EXPERIMENTAL OPEN-LOOP AND CLOSED-LOOP

IDENTIFICATION OF A MULTI-MASS

ELECTROMECHANICAL SERVO SYSTEM

Usama Abou-Zayed, Mahmoud Ashry and Tim Breikin

Control Systems Centre, The University of Manchester, PO BOX 88, M60 1QD, U.K.

Keywords: System identification, black-box model, recursive least square algorithm, local optimal controller, and

multi-mass servo systems.

Abstract: The procedure of system identification of multi-mass servo system using different methods is described in

this paper. Different black-box models are identified. Previous experimental results show that a model

consisting of three-masses connected by springs and dampers gives an acceptable description of the

dynamics of the servo system. However, this work shows that a lower order black-box model, identified

using off-line or on-line experiments, gives better fit. The purpose of this contribution is to present

experimental identification of a multi-mass servo system using different algorithms.

1 INTRODUCTION

An important step in designing a control system is

proper modeling of the system to be controlled. An

exact system model should produce output responses

similar to those of the actual system. The complexity

of most physical systems makes the development of

exact models infeasible. Therefore, in order to

design a controller that is reliable and easy to

understand in practice, simplified system models

should be obtained around operating points and\or

model order reduction (Ziaei, 2000).

System identification is an established modeling tool

in engineering and numerous successful applications

have been reported. The theory is well developed

(Ljung, 1999; Soderstrom, 1989), and there are

powerful software tools available, e.g., the System

Identification Toolbox (SIT) (Ljung, 1997).

Different physical models of electromechanical

servo systems based on multi-mass representation

were discussed in (Abou-Zayed, 2008). Using grey-

box off-line identification, inertial parameters and

parameters describing flexibilities were identified.

The physical parameters estimates showed no

variations in the mechanical parameters, and

acceptable variations in the electrical parameters.

Experimental results in (Abou-Zayed, 2008) show

that a model consisting of three masses connected by

springs and dampers gives an acceptable description

of the dynamics of the servo system. However, this

model is a six-order state-space model.

The objective of this paper is to present our recent

experimental studies on black-box open-loop and

closed-loop identification of a three-mass

electromechanical system. The closed-loop tests are

performed using a local-optimal controller.

The paper is organized as follows. In section 2,

the servo system is described briefly. In Section 3,

the results of black-box off-line identification are

presented. On-line open-loop and closed-loop

identification of the studied system is discussed in

section 4. Finally, Section 5 contains some

conclusions.

