SEMANTIC DATA INTEGRATION FOR PROCESS

ENGINEERING DESIGN DATA

Andreas Wiesner, Jan Morbach and Wolfgang Marquardt

AVT-Process Systems Engineering, RWTH Aachen University, Templergraben 55, 52062-Aachen, Germany

Keywords: Data integration, data consolidation, ontology, XML technologies, engineering design data.

Abstract: During the design phase of a chemical plant, information is typically created by various software tools and

stored in different documents and databases. Unfortunately, the further processing of the data is often

hindered by the structural, syntactic and semantic heterogeneities of the data sources. In fact the merging

and consolidation of the data becomes virtually prohibitive when exclusively conventional database

technologies are employed. Therefore, XML technologies as well as specific domain ontologies are

increasingly applied in the context of data integration. Hence, this contribution gives an outline on an

ongoing research project at the authors’ institute, which aims at the development of a prototypical software

tool, which exploits the benefits of semantic as well as XML technologies, for the integration and

consolidation of design data. Both, ontology and software development is performed in close cooperation

with partners from the chemical and software industries to ensure their compliance with the requirements of

industrial practice.

1 INTRODUCTION

In the course of a chemical plant design project,

information is typically created by disparate tools

and stored in different locations and formats (e.g.

technical documents, CAE systems and simulation

files). However, before further processing, the

scattered information has to be merged and

consolidated. Unfortunately, in practice, data

integration projects are hindered by the inherent

heterogeneities of the underlying sources. (Embury

et al., 2001). As a result the lack of interoperability

between the tools and data stores causes a significant

overhead for the designers as they have to spend

considerable time on the re-entering of data, the

manual consolidation of overlapping data sets, and

the search for information (Galaher et al., 2004). In

order to overcome the aforementioned

heterogeneities, XML is increasingly applied for

data exchange purposes, ultimately becoming a

standard for data interchange between software tools

(Klein, 2002). Hence, various XML-based

applications for data exchange in the field of

chemical engineering already exist or are currently

under development such as CAEX (Fedai and Draht,

2004), XMpLant (Noumonon, 2006) or PlantXML

(Anhäuser et al., 2004).

Thus, at least syntactic and schematic

heterogeneities can be resolved conveniently

between distributed data sources by means of the

XML format. However, XML and its schemas do

not express semantics (Cruz et al., 2004), such that

semantic incompatibility between different XML

sources is inevitable.

For the integration of data from several different

sources, particularly for engineering data, correct

assumptions about the meaning of certain elements

are crucial for the successful information retrieval

and consolidation. In other words, where XML

sources are presented without an explicit agreement

on the semantics of certain tags and document

structures, the task of the correct interpretation of the

data is still an issue (Erdmann and Studer, 2001).

To remedy this problem, a semantic annotation,

also referred to as “semantic lifting” of XML

documents is necessary. Unfortunately, the

semantics assumed by a particular source are rarely

documented, and there is no explicit representation

of a data source’s semantics, in the way that a

schema provides a representation of the data

structure. Hence, the important link missing at this

point is the connection between the structured

information stored in the XML document and the

particular domain knowledge, which relates meaning

to the stored information within the context. To that

190

Wiesner A., Morbach J. and Marquardt W. (2008).

SEMANTIC DATA INTEGRATION FOR PROCESS ENGINEERING DESIGN DATA.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - DISI, pages 190-195

DOI: 10.5220/0001692901900195

Copyright

c

SciTePress

end, ontologies have gained popularity as a

convenient means for the representation of domain

knowledge.

An ontology is an explicit specification of a

conceptualization, typically involving classes, their

relations and axioms for clarifying the intended

semantics (Uschold and Grüninger, 1996). It

basically constitutes a structured framework for the

storage of information and knowledge. Often the

ontologies are linked with the term semantic

technology. By semantic technologies, software

systems are meant that use ontologies as internal

data models. The ontology OntoCAPE (Morbach et

al. 2007, Morbach and Marquardt, 2008) was

explicitly defined for the domain of Computer-

Aided Process Engineering and thus particularly

applicable to the integration of design data in

chemical engineering.

