A DISTRIBUTED HARDWARE-SOFTWARE ARCHITECTURE FOR

CONTROL AN AUTONOMOUS MOBILE ROBOT

Ricardo S. Britto, Andre M. Santana, Anderson A. S. Souza

Adelardo A. D. Medeiros and Pablo J. Alsina

Department of Computating Engineering and Automation, UFRN, Natal, Brazil

Keywords:

Control Architecture, Autonomous Mobile Robot, Hybrid Deliberative-Reactive Paradigm, CAN Bus.

Abstract:

In this paper, we introduce a hardware-software architecture for controlling the autonomous mobile robot

Kapeck. The Kapeck robot is composed of a set of sensors and actuators organized in a CAN bus. Two em-

bedded computers and eigth microcontroller-based boards are used in the system. One of the computers hosts

the vision system, due to the significant processing needs of this kind of system. The other computer is used

to coordinate and access the CAN bus and to accomplish the other activities of the robot. The microcontroller-

based boards are used with the sensors and actuators. The robot has this distributed configuration in order

to exhibit a good real-time behavior, where the response time and the temporal predictability of the system

is important. We adopted the hybrid deliberative-reactive paradigm in the proposed architecture to conciliate

the reactive behavior of the sensors-actuators net and the deliberative activities required to accomplish more

complex tasks.

1 INTRODUCTION

The control architecture of an autonomous mobile

robot aims qualify the vehicle for operating in its en-

vironment using its computational and physical re-

sources. An instance of control architecture must

guarantee the accomplishment of its own tasks in a

robust-stable way. There are many proposed architec-

tures, but there is not a definitive paradigm that imple-

mentates all the functionalities required (Medeiros,

1998).

The more representative paradigms are the hi-

erarchic, reactive and hybrid (deliberative-reactive)

paradigms. In the literature, we can find several ex-

emples of classical control architectures: NASREM,

Subsumption, AuRa, SFX, Saphira and TCA (Mur-

phy, 2000), PyramidNet (Roisenberg et al., 2004),

SHA (Kim et al., 2003), hybrid architecture proposed

by Adouane(Adouane and Le Fort-Piat, 2004), CO-

HBRA (Heinen, 2002), Ly architecture (Ly et al.,

2004) and LAAS architecture (Alami et al., 1993).

A well projected architecture is essential for im-

plementing complex robots. It must have different

kinds of hardware and software modules. Moreover,

architecture must lead the implementation and the re-

lationship of the modules.

This work firstly specify a hardware-software ar-

chitecture for the Kapeck robot. In a second moment,

this architecture will be used to implement a con-

trol organization. Finally, an experiment was made

to demonstrate the proposed architecture.