2 EXPERIMENTAL SETUP

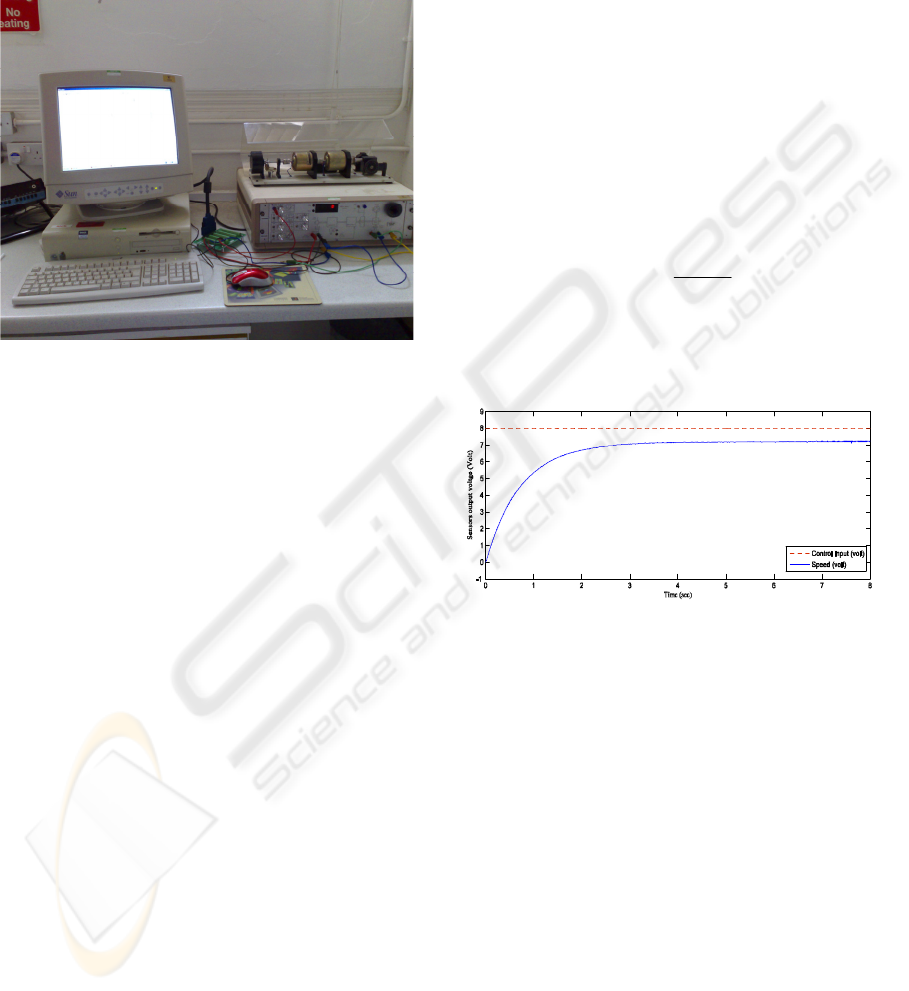

A view from the experimental setup is shown in

Fig.1. The DC servo mechanism setup to be studied

operates at ±10V input voltage with a permissible

output motor shaft speed of 2200 r.p.m. The shaft is

connected to an inertial load through a coupling gear

with ratio (r=1/30).The load shaft carries an absolute

position sensor with linear range ±10V. A personal

computer PC (Pentium III, 700 MHz, 256 MB

RAM), running the MATLAB software, is

188

Abou-Zayed U., Ashry M. and Breikin T. (2008).

EXPERIMENTAL OPEN-LOOP AND CLOSED-LOOP IDENTIFICATION OF A MULTI-MASS ELECTROMECHANICAL SERVO SYSTEM.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - SPSMC, pages 188-193

DOI: 10.5220/0001502601880193

Copyright

c

SciTePress

connected to the servo system setup through a data

acquisition card. This PC is used as a signal

generator for the servo system input. It also used as a

data logger to store the relevant system parameters

at fixed sample time. The third function is a digital

controller for closed-loop identification purposes.

Figure 1: Experimental setup.

The DC servo system setup, shown in Fig.1 can be

viewed as single input single output (SISO) for the

present case, where the motor armature voltage

a

v

is the input, while the output is the angular position

of the load

L

θ

. Since the measurement noise is

fairly small, a reasonable estimate of the load

angular speed

L

ω

is obtained for the identification

purpose. Therefore, the load angular speed will be

used as the output signal.

3 OFF-LINE IDENTIFICATION

OF SERVO SYSTEM

This section presents the results of the study and

realization of the off-line identification of servo

systems for different types of models with different

excitations. First, some dynamical properties of the

system are obtained using the process reaction curve

method. Then, black-box models, describing the

system, are identified.

3.1 Process Reaction Curve

Identification

It is one of the widely used approaches to

predetermine the dynamic behaviour of a system

before performing the data collection for system

identification. An input step signal change is applied

to the system, and the output response is measured.

Rise time, settling time, bandwidth, time constant,

time delay, and type of response can be determined

using the Process reaction curve (Ziegler, 1942).