This contribution reports on the ongoing

research project “Ontology-based integration and

management of distributed design data” at the

authors’ institute, that address the aforementioned

semantic heterogeneities between documents

containing process engineering design data due to

the lack of interoperability between software tools.

The project’s aim is to develop an ontology-based

software prototype, incorporating OntoCAPE, for

the integration and reconciliation of design data

which are available in the XML data format, from

distributed information sources. The project is run in

cooperation with partners from the chemical and

software industries. This paper, however, will

particularly emphasis the conceptual design and

implementation of the novel software tool.

The remainder of the paper is organized as

follows: Section 2 introduces the concept of

“semantic lifting” and gives a brief overview on the

OntoCAPE ontology. In Section 3 the conceptual

design and the implementation of the current

research project are introduced. Finally, Section 4

concludes the contribution by summarizing the

achievements so far.

2 PREREQUISITE FOR

SEMANTIC DATA

INTEGRATION

The main purpose of XML is to provide a

mechanism that can be used to mark-up and

structure documents. This allows machines to

identify pieces of data in a document by their label.

However, these labels themselves do not bear any

meaning with them. Also, it is a common

misconception that XML schema documents can be

used to add meaning to XML documents (Klein,

2002). The goal of XML schema mainly is to

provide structuring prescriptions, e.g. the feature to

build hierarchies of element types, which, however,

do not contain conceptual knowledge, but only

functions as a syntactical shortcut to allow reuse of

complex definitions.

2.1 Semantic Lifting

To associate some meaning with XML documents, it

is necessary to relate the labels with something that

carries meaning. Classes and properties in ontologies

are suitable for that purpose, because ontologies

formally specify the understanding of certain topics

in a particular application domain. A naive way of

establishing the relation between an ontology and

the XML document would be a simple matching of

associated labels from a XML document

syntactically with the names of classes and

properties in the ontology. But meaning can rarely

be assigned by a simple mapping from symbols to

objects since the role of the data implicitly indicated

by the context, e.g. the nested structure of a

document, is not clearly captured this way.

Accordingly, for a reliable data consolidation it is

crucial to unambiguously interpret the data including

its context. To that end, a substantial description of

the XML document’s contents (“semantic lifting”)

by means of an ontology has to be provided in order

to undertake a proper semantic data integration.

The proposed “semantic lifting” follows a two

step approach: step (1) is to lift the XML schema to

the level of an ontology, i.e. a skeleton “schema

ontology” is created which incorporates only the

hierarchical information from the schema expressed

in an ontology language. Step (2) establishes further

relations between concepts and attributes in order to

clarify context information which goes beyond

simple hierarchical interrelations essentially leading

to a “document ontology”. So far, however, most of

the modeling in step (2) has to be done manually.

