MULTIAGENT DESIGN FOR DYNAMIC JOB-SHOP

SCHEDULING USING PASSI

Claudio Cubillos, Silvana Roncagliolo and Leonardo Espinoza

Escuela de Ingeniería Informática, Pontificia Universidad Católica de Valparaíso, Av. Brasil 2241, Valparaíso, Chile

Keywords: AOSE, Planning & Scheduling, Agent System.

Abstract: The present work details the experience on designing a multiagent system devoted to a dynamic Job Shop

setting using the PASSI methodology. The agent system is in charge of the planning and scheduling of jobs

and their operations on a set of available machines, while considering the materials assigned to each

operation. Dynamicity concerns job orders scheduling on-the-fly and the re-schedule caused by changes to

the original plan due to clients, machines or material stocks. The system has been modeled with the PASSI

Toolkit (PTK) and implemented over the Jade agent platform.

1 INTRODUCTION

Agent paradigm has leveraged as an important

modeling abstraction, in areas such as web and grid

services, peer to peer and ambient intelligence

architectures just to mention some cases. In a

multiagent system (MAS) diverse agents

communicate and coordinate generating synergy to

pursue a common goal.

Hence as modeling artifact, agent-based systems

borrow their key characteristics from us, humans,

and our societies. This higher level of abstraction

has allowed agents to tackle the increasing

complexity of nowadays open software systems

where integration, transparency and interoperation

among heterogeneous components are a must.

For this technology to get more mature and

widespread, the use of agent-oriented software

engineering (AOSE) methodologies and tools are a

key factor of success. The present work describes

the design of a multiagent system using a particular

AOSE methodology called PASSI.

The chosen domain for the system corresponds

to the job-shop scheduling problem under a dynamic

scenario in which job requests coming from clients

must be processed on-the-fly and where changes can

occur due to changes in the environment (e.g.

materials stock-out), problems with the service (e.g.

machine delays or break down) or client

eventualities (e.g. due-date change, job

cancellation).

2 RELATED WORK

Diverse proposals of agent-based systems can be

found in literature tackling the job-shop or

production scheduling problem.

In (Fischer, 1994) Fischer proposed a hierarchical

planning structure consisting of six layers: the layer

of the production planning and control system, the

layer of the shop floor control system, the task

coordination layer, the task planning layer, the task

execution layer and the machine control layer.

In (Saad et al., 1995) a Production Reservation

approach was proposed by using a bidding

mechanism based on the Contract Net Protocol -

CNP (Smith, 1978) to generate the production plan.

Other recent CNP-based solutions can be found in

(Váncza, 2000) (Maturana et al., 1999) (Lim, 2002)

and (Usher, 2002).

In AARIA (Parunak et al, 1997), the

manufacturing capabilities (e.g. people, machines,

and parts) are encapsulated as autonomous agents

and use a mixture of heuristic scheduling techniques:

forward/backward scheduling simulation scheduling,

and intelligent scheduling.

In (Maturana et al., 1999) the adaptive multi-

agent manufacturing system architecture called

MetaMorph combined the CNP with mediator-

centric federation architecture was presented.

Although the above works mention the agent

approach for designing the overall system, neither

formal models nor AOSE methodologies are used

for their design mainly due to a lack of maturity

AOSE methodologies at that time.

288

Cubillos C., Roncagliolo S. and Espinoza L. (2008).

MULTIAGENT DESIGN FOR DYNAMIC JOB-SHOP SCHEDULING USING PASSI.

In Proceedings of the Fourth International Conference on Web Information Systems and Technologies, pages 288-291

DOI: 10.5220/0001528502880291

Copyright

c

SciTePress

Therefore, one of the contributions of the present

work is to provide a more formal design of

multiagent system devoted to passenger

transportation using the PASSI methodology, one of

the most relevant agent-oriented software

engineering methodologies nowadays.

3 THE DYNAMIC WORK-SHOP

PROBLEM

The traditional Job-Shop Scheduling Problem

(JSSP), can be described by a set of n jobs {J

j

}

1≤j≤n

which is to be processed on a set of m machines

{M

r

}

1≤r≤m

. Each job has a technological sequence of

machines to be processed. The processing of job J

j

on machine M

r

is called the operation O

jr

. Operation

O

jr

requires the exclusive use of M

r

for an

uninterrupted duration p

jr

, its deterministic

processing time, and each operation O

jr

has pre-

assigned materials {W

i

}

1≤i≤k

. In addition, each job has

a due-date {D

j

}

1≤j≤n

. A schedule is a set of

completion times for each operation {c

jr

}

1≤j≤n;1≤r≤m

that satisfies those constraints. The considered JSSP

involves the scheduling of n jobs J on the m

machines M and consuming k materials W while

minimizing the total tardiness regarding the due-

dates.