2 HARDWARE ARCHITECTURE

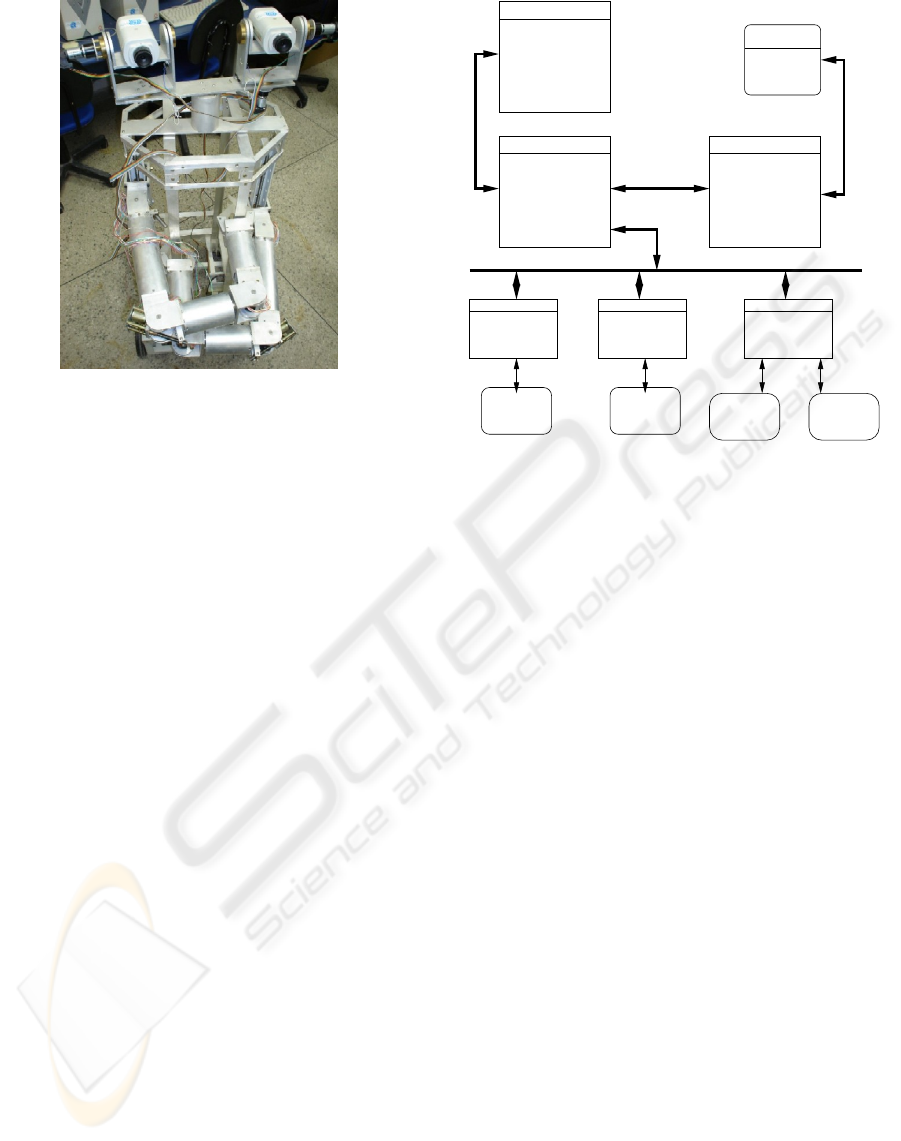

The Kapeck (Figure 1) is a wheeled non-holonomic

multi-task robot. The robot has a differential locomo-

tion system. It has 1 stereo head with 2 cameras and 1

sonar belt with 8 sonars. Moreover, Kapeck has 2 ma-

nipulators with 5 degrees of liberty, but in the current

stage of the project, the manipulators modules are not

included in the proposed architecture, but the modular

feature of the architecture makes easy the inclusion of

these modules in the future.

The differential locomotion system has 2 indepen-

dent wheels with 1 DC motor each one. In addition

to the motor wheels, there are 2 free wheels, without

motors. Each motor wheel has 1 attached optical en-

coder. These optical encoders, as all encoders used in

Kapeck, generate 1024 pulses per revolution.

The stereo head has 5 motors with attached optical

encoders. There are 2 CCD cameras. These cameras

have 1024X768 per pixel max resolution. They cap-

169

S. Britto R., M. Santana A., A. S. Souza A., A. D. Medeiros A. and J. Alsina P. (2008).

A DISTRIBUTED HARDWARE-SOFTWARE ARCHITECTURE FOR CONTROL AN AUTONOMOUS MOBILE ROBOT.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 169-174

DOI: 10.5220/0001498401690174

Copyright

c

SciTePress

Figure 1: Robot Kapeck.

ture 30 frames per second.

All the sensors and actuators (just not cameras)

were attached to a CAN bus (Bosch, 1991). The CAN

protocol was developed in the Bosch Laboratories for

the automobilist industry, but nowadays this protocol

is used in other areas, as robotics. The CAN is very

suitable for systems with many sensors and actuators

and time constraints. This protocol can perform with

multiple masters or in master-slave mode. It supports

velocity of 1 Mbit/s in distances up 30 meters. The

maximum distance supported by CAN is 5 kilome-

ters. When used in this mode, the maximum velocity

reached in a CAN bus is 10 Kbit/s.