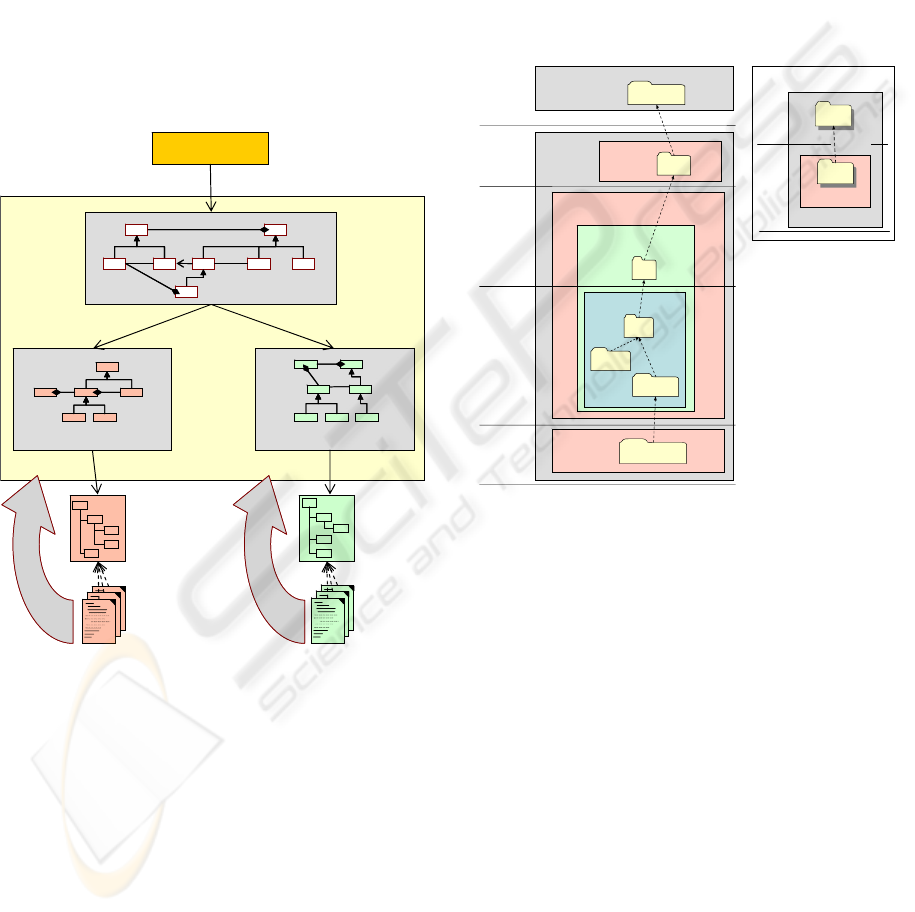

2.2 Prototype Architecture

This software prototype basically represents a

mediation layer, which is placed between the user

and the data sources. The tool follows the local-as-

view approach (Levy, 2001), i.e. the architecture

consists of a global schema (the domain ontology), a

source schema (document ontology) and mappings

as proposed by Lenzerini (2002). A schematic

representation is given in Fig.1. The user interacts

with the tool by querying the global schema, which

constitutes a virtual representation of the data

existing in the data sources. The tool then carries out

SEMANTIC DATA INTEGRATION FOR PROCESS ENGINEERING DESIGN DATA

191

the task of dealing with the sources to retrieve the

information satisfying the user’s request. Moreover,

the source schema provides an internal

representation of the data at the sources. Finally, the

relationships existing between the entities of the

global and source schema are represented by

mappings. By means of these mappings the

aforementioned missing link is established such that

the particular domain knowledge relates meaning to

the source schema. The interaction between the

software prototype and the XML sources is realized

by a specific, bidirectional converter. Therefore, the

new approach basically considers the tool to be

layered on top of an existing XML-data-exchange

architecture, in the sense of “publish and subscribe”,

for serialization.

XMLXML XMLXML

Local SchemaLocal Schema

XML-

Schema

Global SchemaGlobal Schema

describes

XML-

Schema

describes

Mappings

ConvertersConverters

Local SchemaLocal Schema

ConvertersConverters

User

interacts

Figure 1: Schematic representation of the integration tool.

2.3 Domain Ontology OntoCAPE

To enable an adequate description of the contents of

the XML files a comprehensive information model

of the design process of a chemical plant has to be

provided. Such particular domain knowledge is

captured by the OntoCAPE ontology. The formal

ontology OntoCAPE captures consensual knowledge

of the application domain in such a way that it can

be reused and shared across software systems. It

specifies the meaning of the vocabulary terms and

constrains its interrelations (and its possible uses) by

means of axiomatic definitions. Then, specialized

software components (so-called inference engines or

reasoners) can be applied to interpret and reason

about the data.

OntoCAPE has been designed for use with

different types of CAPE tools that support such

diverse tasks as mathematical modeling

(Braunschweig et al. 2002, Yang and Marquardt,

2004), knowledge management (Brandt et al. 2008),

and data integration (Morbach and Marquardt,

2008). An extensive documentation of OntoCAPE

publicity is available at (OntoCAPE, 2007).