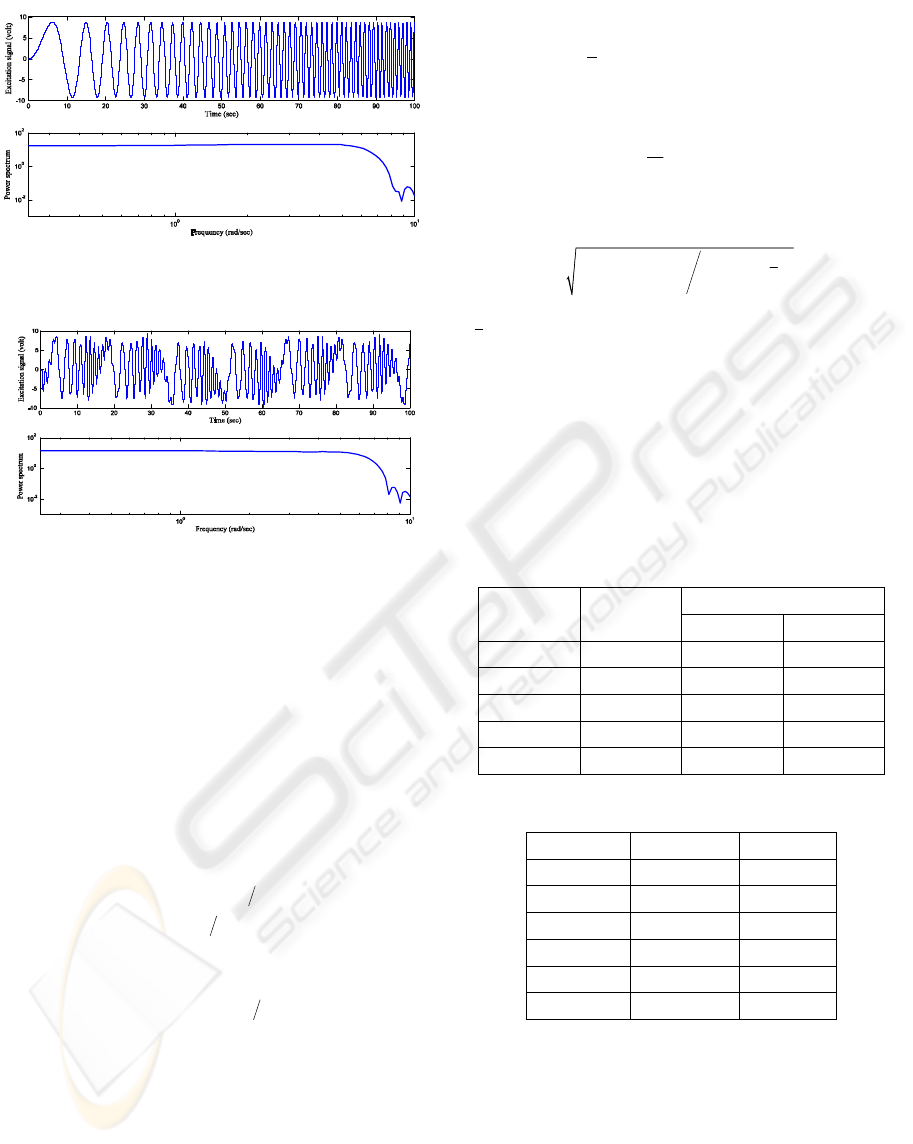

System step response is shown in Fig.2. The sample

time chosen for this step test is 0.01sec to observe

the system dynamical behaviour. An 8V input

voltage (dashed line) is applied to the system. The

output response (solid line) acts like a first order

plus time delay system with average steady state

output 7.18V, rise time about 1.4sec, and bandwidth

around 1.6rad/s. Using the process reaction curve

method the system can be modeled as in the classical

case:

()

1

Ts

d

Ke

Gs

s

τ

−

=

+

(1)

where K is the steady state gain (K = 0.898), T

d

is

the time delay (T

d

= 10 ms), and τ is the time

constant (τ = 0.73sec).

Figure 2: Output response of a step input change.

3.2 Experiment Design

The results of the identification experiments

reported here are based on two data sets where the

excitation signal has different character:

Set 1: A sum of 16 sinusoids with amplitude 1.8 and

equidistant spacing in frequency, between 0.1 and

6.1 rad/sec. The resulting crest factor (Ljung, 1999)

is 1.8 due to the Schroeder phase choice (Schroeder,

1970). The time response and power spectrum of the

set are shown in Fig.3.

