INTEROPERABILITY IN THE PETROLEUM INDUSTRY

Jon Atle Gulla

Department of Computer and Information Science

Norwegian University of Science and Technology, Norway

Keywords: Interoperability, data integration, ontology engineering, enterprise integration.

Abstract: The petroleum industry is a technically challenging business with highly specialized companies and

complex operational structures. Several terminological standards have been introduced over the last few

years, though they address particular disciplines and cannot help people collaborate efficiently across

disciplines and organizational borders. This paper discusses the results from the industrally driven

Integrated Information Platform project, which has developed and formalized an extensive OWL ontology

for the Norwegian petroleum business. The ontology is now used in production reports, and the ontology is

considered vital to semantic interoperability and the concept of integrated operations on the Norwegian

continental shelf.

1 INTRODUCTION

The petroleum industry on the Norwegian

continental shelf (NCS) is technically challenging

with challenging subsea installations and difficult

climatic conditions. It is a fragmented business, in

the sense that there is little collaboration between

phases and disciplines in large petroleum projects.

There are many specialized companies involved,

though their databases and applications tend not to

be well integrated with each other. Research done

by the Norwegian Oil Industry Association (OLF)

shows that there is a need for more collaboration and

integration across phases, disciplines and companies

to maintain the industry’s profitability (OLF,

2005b). The existing standards do not provide the

necessary support for this, and the result is costly

and risky projects and decisions based on wrong or

outdated data.

This paper presents the vision and some main

results of the Integration Information Platform (IIP)

project. The idea of the IIP project was to extend

and formalize an existing terminology standard for

the petroleum industry, ISO 15926. Using Semantic

Web technologies, we have turned this standard into

a real ontology that provides a consistent

unambiguous terminology for selected areas in the

oil and gas industry. The results of the project so far

are promising, and the ontology developed by IIP is

now being adopted by industry and is used in

production reporting to the government.

The work in IIP is the first step towards the

concept of integrated operations in the petroleum

sector. In this long-term vision semantic standards

and tools enable companies to work seamlessly

together across geographical and organizational

borders, and people from different disciplines or

phases can cooperate without terminological

confusion and misunderstandings.

The paper is organized as follows. In Section 2

we go through the structures and challenges in the

subsea petroleum industry, explaining the status of

current standards and the vision of future integrated

operations. Section 3 briefly presents the parts of

the Semantic Web initiative relevant to this project.

Whereas the ontological work in the IIP project is

introduced in Section 4, we discuss the issue of

introducing semantic standards in the petroleum

business in Section 5. Conclusions are found in

Section 6.

2 THE SUBSEA PETROLEUM

INDUSTRY

The Norwegian subsea petroleum industry is

characterized by sophisticated technologies and

highly competent and specialized companies. Many

disciplines and competences need to come together

in oil and gas projects, and their success is highly

affected by the way people and systems collaborate

and coordinate their work. On the Norwegian

33

Atle Gulla J. (2008).

INTEROPERABILITY IN THE PETROLEUM INDUSTRY.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - DISI, pages 33-40

DOI: 10.5220/0001694100330040

Copyright

c

SciTePress

Continental Shelf (NCS) there are traditional oil

companies like Statoil, Norsk Hydro and

ElfTotalFina, but also specialized service companies

like Schlumberger, Haliburton, Baker Hughes, Aker

Kværner, FMC KongsbergSub, and smaller ICT

service companies.

Both the projects and the subsequent production

systems are information-intensive. When a well is

put into operation, the production has to be

monitored closely to detect any deviation or

problems. The next generation subsea systems will

include numerous sensors that measure the status of

the systems and send real-time production data back

to onshore operation centers. For these centers to be

effective, they need tools that allow them to

understand and harmonize data, relate it to other

relevant information, and help them deal with the

situation at hand. There is a challenge in dealing

with the sheer size of this information, but also in

interpreting information that is deeply rooted in very

technical terminologies.

The Norwegian petroleum industry is now facing

a number of challenges (OLF, 2005a): Firstly, as

most of the resources are in the decline phase, we

now produce 2-3 times more oil than what is added

through the development of new fields. Secondly,

the costs on all the bigger fields are increasing

significantly as we enter the decline phase. Thirdly,

we see a development from traditional big oil fields

of 300-400 million Sm3 (standard cubic meters,

equal to 6.29 barrels) to fields of only 3-5 million

Sm3, which also implies that many small and

specialized companies enter the market. Lastly, the

exploration in the north is environmentally very

sensitive and requires new approaches to deal with

climatic and geographical issues.

