesian Networks

Bayesian Networks deal with event probabilities.

They consist of directed acyclic graphs. The nodes

consist of random variables arcs notify dependencies.

An event is defined in a manner, that a random vari-

able fits a specific state. According to (Jensen, 1996)

there is then the possibility to declare rules in the

form:

IF event A has taken place, THEN B has taken

place with certainty x.

In a diagnosis applications event B may be an ob-

served symptom, while A may be a cause. The proba-

bility of B is computable by using the Bayes’ rule:

P(B|A, C) =

P(A|B, C)P(B|C)

P(A|C)

. (1)

The variable C is a context variable therein. Note-

worthy is that the Bayesian Network theory stands

completely on a solid mathematical fundament, see

(Pearl, 2000) for example. There is no approxima-

tion needed like in the Certainty Factor theory. Pearl

showed, that Bayesian Networks admit d-separation.

The usage of this circumstance leads to very effi-

cient computations of the conditional probabilities in

Bayesian Networks.

2.3 Language Formalization

XML has been chosen as base format for the HLD.

Some requirements where:

• integrated UNICODE support,

• automatic support for a validation of instance doc-

uments,

• broad acceptance in industry.

XML is used for example as message transport format

for engineering and commissioning tools (e.g. by the

FDT Group and OPC Foundation), for maintenance

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

340

and application integration purposes (e.g. by the MI-

MOSA Alliance) and for formal device descriptions

(e.g. by PROFIBUS International).

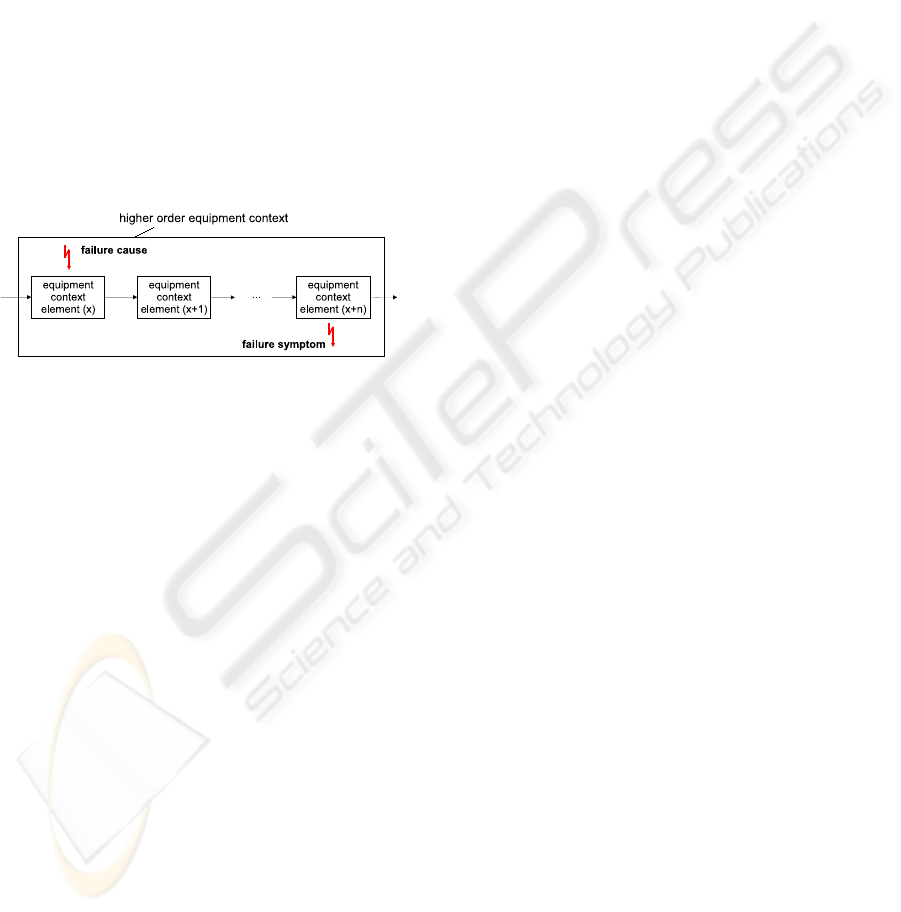

Figure 2 shows the base levels of the XML-

Schema based definition of the HLD. Meta informa-

tion (MetaInf) are used to describe an equipment type

verbally. The other elements contain the formal de-

scription of the algorithmic HLD elements as intro-

duced in the previous sections.