Set 2: A linear swept-frequency sinusoidal signal

with amplitude 9 and time-varying frequency over a

certain band ranges from 0.1 to 6.1rad/sec over a

certain time period 100sec. The resulting input

signal has a crest factor 1.42, and shown in Fig 4.

EXPERIMENTAL OPEN-LOOP AND CLOSED-LOOP IDENTIFICATION OF A MULTI-MASS

ELECTROMECHANICAL SERVO SYSTEM

189

Figure 3: Multi-sine signal time response and power

spectrum.

Figure 4: Chirp sine signal time response and power

spectrum.

3.3 Black-box Transfer Function

Model Identification

The starting point is the general linear model

structure (Ljung, 1999),

,(,)()

y

(t)=G(q )u(t)+H q e t

θθ

(2)

where q denotes the shift operator.

Two different model structures will be studied, and

these are the ARX structure, defined by:

(, ) (,) (,),

(, ) 1 (,)

Gq Bq Aq

Hq Aq

θ

θθ

θθ

=

=

(3)

and the OE structure, where:

(, ) (,) (,),

(, ) 1

Gq Bq Fq

Hq

θ

θθ

θ

=

=

(4)

For the two model structures mentioned above, the

estimation of the model parameters will be carried

out generally using prediction error method (PEM).

The identification experiments are carried out using

the SIT (Ljung, 1997).

Tables 1, and 2 show the results of the estimated

models using data set1 for ARX and OE model

structures respectively. Both data sets show nearly

similar estimates. The notation (ModelStructure pzd)

denotes the p

th

order model with ‘z’ zeroes and

delay‘d’. The comparison is carried out using two

different quantities. The first is MSE as:

()

1

2

ˆ

() ()

1

N

M

SE y t y t

N

t

=−

∑

=

(5)

The second is the FIT:

() ()

()

()

()

22

ˆ

FIT 1 100%

11

NN

yt yt yt y

tt

⎛⎞

⎛⎞

⎜⎟

⎜⎟

=− − − ×

∑∑

⎜⎟

⎜⎟

⎜⎟

==

⎝⎠

⎝⎠

(6)

y is the mean value of the measured output.

Using k-step ahead predictors

ˆˆ

(| ;)yyttk

k

θ

=−

.The

two extreme predictors is defined as:

()()() () ()

11

ˆ

() 1

1

ytHqGqut Hqyt

−−

⎡⎤

=+−

⎢⎥

⎣⎦

(7)

()()

ˆ

()ytGqut=

∞

(8)

Table 1: Comparison of black-box ARX models.

fit

(

cross validation

)

%

Model MSE×10

-3

k

=1

k

=∞

ARX 211 5.95 96.01 85.80

ARX 311 2.29 97.72 80.25

ARX 411 0.76 98.44 84.28

ARX 511 0.58 98.76 83.00

ARX 611 0.35 99.03 82.50

Table 2: Comparison of black-box OE models.

Model MSE×10

-3

fit %

OE 211 39.90 85.53

OE 311 38.20 84.99

OE 321 38.30 84.98

OE 421 37.60 85.66

OE 611 37.70 85.72

OE 621 34.70 86.17

It is clear that for OE models, there is no difference

between both predictors. Otherwise, there is

considerable difference between them. The one-step

ahead predictor can give fits that “look good,” even

though the model may be bad. Therefore, the

simulation fit can be used for invalidating the bad

models.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

190

4 ON-LINE IDENTIFICATION OF

SERVO SYSTEM

4.1 Open-loop System Identification

Experiments are performed to find the discrete-time

model that can best represent the system using RLS

method. Let the system model is given in the form:

11

()() ()(1)Az yt Bz ut

−−

=

− (9)

where z

-1

is the back shift operator, and

112

()1

12

112

()

12

n

a

Az az az a z

n

a

n

b

Bz b bz bz b z

on

b

−

−−−

=+ + + +

−

−−−

=+ + + +

""

""

(10)

