SYNTHESIS OF VELOCITY REFERENCE CAM FUNCTIONS FOR

SMOOTH OPERATION OF HIGH SPEED MECHANISMS

Robert M. C. Rayner and M. Necip Sahinkaya

Department of Mechanical Engineering, University of Bath, Claverton Down, Bath BA2 7AY, U.K.

Keywords:

Cam function, mechanisms, identification, control, simulation.

Abstract:

The purpose of the paper is to improve the dynamic performance of a mechanism used in a packaging machine

in order to run the system at higher speeds with lower vibration and noise levels. A method of synthesising

a velocity demand signal as a function of crank position (i.e. cam function) is demonstrated for a prototype

mechanism and drive system. The method aims to minimise the peak to peak actuation torque requirements

in order to minimise the vibration of the mechanism. First of all, experimental results are utilised to identify

the drive system parameters. A dynamic simulation package is used to model the nonlinear dynamics of the

mechanism. The model based synthesis of velocity reference cam functions is performed at increasing mech-

anism actuation speeds. The performance of the system using the proposed velocity demand cam function is

compared with the conventional constant speed reference case at different running speeds.

1 INTRODUCTION

The dynamic performance requirements of modern

machinery are constantly increasing in terms of op-

eration speed and motional accuracy. To remain

competitive, mechanisms need to run at ever higher

speeds, with greater reliability and be manufactured

at lower cost. To achieve this, machines use a com-

bination of electrical control systems, servo systems

and mechanisms to generate truly mechatronic solu-

tions. At the core of most packaging machines are

multi-linkage mechanisms, which interact with pack-

aging materials and products. These mechanisms

have highly nonlinear dynamic properties and intro-

duce vibrations at high operating speeds.

Much work has been documented on optimum

balancing of mechanisms in order to reduce the vi-

brations at high operating speeds, such as (Kochev,

2000; Lee and Cheng, 1984; Alici and Shirinzadeh,

2006) and others. This method involves the adding of

balancing masses to the mechanism, which increases

the weight and may not always be physically achiev-

able due to factors such as space restrictions. Al-

ternatively, a mechanism can be re-designed or re-

synthesised by considering kinematic and dynamic

cost functions (Conte et al., 1975; Kochev, 2000).

Due to the large number of parameters, conventional

optimisation techniques struggle. Many researchers

tried to formulate new optimisation techniques, such

as genetic algorithms (Connor et al., 1998; Cabr-

era et al., 2002; Laribi et al., 2004; Saxena, 2005),

differential evolution (Price and Storn, 2006), arti-

ficial immune searching (Liu and Xiao, 2005), geo-

metric centroid of precision positions technique (Shi-

akolas et al., 2005), and the time varying dimensions

method (Hansen, 2002).

It has been stated in (Yuan and Rastegar, 2004)

that vibrations experienced during high speed actua-

tion are caused by harmonic content in the output mo-

tion. It has also been argued in (Rastegar and Yuan,

2002) that the amount of harmonic content present in

the motion increases with the magnitude of the peak

to peak torque required to generate the motion. Re-

cently, an iterative method of synthesising a veloc-

ity command cam function has been introduced to re-

duce the peak to peak actuation torque (Sahinkaya

et al., 2007). This method relies on the develop-

ment of a computer model of the system. This model

is based on experimental results and a simulation of

the nonlinear dynamics of the mechanism. This pa-

per extends the aforementioned work by synthesis-

ing optimised cam functions (i.e. velocity profile as

a function of crank angle) to achieve higher output

speeds than that discussed previously, and that used

for the purpose of system identification.The use of

shaped cam functions has demonstrated significant

benefits in terms of reduced peak to peak torque re-

quirements.This is a software based command shap-

ing technique. No redesigning or re-synthesis of the

mechanism is necessary.

