AN ONTOLOGY-BASED APPROACH TO SUPPORTING

DEVELOPMENT AND PRODUCTION OF MICROSYSTEMS

Process-Related Documentation for Process and Application Knowledge

Management in Microsystems Technology

Markus Dickerhof

1

, Oliver Kusche

1

, Daniel Kimmig

1

and Andreas Schmidt

1, 2

1

Forschungszentrum Karlsruhe, Institute for Applied Computer Science Hermann-v.-Helmholtz-Platz 1, D-76344, Germany

2

University of Applied Sciences Karlsruhe, Dept. of Computer Science and Business Information Systems

Moltkestraße 30, D 76133 Karlsruhe, Germany

Keywords: Process knowledge management, Ontologies for technological process description.

Abstract: Knowledge about relations among process steps or dependencies of materials, technologies, designs, tools,

and machines is mostly stored in the product developer’s mind. This also happens when it is talked about

product-related knowledge and the respective technological requirements. This knowledge is lost, if the per-

son leaves the company. The present paper describes a knowledge management approach for a product-

independent description of microsystems processes and outlines a data modelling concept for process-

related information.

1 INTRODUCTION

Planning development and production today means

to proceed along economic and technical parameters

derived from product requirements and customer-

oriented business processes. During the last few

years, many efforts were taken to push “knowledge

management” in industry. The result often

represented not more than a new type of document

management with additional “meta” information on

top to meet the requirements of a company’s quality

management. Documentation of technological

capabilities in microsystems technology (MST)

often leads to a non-reusable, product-specific

documentation of a production design according to

the quality management guidelines. Hence, a lot of

information about the subjacent fabrication know-

how or relations among application requirements,

physical effects, technological constraints, and costs

is not documented or documented in an insufficient

manner. Insufficient in this context means

irretrievable or only customer project-related so that

it cannot be reused for new projects in terms of

Nonaka and Takeuchi’s Seci model (Nonaka and

Takeuchi, 1995). Knowledge of the relations among

process steps or dependencies of materials,

technologies, designs, tools, and machines is mostly

stored in the product developer’s mind. The same

also applies to product requirements and

technological capabilities. The knowledge is lost, if

the employee leaves the company. A fortiori

especially know-how in a key technology like MST

transfer is extremely expensive and time-consuming

for a company..

The present paper describes an approach to over-

co

ming some of the limitations in present MST

product development by providing a specific,

holistic modeling approach for microsystems

technology.

2 KNOWLEDGE MANAGEMENT

FOR MICROSYSTEMS

PRODUCTION

The terms “knowledge” and “knowledge

management” are frequently used in information

technology in many respects. Their scope of use

ranges from the mapping of simple structural

knowledge to the representation of knowledge by

512

Dickerhof M., Kusche O., Kimmig D. and Schmidt A. (2008).

AN ONTOLOGY-BASED APPROACH TO SUPPORTING DEVELOPMENT AND PRODUCTION OF MICROSYSTEMS - Process-Related Documenta-

tion for Process and Application Knowledge Management in Microsystems Technology.

In Proceedings of the Fourth International Conference on Web Information Systems and Technologies, pages 512-516

Copyright

c

SciTePress

means of semantic networks or methods of artificial

intelligence.

Application of these approaches certainly is

feasible in an enterprise and useful in various fields,

where enterprise knowledge is generated. The pre

development or fabrication knowledge and in

particular on the necessary process know-how in the

Microsystems Technology context. As MST is an

interdisciplinary field of technology, special

attention in the early product development phase has

to be paid to influencing factors resulting from

application requirements, which have to be related to

the constraints of the already existing manufacturing

technologies.

2.1 Knowledge and Knowledge

Management in the MST

Development and Production Phase

The basic idea of the process modeling concept to be

presented in this paper is to support product

developers in the early production phase, through a

decision support while the identification of an

appropriate the technological approach that fits best

to a given product requirement.