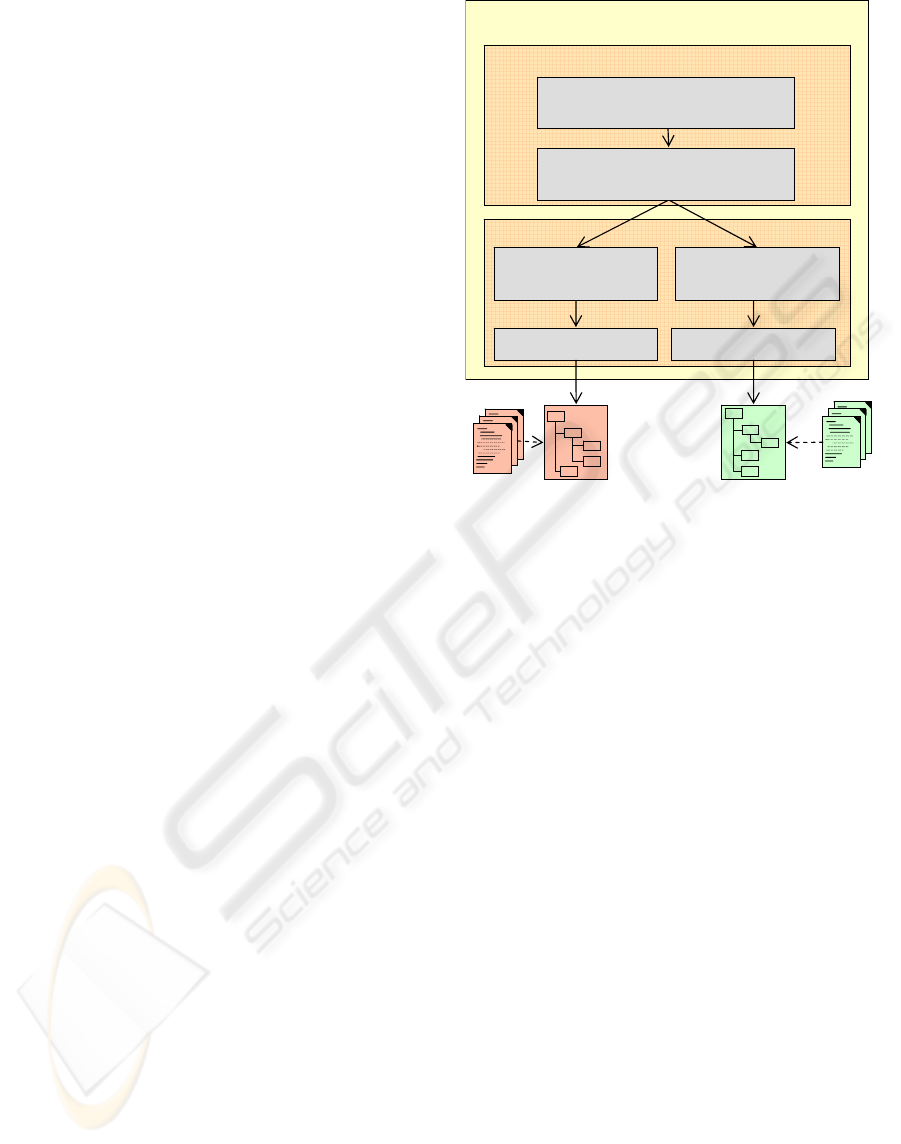

OntoCAPE is organized through three types of

structural elements: layers, modules, and partial

models (cf. Fig. 2).

notation

module

module

Layer

Layer

partial model

module

module

includes

partial model

notation

module

module

Layer

Layer

partial model

module

module

includes

partial model

module

module

Layer

Layer

partial model

module

module

includes

partial model

OntoCAPE

upper_level

Meta Model

applications

Upper

Layer

Application

Specific

Layer

Application

Oriented

Layer

Meta

Layer

system

meta_model

e-procurement

chemical_process_system

CPS_realization

plant_equipment

Conceptual

Layer

fixture

apparatus

machine

plant

Figure 2: A detail of OntoCAPE demonstrating the overall

structure of the ontology.

The layers subdivide OntoCAPE into different

levels of abstraction, thus separating general

knowledge from knowledge about particular

domains and applications. The topmost Meta Layer

is the most abstract one. It holds a Meta Model

which introduces fundamental modeling concepts

and states the design guidelines for the construction

of the actual ontology. Next, the Upper Layer of

OntoCAPE defines the principles of general systems

theory according to which the ontology is organized.

