A SUPPLY CHAIN ONTOLOGY CONCEPTUALIZATION WITH

FOCUS ON PERFORMANCE EVALUATION

Alicia C. Böhm, Horacio P. Leone

Instituto de Desarrollo y Diseño, UTN – CONICET, Santa Fe, Argentina

Gabriela P. Henning

Instituto de Desarrollo Tecnológico para la Industria Química, UNL–CONICET, Santa Fe, Argentina

Keywords: Ontology, Supply Chain Management, Performance Evaluation, Metrics.

Abstract: Organizations all over the world are increasingly aligning in Supply Chains (SCs) in order to perform more

efficiently and to achieve better results. This contribution presents a SC ontology that aims at

conceptualizing and formalizing this domain knowledge. Its goal is to: a) enable a better understanding

among the various stakeholders & b) set the basis for an effective information sharing and the development

of integrations tools. The ontology introduces concepts associated with the SC structure, functions,

resources, and management issues. Since one key component of management is performance assessment,

which must be done along the whole SC, the proposed ontology focuses on performance evaluation issues.

1 INTRODUCTION

To efficiently operate a Supply Chain (SC), all its

participants (suppliers, manufacturers, distributors,

customers, third and fourth party logistics) must

have an enhanced and common understanding of it.

This allows to better communicate and to attain a

genuine integration of the activities executed by the

different functional areas and/or companies. This

challenge has motivated several research efforts that

addressed the development of models aimed at

describing the elements and processes associated

with a supply chain, as well as tackling specific SC

integration problems. Beamon (1998) presented a

review of the models that have been proposed for the

analysis and design of the SC. However, the only de

facto standard is the Supply Chain Operations

Reference (SCOR) model (SCOR, 2007). Although

this model is a good starting point for

communication among SC stakeholders, it provides

a slender modelling of processes, resources and the

relationships among them; so, its formalization

becomes a requirement for a more comprehensive

usage of the model.

Furthermore, performance evaluation is an

important supply chain management issue since it

provides significant information to make decisions

and to assess results. Thus, it can be seen as a basic

prerequisite for improvement.

In recent years, research on SC measurement has

increased significantly. This is reflected by the

growing number of contributions that have been

reported (Beamon, 1999; Brewer and Speh, 2000;

Lambert and Pohlen, 2001; Hausman, 2002;

Kleijnen and Smits, 2003; Gunasekaran et al., 2005;

Gaiardelli et al., 2007; Bhagwat and Sharma, 2007).

Nevertheless, most of these proposals do not

consider the fact that a measurement system may

involve different companies along the SC, and that

this issue could yield semantic problems when

information is shared by these distinct enterprises or

by different organizational areas.

Additionally, many contributions have put

forward several metrics, but their specification is

neither clear nor complete. Therefore, in most cases

it is difficult to distinguish what is supposed to be

measured and how measurements must be done. For

example, the metric identified as ‘Number of

stockouts’, proposed by Beamon (1999), is defined

as ‘Number of requested items that are out of stock’,

but it does not specify which period must be covered

(a week?, a month?, a year?), neither the ‘location’

where it must be measured (concerns a company?,

the whole supply chain?), nor the items being

402

C. Böhm A., P. Leone H. and P. Henning G. (2008).

A SUPPLY CHAIN ONTOLOGY CONCEPTUALIZATION WITH FOCUS ON PERFORMANCE EVALUATION.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - ISAS, pages 402-409

DOI: 10.5220/0001718004020409

Copyright

c

SciTePress

considered (all the products?, a product family?),

etc. Another relevant issue is that there are many

contributions which introduce valuable information

to help managers in the administration and operation

of an appraisal system. However, this matter is just

undertaken in different works in an isolated fashion

and using dissimilar terminology. In consequence,

there is a need to manage precise definitions; thus,

leading to a universal understanding of the SC

domain and measurement concepts, as well as a

proper interpretation of the shared information.