183

M. C. Rayner R. and Necip Sahinkaya M. (2008).

SYNTHESIS OF VELOCITY REFERENCE CAM FUNCTIONS FOR SMOOTH OPERATION OF HIGH SPEED MECHANISMS.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - SPSMC, pages 183-187

DOI: 10.5220/0001501901830187

Copyright

c

SciTePress

2 SYSTEM DESCRIPTION AND

MODELLING

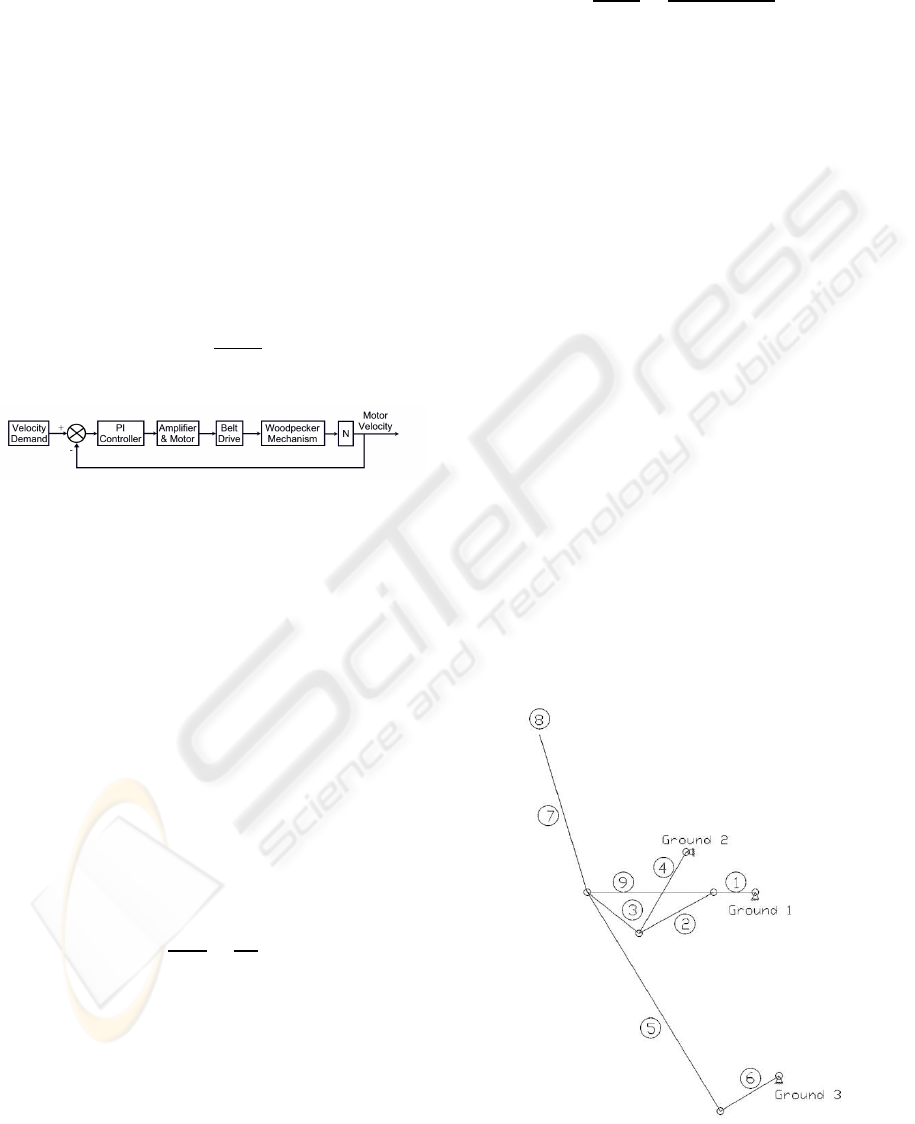

The block diagram of the prototype system consid-

ered in this study is shown in Figure 1. The mech-

anism is a 6-bar mechanism called the woodpecker

mechanism. The purpose of the mechanism is to push

thin products into packaging held in a neighbouring

hopper. The mechanism is driven by an Allen Bradley

MPL 540K-MJ22AA servo controlled with an Allen

Bradley Kinetix6000 drive unit via a belt drive with

a 3:1 gear ratio. The drive unit is fundamentally a PI

controller. The user can configure the drive unit and

monitor the system in real-time using RSLogix5000

control software. The servomotor and the drive sys-

tem is assumed to be a first order lag with a time con-

stant of τ and a gain K

m

.