On the subjacent Conceptual Layer, a conceptual

model of the CAPE domain is established, which

covers such different areas as unit operations,

equipment and machinery, materials and their

thermophysical properties, chemical process

behavior, modeling and simulation, and others. The

two bottommost layers refine the conceptual model

by adding classes and relations required for the

practical application of the ontology: The

Application-Oriented Layer generically extends the

ontology towards certain application areas, whereas

ICEIS 2008 - International Conference on Enterprise Information Systems

192

the Application-Specific Layer provides specialized

classes and relations for concrete applications.

A module assembles a number of interrelated

classes, relations, and axioms, which jointly

conceptualize a particular topic (e.g., the module

‘plant’ provides a conceptualization of chemical

plants). The boundaries of a module are chosen such

that the module can be designed, adapted, and

reused to some extent independently from other

parts of an ontology (Stuckenschmidt and Klein,

2003). Modules addressing closely related topics are

grouped into a common partial model (e.g., the

partial model ‘plant_equipment’ clusters the

thematically related modules ‘fixture’, ‘apparatus’,

and ‘machine’).

The modules presented in Fig. 1, e.g. ‘system’,

‘plant’ etc., comprise the basic principles for the

particular domain knowledge required in the project.

For a comprehensive description of the modules, we

refer to (OntoCAPE, 2007)

3 PROJECT OUTLINE

The project aims at developing a data integration

prototype to address the problem of semantic

interoperability between different engineering

documents generated in a chemical plant design

process. To that end, the tool incorporates ontology-

based information reconciliation of data expressed in

the XML format. Ultimately, the tool is intended to

support the designers by providing an integrated

view on the relevant project data and by enabling

efficient data retrieval. A further functionality of the

tool is the automatic detection of design errors: For

example, a typical design error would be the

interconnection of flanges with inconsistent internal

diameters. As the main objectives, the integration

tool must assemble, integrate and consolidate the

relevant information required in the design process.

