APPLICATION OF A WEB-BASED EDUCATION SYSTEM IN

INDUSTRIAL PROCESSES

Perfecto Mariño, Miguel Ángel Domínguez and Santiago Otero

Electronic Technology Department, University of Vigo, Spain

Miguel Merino

Industrial Management Department, University of Vigo, Spain

Keywords: Technology-transfer, Multimedia Tool, Industrial Processes, University-enterprise Collaboration.

Abstract: The authors present a multidisciplinary project called PROPYME, which is a team effort of the University

of Vigo (Spain) and the FEUGA autonomous government foundation (Galicia, North West of Spain), both

supported by several industrial enterprises from the Information and Communication Technologies (ICT)

market. The main purpose of PROPYME project was to accomplish an innovative technology-transfer task

from university industrial researchers, to Small and Medium Enterprises (SME), for enhancing their

productivity by the automation of their industrial and management processes. This involves a SME´s effort

not only by a financial point of view, but adaptation, knowledge acquisition and organizational changes.

Moreover, embedding ICT´s involves adapting Enterprise Resource Planning (ERP) tools to integrate

vertically process and systems, owned by the SME itself, facing to decision challenges based on economic

value, knowledge and communication concepts. The PROPYME first phase is a portal Web with a

demonstration multimedia tool, text, graphics, animations, audio and video, that shows fifteen industrial

processes based on diverse technologies frequently used for industrial enterprises.

1 INTRODUCTION

The industrial sector should incorporate the

Information and Communication Technologies

(ICT) in the business processes. The automation of

industrial and management processes supposes an

improvement of the productivity in small and

medium enterprises. It supposes an enhancement of

the resources of a country and a major boost to the

progress. Thus, it is necessary design and implement

environments with the aim to transfer information

about industrial automation to enterprises.

This paper shows a multidisciplinary project

called PROPYME. It was promoted from the

University of Vigo (Spain) and FEUGA (Enterprise-

Galician University Foundation) autonomous

government foundation (Galicia, North West of

Spain). It was developed with the collaboration of

several industrial enterprises, which supported the

project with documentation about their industrial

processes and allowing the access to their

installations to get multimedia material (videos).

The first phase of this project is a portal Web

(www.procesospropyme.com) with a demonstration

multimedia tool that shows fifteen industrial

processes based on diverse technologies frequently

used for industrial enterprises. The first phase of

PROPYME was accomplished during two years

with the following tasks: coordination, specification

and development (2004); implementation and

diffusion (2005).

The structure of the multimedia tool is unique for

all industrial processes to ease its understanding.

This structure depicts the most of elements involved

in the introduction of these industrial processes.

Eight implementing elements are included as buttons

in a user-interface upper bar such as (from left to

right): business process, engineering project,

technologies, technological components,

implementation, complexity, applications and cost.

The tool also includes six icons in the user-interface

bottom bar to ease further advanced consults and

direct contact with the experts (researchers team

452

Mariño P., Ángel Domínguez M., Otero S. and Merino M. (2008).

APPLICATION OF A WEB-BASED EDUCATION SYSTEM IN INDUSTRIAL PROCESSES.

In Proceedings of the Fourth International Conference on Web Information Systems and Technologies, pages 452-455

DOI: 10.5220/0001514404520455

Copyright

c

SciTePress

biography, video, glossary, bibliography, regulations

or standards and team’s e-mail).

The seven concepts assessed in the development of

PROPYME´s multimedia tool were:

Demonstrate to the industrial businessman

about the importance and value provided by

ICTs to its business processes.

Have a global knowledge about advantages

and drawbacks using those technologies.

How estimate resources, difficulties, costs and

teaching needs facing organizational changes.

Learning the management of implementation

and maintenance about an automated industrial

process, assessing risks and trade-offs.

Providing an understandable knowledge about

university capabilities and ICT´s enterprises

that give the needed know-how to increase

productivity.

Rising of powerful knowledge elements to

provide a critical analysis about its own

organization.

Supplying the right decision-making

knowledge.