G

m

=

K

m

1+ τs

(1)

Figure 1: Block diagram of the overall system.

Before modelling the nonlinear dynamics of the

woodpecker mechanism, experiments were carried

out to identify the drive system parameters. It was

possible to log the velocity demand, velocity out-

put, acceleration output, position output, and motor

torque. A step input velocity signal was used with

different values of K

P

and constant velocity demand.

The integral gain K

I

was set to zero during the iden-

tification process. To estimate the effective friction

coefficient acting on the motor shaft, the steady state

response over a single crank cycle was considered.

By using the approximate constant speed section of

the cycle, the friction coefficient b can be estimated

from the following transfer function between the mo-

tor torque (the output of ”Amplifier & Motor” block

in Fig. 1) and the motor velocity:

T

m,ss

˙

θ

m,ss

=

N

2

b

(2)

where T

m,ss

and

˙

θ

m,ss

are the average motor torque

and motor speed respectivelyalong the constant speed

section of the steady state cycle, and N is the gear

ratio, i.e. N = 3. This gave a representative fric-

tion coefficient of b = 0.255. In order to identify the

motor/amplifier gain K

m

and the effective rotor iner-

tia, tests were repeated by replacing the woodpecker

mechanism with a disk of known inertia. Thus the

steady state gain of the closed loop system can be

written as:

˙

θ

m,ss

˙

θ

m,ref

=

N

2

K

m

K

p

b+ N

2

K

m

K

p

(3)

By analysing the steady state system response, the

motor/amplifier gain was estimated as K

m

= 0.0883.

Transient motor torque and motor velocity data were

used to determine the effective inertia of motor shaft

and associated pulleys acting on the crank shaft. Thus

I

m

= 0.0071 kgm

2

. Observation of the transient mo-

tor torque and the error signal suggested that the time

constant τ can be taken as zero. This may be due to a

high-gain internal current feedback in the motor drive

circuit.

The dynamic model for the woodpecker mecha-

nism was built in Simulink by using

Dysim

(Haz-

lerigg and Sahinkaya, 1984; Sahinkaya, 2004) sim-

ulation package. The mechanism consists of 6 links

as shown in Figure 2. The physical data is given in

Table 1. A CAD model of the mechanism was used

to obtain these mass and inertia values and the po-

sition of the centre of gravity of each link and local

coordinates of the connection points. The model was

then tested using various demand speed and controller

parameter combinations. For example, Fig. 3 shows

the experimental and simulation results for a constant

speed reference of 300 rpm with K

P

= 20 and K

I

= 0.

The results showed an excellent match between

the experimental and simulated responses for all the

tests conducted with the prototype system. The high

Figure 2: A schematic view of the woodpecker mechanism.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

184

Table 1: Data for the Woodpecker mechanism.

Name No Length Mass Inertia

(mm) (kg) (N·mm

2

)

Crank 1 62 0.927 901

Connector 2 127 0.310 1420

3 103

9 188.3

Upper pivot 4 144 0.414 1310

End-effector 8 0.174 380

Spine 5 348.86 0.482 10550

7 245.19

Lower pivot 6 102 0.123 290

180

200

220

240

260

Motor Velocity (rpm)

0 90 180 270 360

0.4

0.6

0.8

1

Crank Position (degrees)

Motor Torque (Nm)

Figure 3: Simulated (dashed) and experimental (solid)

steady state responses over one crank cycle.

frequency oscillations (of approximately at 15 Hz.)

in the measured response were due to the belt dynam-

ics, which were not included in the analysis. Partic-

ularly encouraging was the reproduction in the simu-

lated results of the velocity trough and corresponding

torque peak resulting from the nonlinear nature of the

mechanism dynamics. The orbit of the end effector is

shown in Figure 4. Normalised crank positions (unity

normalised crank position corresponds to 360

o

crank

angle) are shown on the orbit. The critical portion

of the path is between normalised crank positions of

0.6 and 1.0, where the end-effector interacts with the

product and product feeding mechanism.