Considering all these challenges, this proposal

aims at contributing towards the formalization of the

SC domain and its evaluation system. Since

ontology-based models are expressive and minimize

interpretation ambiguities (Kim and Fox, 2002), the

goal of this paper is to propose an appropriate SC

ontology, named SCOntology. It provides a first

conceptualization of the SC structure, functions,

performance and management concepts. A special

emphasis is made on measurement and evaluation

aspects. Regarding this last issue, an ontology would

enable to make suitable comparisons, which

otherwise could not be done without interpreting the

relevant concepts in the same way.

In the next section the proposed ontology is

presented and an example on its application is

discussed. In section 3, conclusions are drawn.

2 SCOntology

2.1 Methodological Approach

The development of SCOntology was based on the

activities and construction life cycle recommended

by METHONTOLOGY (Fernández-López et al.,

1999). This methodology identifies specification,

conceptualization, formalization and implementation

activities as steps of the development process. In this

contribution, only the first two phases are addressed.

The specification entails the definition of the

ontology purpose, degree of granularity and scope.

In the conceptualization phase, the knowledge of the

domain is organized and structured using external

representations, which are independent of the

implementation languages and environments.

2.2 Specification

In order to specify the scope of the ontology, to

identify the set of relevant terms to be captured and

the relations among them, as well as to define the

characteristics and granularity of the relevant

concepts, a series of informal competency questions

were defined. Some of them are shown below.

1- Which organizations participate in a SC?

2- Which processes executed in a certain

organization are involved in a given SC?

3- How is a given process carried out? Which

activities are involved in its execution?

4- Which are the strategic, tactical and operational

goals of a SC?

5- How is a given goal monitored?

6- Which metrics can be used to assess the

performance of the SC from a customer/internal/

long term point of view?

7- What does a specific metric evaluate?

8- How is a certain metric calculated/computed?

9- Which temporal interval does a measure cover?

10- Which is the most recent measure of a certain

attribute of a given entity?

The most relevant terms to be represented are the

ones highlighted in bold.

The main knowledge sources for the ontology

development are the SCOR model (SCOR, 2007),

the Coordinates enterprise modelling language,

developed by Mannarino (2001), and the concepts

and ideas that resulted from a critical analysis of

other proposals on measurement systems.

The SCOR reference model is a general

framework proposed by the Supply Chain Council

that defines a language to represent the business

activities associated with all phases of satisfying a

customer's demand. In turn, the Coordinates

language allows representing enterprise processes

and their associated resources and products in an

integrated fashion, considering any type of possible

relations among them. It allows the analysis,

representation and comprehension of an enterprise in

terms of several dimensions.

2.3 Conceptualization

Many aspects need to be taken into account in a SC,

such as the network of participating organizations,

the different kinds of flows (material, information

and money), the several operational and

management strategies and practices, etc. Due to this

complexity, it is quite important to have mechanisms

to help analyzing this domain. Since all the domain

concepts cannot be included in just one view, the

proposed ontology considers the following

perspectives: structural, functional, performance and

management. This separation aims at clarifying the

A SUPPLY CHAIN ONTOLOGY CONCEPTUALIZATION WITH FOCUS ON PERFORMANCE EVALUATION

403

model; however, these different viewpoints are

interrelated, as they are part of the same ontology.