2 STRUCTURE OF PROPYME

The PROPYME multimedia tool constitutes an

environment where businessmen and professionals

related to industrial processes can improve their

knowledge about this area. In the present, the tool is

made up of fifteen topics related to industrial

processes: Industrial plant data acquisition,

electronic commerce, production automatic control,

digital dashboard (Jonhson, 2004), ergonomics in

the job (Kohn, 1997), quality management ISO

9001, international knowledge management

(Tapscott, 1999), maintenance management

(Nyman, 2001), environmental management ISO

14000, radiofrequency identification, electronic

instrumentation (Barlett, 2002), automatic

maintenance in production lines (Fowler, 1995),

setup time reduction (Claunch, 1996), traceability

and artificial vision (Jain, 1995).

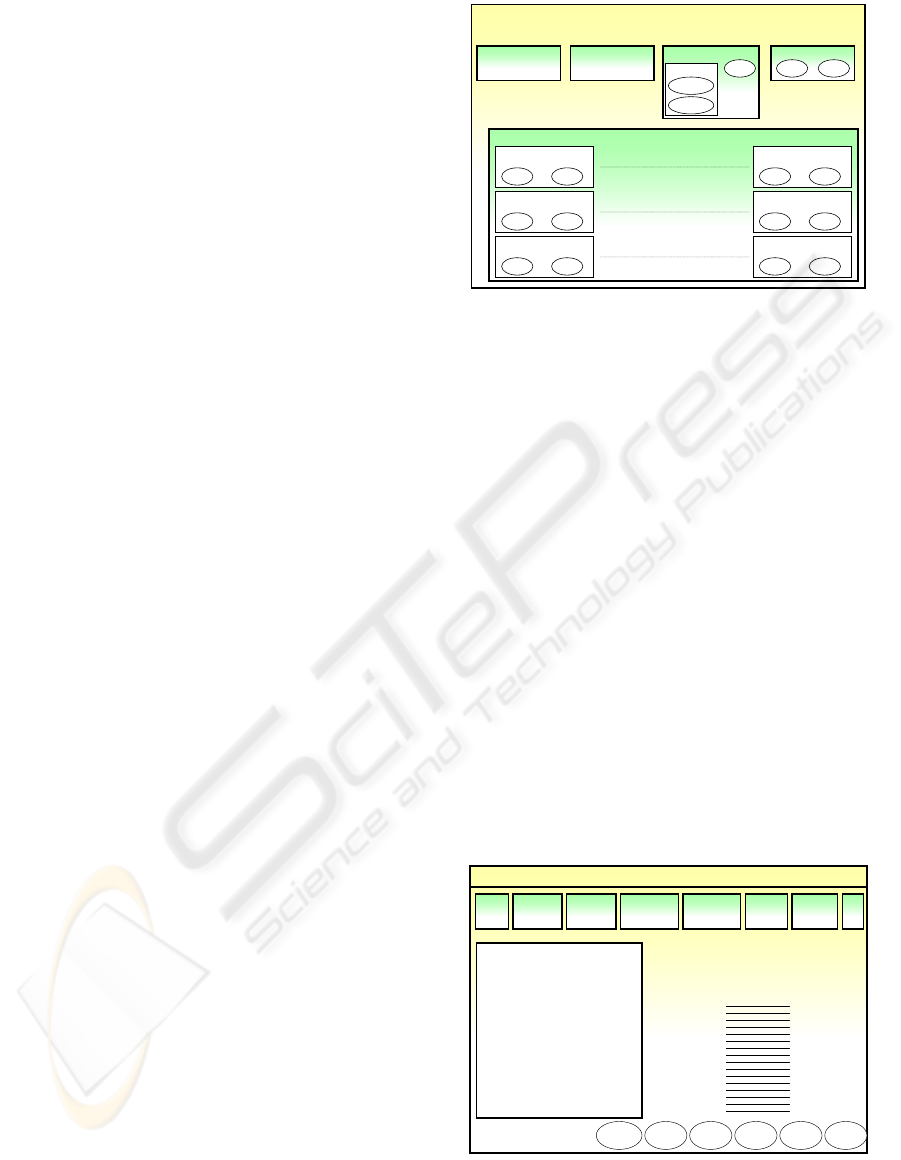

The structure of PROPYME web page is shown

in Figure 1.