3 OPTIMUM CAM PROFILE

The experimental results highlighted a potential prob-

lem when running the system at higher speeds. Of

particular concern was the torque spike and trough

on the return part of the end-effector orbit between

crank positions 90 and 180 degrees. It has been

shown elsewhere (Yuan and Rastegar, 2004) that har-

monic content in the output motion induces vibra-

−0.25 −0.2 −0.15 −0.1 −0.05 0

0.15

0.2

0.25

x−position (m)

y−position (m)

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Figure 4: Orbit of the end-effector.

Figure 5: The process of optimising a velocity cam func-

tion.

tions and that the amount of harmonic content in-

creases with the peak-to-peak magnitude of the ac-

tuation torque (Rastegar and Yuan, 2002). Therefore,

the focus of the paper is to reduce the peak-to-peak

drive torque through shaping the speed reference sig-

nal as a function of crank angle. The machanisms

will not be re-synthesise nor rebuilt. The method sug-

gested in (Sahinkaya et al., 2007) utilises the model of

the drive system estimated from experimental results.

The procedure can be summarised as follows:

(a) Run the simulation of the overallsystem for a con-

stant speed reference signal, and determine a nar-

row torque band from the steady state torque sig-

nal covering the approximate constant torque re-

gion.

(b) Run the simulation again with the same constant

speed reference signal, but with saturation limits

imposed on the drive torque. These limits are de-

termined in (a). Then record the steady state out-

put speed response over a single cycle of crank

logged against crank position.

(c) Use the periodic output speed recorded in (b)

as a velocity cam function and run the simula-

tion without saturation limits to assess the perfor-

mance of the system with this velocity cam func-

tion.

This process is shown in Figure 5 as a block diagram.

The above process is applied to the model of the

prototype system to assess the benefit of the veloc-

ity cam function when the average running speed of

the mechanism is increased from to 100 rpm to 600

rpm. Due to the 3:1 gear ratio, this corresponds to

SYNTHESIS OF VELOCITY REFERENCE CAM FUNCTIONS FOR SMOOTH OPERATION OF HIGH SPEED

MECHANISMS

185

0 90 180 270 360

0.7

0.8

0.9

1

1.1

1.2

Crank position (degrees)

