MANAGING REQUIREMENTS CHANGE AS PLM PROCESS

Mourad Messaadia, Jacqueline Konaté and Abd-El Kader Sahraoui

LAAS-CNRS, Université de Toulouse, 7, avenue du Colonel Roche,31007 Toulouse Cedex 4, France

Keywords: Requirements Engineering, Product Life Cycle Management, System Engineering, Collaboration

Engineering.

Abstract: This paper is on PLM issues within a systems engineering framework. The study considered is mainly

focused on requirements change issue how to integrate it into the PLM information systems. The

contribution is in two steps. Firstly, analyze requirements evolution engineering in terms of collaboration

processes. Secondly, we consider both the final product and requirements change impact on enabling

product, then we illustrate the approach by a case study.

1 INTRODUCTION

One of the most challenges in systems engineering is

the requirements change management. Indeed,

requirements change analysis and implementation in

a system engineering perspective using existing

manufacturing process can be extremely complex

and difficult to master. Requirements Management

is a sub process of Requirements Engineering

(Coulin, 2007). Since requirements can change any

time, their management must covers system life

cycle in order to take account requirements

evolution.

Currently, the required information to effectively

and efficiently manage the complete product

lifecycle: handling requirements change and

managing both end products and enabling products

of the manufacturing process, are more often

distributed among several different systems that are

not integrated. The PLM (Product Lifecycle

Management) platform covers all steps in the

product lifecycle. However, PLM unfortunately

lakes of requirements change handling techniques.

For an enterprise using PLM platform, exploring

new concepts and taking advantage of new

technologies lead to requirements change through

this platform. So, it is important to firstly investigate

what additional solutions and improvements of PLM

(Product Lifecycle Management) can provide

solution for requirements change problems; and then

consider a technique to integrate requirements

change process within system engineering for

manufacturing using PLM.

It is important to note that collaboration is

required in this process. Indeed, collaboration is an

efficient and effective way to address requirements

change.

This paper analyzes collaborative requirements

change process and proposes a mean to introduce

this process in PLM according system approach. A

simple illustration with about bicycle manufacturing

shows how our approach can be implemented and

transferred into practice. This example is easy to

understand, and does not require substantial

background explanation.

The remainder of this paper is organized as

follow: Section 2 presents areas and concepts used

in the paper, section 3 is about collaboration in

requirements change, section 4 presents PLM and

shows requirement change thought product lifecycle,

section 5 illustrates our approach through a bicycle

example and finally conclusions and perspectives

are presented in section 6.

2 BACKGROUND

Requirements changes can cause significant

problems leading ripple effects through

manufacturing system and product development

process. It is obvious that early detection and

correction of the potential problems during

requirement analysis phase may considerably

alleviate a lot of problems later during testing and

maintenance. Unfortunately, for any system, all

change requests do not occur during the first steps of

224

Messaadia M., Konaté J. and Kader Sahraoui A. (2008).

MANAGING REQUIREMENTS CHANGE AS PLM PROCESS.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - ISAS, pages 224-230

DOI: 10.5220/0001689602240230

Copyright

c

SciTePress

system development. In addition, almost current new

systems are an evolution of existing systems

(aircrafts, robots, telecommunication, etc.), and most

of change occurs in these cases: the change of the

design/implementation, integrating new technologies

without changing the functional requirements, and

change the functional requirements of product by

adding new requirements as security. Adding,

deleting and modifying are the three types of

requirements changes.

Since systems are increasing large and complex,

requirements traceability (Sahraoui, 2005) became

necessary in the development process. Once the

traceability is defined through a traceability model,

the consequences of upgrades can be more obvious.

Traceability allows predicting dependencies between

requirements and the parts of the system, and it can

decrease costs. Indeed, the cost is dependent of the

number of changes needed for a requirement, i.e.

implementation effort of a requirement change. The

traceability process can be described in two

manners: Backward (from design to System

Requirement Specification: SRS) and Forward (from

SRS to design) (Jamal, 2006). In this paper we use

the traceability process to make the link between the

different parts of the system.