MAIN PAGE

ProPyme

Explanatory text

Industrial processes

Industrial plant

data acquisition

Process Details

Quality managent

ISO 9000

Process Details

Ergonomics in job

Process Details

Authors

List of authors and

Information about them

Multimedia

Animation

Video

Descriptive

Explanatory

News

Late Previous

Electronic instrumentation

Process Details

Identification by

radio frequency

Process Details

Artificial vision

Process Details

Figure 1: Structure of PROPYME web page.

The user can see in an easy way a summary of every

industrial process included in the tool. The tool

shows one box for each process with a brief

description of the process and a descriptive

animation. Thus, the user can get the concept of the

process in a short time and in a friendly way. The

user can choice one process and see all the

information about it or only the details.

All the processes have the same structure to ease

its understanding. The access to the information of

the process is structured as it is shown in Figure 2.

The information is shown to the user in a

standardized way for all processes with the aim to

ease the use of the tool and reduce the time to get the

required information. This standardization is one of

the main advantages of this tool.

The user can access to different information

about the industrial process with the buttons placed

in the upper part of the user-interface. The

information is presented with an explanatory text

supplemented with an animation. The animations are

a very important contribution in this tool because

allow that the user understand the concepts better.

NAME OF THE PROCESS

Business

process

Engineering

project

Technologies

Technological

components

Implementation Complexity Applications Cost

ANIMATION

PROCESS

Explanatory test about the chosen item

Glossary Coordinator Video Bibliography Standard Contact

Figure 2: Components of the processes.

APPLICATION OF A WEB-BASED EDUCATION SYSTEM IN INDUSTRIAL PROCESSES

453

The user-interface enables the access to videos about

the selected topic. Videos are essential in any

multimedia tool because concepts that have a

difficult explanation with words are understood

better with a video about a real experience of an

industrial process including this concept.

Often, the explanatory texts of technical topics

include words or terms that their meanings are not

familiars. A complete glossary about industrial

processes terms has been development for this tool.

A lot of technical terms (bluetooth, fieldbus, data

logger, Electromagnetic Compatibility, etc.) are

defined in a clear and brief way. This glossary

supposes a considerable help for the user.

The tool also includes a complete bibliography

about every topic and information about standards so

that the users can deepen and increase their

knowledge.

3 EXAMPLE OF INDUSTRIAL

PROCESS

An example of an industrial process included in the

PROPYME tool is shown in this section to illustrate

better the philosophy of this environment.

The electronic instrumentation processes are

very important in the industry (Mariño, 2003). The

electronic instrumentation is a discipline dedicated

to measure any parameter, to converter these

parameters in electrical values and to manage these

values to provide the adequate information to a

control system, a human operator or both.

The multimedia PROPYME tool included

complete information about electronic

instrumentation, which is very important for

professionals in the field of the control systems. The

electronic instrumentation processes are described.

The user can get information about the aims,

main application fields, methodology for

implementation, used technologies, components,

requirements, development process, cost, application

examples and bibliography.

3.1 Business Process

The elements of an Electronic Instrumentation

System (EIS), aims, advantages, drawbacks and

main application fields are described in this section.

Each concept is illustrated by one video or

animation. For example, the user can see a video

about an electronic instrumentation system to

evaluate the injuries of persons in automobile

accidents. The video shows the crash of an

automobile against a wall. The automobile has

installed a crash test dummy with several sensors.

An instrumental laboratory captures data of these

sensors. The system also uses artificial vision to

extract data about the movement of the crash test

dummy and about the deformation of the automobile

Thus, report about injury levels in several body parts

and physical parameters (three axial acceleration,

force, moment of inertia, etc.) can be obtained.

3.2 Engineering Project

The engineering project informs to the user about

the project management (cost, profits, work

planning), methodology, enterprises of electronic

instrumentation and basic elements in an EIS. The

sequence of phases that should be followed in the

development of an EIS is:

Requirements for the implementation.