All these trends pose a challenge to the

profitability of existing and future petroleum fields

on NCS. While the costs of old large fields are

increasing, the new ones are financially less

attractive due to scalability problems. The multitude

of companies involved, with their own applications

and databases, makes coordination and collaboration

more important than in the past. For the industry as

a whole, this severely hampers the integration of

applications and organizations as well as the

decision making processes in general:

• Integration. Even though there is some

cooperation between companies in the

petroleum sector, this cooperation tends to be

set up on an ad-hoc basis for a particular

purpose and supported by specifically designed

mappings between applications and databases.

There is little collaboration across disciplines

and phases, as they usually have separate

databases structured according to different

goals, processes and terminologies. It is of

course possible to map data from one database

to another, but with the complexity of data and

the multitude of companies and applications in

the business this is not a viable approach for the

industry as a whole.

• Decision Making. A current problem is the

lack of relevant high-quality information in

decision making processes. Some data is

available too late or not at all because of lack of

integration of databases. In other cases relevant

data is not found due to differences in

terminology or format. And even when

information is available, it is often difficult to

interpret its real content and understand its

limitations and premises. This is for example

the case when companies report production

figures to the government using slightly

different terminologies and structures, making

it very hard to compare figures from one

company to another.

XML is already used extensively in the petroleum

industry as a syntactic format for exchanging data.

Over the last few years, there have been several

initiatives for defining semantic standards to support

information sharing in the business, but they have

typically been limited to particular disciplines,

companies or activities.

2.1 ISO 15926 Integration of Life-Cycle

Data

ISO 15926 is a standard for integrating life-cycle

data across phases (e.g. concept, design,

construction, operation, decommissioning) and

across disciplines (e.g. geology, reservoir, process,

automation). It consists of 7 parts, of which part 1, 2

and 4 are the most relevant to this work. Whereas

part 1 gives a general introduction to the principles

and purpose of the standard, part 2 specifies the

representation language for defining application-

specific terminologies. Part 2 comes in the form of a

data model and includes 201 entities that are related

in a specialization hierarchy of types and sub-types.

It is intended to provide the basic types necessary for

defining any kind of industrial data. Being specified

in EXPRESS (International Standards Association,

2007), it has a formal definition based on set theory

and first order logic.

Part 4 of ISO 15926 is comprised of application

or discipline-specific terminologies, and is usually

referred to as the Reference Data Library (RDL).

These terminologies, described as RDL classes, are

ICEIS 2008 - International Conference on Enterprise Information Systems

34

instances of the data types from part 2, are related to

each other in a specialization hierarchy of classes

and sub-classes as well as through memberships and

relationships. If part 2 defines the language for

describing standardized terminologies, part 4

describes the semantics of these terminologies. Part

4 today contains approximately 50.000 general

concepts like motor, turbine, pump, pipes and

valves.

ISO 15926 is still under development, and only

Part 1 and 2 have so far become ISO standards. In

addition to adding more RDL classes for new

applications and disciplines in Part 4, there is also a

discussion about standards for geometry and

topology (Part 3), procedures for adding and

maintaining reference data (Part 5 and 6), and

methods for integrating distributed systems (Part 7).

Neither ISO 15926 nor other standards have the

scope and formality to enable proper integration of

data across phases and disciplines in the petroleum

industry.

2.2 Integrated Operations

The Norwegian Oil Industry Association launched

the Integrated Operations program in 2004. The

fundamental idea is to integrate processes and

people onshore and offshore using new information

and communication technologies. Facilities to

improve onshore’s abilities to support offshore

operationally are considered vital in the first phase

of this program. Personnel onshore and offshore

should have access to the same information in real-

time and their work processes should be redefined to

allow more collaboration and be less constrained by

time and space. OLF has estimated that the

implementation of integrated operations on NCS can

increase oil recovery by 3-4%, accelerate production

by 5-10% and lower operational costs by 20-30%

(OLF, 2005b).

Central in the program is the semantic and

uniform manipulation of heterogeneous data that

can be shared by all relevant parties. Decisions

often depend on real-time production data,

visualization data, and background documents and

policies, and the data range from highly structured

database tables to unstructured textual documents.

This necessitates intelligent facilities for capturing,

tracking, retrieving and reasoning about data.