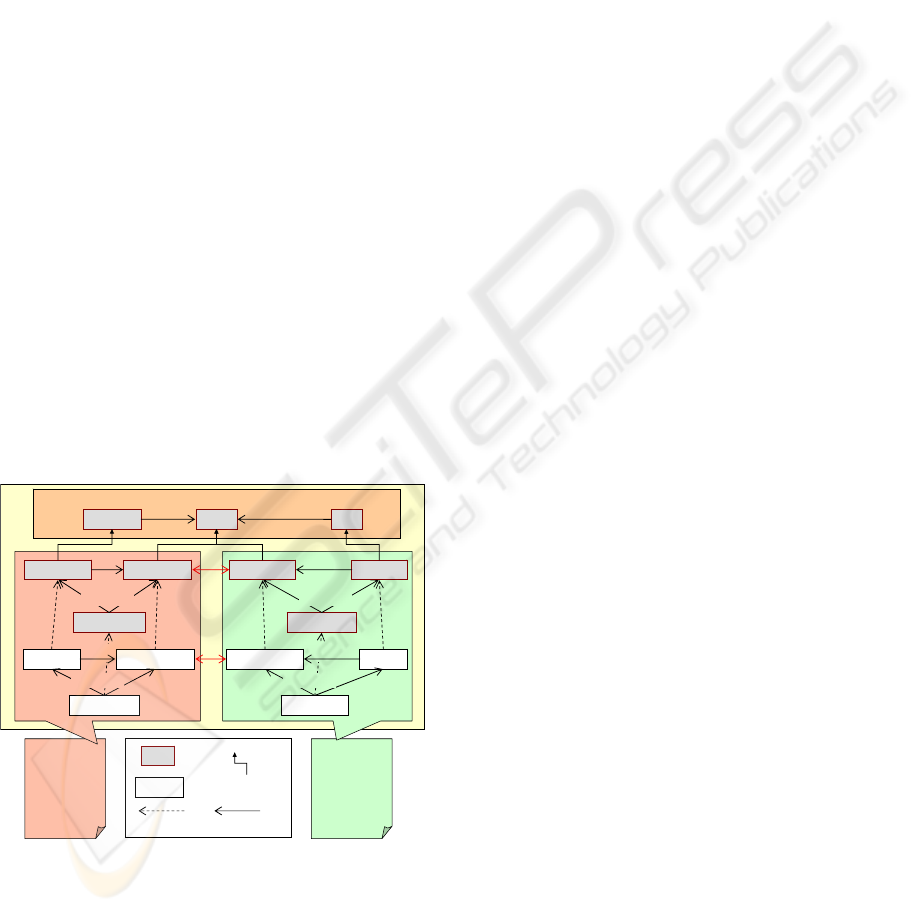

3.1 Method

The software prototype follows a two-step approach

for data integration: In step (1), the current and

relevant information is identified, extracted, and

prepared for further processing; in step (2), the

information is integrated, and their inconsistencies

are reconciled. As prerequisite, both steps require a

“semantic lifting” of the information stored in the

XML files. The integration steps are carried out in

the comprehensive information base (CIB). Fig.3

gives a schematic representation.

XMLXML

XMLXML

Schema ontologySchema ontology

Document

ontology

Document

ontology

XML-

Schema

describes describes

Comprehensive Information Base (CIB)

2. Step: Data integration

and consolidation

1. Step: Current data selection

(optional)

Local Schema

Global Schema

Figure 3: Schematic representation of the CIB.

For testing purposes, the integration tool

currently employs PlantXML files, which is a data

exchange format realized via XML files that comply

with a company-internal standard schema.

PlantXML is the existing in-house solution for the

information exchange between application tools

which has been implemented by the engineering

department of our project partner Evonik Degussa

(Anhäuser et al., 2004): PlantXML defines specific

XML schemata for the different phases and crafts of

a design project: XML-EQP for the design of

machines and apparatuses, XML-EMR for the

design of instruments and control systems, XML-

RLT for piping engineering, and XML-SiAr for the

design of fittings and safety valves. However, the

novel integration tool is designed in such a way, that

it can process any data in the XML format as long as

it complies with an available XML schema.

In step (1), the relevant information items from

each of the scattered sources in terms of PlantXML

files must be identified, extracted, and assembled in

the CIB. PlantXML’s organization and structure is

accommodated to the project designers’ workflow

and supports parallel and distributed workmanship

according to the complex workflow of a design

project, e.g. split of work, concurrent engineering,

and distributed engineering. Correspondingly, in the

course of a project several instances of the different

PlantXML schema are generated. In other words,

different versions of identical real world items exist.

Hence, no stringent versioning of the data items is

possible according to the complex workflow of

SEMANTIC DATA INTEGRATION FOR PROCESS ENGINEERING DESIGN DATA

193

identical real world objects in different crafts. Thus,

a versioning of the data items is required, i.e., the

current information of each source has to be

determined. Furthermore, redundant information has

to be detected and rejected. At the end of step (1) the

designer may choose one of the two options: the pre-

processed data can either be reconverted to the

PlantXML format and thus be integrated in the

existing workflow, or one obtains a pre-processed

data set for further processing in step (2). Note that

step (1) is optional. Considering an alternative XML

data set with an existing versioning procedure, the

actual and relevant information may be extracted to

the CIB for a direct processing at step (2).

Step (2) performs the actual integration, which

essentially requires the merging of the current

information from each source and the check for

inconsistent information from the different sources.

For the latter, the global schema (domain ontology

based on OntoCAPE) established within the CIB

provides the necessary vocabulary in terms of

classes and relations, and defines the feasible

interrelations between the vocabulary terms. This

way, it can be checked if the semantic representation

of the merged information complies with the feasible

interrelations defined in the domain ontology. As a

result, potential design errors and inconsistencies

can be detected and reported to the designer. A

typical example for step (2) is given in Fig. 4, where

the connection of a vessel extracted from the XML-

EQP schema to a pipe taken from the XML-EMR

schema is validated against the domain ontology.

domain

ontology

Equipment Pipe

isAttachedTo

Nozzle

has 0..n 0..2

RLT_File_12

<Pipe_23>

<Nozzle id=„1">

…

</Nozzle>

…

</Pipel_23>

EQP_File_22

<Vessel_11>

<Nozzle id=„1">

…

</Nozzle>

…

</Vessel_11>

Vessel_11 Pipe_23Nozzle_EQP_1

EQP_File_22 RLT_File_12

Nozzle_RLT_1

sameAs

hasContent

has

hasContent

attachedTo

instantiation association

specialisation

class

instance

instantiation association

specialisation

class

instance

sameAs

RLT-SchemaEQP-Schema

0..n 0..n

Vessel_EQP Nozzle_EQP

hasContent

has

Pipe_RLTNozzle_RLT

hasContent

0..n 0..n

attachedTo

Document

ontology

Document

ontology

Figure 4: Application example of the CIB.