On the other hand, the dynamic variant of the

problem adds the fact that the jobs to be processed

are not known in advance and that they must be

scheduled as they arrive. In addition, environmental

changes can cause some events to happen, such as a

machine delay or breakdown, a client

canceling/modifying a job order, among others.

Therefore, the objective is to obtain a schedule that

also minimizes the number of non-placed jobs. It is

one of the most hard NP-complete combinatorial

optimization problems.

4 THE AGENT ARCHITECTURE

The multiagent job-shop scheduling system stands

over the Jade Agent Platform (Bellifemine et al.,

1999), and was modelled with PASSI, an agent-

oriented software development methodology,

supported by the PASSI ToolKit (PTK, 2005) to be

used as an add-in for Rational Rose.

4.1 Agent Identification (A.Id.)

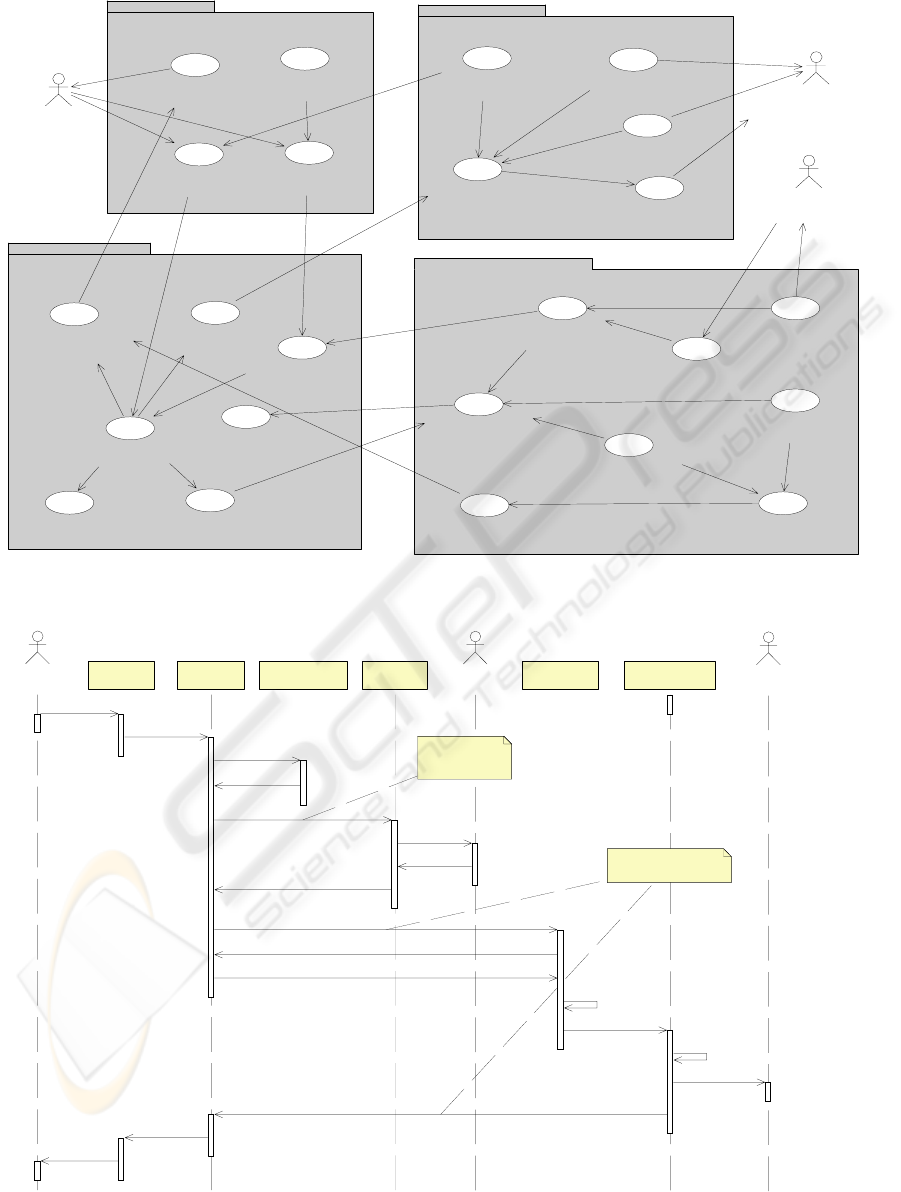

The diagram in Figure 1 shows the identified use

cases for this job-shop system and the leveraged

agents.

Firstly, the Client agent is a GUI agent in charge

of the communication between an actual client and

the rest of the system, providing the possibility of

generating a job order, and to communicate

inbound/outbound eventualities regarding such order

due to changes in the environment (e.g. order

modification/cancellation from client, order

delay/reject from the system).