The first generation of OLF’s integrated

operations includes the definition of common

terminologies that enable the automatic transfer of

data between applications in the same discipline or

inside the same company. Onshore operation centers

for monitoring and controlling subsea oil

installations are also part of this generation. The

second generation requires complete formal

ontologies that cover multiple domains and

disciplines and support reasoning and inference of

data using real-time data and rules. This will allow

operators and vendors to integrate their operation

centers, and subsea installations can to some extent

control themselves using smart sensors and rule-

based control systems that make use of semantic

standards to integrate and interpret data from highly

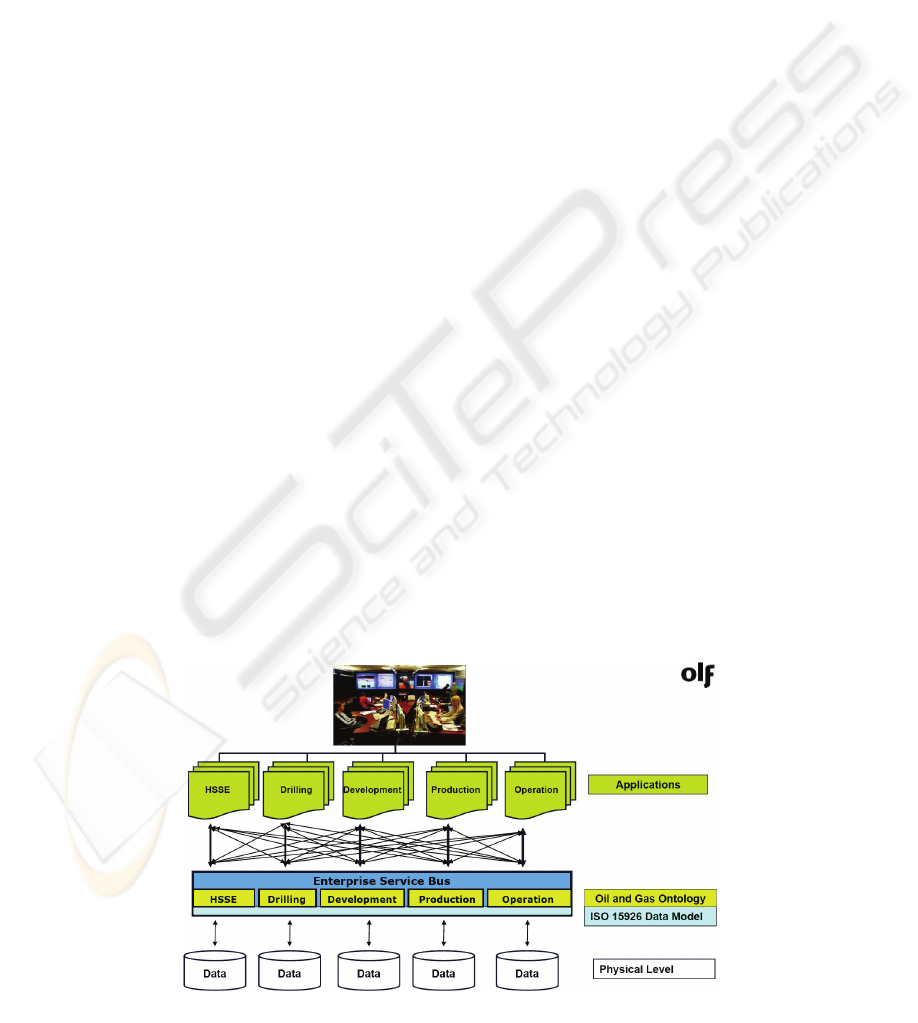

heterogeneous sources. Figure 1 shows how a

comprehensive oil and gas ontology based on ISO

15926 is intended to support integration across

disciplines and phases.

3 SEMANTIC WEB AND

INTEROPERABILITY

“The Semantic Web is an extension of the current

web in which information is given well-defined

meaning, better enabling computers and people to

Figure 1: An oil and gas ontology allows cooperation across companies and disciplines (adapted from OLF).

INTEROPERABILITY IN THE PETROLEUM INDUSTRY

35

work in cooperation” (Berners-Lee et al., 2001).

The Semantic Web is a collaborative effort led by

W3C with participation from a large number of

researchers and industrial partners. The general idea

is to annotate data and services with machine-

processable semantic descriptions. These

descriptions must be specified according to a certain

grammar and with reference to a standardized

domain vocabulary. The domain vocabulary is

referred to as an ontology and is meant to represent a

common conceptualization of some domain. The

grammar is a semantic markup language, as for

example the OWL web ontology language

recommended by W3C. With these semantic

annotations in place, intelligent applications can

retrieve and combine documents and services at a

semantic level, they can share, understand and

reason about each other’s data, and they can operate

more independently and adapt to a changing

environment by consulting a shared ontology (Sheth

et al., 2002; Zhong et al., 2002).

Interoperability can be defined as a state in

which two application entities can accept and

understand data from the other and perform a given

task in a satisfactory manner without human

intervention. We often distinguish between

syntactic, structural and semantic interoperability

(Aguilar, 2005; Dublin Core, 2004):

• Syntactic interoperability denotes the ability of

two or more systems to exchange and share

information by marking up data in a similar

fashion (e.g. using XML).