Normalised Motor Reference Velocity

Constant demand

100rpm cam function

300rpm cam function

450rpm cam function

600rpm cam function

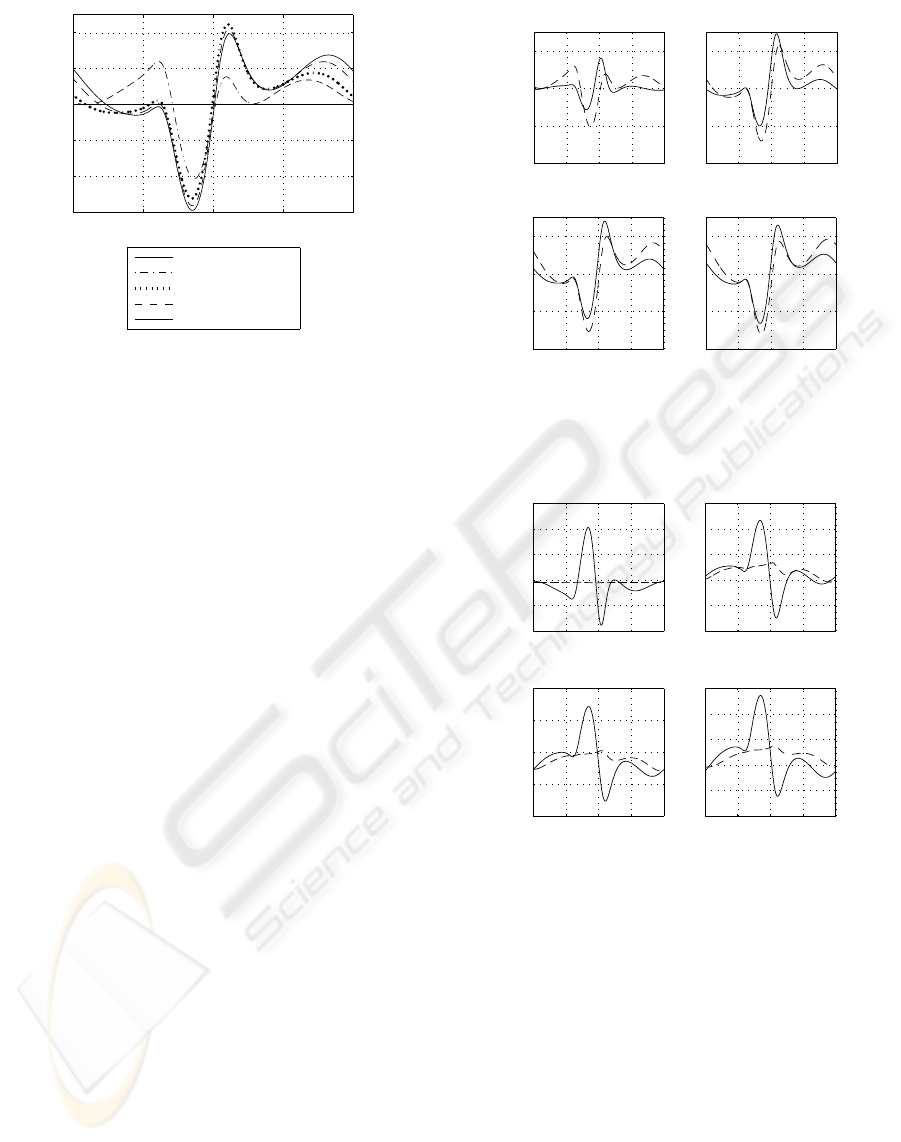

Figure 6: Velocity reference cam functions at different av-

erage crank speeds.

motor speeds from 300 rpm to 1800 rpm. The con-

troller parameters are set to K

P

= 20 and K

I

= 400.

Figure 6 shows the synthesised cam functions at 300,

900, 1350, and 1800 rpm of the motor speed. For ease

of comparison, the velocity reference signals are nor-

malised by their corresponding constant speed values.

Note that in each case the achieved average cyclic ve-

locity of the mechanism corresponded closely to the

demand velocity.