In the example that we adopted, new

requirement is related to comfort (comfortable

bicycle) what results into the addition of shock

absorber. It acts to add a new requirement about

spring, then evaluate the impact of this change on

other parts of bicycle (frame, fork, sit). The next

phase is the realization of this change and finally its

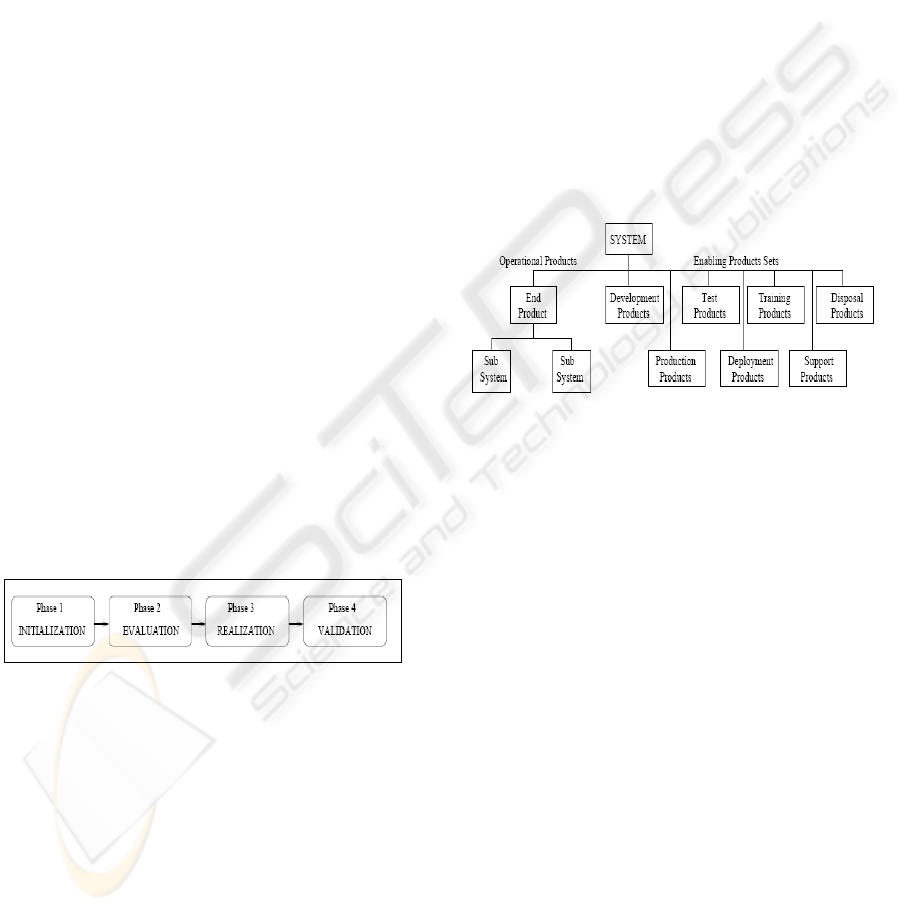

validation. The figure 1 shows the four different

phases of our requirements change process.

Figure 1: Requirements change process.