Industrial activities in this field are discussed in

white papers and other documents (Bouwstra et al.,

2003). Scientific activities like the pretzel model

comprise models for the subset of silicon-MST field

(Wagener et al., 2002) which unfortunately cannot

be transferred easily (Brueck et al., 2007). Other

scientific approaches for the sub-group of precision

technologies mainly concentrate on a feature-based

approach, which primarily focuses on the relations

between geometrical primitives and technical

capabilities/constraints. They do not consider the

relation between technologies and the corresponding

application properties that are of relevance in the

product development context.

2.2 Technical Aspects and

Competences for the Description of

MST Knowledge

As microsystems typically are parts, components or

subsystems integrated in macrosystems, it is useful

to distinguish between parameters that are of

relevance to the “macro world” product and

production oriented parameters of a technology

itself. The former mostly include economic

constraints or describe capabilities of a technology,

e.g. related to the physical effects to fulfil the task

given (e.g. surface roughness as a factor influencing

optical properties). The latter allow the user to

investigate the technology itself (material,

technology, design, equipment, tools, etc.).

• Process parameters describe technical factors

that can be achieved in a reliable manner

(material parameters, milling tool size, feed,

milling velocity, etc…)

• Product properties represent the resulting

capabilities, e.g. resulting minimum grooves,

surface roughness, which again correlate with

application-specific requirements resulting

from physical effects often utilized in sensor

or actuator applications.

So far there exists no direct description of the

relation between process capabilities and application

requirement. Information on a descriptive level often

is stored in “Design rules” allowing for a basic

assessment of relations almost for a very narrow

range of tasks.

2.2.1 The ProWiDa Modeling Approach

At Forschungszentrum Karlsruhe, a new modeling

approach has been developed to allow for a full

description of the key influencing factors in MST.

The basic concepts were defined in the ProWiDa

approach (Dickerhof et al., 2004). In the ProWiDa

terminology, these elements are designated as

technological aspects for the characterization of

process related parameters. An analysis of the most

influencing production factors led to the definition

of five (six) factors of influence for microsystems

technology:

• Materials (two: substrates plus layers)

• Procedure

• Geometry

• Machines

• Tools

Material, procedure, and geometry are almost

sufficient for a definition of parameter sets that may

be compared approximately with the design rules

already known from silicon MST. These parameter

sets are of relevance to the design engineer or

marketing department to identify the feasibility of a

customer’s request.

Each technological aspect can be refined by a

taxonomy. For instance, the procedures on the next

lower hierarchy level can be divided into coating

methods, subtractive methods, etc. In this case, an

is-a relation is used as a basis. This also applies to

all the other technological aspects.