A model of the system in (9) can be presented in the

form of

() ()

T

yt t

ϕ

θ

=

(11)

where

θ

is a vector of unknown parameters defined

by:

,,,,,

1

T

aab b

no n

ab

θ

⎡⎤

=

⎣⎦

"" ""

(12)

and φ is a vector of regression which consists of

measured values of inputs and outputs

( ) ( 1), , ( ), ( 1), , ( 1)

T

t yt yt n ut ut n

ab

ϕ

⎡⎤

=− − − − − − −

⎣⎦

"" "" (13)

The model given in (11) presents an accurate

description of the system. However, in this

expression the vector of system parameters

θ

is

unknown. It is important to determine it by using

available data in signal samples at system output and

input. For that purpose a model of the system is

supposed

ˆ

ˆ

() () ( 1)

T

yt t t

ϕθ

=− (14)

For the RLS algorithm to be able to update the

parameters at each sample time, it is necessary to

define an error. The model prediction error, ε(t) is a

key variable in RLS algorithm and is defined as

ˆ

ˆ

() () () () () ( 1)

T

tytytyt tt

εϕθ

=−=− − (15)

The error ε(t) is the difference between the system

output and the estimated model output. This model

prediction error is used to update the parameter

estimates as

ˆˆ

() ( 1) () () ()tt Pttt

θθ ϕε

=−+

(16)

where the estimator covariance matrix P(t) is

updated using

1

() () ( 1)

() ( 1)

() ( 1) ()

T

ttPt

Pt Pt I

p

T

tPt t

ϕϕ

λ

λϕ ϕ

⎡

⎤

−

⎢

⎥

=−−

⎢

⎥

+−

⎣

⎦

(17)

where the subscript ‘p’ is the dimension of the

identity matrix, p=n

a

+n

b

+1, λ is the forgetting

factor, 0<λ≤1. The property of the forgetting factor,

λ, is that λ controls the speed of parameter

convergence: λ=1 yields the slowest speed, but

provides the best robustness towards noise, and

decreasing values of λ result in increasing speed of

parameter convergence. In general, choosing

0.98<λ<0.995 gives a good balance between

convergence speed and noise susceptibility

(Alexander, 2001).

Application of RLS method demands supposition of

the initial values of P(t) and

ˆ

()t

θ

. The technique

which is chosen as estimates and then allowed to

settle to their final values as the program goes

through several iterations. There is no unique way to

initialize the algorithm. One suggestion is using a

supposition that the system is an integrator of the

first order with unit gain to set

ˆ

(0)

θ

. While, a

standard choice of P(0) is the unit matrix scaled by a

positive scalar α, (i.e. P(0)=αI

p

), where α is

recommended to be chosen 1<α<10

3

depending on

the existence of prior knowledge about the system

parameters (Wellstead, 1991).

A square wave perturbation signal with a frequency

of approximately 0.2 of the system bandwidth

ensures that most of the square wave power,

associated with the first three harmonic components,

is inside the system bandwidth. A square wave

perturbation signal with a frequency of f=0.05Hz

that is superimposed on a step signal was applied to

the system input. The RLS algorithm is implemented

for experimental tests using SIMULINK and real-

time windows target.

Table 3: MSE for different estimated models.

Order 1

st

2

nd

3

rd

4

th

5

th

MSE 0.00617 0.00368 0.00357 0.00355 0.00392

For comparison purposes, Table 3 shows the MSE

calculated for different model orders. Third order

EXPERIMENTAL OPEN-LOOP AND CLOSED-LOOP IDENTIFICATION OF A MULTI-MASS

ELECTROMECHANICAL SERVO SYSTEM

191

model appears to be suitable for describing the

system. Further increase in the model order brought

no significant improvement.