2.1 Systems Engineering

The International Council on Systems Engineering

(INCOSE) defines Systems Engineering as “an

interdisciplinary approach and means to enable the

realization of successful systems. It focuses on

defining customer needs and required functionality

early in the development cycle, documenting

requirements, then proceeding with design synthesis

and system validation while considering the

complete problem including manufacturing and

testing” (INCOSE, 2008). Subsequently we have

selected the EIA-632 standard (ANSI/EIA-632-

1998, 1998) as a suitable Systems Engineering

framework to found our approach. Accordingly we

consider the final product of a manufacturing

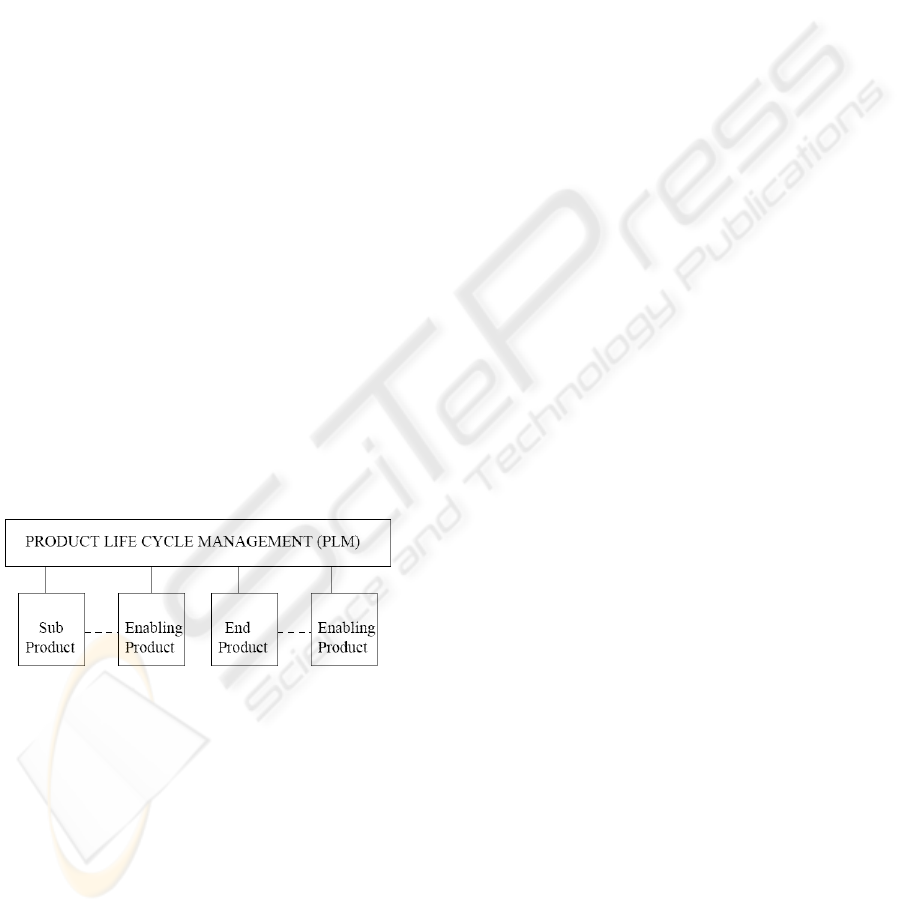

process as a system. As shown in figure 2, system

has logical and physical composition: operational

products and enabling products. Operational

products include end product as well as sub-

assemblies, sub-parts, and sub-products. The

enabling products are products which support and

which are involved in operational products

manufacturing, such as machinery and tools. So,

enabling products are concerned with performance

of manufacturing process, whereas operational

products tend to be either inputs or outputs of

process itself. It is possible to see that there may be

multiple end products for a single system, likewise

each sub system represents system its own end

products and the sets of enabling products.

Figure 2: System engineering framework (ANSI/EIA-632-

1998, 1998).

The application of this model to a bicycle: "end

product" is bicycle, sub systems are (Wheel, Pedals,

Saddle, Fork, Tire, ...) and the "enabling products"

which interest us is system of bicycle manufacturing

(Cutting and forming machines, Humans, ...). The

Product Life Cycle Management (PLM), a platform

for the system management covers above steps will

be presented in following subsection.

2.2 Product Life Cycle Management

The management of informations is central in

product development process. These informations

are from product definition, its manufacturing, and

its maintenance until its disposal. Managing such

information in complex industrial context requires a

systematic and controlled method. PLM is

considered as a strategic approach of information

management. PLM has emerged as the new method

in industrial companies to better manage product

development and manufacturing from the beginning

to the end of the product life cycle. Unlike to

Systems Engineering, now there are no PLM

MANAGING REQUIREMENTS CHANGE AS PLM PROCESS

225

standards for manufacturing processes. In most cases

the installation of PLM system requires redefinition

of various manufacturing processes, a better

communication and integration between both

internal and external related heterogeneous systems.