Due to the short sampling periods needed to ac-

cess the sensors and actuators, the presence of real

parallelism in the execution of the robot process is

needful. Thus, the proposed hardware architecture of

Kapeck (Figure 2) was developed to allow distributed

processing, using the robot 10 processors. This archi-

tecture is modular, which means the inclusion of new

hardware modules, like the software ones, is possible

and easy.

The hardware architecture is composed of 1 desk-

top computer, 2 embedded computers and 8 micro-

controlled boards. The embedded computers and mi-

crocontrolled boards are inside robot. This hardware

configuration permits the real parallel execution of the

software modules of robot.

The monitor computer (Figure 2) stays outside

Kapeck and communicates with the robot through

a wireless net (IEEE 802.11b). This computer has

the user interaction software module. This module

watches and interacts with Kapeck.

The kapeck1 computer (Figure 2) contains the

software responsible for the deliberation of the robot.

Microcontrolled

1A

Board

Encoder

and

Motor

Microcontrolled

Board

7A

...Sonar 1 Sonar 8

Pentium III 1GHz

HD IDE 20 GBHD IDE 20 GB

Linux Fedora 5Linux Fedora 5

Ethernet

Pentium III 1GHz

IEEE 802.11b

kapeck1 kapeck2

SC−60

Cameras

256 MB RAM 128 MB RAM

CAN Bus

PCI−CAN Card

Encoder

and

Motor

...

Microcontrolled

Board

PCI Frame Grabber

Athlon 64 2GHz

HD IDE 40 GB

Linux Fedora 5

Monitor

1GB RAM

Figure 2: Hardware Architecture.

It is responsible for the interface with the monitor

computer, passing to user interaction software mod-

ule information about the robotic system. Moreover,

kapeck1 can execute commands passed by monitor.

The kapeck2 computer (Figure 2) contains the

vision system (visonSis). The vision system was

placed in a separated computer due to its great com-

putational requirement. This computer communicates

with the kapeck1 using a TCP/IP Ethernet peer-to-

peer net (crossover cable).

The microcontrolled boards are responsible for

the lower control of the sensors and actuators of

Kapeck. In this way, there is a performance gain of

the robotic system due to the dedicated processing of

these boards, releasing the embedded computers to

other tasks. These boards are connected to a CAN

bus configured in master-slave mode. The CAN bus

is connected to the kapeck1 computer. Only the mas-

ter of the CAN bus, contained inside kapeck1, can

permit the access of sensors and actuators to the bus.

All the boards have a PIC 18F258. This microproces-

sor was chosen due to its embedded support to CAN

protocol . It also has PWM (Pulse Width Modulation)

generator, timers and IO ports, needful to the applica-

tions. There are 2 kinds of boards, one called motor

controller board, and another called sonar controller

board.

The motor controller board is responsible to gen-

erate the PWM signal for one motor through the PID

(Proportional Integral Derivative) control algorithm,

receiving from the high level controller the position

references or the velocity references. This board also

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

170

has the function of acquiring encoder measurement.

When the board is attached to a stereo head motor,

the board receives a limit switch signal. The measure-

ments are returned to kapeck1 computer. The embed-

ded PID control algorithm uses the measurements of

encoder and limit switch. The sampling period exper-

imentally chosen to the control cycle of the embedded

PID controller is 10 ms.

The sonar controller board is responsible for the

sonar functioning. It collects asynchronously sonar

measurement when kapeck1 requires such measure-

ments. The board returns to kapeck1 the range mea-

surement to the nearest obstacle.

3 SOFTWARE ARCHITECTURE

To take advantage of the distributed hardware of

Kapeck, the software modules of robot must be able

to execute in parallel way. To make it possible, this

work proposes two mechanism that permits parallel

execution of software modules. One of them is the

blackboard. The blackboards are shared memory area

that permits the interaction between software modules

(Hayes-Roth, 1985). The other mechanism is a logic

representation of the CAN bus called procCAN.

3.1 Blackboards

The blackboards are implemented by 3 C++ class

called bBoard, bBoardAtt, bBoardRe and the soft-

ware module called bBoardServer.