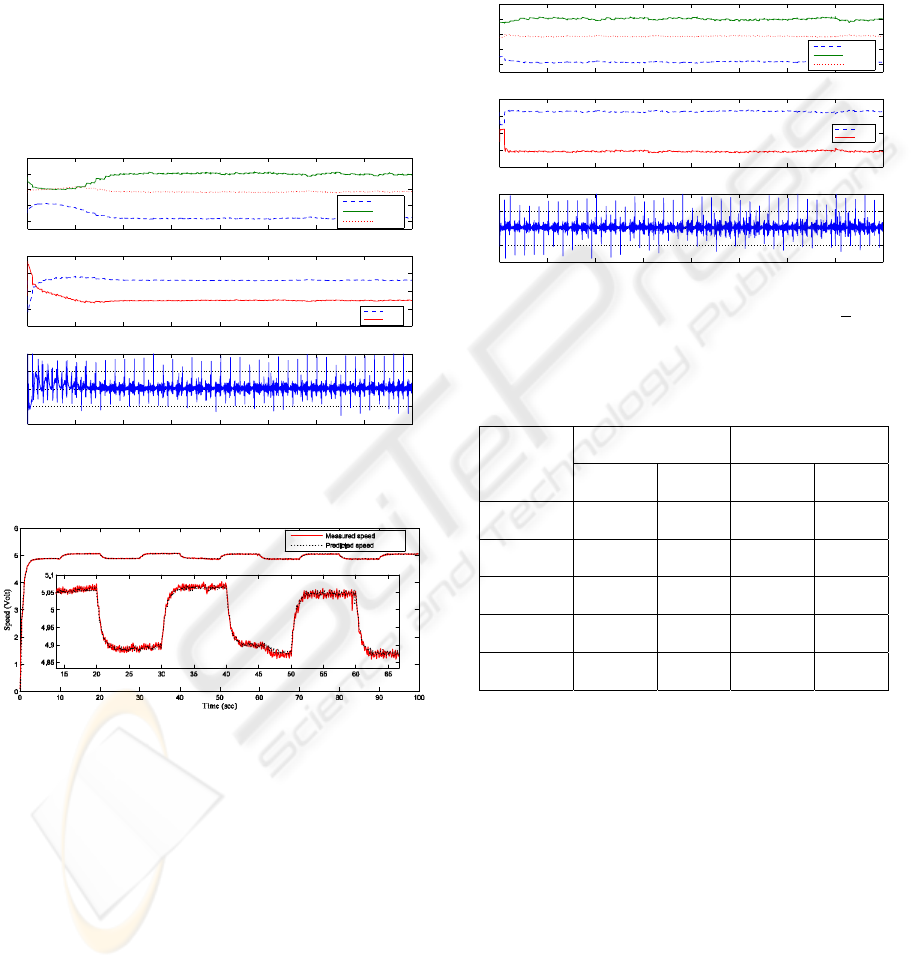

The performance of the estimated parameters and

the model output error for a third-order model are

shown in Fig. 5. Estimated parameters converge

after a certain time. The speed of parameter

convergence depends on the forgetting factor used.

Faster parameter convergence can be obtained if the

value of the forgetting factor is reduced, but noise

amplification. The measured system output and

predicted model output is shown in Fig. 6. It can be

seen that both output signals are in good agreement.

0 50 100 150 200 250 300 350 400

−0.2

−0.1

0

0.1

0.2

Time [Sec]

(c) Error signal

0 50 100 150 200 250 300 350 400

−2

−1

0

1

2

(a) Output parameters

0 50 100 150 200 250 300 350 400

−0.4

−0.2

0

0.2

0.4

(b) Input parameters

b1hat

b2hat

a1hat

a2hat

a3hat

Figure 5: Open-loop estimated parameters for 3rd order

model.

Figure 6: Measured and predicted speed for 3rd order

model.

4.2 Closed-loop System Identification

Closed-loop identification using direct method is

considered in this section. Knowledge of the

controller or the nature of the feedback is not a

certain requirement. A local-optimal controller

(Abou-Zayed, 2008) that provides stable closed-loop

servo operation is implemented, using SIMULINK

and real-time windows target.