We propose a definition of PLM which states that

PLM is the integration of all data and information

systems related to all phases of a product lifecycle,

and processes concerned with managing this

information and relationships between those

systems. Subsequently we consider PLM as both a

short of Enterprise Application Integration (EAI)

tool managing the translations necessary for the

different systems to communicate, and also as a set

of defined processes that dictates the possible

interactions with PLM system and how those are

translated to the individual systems. Thus, we

consider PLM as both a system and a set of

processes. Figure 3 shows a PLM system which

depends on integration of all systems concerned with

product life cycle. For example: SCM (Supply Chain

Management), ERP (Enterprise Resource Planning),

MES (Manufacturing Execution System), CRM

(Customer Relationship Management) and DMS

(Design Maintenance System) systems. This also

extends to systems supporting other major business

functions, such as sales and marketing, human

resources, and finance. Typically, much of

manufacturing information such as material bills,

production routings, work orders, sales orders,

purchase orders, and so on are found in the ERP

system.

Figure 3: A product life cycle management system.

We consider again our example. Once the

bicycle has been defined via SE and the new

requirement emitted has been identified, we need a

system which manages the information of product

(requirement and all decisions) during the phases of

life cycle, especially the manufacturing phase. For

this purpose, we adopted PLM approach by

highlighting collaboration aspect. Following

subsection addresses collaboration issue in

requirements change context.

3 COLLABORATION IN

REQUIREMENT

ENGINEERING

During the first steps of Requirements Engineering

such as Requirements Elicitation phase, people

express their requirements by communicating via

different means (text, images, e-mails,

conversations, meetings, etc.). So, it is important

that words have the same meaning for each

participant. To do to this, people must converge

towards same meaning of concepts. In (Briggs et al.,

2003) and (Fruhling et al., 2007), there are some

patterns of collaboration including “generate” and

“reduce” patterns. The former allows the move from

few to more concepts whereas the latter to move

from more concepts to few concepts. So, a “reduce”

pattern can be used bring convergence in concepts

signification. Likewise, in order to get many ideas or

concepts, we can rely on a “generate” pattern to

reduce the omission of requirements. Whatever the

measures to take during the initial phase of

requirements engineering, it is not possible to ensure

the completeness and the consistency of the set of

the overall requirements for the first time.

In order to evaluate requirements in

“harmonious” manner throughout system life cycle,

it is important to approach the problem

collaboratively. In collaboration, actors, their roles

and processes are essential. Next subsections present

these different points.

3.1 Collaboration Actors and

Requirements Dependencies

Here, actors are any all concerned with system

development: requirements engineers, system

designers, developers, other stakeholders and final

users. In other words, they are: engineers, users and

others stakeholders.

Involving of all these parts is necessary because

system is consisted by subsystems interoperating as

our bicycle. If there is a change in one subsystem,

other parts can be impacted by this change. For

example, let a change requirement request as: the

bicycle saddle must bear a person of 100 pounds.

This change brings requirements changes for wheels,

frames and other parts. Through requirements

traceability, it is possible to keep changes historic

and dependencies between requirements for further

analysis.