• Structural interoperability means that the

systems share semantic schemas (data models)

that enable them to exchange and structure

information (e.g. using RDF).

• Semantic interoperability is the ability of

systems to share and understand information at

the level of formally defined and mutually

accepted domain concepts, enabling machine-

processable interpretation and reasoning.

For the Semantic Web technology to enable

semantic interoperability in the petroleum industry,

it needs to tackle the problem of semantic conflicts,

also called semantic heterogeneity. Since the

databases are developed by different companies and

for different phases and/or disciplines, it is often

difficult to relate information that is found in

different applications. Even if they represent the

same type of information, they may use formats or

structures that prevent the computers from detecting

the correspondence between data. For example, the

tables ORG_NAME and COMPNY in two different

applications may in fact contain the same

information about organizations. Similarly, while a

time period may be modeled with the variables

“StartTime” and “Endtime” in one database, the

same information may be represented with

“StartTime” and “Duration” in another (see for

example (Pollock & Hodgson, 2004)). Even for

concepts that are well understood and subjected to

international conventions, the definitions may be

slightly different from one source to another. The

descriptions of ‘mean time between failure’ in

Figure 2, which are extracted from various sources

used in the petroleum industry, are almost identical,

but it turns out that the differences are large enough

to cause problems when data about mean times are

transferred between applications.

Mean time between failure

1 “A period of time which is the mean period of time

interval between failures”

2 “The time duration between two consecutive

failures of a repaired item” (International

Electrotechnical Vocabulary online database)

3 “The expectation of the time between failures”

(International Electrotechnical Vocabulary online

database)

4 “The expectation of the operating time between

failures” (MIL-HDBK-29612-4)

5 “Total time duration of operating time between two

consecutive failures of a repaired item”

(International Electrotechnical Vocabulary online

database)

6 “Predicts the average number of hours that an item,

assembly, or piece part will operate before it fails”

(Jones, J. V. Integrated Logistics Support

Handbook, McGraw Hill Inc, 1987)

7 “For a particular interval, the total functional life of

a population of an item divided by the total number

of failures within the population during the

measurement interval. The definition hoolds for

time, rounds, miles, events, or other measure of life

units”. (MIL-PRF-49506, 1996, Performance

Specification Logistics Management Information)

8 “The average length of time a system or component

works without failure” (MIL-HDBK-29612-4)

Figure 2: Different definitions of ‘mean time between

failure’.

The Semantic Web’s approach to these problems

is the construction of shared formal ontologies of all

important domain concepts. These may be specified

in OWL, which is a semantic markup language

based on Description Logic. It has an XML syntax,

is built on top of RDF(S)’s property statements and

class hierarchies, and adds constraints for class

membership, equivalence, consistency and

classification (Antoniou et al., 2005; W3C, 2006).