The bBoard class is used to create and destroy

the blackboards. This class also manages the access

to the blackboard created in mutual exclusion, using

semaphores. It is used by the system initiator mod-

ules, responsible to initiate the other software mod-

ules and create all blackboards and semaphores used

to exchange information inside the robot. All black-

board, when it is created, receives an unique identifi-

cation key (ID).

The bBoardAtt class is used to attach to existing

blackboards. This class provides the read-write prim-

itives of blackboard.

The bBoardRe class has the same methods and it

functions like the bBoardAtt, but it is used to attach

to a remote blackboard, created in another Kapeck

computer. The utilization of local and remote black-

boards is transparent to the client program, because

both classes have the same read-write methods.

The bBoardServer is a software module imple-

mented in both embedded computers. It uses in-

stances of bBoardAtt to accomplish the read-write

operations of local blackboards in the name of the re-

mote clients.

An example of architecture that uses blackboards

is the COHBRA architecture (Heinen, 2002). CO-

HBRA has a central blackboard where the software

modules share information. This approach is differ-

ent of the one used in this work, where there are many

distributed blackboards.

3.2 procCAN

This class makes transparent to the software mod-

ules the hardware features of the robot. The exis-

tence of this class makes easy hardware alterations

of the Kapeck, since it disconnects the software mod-

ules implementation from the hardware modules. The

software modules operate on the logic CAN bus, that

encapsulates the real CAN bus.

The CAN protocol has a native mechanism that

controls the simultaneous access to the bus. It uses the

CSMA/CA protocol (Carrier Sense - Multiple Access

with Collision Avoidance) (Bosch, 1991) to do that.

However, Kapeck has a node attached to the CAN

bus (kapeck1 computer) that contains many process

competing internally for the access to the CAN bus.

In this situation, the existence of a mechanism that

guarantee the mutual exclusion access of the bus is

needed, since the absence of this kind of mechanism

can create message collisions before these messages

reach the bus.

The mutual exclusion of the bus is guaranteed by

using the CAN bus in master-slave mode and using

a bus arbiter. All the methods implemented by the

procCAN class internally require the access to the real

CAN bus to the bus arbiter. If the bus is busy and a

software module requires the permition to access the

bus, the requiring module will be blocked until the ar-

biter concedes the access permition. When the access

permition is conceded, the requiring module must ex-

ecute the desired actions and after it must signal to

the bus arbiter that the bus is free to be used to other

modules.

An example of architecture that uses the CAN

protocol is the architecture present in Coronel work

(Coronel et al., 2005). In this work is used high-level

communication protocol, on the CAN protocol, called

SCoCAN (Shared Channel on CAN) to control bus

access.