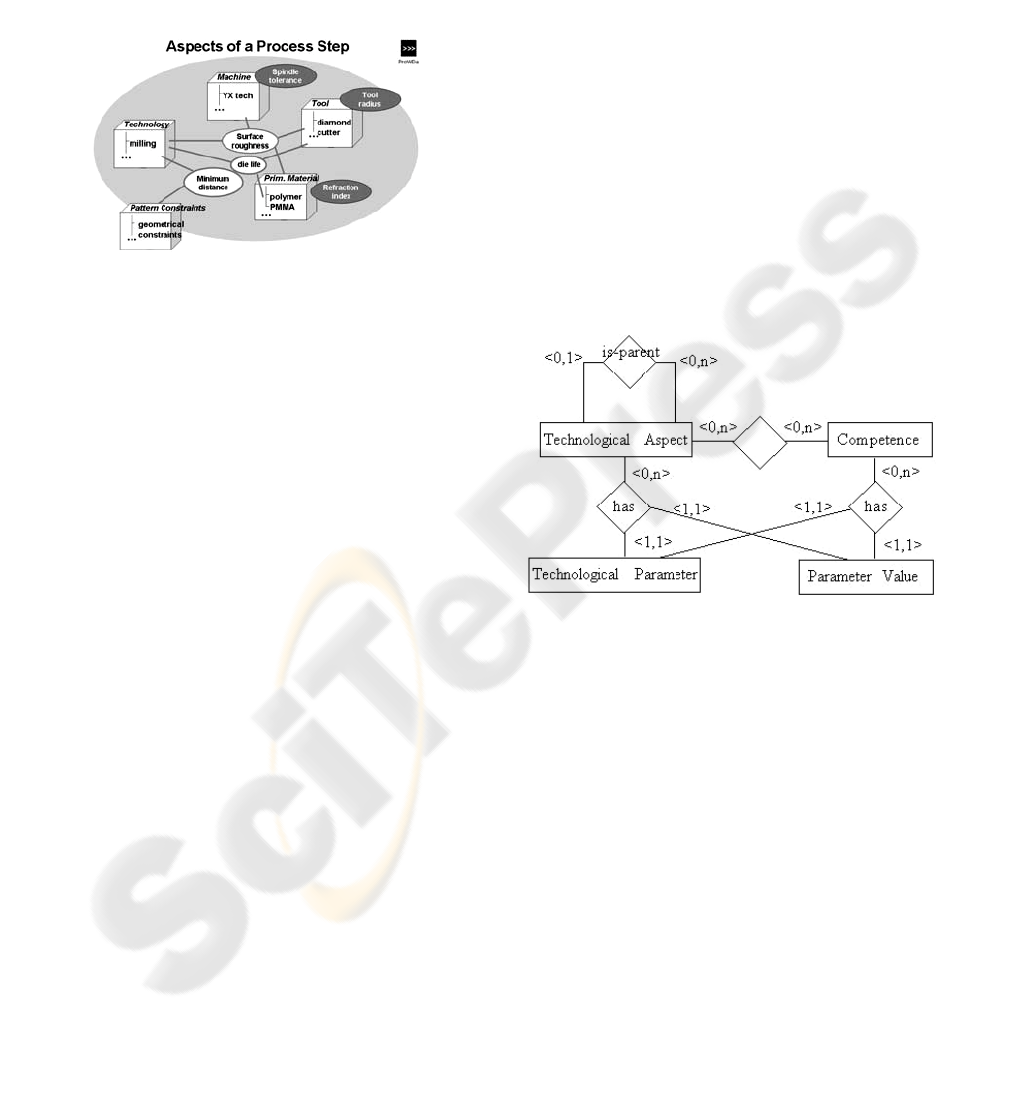

A schematic overview of the relations between

the technology-oriented aspects and the subsequent

technological properties is given in Figure 1.

AN ONTOLOGY-BASED APPROACH TO SUPPORTING DEVELOPMENT AND PRODUCTION OF

MICROSYSTEMS - Process-Related Documentation for Process and Application Knowledge Management in

Microsystems Technology

513

Hence, the ”technological aspects“ form a

number of taxonomy trees or hierarchies. In this

context, each parameter in such a tree will be

assigned to a node in the hierarchical tree. A

technical parameter consists of a designator, an

optional (mostly numerical) default value or (partial)

interval, and the respective unit.

Figure 1: Technology-oriented “aspects” of a process step.

As a rule, a technical parameter refers to either

the product to be manufactured (what exactly is

manufactured - product-related) or to the production

itself (how is it produced - production-related). In

the individual hierarchy trees, the technical parame-

ters are inherited along the is-a relations. This means

that a technical parameter does not only apply to the

concrete node in the hierarchy tree, but also to all of

its subnodes. This is in agreement with the classical

structural inheritance known from object-oriented

programming languages.

In the inheritance hierarchy, the given value (or

interval) of a technical parameter and, hence, the

underlying unit may change from node to node.

To fulfill the requirement of linking

technological aspects with the product requirements

not only a single specific aspect becomes of

relevance. Furthermore, the combination of all

aspects leads to a “real world” view, comparable to

what one could define as a companies “know how”.

As the combinations of the major influencing

aspects finally describe the company’s technological

know how of producing a specific micropart,

component or subsystem, the resulting n-tupel is

referred to in the ProWiDa methodology as

“competence“. Such a competence consists of

additional, more product-related parameters for the

description of the resulting product properties.