Order agents are devoted to the job order

management, its breakdown into operations, the

request of necessary materials for each operation

execution to Stock agents, and the request to

Machine agents for the scheduling of each operation.

Machine agents encapsulate each real machine,

being primarily in charge of its schedule

management. This involves processing requests

coming from Order agents and performing the

scheduling process. It also manages eventualities

that can cause schedule changes due to the machine

itself (e.g. delay or breakdown), due to material

supply problems (e.g. delay on delivery), or even

due to client changes (e.g. order cancellation or

modification). For all the above, it carries out a

search in the solutions state space by implementing

an optimization heuristic. In the actual system, a

search algorithm presented by (Yoo et al., 2002),

inspired in simulated annealing was implemented.

Finally, Stock agents main goal are to maintain

adequate levels of materials by generating supply

orders (to the Stock Administrator), and to provide

the necessary materials for the execution of each

operation.

4.2 Roles Identification (R.Id.)

Roles Identification consists in exploring all the

possible paths of the preceding Agents'

Identification Diagram in Figure 2. In fact, each

“<<communicate>>” relationship among two agents

can be in one or more scenarios showing interacting

agents working together to achieve certain desired

system behavior.

As example, the following Figure 3 shows the

scenario in which the Client actor requests the

system to process its job. Each object in the diagram

is described following the <role>:<agent>

convention.

This scenario involves all actors and agents in the

system. It starts with the Client requesting its order

processing through the GUI (Client agent), the

interface generates a JobOrder with all the details

and forwards the request to the manager role of the

Order agent. This agent breaks down the job

obtaining an Operation List containing the sequence

of required operations and related materials. The

manager role requests the Stock agent for the

availability of the materials needed for each Opera-

MULTIAGENT DESIGN FOR DYNAMIC JOB-SHOP SCHEDULING USING PASSI

289

Order Agent

<<Agent>>

Client Agent

<<GUI Agent>>

Stock Agent

<<Agent>>

Machine Agent

<<Agent>>

Stock Administrato

(from 01-Domain Des...

)

Material check-out

(from Stock Agent)

Stock Lev el Determining

(f rom St ock Agent )

Material Request

(f rom St ock Agent )

Stock Management

(f rom St oc k Agent )

<<extend>>

<<include>>

<<extend>>

Inform Assignment

(f rom Client Agent )

Generate Material

(f rom St oc k Agent )

<<ext end>>

Orden Deletion

(f rom Client Agent )

Client

(from 01-Dom

a

...)

Div ide Job Order

(f rom O rder Agent )

Request Materials

(f rom O r der Agent )

<<communic ate>>

Generate Order

(f rom Client Agent )

<<communic ate>>

Inf orm Operations Plan

(f rom Mac hine Ag. . .

Machine's Operations Plan

Management

(f rom Machine Ag. ..

<<include>>

Order Modif ication

(f rom Client Agent )

<<extend>>

Send Processing Request

(f rom O rder Agent )

Perf orm Modif ication

(f rom Machine A g. ..

<<include>>

Operation Assignment

(f rom Machine A g. ..

<<include>>

Prov ide Order Inf ormat ion

(f rom O rder Agent )

Manage Order Ev ents

(f rom O r der Agent )

<<communic ate>>

Requests Processing

(f rom Machine Ag. ..

<<communic ate>>

<<extend>>

<<extend>>

<<communicate>>

Schedule Changes

Notification

(from Machine Ag...

Operator GUI

(from 01-Dom

a

...)

Mac hine Ev ent s

Management

(f rom Machine Ag. . .

<<communicate>>

<<extend>>

<<extend>>

Schedule Changes

Communication

(f rom Mac hine Ag. . .

<<extend>>

Scheduled Operations'

Management

(f rom O rder Agent )

<<communicate>>

Manage Job Order

(f rom O r der Agent )

<<include>>

<<include>>

<<include>>

<<include>>

<<include>>

<<communic ate>>

Figure 1: Agent Identification Diagram for the Job-shop scheduling system.

Scheduler :

Machine Agent

Scheduler :

Machine Agent

: Client: Client

Interf ace :

Client Agent

Interf ace :

Client Agent

Manager :

Order Agent

Manager :

Order Agent

Breakdown

Manager : Or...

Breakdown

Manager : Or...