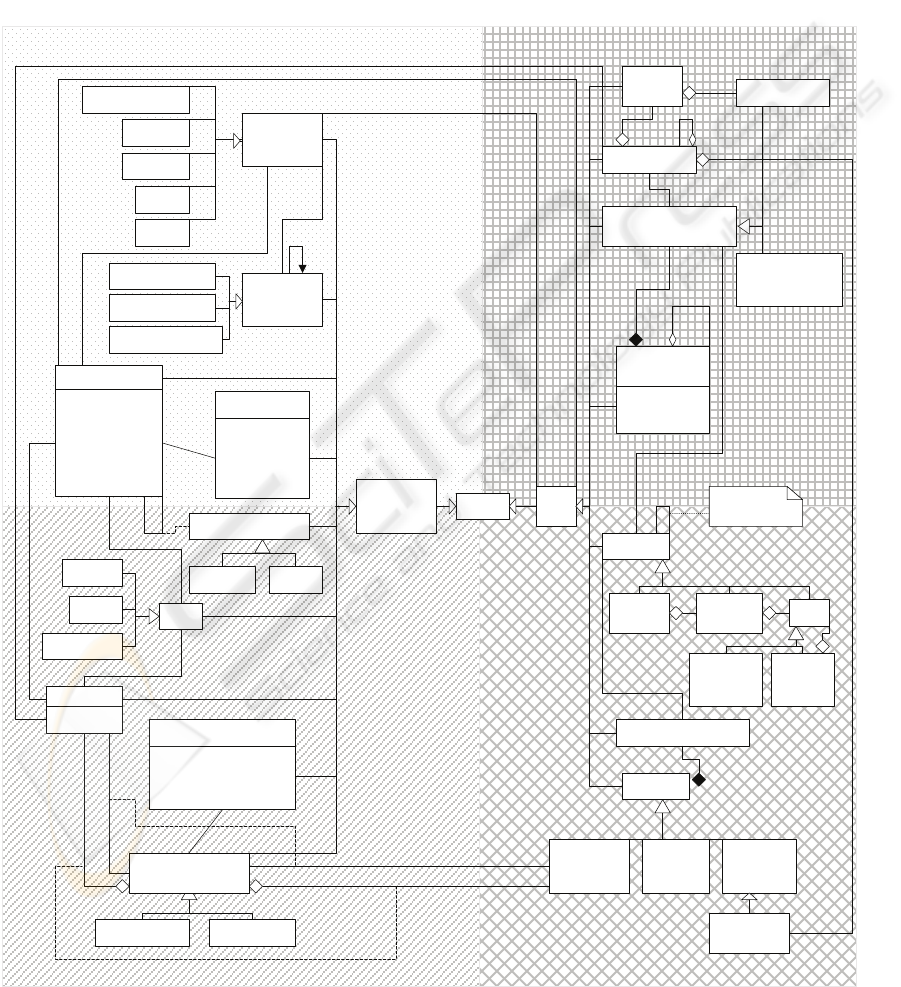

Figure 1 presents a UML diagram that includes

the different SCOntology views, their associated

concepts and relationships. Table 1 defines the main

concepts. The Entity concept is introduced in this

model in order to abstract any concrete or

conceptual thing of interest in the SC domain.

Nevertheless, this notion is specialized in SC Entity

and SC Information Entity. The former represents

the entities that are direct components of a SC,

which are related to the SC structural and functional

aspects, and the latter represents those entities

involved in the SC description (SC meta

information), which correspond to the SC

management and performance information views.