A competence can be also seen as a product

independent generalization of the above mentioned

product specific “design rules” in MST production

today. For instance, the combination of a process,

the material to be processed, and the processing

machine describes a competence by the product

property parameter “surface roughness”.

In analogy to the technological aspects, a

competence may be enriched by additional

parameters that cannot be derived from the

individual hierarchy trees of the technical aspects.

2.2.2 Corresponding Data Model

Due to the high dynamics of the processes,

machines, and materials used in MST, static

modeling of the technical aspects and parameters in

the form of a class hierarchy (technical aspects) with

the corresponding attributes (technical parameters)

cannot be applied.

Instead, these artefacts have to be modeled on a

Meta level. This allows for the dynamic

adaptation/extension of these aspects at runtime.

Figure 2 shows an excerpt from the underlying

metamodel of the application, which models the

relationships presented in Figure 1.

Figure 2: ER model of the ProWiDa metamodel.

Together with the “is-parent” relation, the entity

“technical aspects” forms the generalization

hierarchies for the technical aspects (procedure,

material, …). Consequently, each entity that does

not refer to a corresponding parent node is

considered to be the root of a taxonomy. Hence, the

requirement of flexible taxonomies is fulfilled.

The technical parameters that are related to the

technical aspects via the relation “has” allow for an

allocation of the production- and product-specific

parameters to the technical aspects. According to the

semantics of the application, the technical

parameters of the technical aspects are inherited to

all specializations (child nodes in the taxonomy

tree).

Separation between the technical parameter and

parameter value allows for the variation of the given

default value (or interval) for a technical parameter

in the individual taxonomies.

WEBIST 2008 - International Conference on Web Information Systems and Technologies

514

The “competence” entity is related to the

technical aspects via an n:m relationship. This

means that a “competence” consists of n technical

aspects. Vice versa, a technical aspect may occur in

n “competences”. However, this n:m relationship is

subject to a semantic constraint that cannot be

expressed by the ER model: Since the technical

aspects on level 1 of the tree form independent

taxonomies, a competence may only be related to

such technical aspects that do not have a node as a

common parent (i.e., that originate from different

taxonomies). Thus, it is ensured Together with the

“is-parent” relation, the entity “technical aspects”

forms the generalization hierarchies for the technical

aspects (procedure, material, …). Consequently,

each entity that does not refer to a corresponding

parent node is considered to be the root of a

taxonomy. Hence, the requirement of flexible

taxonomies is fulfilled.

The technical parameters that are related to the

technical aspects via the relation “has” allow for an

allocation of the production- and product-specific

parameters to the technical aspects. According to the

semantics of the application, the technical

parameters of the technical aspects are inherited to

all specializations (child nodes in the taxonomy

tree).

Separation between the technical parameter and

parameter value allows for the variation of the given

default value (or interval) for a technical parameter

in the individual taxonomies.

The “competence” entity is related to the

technical aspects via an n:m relationship. This

means that a “competence” consists of n technical

aspects. Vice versa, a technical aspect may occur in

n “competences”. However, this n:m relationship is

subject to a semantic constraint that cannot be

expressed by the ER model: Since the technical

aspects on level 1 of the tree form independent

taxonomies, a competence may only be related to

such technical aspects that do not have a node as a

common parent (i.e., that originate from different

taxonomies). Thus, it is ensured that each

competence from each taxonomy tree contains a

single value of a technical aspect only.

2.3 Knowledge about Relations among

and Constraints of Process Steps

State-of-the-art process documentation typically is

performed in line with the requirements of a quality

management system which usually describes product

specific processes on an organizational level. The

ProWiDa methodology aims at showing the relations

among the process steps in a more transparent and

with that transferable manner, which also allows for

an improved reusability of the product specific

production information. These meta parameters are

additional or different properties resulting from the

combination of single process steps in a process

sequence or process chain.