ICEIS 2008 - International Conference on Enterprise Information Systems

36

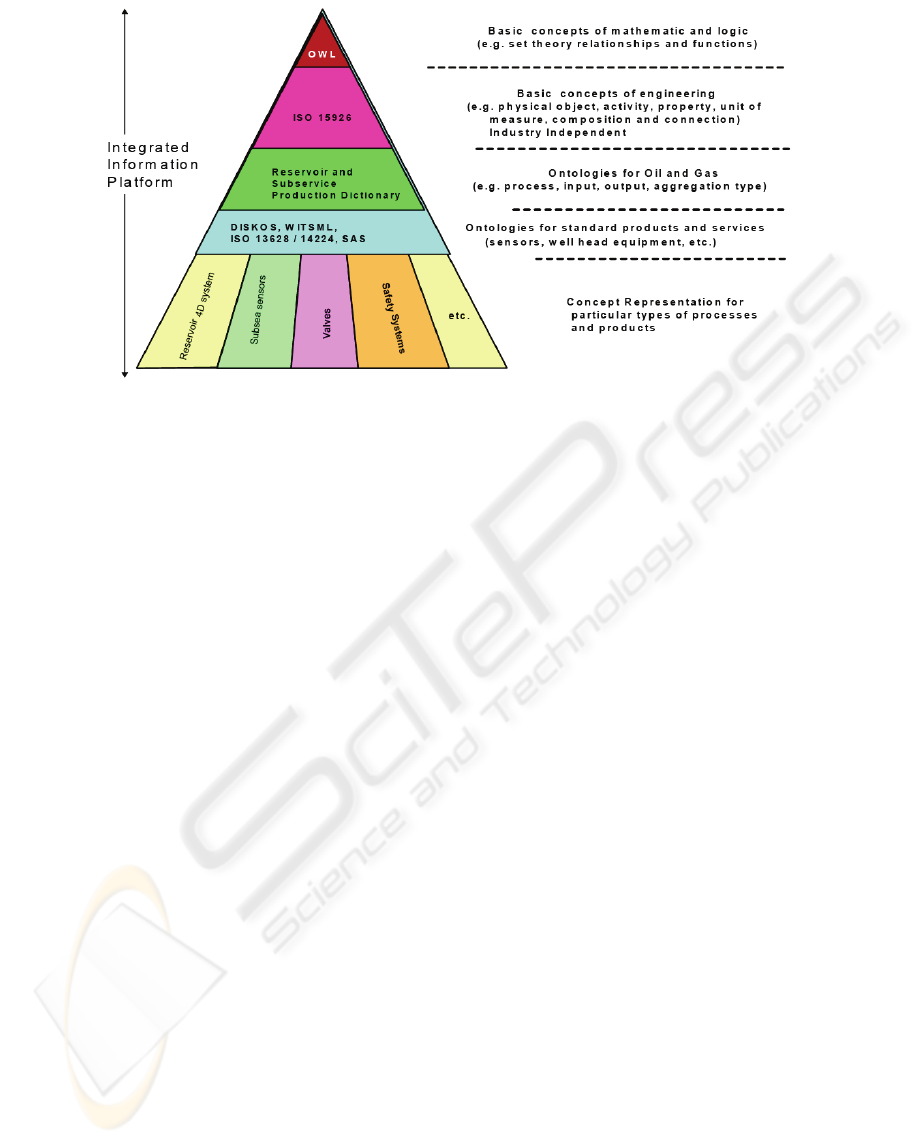

Figure 3: The standardization approach in IIP.

4 DEVELOPING OIL AND GAS

ONTOLOGIES

The Integrated Information Platform (IIP) project

was a collaboration project between companies

active on NCS and academic institutions, supported

by the Norwegian Research Council (Sandsmark &

Mehta, 2004). Its long-term target was to increase

petroleum production from subsea systems by

making high quality real-time information for

decision support accessible to onshore operation

centers. The IIP project started in June 2004 and

terminated at the end of June 2007 with a total

budget of 26 million NOK (about 3.25 million

Euro). The participants included Det Norske

Veritas, Statoil, Norsk Hydro, Cap Gemini,

Poseidon, OLF, FMC Technologies, National

Oilwell Varco, OilCamp, POSC, IBM and NTNU.

The project addressed the need for a common

understanding of terms and structures in the subsea

petroleum industry. The objective was to ease the

integration of data and processes across phases and

disciplines by providing a comprehensive

unambiguous and well accepted terminology

standard that lends itself to machine-processable

interpretation and reasoning. This should reduce

risks and costs in petroleum projects and indirectly

lead to faster, better and cheaper decisions

The project has identified a representative set of

real-time data from reservoirs, wells and subsea

production facilities. The OWL web ontology

language was chosen as the markup language for

describing these terms semantically in an ontology.

The entire standard is thus rooted in the formal

properties of OWL, which has a model-theoretic

interpretation and to some extent support formal

reasoning. A major part of the project was to

convert and formalize the terms already defined in

ISO 15926 Part 2 (Data Model) and Part 4

(Reference Data Library). Since the ISO standard

addresses rather generic concepts, though, the

ontology also includes more specialized

terminologies for the oil and gas segment. Detailed

terminologies for standard products and services

were included from other dictionaries and initiatives

(DISKOS,WITSML, ISO 13628/14224, SAS), and

the project also opened for the inclusion of terms

from particular processes and products at the bottom

level. In sum, the ontology built in IIP has a

structure as shown in Figure 3.

The ontology engineering approach in IIP was a

combination of converting formal ISO 15926

definitions to manual modeling and verification of

ontological structures. Due to the formality of ISO

15926’s EXPRESS notation most of the ISO

concepts could be automatically converted into legal

OWL constructs. The manual modeling part was led

by Det Norske Veritas and was handled by multi-

disciplinary teams with years of experiences from

standardization work and modeling projects.

This conversion of ISO 15926-2/4 from

EXPRESS gave us an OWL hierarchy that has

formed the backbone of the new oil and gas

ontology. Additional terms were gradually and

manually added to this hierarchy to reflect the larger

scope of the new standard. In these initial stages it

was considered important to concentrate on

hierarchical relationships between concepts.