3.2 Implementation

The core of the implementation is the CIB as

mentioned before. Essentially, we intend to use

semantic technologies for the realization of the

prototypical software tool as far as possible.

An advantage of ontology-based systems over

conventional database technology is the possibility

to partially automate the information integration

process. The inference mechanism of deduction (i.e.

execution of production rules) is especially

applicable for this aim. Deduction is particularly

useful for merging and consolidating of distributed

information (Maier et al., 2003) and thus decided to

employ a deductive language (and a compatible

inference engine) for the integration tool.

However, some of the requirements on the CIB

might still be achieved more conveniently by

conventional database technologies. As an example

consider mass data which do not require a semantic

enrichment for consolidation purposes.

Thus, an implementation basis has to be chosen

which fulfils the requirements for both technologies

equally well. Accordingly, the development system

OntoStudio (OntoStudio, 2007), which has been

developed by the project partner ontoprise, serves as

the implementation basis. Unlike most other

ontology-based systems available today, OntoStudio

is scalable and thus suitable for processing of large

data as it is presumed in this project.

It relies on the deductive ontology language F-

Logic (Kifer et al., 1995), which allows the

definition of rules for integration and mapping

purposes, and the formulation of queries. These rules

represent declarative knowledge in the form “if A

then B”, where A and B are statements about the

extracted information expressed by means of

ontological terms. This approach is more intuitive

and less error-prone than conventional database

integration, especially in complex contexts with

many relations between the data objects (Maier et

al., 2003).

So far, the CIB has been tested against small to

medium size data quantities and has been able to

fulfill all requirements. However, in future tests the

complexity and amounts of real plant data will prove

the applicability for real world data in the chemical

industry. Therefore, the aforementioned ability to

combine conventional database and semantic

technologies in the CIB will be exploited.

4 CONCLUSIONS

This contribution reports on a current research

project at the authors’ institute that deals with the

development of a prototypical software tool for the

integration and reconciliation of distributed design

data like they are arising in a typical design project

in chemical engineering. Based on the existing

ICEIS 2008 - International Conference on Enterprise Information Systems

194

integration solution PlantXML, which provides

syntactic and structural homogeneous data sets

accomplished by means of XML, the tool

particularly aims at resolving semantic

heterogeneities between the distributed information

by defining an explicit representation of a data

source’s semantics by means of ontologies. To that

end, the prototype incorporates the formal ontology

OntoCAPE for the representation of the particular

domain knowledge. Ultimately, the tool will extract,

merge, and consolidate data from files in the

PlantXML format in order to create a comprehensive

information base (CIB). As a result, the further

processing in the CIB will provide a detection and

visualization of design errors.

The CIB, executing the information integration

and reconciliation, is implemented in the design

environment OntoStudio. The OntoCAPE ontology,

is represented in the deductive ontology language F-

Logic within OntoStudio.

REFERENCES

Anhäuser, F., Richert, H., Temmen, H., 2004. PlantXML-

integrierter Planungsprozess mit flexiblen Bausteinen.

atp- Automatisierungstechnische Praxis 46:10, 61-71.

Brandt, S.C., Morbach, J., Miatidis, M., Theißen, M.,

Jarke, M., Marquardt, W., 2008. An ontology-based

approach to knowledge management in design

processes. Comp. Chem. Eng., 32, 320-342.

Yang, A., Braunschweig, B., Fraga, E., Guessoum, Z.,

Marquardt, W., Nadjemi, O., Paen, D., Piñol, D.,

Roux, P., Sama, S., Serra, M., Stalker, I., 2007. A

multi-agent system to facilitate component-based

process modelling and design. Comput. Chem. Eng., in

press.

Cruz, I., Xiao H., Hsu F., July 7-9 2004. An Ontology-

based Framework for XML Semantic Integration.

Eighth International Database Engineering and

Applications Symposium, IDEAS'04, Coimbra,

Portugal, University of Illinois at Chicago.