2.3.1 Modeling of Technological Parameters

along the MST Process Chains

The modeling component allows for a simplified

modeling of MST processes (sequential and

parallel). Three major elements serve to describe a

complete production process:

The process chain element represents an

order/product-specific set of process sequences. It is

equivalent to the model of a product or customer-

related production process.

The process sequence represents a characteristic

of a basic technology.

A technology is represented by a set of process

steps. The process step itself is the smallest

modeling element (represented by a competence)

which represents a subtask that has to be executed

when processing a technology.

The complexity of such a process chain directly

depends on the complexity of the MST system to be

produced. MST parts may consist of a small amount

of process sequences, while complex MST

subsystems, e.g. a sensor, comprise larger numbers

of process sequences, completed by additional

sequences for assembly and manufacturing.

2.3.2 Corresponding Data Model

To model the workflow functionality, a simple, but

flexible model is selected (figure 3), as described in

the section above. The key component is the

“activity” that is given by the above specializations

of “process chain”, “process sequence”, and

“process step”. Any complex hierarchical workflow

can be modeled by the two types of relations of

“hierarchy_relation” and “flow_relation”. The basic

element to generate the workflow, however, must be

an activity entity of the type “process step” that is

related to a “competence”. Consequently, the

“competences” defined above are the basic elements

of the workflow. In analogy to the “technological

aspects”, adding of additional “technological

parameters” is possible.

AN ONTOLOGY-BASED APPROACH TO SUPPORTING DEVELOPMENT AND PRODUCTION OF

MICROSYSTEMS - Process-Related Documentation for Process and Application Knowledge Management in

Microsystems Technology

515

Figure 3: Workflow model.

Remark: The focus of this first stage modeling

approach has been set on the ability to identifiy

process-step overlapping relations. This primary

goal was achieved through a reduction of modeling

options. For an enhanced modeling of process

chains, modeling methods with a strong focus on

economic aspects like Petri nets, workflow modeling

or event-driven process chains may be more

adequate and will be considered in future versions of

ProWiDa.

3 SUMMARY AND OUTLOOK

The paper basically describes a knowledge

management approach for MST production

technologies. It allows for a product-independent

definition, storage, and retrieval of design rules,

business rules, and process parameters for the

development of microsystems products according to

the customers’ needs. The approach is based on a

generic database concept for the flexible

combination of parameter sets attached to product-

and fabrication-relevant aspects. First prototype

interfaces to enterprise information systems and

components for the analysis of data collected in this

specific manner have been implemented or are under

development. They will allow for the import of

measuring data from production and, hence, for a

continuous optimization of business rules/design

rules based on “real-world” process data. A first

prototype of a process chain analyzer for identifying

the most appropriate solution path related to a

specific task given has been developed and shall be

improved in the next years.

REFERENCES

Nonaka, I.; Takeuchi, H.: The Knowledge-Creating

Company: How Japanese companies create the

dynamics of innovation. Oxford University Press,

New York; 1995.

Bouwstra, S., Da Silva, M.; Schroepfer, G.; White paper:

Towards Standardization of MEMS Materials

Characterization; Conventor Inc.; 2003

Wagener, A., Popp, J. ; Hahn, K. ; Brück, R.; PDML A

XML Based Process Description Language. In:

Proceedings of the 9th European Concurrent

Engineering Conference, Modena, 2002. – ECEC

2002

Brueck, R.; Dickerhof, M.; Hahn, K.; Langbein, I.;

Towards an integrated design approach in Si+non Si

MEMS Methodology; Presentation at the Patent-

Dfmm Workshop in Berlin, Germany, 2007

Dickerhof, M., Binnig, C., Gengenbach, U.; Doing the

next step- From a process related documentation to

process knowledge management in non silicon

Microsystems Technology; Proceedings of the 9th

Conference on the Commercialisation of Micro and

Nano Systems, Edmonton, Canada, 2004. -

COMS2004

WEBIST 2008 - International Conference on Web Information Systems and Technologies

516