Prov ider :

Stock Agent

Prov ider :

Stock Agent

: Stock

Administrator

: Stock

Administrator

Reques t Manager

: Machine Agent

Reques t Manager

: Machine Agent

: Operator GUI : Operator GUI

1: Request Order Processing

2: Send Order (JobOrder)

3: Get Operations (JobOrder)

4: Send Operations (Operations List)

5: Request Materials (Operation)

8: Conf irm Stock Lev el (St ock Lev el)

6: Check Stock (Material)

7: Actual Stock (Stock level)

9: Send Schedule Request (Operation)

10: Check Order Status

for each

operation within

the job order

11: Send Order Status (Order Status)

13: Assign Operation (Operation)

14: Update Operation Plan

12: Sequence Operation (Actual Start Time)

15: Inf orm Operation Plan (Machine Sc hedule)

16: Inf orm Operation Sc hedule (Actual Start Time)

f or each operation

within the job order

17: Conf irm Job Order Schedule (Finish Date)

18: Job Order Processing Inf ormed

Figure 2: Roles Identification Diagram for the “Client Requests Job Processing” scenario.

WEBIST 2008 - International Conference on Web Information Systems and Technologies

290

tion. On its turn, the Stock agent checks the Stock

Level of each item in the operation’s Material List

and reserves the required amount.

With the materials availability confirmation the

Order agent starts sequentially requesting Machine

agents to schedule their operations. The scheduler

role of the Machine calls the optimization heuristic

to search for feasible alternatives selecting the best

one according to the active UtilityFunction. Once

found, the operation is programmed into the actual

MachineSchedule, then new operation schedule is

informed to the operator (through the Operator GUI

actor) and the corresponding Order agent is

informed about the scheduled operation indicating

its Actual Start Time.

Finally, once all operations successfully

scheduled, the Order agent informs the Client about

the FinishDate for the entire job.

5 CONCLUSIONS

The design of an agent-based software architecture

for dynamic job shop scheduling was described.

The agent formalization with PASSI promotes

the system maintainability, its ability to cope with

newer requirements and the possibility to scale and

integrate other actors and systems.

Next steps consider the implementation of diverse

scheduling algorithms (e.g. genetic algorithm, tabú

search, SA) for job-shop in order to refine and

demonstrate the extensibility of our solution.

ACKNOWLEDGEMENTS

This work is part of Project No. 209.746/2007

entitled “Coordinación en una sociedad

multiagentededicada a la programación y control

bajo ambiente dinámico”, funded by the Pontifical

Catholic University of Valparaíso (www.pucv.cl).

REFERENCES

Bellifemine, F. et al. 1999. JADE - A FIPA Compliant

Agent Framework. C-SELT Internal Technical Report.

Burrafato, P., and Cossentino, M. 2002. Designing a

multiagent solution for a bookstore with the PASSI

methodology. In 4th International Bi-Conference

Workshop on Agent-Oriented Information Systems

(AOIS-2002).

Fischer, K. 1994. The design of an intelligent

manufacturing system. Proc. of CKBS’94, University

of Keele, England, pp. 83–99.

Lim, M. K. and Zhang, Z. 2002. Iterative multi-agent

bidding and co-ordination based on genetic algorithm.

Proceeding of 3 Complex Systems, and E-Businesses,

Erfurt, pp. 682--689.

Maturana F, Shen Weiming, Norrie D. 1999. MetaMorph:

an adaptive agent-based architecture for intelligent

manufacturing. International Journal of Production

Research, 37: 2159-2173,.

Parunak, H.V.D., Baker, A.D. And Clark, S.J. 1997. The

AARIA agent architecture: an example of

requirements-driven agent-based system design. Procs.

1st Int. Conf. on Autonomous Agents, Marina del Rey,

CA.

PTK. 2007. The PASSI Toolkit (PTK) Available at

http://sourceforge.net/projects/ptk. Accessed on

09/10/2005

Saad, A., Biswas, G., Kawamura, K., Johnson, M. E.

Salama, A. 1995. Evaluation of contract net-based

heterarchical scheduling for flexible manufacturing

systems. Procs. Int. Joint Conf. on Artificial

Intelligence, Workshop on Intelligent Manufacturing,

Montreal, Canada, pp. 310-321.

Smith, R. G. and R. Davis. 1978. Distributed Problem

Solving: The Contract Net Approach. Proceedings of

the 2nd National Conference of the Canadian Society

for Computational Studies of Intelligence.

Usher, J.M. 2002. Negotiation-based Routing in Job Shops

via Collaborative Agents. World Manufacturing

Congress, Distributed Intelligence in Technology,

Economic and Social Applications: An International

Symposium, Workshop on Agent-Based Process

Planning and Scheduling, Rochester, New York.

Váncza, J. and Márkus, A. 2000. An agent model for

incentive-based production scheduling. Computers in.

Industry, Vol. 43, Issue 2,pp. 173-187.

Yoo, M. J., Müller, J. P. “Using Multi-agent System for

Dynamic Job Shop Scheduling”. 4th Int. Conf. on

Enterprise Information System (ICEIS 2002), Ciudad

Real, Spain, April 2002.

MULTIAGENT DESIGN FOR DYNAMIC JOB-SHOP SCHEDULING USING PASSI

291