Figure 7 shows the corresponding steady state

crank velocity output over a single crank cycle. Es-

pecially at higher speeds, the change in system re-

sponse is minimal compared with the constant speed

reference signal cases. Despite small variations in the

output velocity profile, the use of the optimised cam

function has significant benefits, greatly reducing the

peak to peak drive torque requirements as shown in

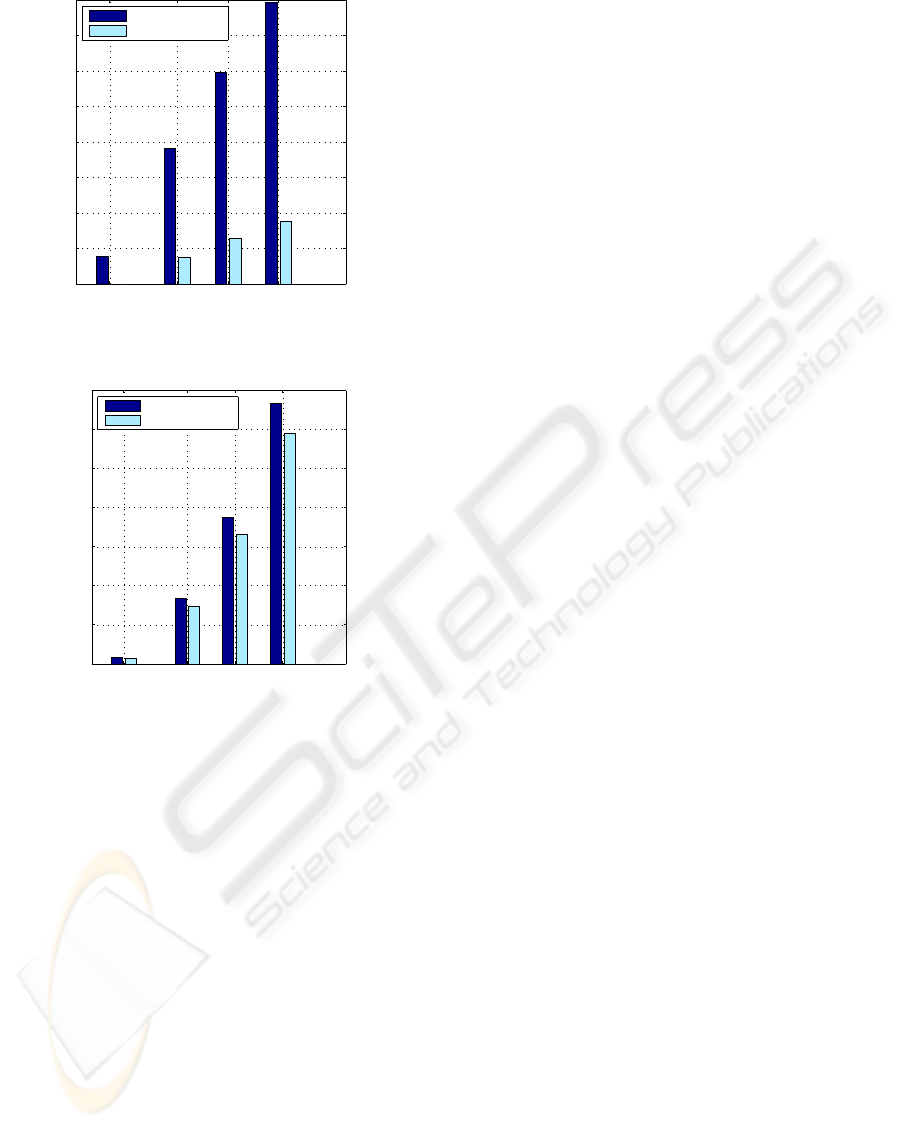

Figure 8. The benefit of the optimised cam function

can be better appreciated from Figure 9, where the

reduction in peak to peak torque variations are 99%,

80%, 78%, and 78% for the crank speeds of 100, 300,

450, and 600 rpm respectively.

Although it is not included in the optimisation pro-

cess, the optimised velocity cam functions also reduce

the maximum drive motor power requirements com-

pared with the constant velocity signal case as shown

in Figure 10.

4 CONCLUSIONS

This paper demonstrates the benefit of using a veloc-

ity cam function as a velocity demand signal to reduce

the peak to peak actuation torque of a servo driven

mechanism. The drivesystem parameters were identi-

fied using experimental data, and then combined with

0 90 180 270 360

0.6

0.8

1

1.2

100 rpm

Crank Velocity

0 90 180 270 360

0.6

0.8

1

1.2

300 rpm

0 90 180 270 360

0.6

0.8

1

1.2

450 rpm

Crank position (degrees)

Crank Velocity

0 90 180 270 360

0.6

0.8

1

1.2

600 rpm

Crank position (degrees)

Figure 7: Normalised crank velocity output at different

crank speeds (solid: constant reference, dashed: shaped ref-

erence).

0 90 180 270 360

0.4

0.6

0.8

1

1.2

1.4

100 rpm

Motor Torque (Nm)

0 90 180 270 360

0

1

2

3

4

5

300 rpm

0 90 180 270 360

0

2

4

6

8

450 rpm

Crank position (degrees)

Motor Torque (Nm)

0 90 180 270 360

0

2

4

6

8

10

600 rpm

Crank position (degrees)

Figure 8: Drive torque at different crank speeds (solid: con-

stant reference, dashed: shaped reference).

a nonlinear dynamic model of the mechanism. The

identification was carried out at a crank speed of 100

rpm. The accuracy of the computer model has been

verified using experimental results. Utilising the com-

puter model, a three-stage synthesis of the velocity

demand cam functions has been performed at much

higher operational speeds up to 600 rpm. The results

show that a reduction in peak to peak actuation torque

of as much as 80% can be achieved at high speeds

without significantly affecting the speed response of

the system. Although no effort has been made to min-

imise the energy consumption, sizable reductions in

the maximum motor power requirements have also

been predicted.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

186

100 300 450 600

0

1

2

3

4

5

6

7

8

Crank speed (rpm)

Peak to peak variation (Nm)

constant demand

shaped demand

Figure 9: Peak to peak drive torque variations at different

crank speeds.

100 300 450 600

0

200

400

600

800

1000

1200

1400

Crank speed (rpm)

Maximum power requirement (W)

constant demand

shaped demand

Figure 10: Maximum drive power requirements at different

crank speeds.