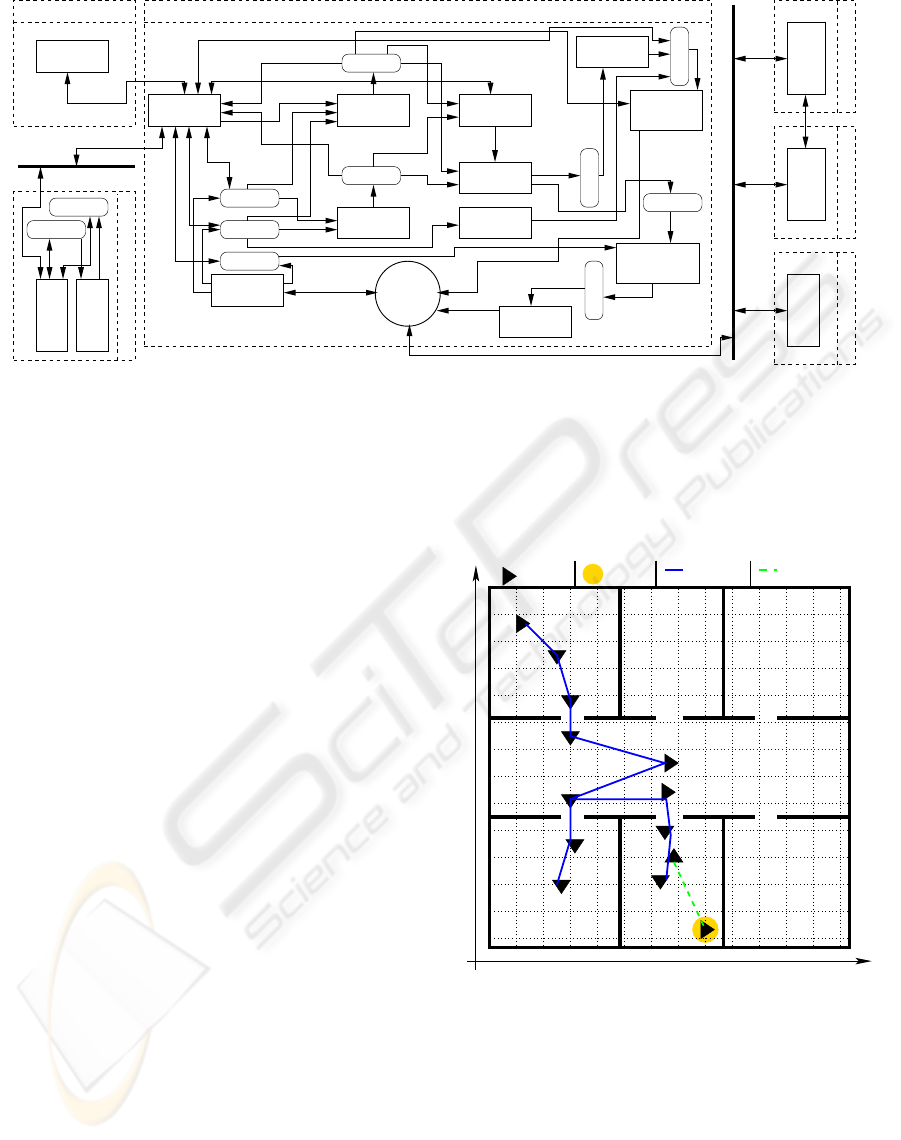

4 CONTROL ORGANIZATION

The control organization developed for Kapeck (Fig-

ure 3) was based in hybrid deliberative-reactive

A DISTRIBUTED HARDWARE-SOFTWARE ARCHITECTURE FOR CONTROL AN AUTONOMOUS MOBILE

ROBOT

171

paradigm. We adopted this paradigm to concil-

iate the reactive behavior of the sensors-actuators

net and the deliberative activities required to ac-

complish more complex tasks. Thus, the con-

trol organization is composed of the follow-

ing software modules: Perception, Localizer,

Cartographer, actionPl, pathPl, refRoGen,

avoiderObs, posCon, headCon, refHeGen and vi-

sionSis.

The Perception module is responsible for

adquires all the sensor measurements. It requires

measurements of sonars and encoders, in a fixed sam-

pling period. This module writes in blackboards the

received measurements. Perception writes in 3 dif-

ferent blackboards: one to write angular displacement

of wheels, other to write angular displacement of head

parts and a third blackboard to write the sonars mea-

surements.

The Localizer module was designed to localize

the robot in the current map. It reads data from black-

boards where Perception writes. This module cal-

culates the robot position using odometry. The calcu-

lated robot position is exported to a different black-

board.

The Cartographer maps the environment using

data exported by Perception. The map can be con-

structed in real-time or, in known environment, be a

priori defined. The generated or a priori known map is

exported to a blackboard. In the experiment presented

in this work, we used a priori known topologic map

with metric information, implemented as a graph.

The actionPl reads data from blackboards where

Localizer and Cartographer export data. Know-

ing the global task of the robot, this module deter-

mines the action to execute. In the experiment pre-

sented in this work, the robot global task is to explore

a building with many environments until find a known

mark. In this way, there are 4 possible actions:

1. Go to the center of a non-explored environment;

2. Explore a non-explored environment using the

stereo head;

3. Go to the mark, if and when it is discovered;

4. Go to another non-explored environment.

The topologic map of building is a priori known.