Element acquisition: selection of elements,

measurement processing and selection of

communication elements, visual display units,

actuators, etc.

Development process (viability).

Operation process (robustness).

3.3 Technological Components

One important concept in the EIS is the used

technologies and technological components. In these

sections, the user can get knowledge about the basic

components of an EIS, application fields, advantages

and drawbacks. A complete description of the

technological components taking part in an EIS and

different ways of integration of these components

are shown too.

3.4 Implementation and Complexity

The PROPYME tool explains in these sections the

development and operation processes and the

requirements for the implementation (specifications,

physical and human resources and applicability).

With respect to the complexity, the user can see that

an EIS is a set of diverse technologies. Knowledge

about electronic engineering, specialization on

physical, chemical, biological or environmental

phenomena, transducers, software engineering,

electrical engineering, system analysis,

communication engineering, mechanical engineering

and system integration are necessary to design,

install and implement an EIS in a satisfactory way.

WEBIST 2008 - International Conference on Web Information Systems and Technologies

454

3.5 Applications and Cost

Some interesting applications of EIS, such as

meteorology and communications and transformer

monitoring, are exposed in these sections.

The user can know as an EIS is used to

design a data acquisition system for meteorology

integrating millimetre bands radio communication.

This project was implemented in the North West of

Spain. The read of meteorological variables is made

with automatic data acquisition system using

elements distributed in the covered area of

meteorological radar. Figure 3 shows a map with the

localization of the system elements (weather radar,

WS: Weather Stations, CWN: Central Wireless

Node, SWN: Secondary Wireless Nodes).

There are strategic and tactical reasons to

justify an EIS. The cost of the system should take

into account the cash flow in the time (costs and

profits). The result is a calculation of the Return Of

Investment (ROI). Each application should be

considered and justified by its own merits.

The PROPYME tool shows the parameters to

take into account in the cost calculation. The user

can see an example of the cost calculation of an EIS

for transformers monitoring in electrical power

distribution substations.

4 CONCLUSIONS

This paper introduces the PROPYME project that is

a multidisciplinary work for innovative technology-

transfer in industrial automation.

Figure 3: Elements of the meteorological System.

The first phase of this project is a computer and

Web-based software with fifteen industrial

processes. Users can access to a complete

documentation about these industrial processes with

a continuous support by the authors. The main

advantages of this multimedia tool are:

A complete and classified documentation

about industrial automation processes.

The structure is unique for all processes, which

makes the access to the concepts easier.

The tool represents a great effort of

collaboration between university and

enterprises.

The animations and videos help to understand

the concepts in a friendly way.

ACKNOWLEDGEMENTS

The authors are grateful to the sponsors of

PROPYME project: University of Vigo, FEUGA,

IGAPE and COMUNITEL. We also want to

mention our debt to all industrial enterprises that

generously opened their facilities for filming real

video pictures about particular industrial processes,

providing us the necessary multimedia material for

developing this project.

REFERENCES

Barlett, T., 2002. Industrial control electronics, devices,

systems and applications, Thomson Learning.

Claunch, J., 1996. Set-up Time Reduction, Irwin.

Fowler, J., 1995. STEP for data management exchange

and sharing, Technology Approisals Ltd.,

Twickenham, UK.

Jain, R., Kasturi R., Schunck, B.G., 1995. Machine vision,

McGraw-Hill.

Jonhson, M., 2004. “Incoming intelligence”,

Computerworld, Vol. 38, Issue 25, p. 20.

Kohn, J.P., 1997. The ergonomic casebook: Real world

solutions, Lewis Publishers.

Mariño, P., 2003. Communications in enterprises:

Standards, networks and services (in Spanish), Ra-Ma,

2ª edition.

Nyman, L., 2001. Maintenance planning, scheduling and

coordination.

Tapscott, D. et al., 1999. Creating value in the network

esconomy, H.B.R. Book, Boston.

APPLICATION OF A WEB-BASED EDUCATION SYSTEM IN INDUSTRIAL PROCESSES

455