Embury, S.M., Brandt, S.M., Robinson, J.S., Sutherland,

I., Bisby, F.A., Gray, W.A., Jones, A.C., White, R.J.,

2001. Adapting integrity enforcement techniques for

data reconciliation. Inf. Syst., 26(8), 657-689.

Erdmann, M., Studer, R., 2001. How to structure and

access, XML documents with ontologies. Data &

Knowledge Engineering, 36(3), 317 – 335.

Fedai, M., Drath, R., 2004. CAEX – ein neutrales

Austauschformat für Anlagendaten – Teil 1. In: atp-

Automatisierungstechnische Praxis 46:2, 52-56.

Galaher, M.P., O’Connor, A.C., Dettbarn Jr., J.L., Gilday,

L.T., 2004. Cost analysis of inadequate

interoperability in the U.S. capital facilities industry.

In: Technial Report NIST GCR 04-867. NIST-

National Institut of Standatds and Technology.

Kifer, M., Lausen, G., Wu, J.. Logical foundations of

object-oriented and frame-based languages. In:

Journal of the ACM (42:4).

Klein, M., 2002. Interpreting XML Documents via an

RDF Schema Ontology. In: 13th International

Workshop on Database and Expert Systems

Applications (DEXA'02), dexa, 889.

Lenzerini, M., 2002. Data integration: A theoretical

perspective. In: Proc. Of the 21

st

ACM SIGACT

SIGMOD SIBART Symp. On Principles of Database

Systems (PODS 2002), 233-246.

Levy, A. Y., 2001. Answering queries using views: a

survey. VDBL Journal

Maier, A., Aguado, J., Bernaras, A., Laresgoiti, I.,

Pedinaci, C., Pena, N., Smithers, T., 2003. Integration

with ontologies. In: Reimer, U., Abecker, A., Staab,

S., Stumme, G., (eds.): Professionelles

Wissensmanagement – Erfahrungen und Visionen,

Beiträge der 2. Konferenz Professionelles

Wissensmanagement.

Morbach, J., Marquardt, W., 2008. Ontology-Based

Integration and Management of Distributed Design

Data. To appear in: Nagl, M., Marquardt, W., (eds.):

Collaborative and Distributed Chemical Engineering

Design Processes: From Understanding to Substantial

Support, Springer. Berlin, Chapter 7.1.

Morbach, J., Theißen, M., Marquardt, W., 2008.

Integrated Application Domain Models for Chemical

Engineering. To appear in: Nagl, M., Marquardt, W.,

(eds.): Collaborative and Distributed Chemical

Engineering: From Understanding to Substantial

Design Process Support, Springer. Berlin, Chapter 2.6.

Morbach, J., Yang, A., Marquardt, W., 2007. OntoCAPE –

a large-scale ontology for chemical process

engineering. Eng. Appl. Artif. Intel., 20(2), 147-161

Noumonon Consulting Limited, 2006. Open Access to

Intelligent Process Plant models. Website:

http://www.noumenon.co.uk/XMpLantOverview.html.

OntoCAPE, 2007, Access OntoCAPE, Website:

http://www.avt.rwth-

aachen.de/AVT/index.php?id=486

OntoStudio, 2007, OntoStudio Website: http://www

.ontoprise.de/content/e1171/e1249/index_eng.html

Stuckenschmidt, H., Klein, M., 2003. Integrity and

Change in Modular Ontologies. In: Proceedings of the

International Joint Conference on Artificial

Intelligence - IJCAI '03, Acapulco, Mexico, Morgan

Kaufmann, 900-905.

Uschold, M., Gruninger, M., 1996. Ontologies: Principles,

Methods and Applications. In: Knowl. Eng. Rev., 11,

93-155.

Yang, A., Marquardt, W., 2004. An Ontology-Based

Approach to Conceptual Process Modeling. In:

Barbarosa-Póvoa, A., Matos, H., (eds.): Proceedings

of the European Symposium on Computer Aided

Process Engineering – ESCAPE 14, Elsevier, 1159-

1164.

SEMANTIC DATA INTEGRATION FOR PROCESS ENGINEERING DESIGN DATA

195