ICEIS 2008 - International Conference on Enterprise Information Systems

226

3.2 Collaboration Processes

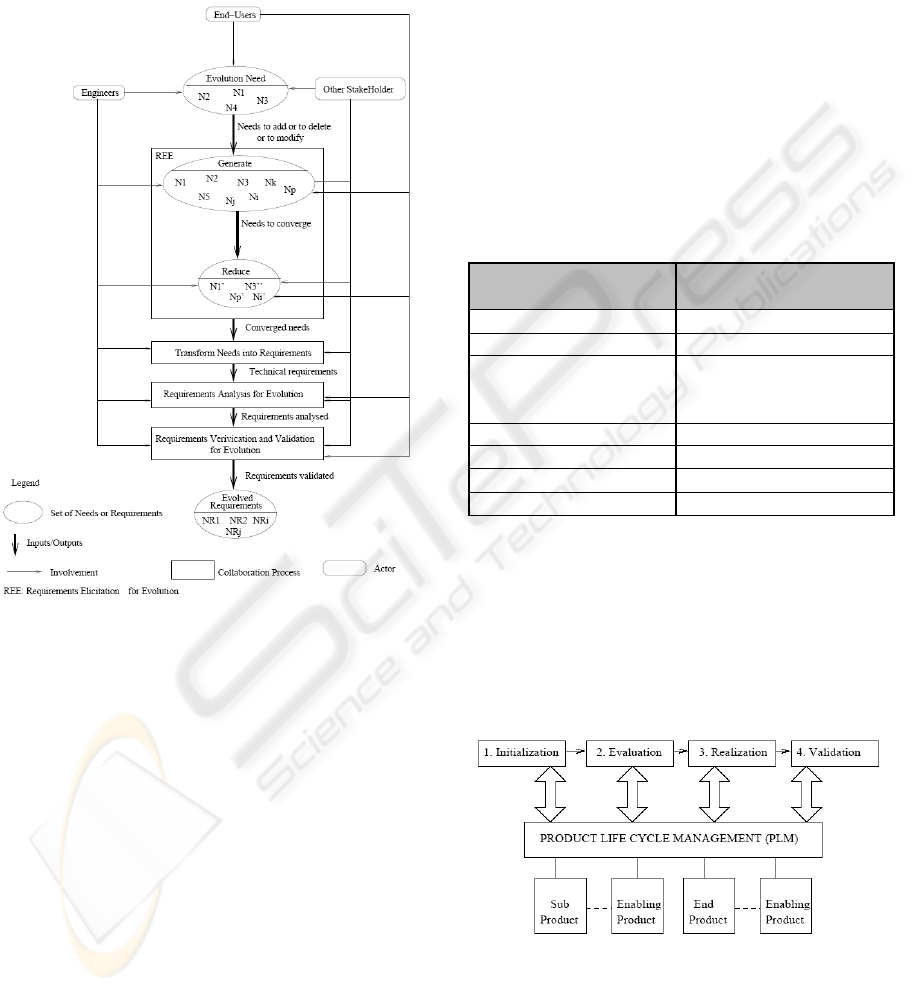

The requirement change request is emitted by at

least one actor identified in the previous subsection.

(engineer, end user, other stakeholder) as showed in

figure 4.

Figure 4: Collaborative requirements change process.

They start by express some needs (N1, N2, N3, and

N4). Then all people concerned with these changes

of needs can intervene by expressing all possible

ideas. This leads to several needs, i.e., generate

needs. Normally, during this step most of needs

change are identified and almost all their eventual

impacts. After, it is important to ensure that behind

every need expressed by participants, every

participant has the same idea about it and that there

are no redundancy. This allows convergence

between actors and reduces the number of needs to

be changed. Needs resulting from reduce step are

(N1’, N3’, Ni’, Np’). The other steps are classical

steps in the engineering requirements. The final

result is a set of new requirements (NR) or evolved

requirements (NR1, NR2, NRi, NRj). Since PLM

allows collaboration and it covers system life cycle,

in next subsections we integrate these considerations

in system engineering processes in the PLM context.

4 PRODUCT LIFE CYCLE FOR

SYSTEM ENGINEERING

This section explains how requirements change can

be managed using PLM in System Engineering

context. We achieve this by detailing what PLM

must provide in order to satisfy the request of this

requirements change at each phase of the process.

Table 1 presents relationships between data in

systems engineering phases and product lifecycle

management phase. In our example about bicycle,

final end product (or system) would be finished and

complete bicycle. Subsystems would include things

like wheels, handlebars, and frame.

Table 1: Relationships between PLM data and systems

engineering phases.