ACKNOWLEDGEMENTS

The authors acknowledge the support of the Engi-

neering and Physical Sciences Research Council (EP-

SRC) of the U.K. and the industrial partner ITCM,

Coventry, UK through the EPSRC Industrial Case

Studentship Award Voucher No: 05002188.

REFERENCES

Alici, G. and Shirinzadeh, B. (2006). Optimum dynamic

balancing of planar parallel manipulators based on

sensitivity analysis. Mechanism and Machine Theory,

41(12):1520–1532.

Cabrera, J. A., Simon, A., and Prado, M. (2002). Opti-

mal synthesis of mechanisms with genetic algorithms.

Mechanism and Machine Theory, 37(10):1165–1177.

Connor, A. M., Douglas, S. S., and Gilmartin, M. J. (1998).

The use of harmonic information in the optimal syn-

thesis of mechanisms. Journal of Engineering Design,

9(3):239–249.

Conte, F. L., George, G. R., Mayne, R. W., and Sadler,

J. P. (1975). Optimum mechanism design combining

kinematic and dynamic-force considerations. Journal

of Engineering for Industry-Transactions of the Asme,

97(2):662–670.

Hansen, J. M. (2002). Synthesis of mechanisms using

time-varying dimensions. Multibody System Dynam-

ics, 7(1):127–144.

Hazlerigg, A. D. G. and Sahinkaya, M. N. (1984). Com-

puter aided design of non-linear systems. In ACC 84

Conference, pages 1498–1503.

Kochev, I. S. (2000). General theory of complete shaking

moment balancing of planar linkages: a critical re-

view. Mechanism and Machine Theory, 35(11):1501–

1514.

Laribi, M. A., Mlika, A., Romdhane, L., and Zeghloul, S.

(2004). A combined genetic algorithm-fuzzy logic

method (ga-fl) in mechanisms synthesis. Mechanism

and Machine Theory, 39(7):717–735.

Lee, T. W. and Cheng, C. (1984). Optimum balancing

of combined shaking force, shaking moment, and

torque fluctuations in high-speed linkages. Jour-

nal of Mechanisms Transmissions and Automation in

Design-Transactions of the Asme, 106(2):242–251.

Liu, Y. and Xiao, R. B. (2005). Optimal synthesis of mech-

anisms for path generation using refined numerical

representation based model and ais based searching

method. Journal of Mechanical Design, 127(4):688–

691.

Price, K. and Storn, R. (2006). Differential evolution (DE),

http://www.icsi.berkeley.edu/ storn/code.html. Elec-

tronic Citation.

Rastegar, T. and Yuan, L. (2002). A systematic method for

kinematics synthesis of high-speed mechanisms with

optimally integrated smart materials. Journal of Me-

chanical Design, 124(1):14–20.

Sahinkaya, M. N. (2004). Inverse dynamic analysis of mul-

tiphysics systems. Proceedings of the Institution of

Mechanical Engineers Part I- Journal of Systems and

Control Engineering, 218(I1):13–26.

Sahinkaya, M. N., Rayner, R. M. C., Vernon, G., Shirley,

G., and Aggarwal, R. K. (2007). Synthesis of demand

signals for high speed operation of a packaging mech-

anism. In ASME International Design Engineering

Technical Conferences & Computers and Information

in Engineering Conference (IDETC).

Saxena, A. (2005). Synthesis of compliant mechanisms for

path generation using genetic algorithm. Journal of

Mechanical Design, 127(4):745–752.

Shiakolas, P. S., Koladiya, D., and Kebrle, J. (2005). On the

optimum synthesis of six-bar linkages using differen-

tial evolution and the geometric centroid of precision

positions technique. Mechanism and Machine Theory,

40(3):319–335.

Yuan, L. F. and Rastegar, J. S. (2004). Kinematics synthe-

sis of linkage mechanisms with cam integrated joints

for controlled harmonic content of the output motion.

Journal of Mechanical Design, 126(1):135–142.

SYNTHESIS OF VELOCITY REFERENCE CAM FUNCTIONS FOR SMOOTH OPERATION OF HIGH SPEED

MECHANISMS

187