2.4 Integration Concept

A machine or plant is mostly an assembly of equip-

ment of different vendors. Thus the diagnosis de-

scriptions have to integrate and extend descriptions

of aggregated equipments. Figure 3 gives an abstract

overview of assembled equipment element as consid-

ered in HLD descriptions.

Figure 3: High level elements of the HLD specification.

An equipment is described by a single HLD file. If it

contains other types of equipment then these are ref-

erenced as contexts (see also figure 2). It is possible

to define rules or Bayesian Networks, which contain

variables of the aggregated equipment contexts since

they are referenced by context paths to variables.

2.5 Wisas - A HLD Tool Chain

It is necessary to show, that the approach leads to

an efficient diagnosis, in order to gain attention and

acceptance by industrial companies. But it is also

necessary to show how various tools may downsize

the effort for creation and maintenance of the knowl-

edge bases. A tool chain is built in the WISA project,

which is called WISAS and which consists of follow-

ing components:

• Editor. Involved industrial partners showed that

it is necessary to leave the vocabulary of AI tech-

nologies but to use the vocabulary of maintainers.

This language transformation is done by a graph-

ical editor component.

• Validator. This component is necessary to support

creation of correct HLD files.

• Interpreter. This is the reasoning component for

interpretation of HLD files.

• Documentation generator. It is assumed that in-

dustrial companies want to provide written docu-

ments for diagnosis. This component is dedicated

to reach that goal.

• Package management. There is a need to deliver a

bunch of HLD files for description of higher order

equipment. There may be complex dependencies,

which are handled by a package build tool and a

HLD repository maintenance tool, which may use

Internet connections.

• Planning system integration. The last but yet un-

finished part of the project is to define adapters to

ERP and CMMS systems.

3 CONCLUSIONS

The initial problem to reduce the effort for creation

of knowledge bases for intelligent industrial diagno-

sis systems has been solved by a modularization of

the knowledge bases. It has been shown that the in-

dustrial relevance will only be reached if there will

be a standardization process. Therefore the project

WISA proposes a knowledge description language for

the special purpose of industrial diagnosis. A proto-

typical tool chain has additionally been developed in

order to find more acceptance at industrial companies.

There have been critical discussions about the ap-

proach especially if XML is the right base technology.

Some advantages as the possibilities to validate and

transform XML files has been higher rated than the

disadvantage of poor parsing performance compared

to special language parsers.

There are some open questions regarding time and

space complexity. These questions will be answered

until the end of the project in August 2008. Imple-

mentation of future HLD interpreters and editors will

benefit from using on-line data, which could be used

for automatic triggering a diagnosis process but also

for learning procedures for the Bayesian Networks.

REFERENCES

Jensen, F. V. (1996). An introduction to Bayesian networks.

UCL Press Limited, London, 1st edition edition.

Norvig, P. (2004). Paradigms of artificial intelligence pro-

gramming: case studies in Common Lisp.

Pearl, J. (2000). CAUSALITY Models, Reasoning, and In-

ference. Cambridge University Press, Cambridge, 1st

edition edition.

Russell, S. and Norvig, P. (2003). Artificial Intelligence: A

Modern Approach. Prentice-Hall, Englewood Cliffs,

NJ, 2nd edition edition.

WISA - A Modular and Hybrid Expert System for Machine and Plant Diagnosis

341