Systems Engineering

phases

Product Lifecycle

Management data

Requirements

Design Change

Manufacturing Workflow

Structure

Inventory

Testing

Operation

Maintenance

Disposal

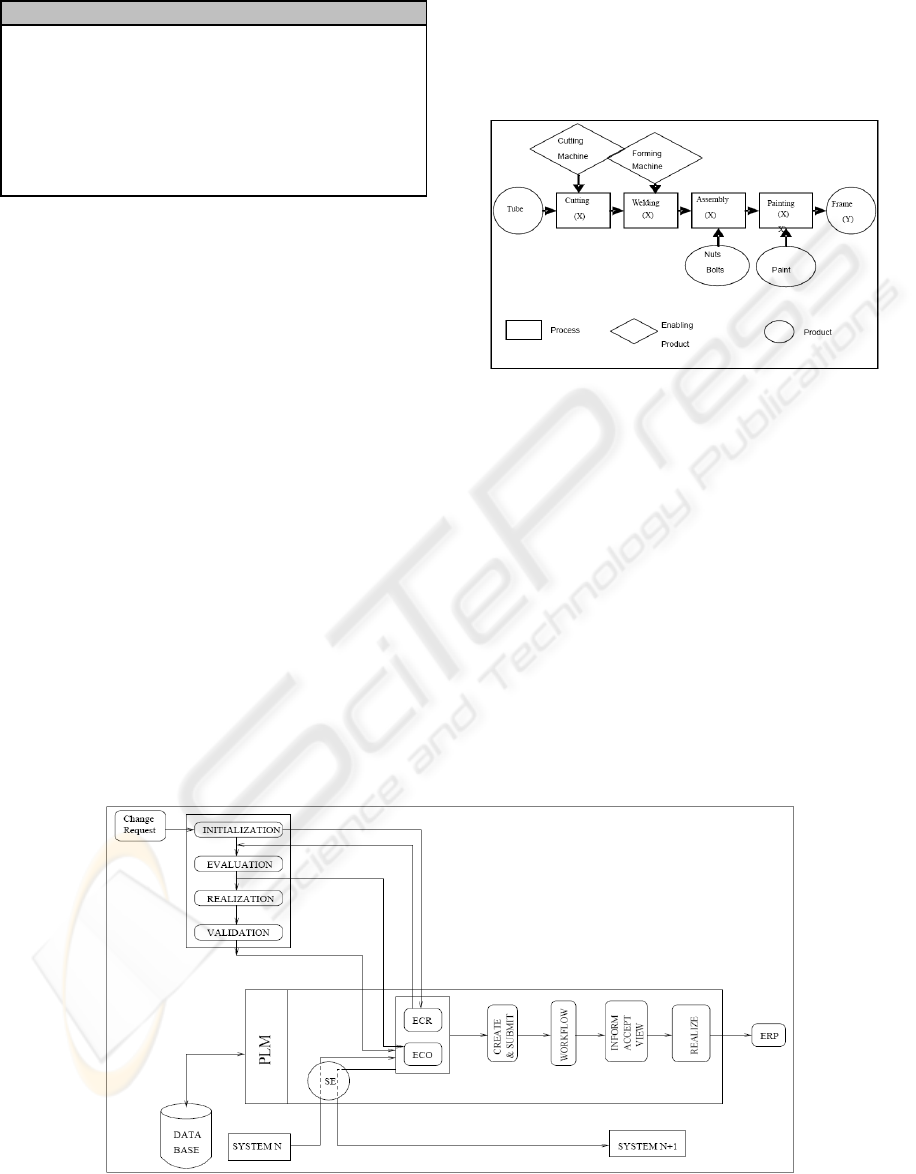

The figure 6 illustrates how PLM integrates

requirements change process and the top-down

approach of engineering system (system

composition). The Four phases shown in figure 6 are

described in detail in following subsections. In

addition, inputs, outputs and data handled in

different corresponding steps are presented in the

tables.

Figure 6: PLM for Requirements change process in

systems Engineering.

MANAGING REQUIREMENTS CHANGE AS PLM PROCESS

227

Table 2: Initialization process.