The estimated parameters for the third-order model

are shown in Fig. 7. The parameters converge faster

than open-loop identification. Further, the variations

in the estimated parameters are smaller than that

obtained from the open-loop identification. This

phenomenon is due to the closed-loop feedback

control since the local-optimal controller filters high

frequency signal components and limits the

bandwidth.

0 50 100 150 200 250 300 350 40

0

−0.2

−0.1

0

0.1

0.2

Time [Sec]

(c) Error signal

0 50 100 150 200 250 300 350 40

0

−0.2

−0.1

0

0.1

0.2

(b) Input parameters

0 50 100 150 200 250 300 350 40

0

−2

−1

0

1

2

(a) Output parameters

b1hat

b2hat

a1hat

a2hat

a3hat

Figure 7: Closed-loop estimated parameters for 3

rd

order

model.

Table 4: Estimated parameters of third-order model for

open-loop and closed-loop experiments.

Open-loop Closed-loop

Parameters

Magnitude Variation Magnitude Variation

a

1

-1.821 0.204 -1.855 0.082

a

2

1.065 0.172 0.942 0.136

a

3

-0.122 0.144 -0.131 0.080

b

1

0.132 0.025 0.125 0.008

b

2

-0.105 0.029 -0.113 0.009

Table 4 shows the third-order parameters estimates

for both open-loop and closed-loop experiments. It

shows smaller variations for all parameters

estimated using closed-loop experiment. That comes

due to the closed-loop local-optimal control which

filters high frequency signal components and limits

the bandwidth

5 CONCLUSIONS

This paper presents theoretical and experimental

identification of a three-mass electromechanical

servo system using different algorithms. The aim of

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

192

this research is also to highlight some of the more

practical implications of plant identification and to

describe the well-established algorithm, recursive

least squares, used to perform system identification.

On-line open-loop and closed-loop identification of

the studied system is discussed. A real-time

implementation of the RLS estimator is presented

using SIMULINK and real-time windows target.

The application of the RLS method is also

demonstrated on a real-time experimental set-up

such that it is practical and easy to use. A third-order

discrete-time linear model is shown to be flexible

enough to fit the observations well. It also became

apparent that the order of the suitable linear model

was lower than the theoretical one. Closed-loop

identification gives faster parameters convergence

than open-loop identification. Further, the variations

in the estimated parameters are smaller than that

obtained from the open-loop identification. This

phenomenon is due to the closed-loop local-optimal

control which filters high frequency signal

components and limits the bandwidth.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the support of

this work by the EPSRC grant EP/C015185/1.

REFERENCES

Abou-Zayed, U., Ashry, M., & Breikin, T. (2008).

Implementation of local optimal controller based on

model identification of multi-mass electromechanical

servo system. Paper presented at the Proceedings of

the 27th IASTED International Conference on

Modelling, Identification, and Control.

Alexander, C. W., & Trahan, R. E. (2001). A comparison

of traditional and adaptive control strategies for

systems with time delay. ISA Transactions, 40(4),

353-368.

Ljung, L. (1997). System identification toolbox : for use

with MATLAB. Natick, Mass.: MathWorks Inc.

Ljung, L. (1999). System identification: theory for the

user. Upper Saddle River, N.J.; London: Prentice Hall

PTR: Prentice-Hall International.

Schroeder, M. (1970). Synthesis of low-peak factor signals

and binary sequences with low autocorrelation. IEEE

Trans. Inform. Theory, IT-16, 85-89.

Soderstrom, T. (1989). System identification. New York;

London: Prentice Hall.

Wellstead, P. E., & Zarrop, M. B. (1991). Self-tuning

systems: control and signal processing. Chichester:

Wiley.

Ziaei, K., & Sepehri, N. (2000). Modeling and

identification of electrohydraulic servos.

Mechatronics, 10(7), 761-772.

Ziegler, J. G., & Nichols, N. B. (1942). Optimum settings

for automatic controllers. Transactions of the ASME,

64, 759-768.

EXPERIMENTAL OPEN-LOOP AND CLOSED-LOOP IDENTIFICATION OF A MULTI-MASS

ELECTROMECHANICAL SERVO SYSTEM

193