Relationships and constraints of classes and

relationships, which are needed for more

INTEROPERABILITY IN THE PETROLEUM INDUSTRY

37

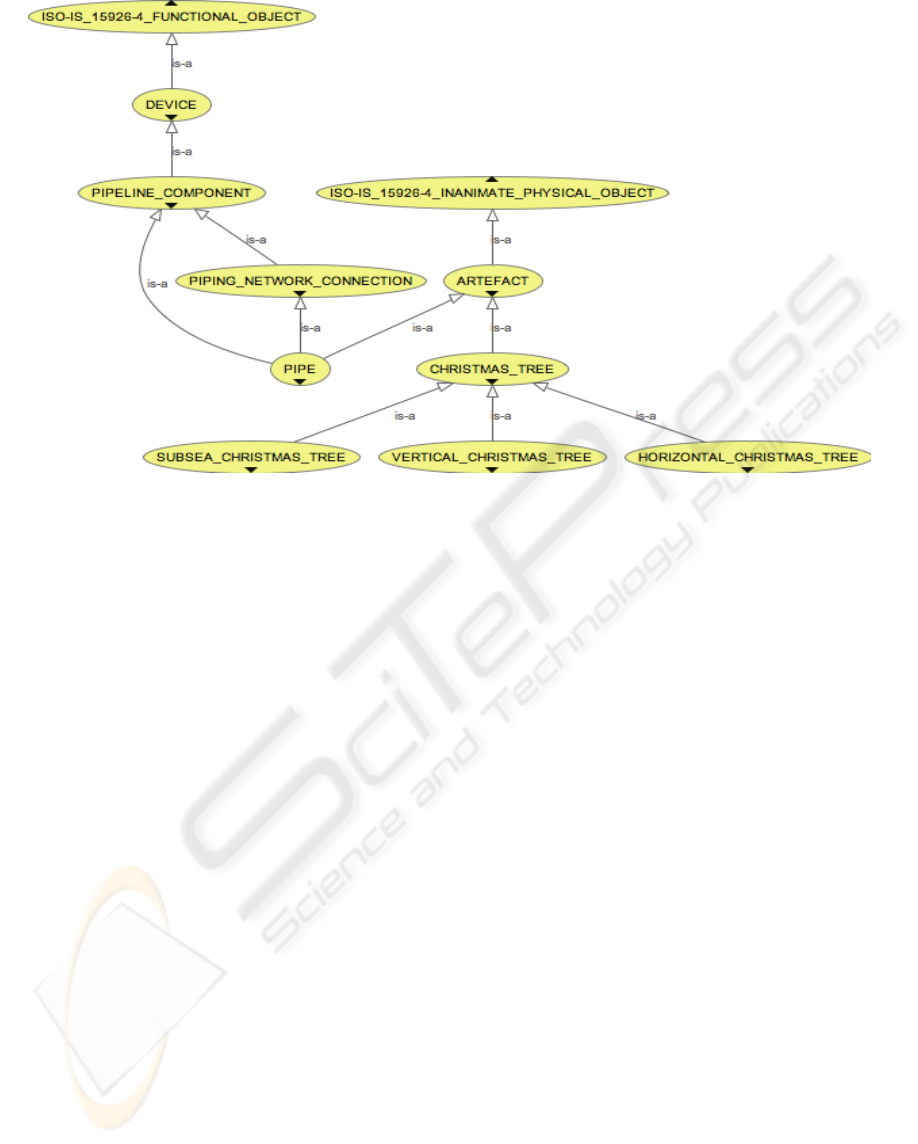

Figure 4: Christmas tree OWL hierarchy.

sophisticated reasoning with rules, are assumed to be

added over time as the ontlogy matures.

Take for example the concept Christmas tree,

which is an assembly of parts that is connected to

the top of a wellhead to control the flow out of the

well. Its OWL definition (without relationships and

constraints) is:

<owl:Class rdf:about="#CHRISTMAS_TREE">

…

<dc:description

rdf:datatype="http://www.w3.org/2001/XMLSchema#strin

g">

An artefact that is an assembly of pipes and

piping parts, with valves and associated

control equipment that is connected to the top

of a wellhead and is intended for control of

fluid from a well.

</dc:description>

<dc:title

rdf:datatype="http://www.w3.org/2001/XMLSchema#strin

g">

CHRISTMAS TREE

</dc:title>

…

<rdfs:subClassOf rdf:resource="#ARTEFACT"/>

</owl:Class>

These statements give us an informal definition

of Christmas trees and reveal that they are

subclasses of artefact. Looking at the excerpt of the

class hierarchy in Figure 4, we see that there are at

least three types of Christmas tree (subsea, vertical,

and horizontal). It is a specialization of Artefact,

which in turn is an Inanimate physical object that is

made or given a shape by man. The Pipe class is

also a specialization of Artefact, but it is also a

specialization of two other classes. This is quite

natural, as the pipe both has a physical (artefact) and

a functional dimension (pipeline or network

connection). More details about the construction of

the ontology can be found in (Christiansen et al.,

2005).