Input Steps Data Output

New or modified

requirement(s)

1. Identify change

• Applicant

• Type

• Rationale

2. Examine traceability

• Type

• Links

3. Assign resources

4. Submit request

Engineering

Change

Request

(ECR)

Phase 1: Initialization

Initialization phase in requirements change process

involves determining the sources and justifications

of change from system actors. When a requirement

change is initiated, PLM system provides the basis

for creation of an ECR (Engineering Change

Request). Person presenting ECR defines the change

context, items (parts, assemblies, or documents)

affected by this change, and a description of the

change reasons. An ECR can contain other

documents such as CAD (Computer Aided Design)

drawings. In PLM system, ECR is delivered to the

responsible of change according to the defined

workflow.

Phase 2: Evaluation

Evaluation phase in requirements change process

involves the development of possible solutions,

analysis of their impact, and make a decision. This

stage may also include some degree of prototyping

depending on complexity of required changes. It

may also include a formal manufacturability study

with feedback to design stage. This phase begins

when an ECR is emitted (it is also possible that an

ECO (Engineering Change Order) has been emitted

directly). ECR is delivered by PLM system to

responsible as defined in Workflow Management

System. When it is clear what kind of changes will

be made in the processes and products, actors of

changes can emit an ECO. The decision to make

about change request must take into account links

between required product changes, and required

changes within other processes like manufacturing

process. In the case of manufacturing, only complete

manufacturing process can provide necessary

perspective in order to identify from physical form

of product which parts, processes and components

are affected. It also highlights link between end

products (system and all subsystems) and enabling

products and also the manner to produce final

product. After all these steps, responsible will

generate an ECO within PLM system.

Phase 3: Realization

Realization phase of requirements change process is

more important and includes change implementation

across organization. This phase may also include

some prototypes.

Requirements change can cause one or more of

following required changes:

• Changes in process (new processes version

X+1)

• Changes in products (new version of products

Y+1)

• Changes in enabling products (new version of

enabling products Z+1)

Humans involved (collaboration actors) in the

process such as machine operators could be

considered as enabling products. They can also

change if the process they perform changes, e.g.

additional training.

Table 3: Evaluation process.

Input Steps Data Output

Engineering

Change

Request

(ECR)

•

Review system

documentation

• Determinate Impact

on process, end

products and

enabling products.

• Classify change and

explore similar

change

• Identify system

design impacts

• Specify and design

change

• Evaluate change

request

• Approval authority

Engineering

Change

Request

(ECR)

Decomposi-

tion of the

Systems

Traceability

of the

Requirements

Engineering

Change

Order (ECO)

Table 4: Realization process.

Input Steps Data Output

Engineering

Change

Request

(ECR)

•

Review system

documentation

• Determinate Impact

on process, end

products and

enabling products.

• Classify change and

explore similar

change

• Identify system

design impacts

• Specify and design

change

• Evaluate change

request

• Approval authority

Engineering

Change

Request

(ECR)

Decompositio

n of the

Systems

Traceability

of the

Requirements

Engineering

Change

Order

(ECO)

ICEIS 2008 - International Conference on Enterprise Information Systems

228

Table 5: Validation process.

Inpu

t

S

teps

D

ata Outpu

t

Verification

planning

• Generate test cases

for the change

• Update test suite

• Perform

integration testing

• Conduct

acceptance testing

• Approve change

Change

approval

Phase 4: Validation

Validation may occur in many levels during an

extended period. Indeed, this phase is a set of steps

of verification by testing. For example, if response

come as a result of customer request, then validation

process must is applied until end users arrive to use

new final product.

5 APPLICATION TO BICYCLE

SYSTEM

In this section we apply our approach to an example

manufacturing process. Each association between

product and production systems can be managed as a

connection between systems of each hierarchical

system structure.

In example of the bicycle (see Figure 7), we can

see manufacturing process (X) which defines

manufacturing of all parts of bike until to get end

product. PLM system manages decisions when new

requirement is emitted, for example, adding a spring

in bicycle frame. In fact, when requirement is

emitted, it is transferred via PLM towards a team.