The exploration is done using depth search in the

graph that represents the connection topology of the

building.

In the case of action 1, an action corresponds to

go to the center of environment where the robot is.

An action 2 corresponds to execute specifc movi-

ments with the stereo head. These movements are

executed when robot reaches the center of the envi-

ronment. Such actions have as objective to provide to

visionSis a better pose to capture and process the

images.

The action 3 corresponds to go to the mark posi-

tion, discovered by visionSis. This action is trig-

gered only when the robot accomplishes its global

task. When this action happens, the building explo-

ration is finalized.

In the case of action 4, an action means go to a

non-explored environment. The path from the current

environment to the nearest non-explored environment

is determined by Dijkstra algorithm (Cormen et al.,

2002). All the possible paths are pre-calculated at the

initialization of the robot, because the map is a priori

known and it has little dimensions (in the case of the

experiment of this work). Thus, the actionPl is re-

sponsible for the execution of the depth search on the

map and for the election of the correct action in each

moment of robot execution.

The actions are synchronously passed to the

pathPl module. If the actionPl triggers an action

1, the pathPl exports the center position of current

environment. If the actionPl triggers an action 2,

the pathPl exports the positions that the stereo head

parts must reach. If the actionPl triggers an action 3,

the pathPl exports the position of discovered mark.

If the actionPl triggers an action 4, the pathPl gen-

erates a geometric path from the current environment

to the final desired one, passing through the environ-

ments between them. Two blackboards are used by

the pathPl module: One to export the data needed to

move the robot from an environment to another; other

blackboard to export data needed to move the stereo

head parts.

The refHoGen module reads the blackboard where

pathPl writes. It generates the reference positions in

each sampling period and exports these references in

a different blackboard.

The posCon is a reactive module that generates

velocities percentages for wheel motors using PID al-

gorithm to move the robot to a position read from

the blackboard where refHoGen exports data. These

percentages are sent to motor controller board, pro-

viding the reference to the embedded controller of

them. This module also reads the data exported by

Localizer, needed by the PID controller.

The avoiderObs reads sonar measurement ac-

quired by Perception module. The avoiderObs

monitors read data in order to identify obstacles in

the robot path. If an obstacle is detected, a safety

position is generated and exported to the blackboard

where refHoGen exports.

The headCon functions like posCon module, but

it reads references from blackboard where refHeGen

module writes data.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

172

Blackboard

Blackboard

Blackboard

Blackboard

Blackboard

Blackboard

Blackboard

Blackboard

Blackboard

Blackboard

Blackboard

IEEE 802.11b

Ethernet

1A a 7A

Monitor

kapeck1

kapeck2

visionSis

Perception

Localizer

Cartographer

actionPl

pathPl

avoiderObs

headCon

refHeGen

posCon

refRoGen

bBoardServer

Interface

User

bBoardServer

CAN

Arbiter

1A a 7A

Controller

Supervisor

Sonar

Sonar Board

Encoder Velocity

Control

CAN Bus

Figure 3: Control Organization.

The refHeGen function in to possibles behaviors:

Standard behavior and Exploring behavior. In the

standard behavior, this module generates and exports

to a blackboard specific positions possible to reach

by the stereo head parts. In the exploring behavior

(started when actionPl triggers an action 2 and fin-

ished when the action 2 finishes), refHeGen starts to

read and export the positions generated by pathPl.

The visionSis processes the camera images to

find the desired mark. When the mark is discov-

ered, visionSis signals to actionPl. After this,

actionPl triggers an action 3. Together with the sig-

nal, visionSis exports the robot position to a black-

board.

5 EXPERIMENTAL RESULTS

The experiment developed in this work to demon-

strate the proposed architecture consists in a robot

that explores a priori known map to find a mark.

When the robot finds the mark, it goes to its

position. This experiment contains the follow-

ing software modules of proposed control organi-

zation: Perception, Localizer, Cartographer,

actionPl, pathPl, refRoGen, posCon, headCon,

refHeGen e visionSis.