The IIP project has now converted the ISO

15926 Part 2 (210 elements) and Part 4 (about

50.000) elements into OWL class hierarchies. In

addition, we have incorporated additional terms

from the following disciplines:

• Geometry and topology: ca. 400 terms

• Drilling and logging: ca. 2.700 terms

• Production: ca. 2.000 terms

• Safety and automation: ca. 150 terms

• Subsea equipment: ca. 1.000 terms

• Reservoir characterization

• Reliability and maintenance

The Tyrihans oil field, operated by Statoil, was

used as a case in the IIP project. This means that the

initial terms included in the ontology were based on

the Tyrihans specifications, though they had been

generalized and verified against other specifications

as well, like ISO 13628 “Petroleum and natural gas

industries – Design and operation of subsea

production systems”. The ontology is the basis for

developing new semantically interoperable

applications, and IIP has already started

experimenting with integrated visualization and

information retrieval environments.

ICEIS 2008 - International Conference on Enterprise Information Systems

38

5 INDUSTRIAL ADOPTION OF

SEMANTIC STANDARDS

In recent years a number of powerful new ontologies

have been constructed and applied in domains like

medicine and biology, where Semantic Web

technologies and web mining have been exploited in

new intelligent applications (Aguilar, 2005; Gene

Ontology Consortium, 2000; Pisanelli, 2004).

However, these disciplines are heavily influenced by

government support and are not as commercially

fragmented as the petroleum industry. Creating an

industry-wide standard in a fragmented industry is a

huge undertaking that should not be underestimated.

In this particular case, we have been able to build on

an existing standard, ISO 15926. This has ensured

sufficient support from companies and public

institutions. There is still an open question, though,

what the coverage of such an ontology should be.

There are other smaller standards out there, and

many companies use their own internal

terminologies for particular areas. The scope of this

standard has been discussed throughout the project

as the ontology grew and new companies signalled

their interest. For any standard of this complexity, it

is important also to decide where the ontology stops

and to what extent hierarchical or complementing

ontologies are to be encouraged. Techniques for

handling ontology hierarchies and ontology

alignment and enrichment must be considered in a

broader perspective.

As far as the construction of the ontology is

concerned, there was a need for both domain experts

and ontology engineers. Since both the syntax and

the semantics of OWL are non-trivial, it cannot be

assumed that domain experts do the modeling

themselves. To handle the complexity, the IIP

project decided to model only the hierarchical

relations in the first round, delaying relationships

and constraints until the hierarchies were stable. For

later update and quality assessment, it may be useful

to use text mining techniques for automatic term

extraction (Gulla et al., 2004; Maedche, 2002).

The quality of ontologies is a delicate topic. It is

important to choose an appropriate level of

granularity. In this project we have been fortunate

to have an existing standard to start with. What was

considered satisfactory in ISO 15926 may however

not be optimal for the ontology-driven applications

that will make use of the future ontology.

Ultimately, we need to consider how the ontology

will be used in these applications and the nature of

the source data to be annotated with ontological

descriptions.

Since the Semantic Web is still a rather

immature technology, there are still open issues that

need to be addressed in the future. One problem in

the IIP project is that we needed the full expressive

power of OWL (OWL Full) to represent the

structures of ISO 15926-2/4. Reasoning with OWL

specifications is then incomplete. The lack of

industrial SW applications is another issue worth

taking into consideration. There may be

performance and maintenance complexities that are

still unclear with such an untested technology.

However, there is now a large community promoting

SW technologies and developing innovative

applications, and the first commercial products have

also emerged. Additionally, the tool development in

IIP indicates that the technology can form the

semantic foundation for a new generation of

intelligent, interoperable information services.

The success of the new ontology, and

standardization work in general, depends on the

users’ willingness to commit to the standard and

devote the necessary resources. If people do not

find it worthwhile to take the effort to follow the

new terminology, it will be difficult to build up the

necessary support. This means that it is important to

provide environments and tools that simplify the use

and maintenance of the ontology. Intelligent

ontology-driven applications must demonstrate the

benefits of the new technology and convince the

users that the additional sophistication pays off. A

positive sign is that daily production reports and

daily drilling reports are now standardized across

companies with the help of our ontology, and the

major oil companies on NCS as well as IBM are

now working on a similar semantic standarization of

monthly production reports. The industry has

received the standard with enthusiasm and are

already planning new projects for further expansion

of the standard and the development of appropriate

semantic applications.