Management Concepts

Perf ormance Concepts

Functional Concepts

SC Structural Concepts

Value

Aggregation OP

Product

Process

Business

Process

Process

Element

Task

Complex

Tas k

Elementary

Task

Resource Perspective

Financial

Resource

Mat erial

Resource

SC

Entity

Entity

Responsiv eness

Reliability

Flexibility

Assets

Costs

Customer Facing

Long Term Facing

Internal Facing

Meas ure

value

timepoint

period

normalized

value

Metric Dependency

Increase Reduce

Strategic

Tac t ical

Operational

description

ty pe= {qualitativ e,

quantitativ e}

method

AggregationDisaggregation

Sub OU

0..n

SC

Mark et

Customer OP

1..n

1

0..n

1..n

0..n

Temporal

Relationship

Resource

0..1

0..n Associated HR

0..n

Asso

ciated

HR

Vertical Integration

1

1

0..1

Goal Component

0..n

Level

1..n

0..n

0..n

1..n

0..n

1

1

0..n

SC

Information

Entity

Performance

Dimens ion

1

Influenc e

1

IR Component

1.n

1..n

0..n

2..n

2..n

2..n

0..n

0..n

2..n

2..n

0..n

0..n

0..n

0..n

0..n

0..n

1

1..n

Related Goal

Related IR

name

responsable

Sub SC

Supply Chain

1

1

1

1

1

1

1

1

11

1

1

1

0..n

0..n

Organizational

Perspectiv e

Goal

description

Metric

definition

unit of measure

f requency

normalization

criteria

target

allowed tolerance

0..n

0..n

Performance

Attribute

Hierarchical

Relationship

Information

Resource

Organizational

Unit

{or}

{or}

Figure 1: SCOntology. UML diagram.

ICEIS 2008 - International Conference on Enterprise Information Systems

404

Table 1: SCOntology. Main concepts description.

SCOntology

View

Concept Name Description

Business Process

A structure of activities designed for action with a focus on end customers and on the dynamic

management of flows involving products, information, cash, knowledge and/or ideas (Lambert et

al., 1998).

Financial Resource Money, credit, etc. associated with a Process.

Information Resource Information involved in a Process.

Material Resource Physical thing that participates in a Process.

Performance

Information

Information involved in the evaluation of a SC Entity.

Process

Activity or structure of activities intended to achieve a result, which entails the utilization of

time, material, space, expertise or other resources.

Process Element Business Process component activity. In the SCOR model, it represents a level three process.

Product Individual or group of material resources resulting from a Process.

Resource Physical or conceptual means involved in a Process, as personnel, equipment, material, etc.

Resource Perspective

A view of a Resource focused only on those aspects or characteristics that are of interest to a

Process.

Functional View

Task

Process Element component activity. In the SCOR model, it represents a level four or a higher

level process.

Aggregation

Hierarchical relationship that exists among an information resource, and other information

resources of lower aggregation level.

Disaggregation

Hierarchical relationship existing among an information resource and other information resources

of higher aggregation level.

Goal A desired situation or general purpose toward which efforts are directed.

Hierarchical

Relationship

Relationship that exists among information resources of different degrees of granularity.

Level

A management-based grouping associated with the scope and time horizon of decisions, actions

or plans.

Metric Dependency Conditioning relationships between performance metrics.

Management View

Vertical Integration

Specifies the way the information integration is tackled according with the hierarchical

relationships among the information resources that are involved.

Measure

Value that results from a measurement done by means of a given metric, as well as its normalized

value.

Metric Method that allows evaluating a particular Performance Attribute of a SC Entity.

Performance Attribute Measurable property of SC Entities.

Performance View

Performance

Dimension

Performance point of view. It is used to qualify Performance Attributes.

Customer OP View of an Organizational Unit corresponding to a customer role of a Supply Chain.

Organizational

Perspective

A given view that an Organizational Unit presents with respect to a SC in which it is involved.

Organizational Unit

It might be a company, corporation, firm, enterprise or institution, or a part of it, having its own

function(s) and administration, which supplies and/or acquires products or services.

SC Market

Group of customers (Organizational Units with the role of customers in a given SC) that share

some characteristics.

Supply Chain

The network of business units, form original suppliers to end-customers, which transforms raw

materials into final products, besides other value-adding companies such as logistics providers.

SC Structural View

Value Aggregation OP View of an Organizational Unit corresponding to a value incorporating role in a Supply Chain.

A SUPPLY CHAIN ONTOLOGY CONCEPTUALIZATION WITH FOCUS ON PERFORMANCE EVALUATION

405

2.3.1 SC Structural Concepts

The structural view includes Supply Chain concepts,

along with the ones representing the various

organizations which participate in a SC, and the

roles these enterprises assume in different SCs. The

main concepts of this perspective, such as Supply

Chain, Organizational Unit (OU) and Organizational

Perspective, are described in Table 1.