This team takes into account initial links between

bicycle and its manufacture system in order to define

impact of adding a spring to bicycle. PLM is

responsible to convey ECR emission to be validated

in order to establish new bicycle (Y+1) with spring

and its new manufacturing processes (X+1).

Figure 7: Bicycle Frame Manufacturing Process.

PLM is also responsible to safeguard and bring up to

date new product and its manufacturing process (see

Figure 8). In the figure 8, collaboration occurs at

every step in accordance with what has been

established in section 3 about collaboration.

Initialization phase matches to “Evolution Need”

phase in term of collaboration. Similarly phases of

evaluation and realization phases correspond to the

“generate” and “reduce” in the sense of

collaboration. By integrating system engineering

(SE) approach in PLM, a new system (SYSTEM

N+1) is constructed. The collaborative processes are

also taken into account and defined in advance. All

versions of system are stored in a data base (DATA

BASE).

Figure 8: Bicycle Frame Manufacturing Process.

MANAGING REQUIREMENTS CHANGE AS PLM PROCESS

229

6 CONCLUSIONS

AND PERSPECTIVES

The link established by SE allows us to identify the

change impact in product and into manufacturing

system. This paper defines new processes of

manufacturing from requirement change. Since one

essential purpose of PLM is to allow collaboration

between people, we also integrate collaboration aspect

into PLM. However, we do not always know some

data to be exchanged through the steps of product life

cycle like shown in table 2 and 5. These issues will be

addressed by further research study.

ACKNOWLEDGEMENTS

We would like to thank Coulin chad and El-Jamal

Hani for their collaboration and the useful comments

on early drafts of this paper and the discussions on

requirements elicitation and evolution.

REFERENCES

ANSI/EIA-632-1998 EIA (1998). EIA Standard: Processes

for Engineering a System.

Coulin, AEK. Sahraou and Zowghi (2005). Towards a

collaborative and combinational approach to

requirements elicitation within a systems engineering

framework. 18th International Conference on Systems

Engineering (ICEng'05), Las Vegas (USA).

Coulin, C.: A Situational Approach and Intelligent Tool for

Collaborative Requirements Elicitation. Phd thesis,

LAAS report 07636. University of Sydney and Université

de Toulouse, 2007.

INCOSE: What is System Engineering. http://

www.incose.org/practice/whatissystemseng.aspx,

accessed in March 2008.

Jamal, AEK. Sahraoui (2005). Customising systems

engineering concepts: case study on concurrent

engineering Context. ESEC, European symposium on

concurrent engineering systems.

Jamal: Contribution à l'évolution des exigences et son

impact sur la sécurité. Phd. Thesis, University Paul

Sabatier, sept. 2006.

Lardeur, C Auzet. (2003). Deployment of SE including

Manufacturing Systems development: Theoretical

Aspects. The 13th Annual International Symposium

INCOSE, Washington, DC, USA.

Messaadia, M.H, El-Jamal and AEK Sahraoui (2005)

Systems Engineering Processes Deployment for PLM.

Saaksvuori, A, A. Immonen (2004). Product lifecycle

Management. Springer-Verlag Berlin. Heidelberg

www.incose.org INCOSE (2005).

Konaté, J. and Sahraoui A.E.K. (2007). Collaboration in

Requirement Engineering Process. In Proceedings: 13th

International Conference on Concurrent Enterprising,

Sophia Antipolis, France, 04-06 June 2007.

Briggs R.O., de Vreede G. J., Nunamaker and J. F. JR

(2003). Collaboration Engineering with ThinkLets to

Pursue Sustained Success with Group Support Systems.

Journal of Management Information Systems, 19(4): 31-

64.

Anderson S. and Felici M.(2003) Quantitative Aspects of

Requirements Evolution. In Proceedings of 26

th

Annual

international Conference in Computer Software and

Applications, 27- 32

Hassin J., Rilling J. and Hewitt J. (2005). Change impact

analysis for requirement evolution using use case maps.

In Proceedings of the Eighth International Workshop on

Principles of Software Evolution, 81-90

ICEIS 2008 - International Conference on Enterprise Information Systems

230