In the Figure 4 we present the experimental re-

sults. In the moments T0, T3, T6 and T10 the

actionPl triggers an action 1. In the moments T1,

T4, T7 and T11 the actionPl triggers an action 2. In

the moments T2, T5, T8 and T12 the actionPl trig-

gers an action 4. In the moment T13 visionSis iden-

tifies the mark, signaling to actionPl. So, actionPl

triggers a action 3. At this moment, the robot dis-

cards the rest of path generated in moment T12 and

goes to the mark, using the coordinates provided by

visionSis. In the moment T14 the robot reaches the

mark and accomplishes the global task.

Y

X

T0

T1

0

T2

T3

T6

T7

T9

T10

T13

T14

T8

T12

T11

T4

T5

− Mark

− Original − Alternative

− Robot

Path Path

Figure 4: Experimental Results.

6 CONCLUSIONS

This work presented the main ideas of a hardware-

software architecture for an autonomous mobile

robot. In particular, we propose the using of black-

boards to implement the interection between software

modules. We also presented the CAN bus access

mode, using a logical representation of the real CAN

A DISTRIBUTED HARDWARE-SOFTWARE ARCHITECTURE FOR CONTROL AN AUTONOMOUS MOBILE

ROBOT

173

bus. The proposed architecture tries to manage not

only the organization software aspects, but also the

hardware organization and the interaction between

hardware and software modules. The concepts pre-

sented were applied to Kapeck. We pretend in next

works improve the software modules of the control or-

ganization and develop hardware and software mod-

ules to control the manipulators. In the current stage

of the work, we use a simple mechanism to coordi-

nate the access to the CAN bus. An evolution of the

work could be the utilization of a high-level protocol

on CAN.

REFERENCES

Adouane, L. and Le Fort-Piat, N. (2004). Hybrid behavioral

control architecture for the cooperation of minimal-

ist mobile robots. In Proceedings of ICRA’04, pages

3735–3740, New Orleans,USA.

Alami, R., Chantila, R., and Espiau, B. (1993). Designing

an inteligent control archtecture for autonomous mo-

bile robots. In Proceedings of ICAR’93, pages 435–

440, Tokyo, Japan.

Bosch, R. (1991). Bosch CAN specification. Technical re-

port, Bosch Gmbh.

Cormen, T. H., Leiserson, C. E., Stein, C., and Rivest, R. L.

(2002). Algoritmos: Teoria e Prtica. Campus, 1 edi-

tion.

Coronel, J. O., Benet, G., Sim, J. E., Prez, P., and Albero,

M. (2005). CAN-based control architecture using the

SCoCAN communication protocol. In Proceedings of

ETFA’05, Catania, Italy.

Hayes-Roth, B. (1985). A blackboard architecture for con-

trol. In Artificial Inteligence 26.

Heinen, F. J. (2002). Sistema de controle hbrido para robs

mveis autnomos. Master’s thesis, Centro de Cincias

Exatas e Tecnolgicas, UNISINOS, San Leopoldo, RS.

Kim, J.-O., Im, C.-J., Shin, H.-J., Yi, K. Y., and Lee, H. G.

(2003). A new task-based control architecture for per-

sonal robots. In Proceedings of IROS’03, pages 1481–

1486, Las Vegas, USA.

Ly, D. N., Asfour, T., and Dillmann, R. (2004). A mod-

ular and embedded control architecture for humanoid

robots. In Proceedings of IROS’04, pages 2775–2780,

Sendai, Japan.

Medeiros, A. A. D. (1998). A survey of control archi-

tectures for autonomous mobile robots. Journal of

Brazilian Computer Society.

Murphy, R. R. (2000). Introduction to AI Robotics. MIT

Press, Cambridge, Massachusetts 02142, 2 edition.

Roisenberg, M., Barreto, J. M., Silva, F. d. A., Vieira, R. C.,

and Coelho, D. K. (2004). Pyramidnet: A modu-

lar and hierarchical neural network architecture for

behavior-based robotics. In Proceedings of ISRA’04,

pages 32–37, Queretero, Mexico.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

174