6 CONCLUSIONS

The Integrated Information Platform project is one

of the first attempts at applying state-of-the-art

Semantic Web technologies in an industrial context.

Existing standards have been converted and

extended into a comprehensive OWL ontology for

reservoir and subsea production systems. The

intention is that this ontology will later be approved

as an ISO standard and form a basis for developing

interoperable applications in the industry.

With the new ontology at hand, the industry will

have taken the first step towards integrated

operations on the Norwegian Continental Shelf.

Data can be related across phases and disciplines,

helping people collaborate and reducing costs and

INTEROPERABILITY IN THE PETROLEUM INDUSTRY

39

risks. However, there are costs associated with

building and maintaining such an ambitious

ontology. It remains to be seen if the industry is

able to take advantage of the additional expressive

power and formality of the new ontology. The work

in IIP indicates that both information retrieval

systems and sensor monitoring systems can benefit

from having access to an underlying ontology for

analyzing data and interpreting user needs.

As the class hierarchies in the ontology are

completed, the emphasis of the IIP project will be

put on adding more relationships and constraints to

the ontology. This also includes specifying rules

that will be used to analyze anomalies in the real-

time data from subsea sensors. At that point we can

start exploiting the logical properties of OWL and

start experimenting with the next generation rule-

based notification systems. We can also use agents

to simplify the coordination of work and improve

cooperation along the entire value chain. We will

then see if a strong semantic foundation makes it

easier for us to handle and interpret the vast amount

of data that are so typical to the petroleum industry.

ACKNOWLEDGEMENTS

This research is funded by the Integrated

Information Platform for reservoir and subsea

production systems project under the Petromax

research program.

REFERENCES

Aguilar, A. (2005). Semantic interoperability in the

context of e-health: CDH Seminar.

http://m3pe.org/seminar/aguilar.pdf.

Antoniou, G., Franconi, E., & van Harmelen, F. (2005).

Introduction to semantic web ontology languages. In

N. Eisinger & J. Maluszynski (Eds.), Reasoning web,

first international summer school. Malta: Springer.

Berners-Lee, T., Hendler, J., & Lassila, O. (2001). The

semantic web. Scientific American, 284(5), 34-43.

Christiansen, T., Jensen, M., & Valen-Sendstad, M.

(2005). Defining iso 15926-4 reference data library

classes in owl: The Norwegian Oil Industry

Association. http://www.olf.no/io/kunnskapsind/?28

140.pdf.

Dublin Core. (2004). Dublin core metadata glossary:

http://library.csun.edu/mwoodley/dublincoreglossary.h

tml.

Gene Ontology Consortium. (2000). Gene ontology: Tool

for the unification of biology. Nature Genet, 25, 25-

29.

Gulla, J. A., Brasethvik, T., & Kaada, H. (2004, June). A

flexible workbench for document analysis and text

mining. Paper presented at the 9th International

Conference on Applications of Natural Language to

Information Systems (NLDB'04), Salford.

International Standards Association. (2007). Industrial

automation systems and integration - product data

representation and exchange. Par 11: Description

methods: The express language reference manual.:

http://www.iso.org/iso/en/CatalogueDetailPage.Catalo

gueDetail?CSNUMBER=18348.

Maedche, A. (2002). Ontology learning for the semantic

web: Kluwer Academic Publishers.

OLF. (2005a). Digital infrastructure offshore - common

network operation management for digital

infrastructure offshore on the norwegian continental

shelf: The Norwegian Oil Industry Association.

OLF. (2005b). Integrated work processes: Future work

processes on the norwegian continental shelf: The

Norwegian Oil Industry Association.

Pisanelli, D. M. (Ed.). (2004). Ontologies in medicine.

Volume 102 studies in health technology and

informatics: IOS Press.

Pollock, J. T., & Hodgson, R. (2004). Adaptive

information: Improving business through semantic

interoperability, grid computing, and enterprise

integration: Wiley Publishers.

Sandsmark, N., & Mehta, S. (2004). Integrated

information platform for reservoir and subsea

production systems, Proceedings of the 13th Product

Data Technology Europe Symposium (PDT 2004).

Stockholm.

Sheth, A., Bertram, C., Avant, D., & Hammond, B.

(2002). Managing semantic content for the web. IEEE

Internet Computing, July/August, 80-87.

W3C. (2006). Owl web ontology language overview.

Http://www.W3c.Org/tr/owl-features/.

Zhong, N., Liu, J., & Yao, Y. (2002). In search of the

wisdom web. Computer, 27-31.

ICEIS 2008 - International Conference on Enterprise Information Systems

40