To reflect the fact that a given Organizational

Unit (factory, warehouse, retail store) can participate

in various SCs, the Organizational Perspective (OP)

concept was included. It captures the different

viewpoints that an OU presents with respect to the

various SCs in which it participates. In a given SC,

an OU could assume either the role of a customer or

the one of a value aggregation node. Therefore, the

Organizational Perspective concept is specialized

into Customer OP and Value Aggregation OP.

Supply Chains are usually differentiated

according to the characteristics of the delivered

product/s and the diverse target markets. These ideas

are captured by the association of the Supply Chain

class with one or more Products and a SC Market.

The Product class denotes individual or groups of

goods having common characteristics. The SC

Market concept represents a group of buyers of a

particular good or service, and it is composed of

Customer OPs.

2.3.2 Functional Concepts

The functional view is concerned with activities or

processes performed in the SC and the means

involved in them. The most important definitions are

depicted in the Functional View section of Table 1.

As seen in Figure 1, Processes are hierarchically

decomposed, as the basic structure of the SCOR

model suggests, in at least three levels of detail,

ranging from Business Processes (higher level) to

Process Elements and Tasks (lower level). These can

be Complex or Elementary, depending on if they are

composed of other tasks or not.

Processes can be associated with several

Organizational Perspectives and they can participate

in various SCs. This is due to the fact that a given

process could cross various functional areas and/or

companies (when they are integrated) and, at the

same time, it could also be executed to achieve

results on different SCs. For instance, a Warehouse

Delivery process can be done in the same way,

involving the same resources and methods, for

certain pharmaceutical and food product SCs.

Additionally, the execution of a given Process

may depend on the temporal ordering defined among

the Processes, represented in the model by temporal

relationships.

Resources are also included in this view. Despite

they are not functional in nature, resources are

integrated in this perspective because they are

closely related with functions. They not only are

essential assets (as materials, equipment, personnel,

etc.) associated with Processes, but also their

availability can restrain the capacity to execute the

Processes in which they participate. Resources can

be physical or conceptual things and may assume

different roles depending on the Process in which

they participate. Therefore, in order to consider only

those Resource characteristics that are of interest in

a given context, the Resource Perspective class is

defined.

2.3.3 Management Concepts

The management view comprises management

information about the SC. The most relevant

concepts are defined in Table 1 and shown at the

bottom left section of Figure 1.

Management information has different degrees

of granularity due to various reasons, like error

minimization, data availability, etc. In general, the

information used at higher decision levels is more

aggregated than the one employed by lower level

activities. However, these information pieces are

generally interrelated and it is very important to

capture their links. With this aim, SCOntology has

incorporated the Hierarchical Relationship concept,

which makes explicit the participation of

information in diverse Aggregation or

Disaggregation relationships. The Vertical

Integration concept denotes the manner in which the

integration is performed in each Hierarchical

Relationship.

The Goal concept is a useful management

concept incorporated into the ontology. It has been

established at different decision levels (Strategic,

Tactical or Operational) for the proper management

of SCs. Since it is essential to control Goals by

means of appropriate Metrics, the attainment of a

certain Goal can be monitored by, at least, one

Metric. In addition, a particular Goal could be

aggregated from or disaggregated into other goals.

For this reason, specific links between the Goal

concept and the Hierarchical Relationship one are

included in the ontology (see Figure 1).

2.3.4 Performance Concepts

The performance perspective groups those notions

associated with performance evaluation. The main

ICEIS 2008 - International Conference on Enterprise Information Systems

406

concepts are introduced in Table 1. They are also

shown at the upper left section of Figure 1.

Supply chain entities (SC Entity in Figure 1),

being elements that participate in SCs, could have

performance attributes to be assessed.

It should be noted that a performance attribute of

a certain SC entity can be evaluated by means of one

or more metrics, each one having its own values. On

the contrary, a Metric can only be associated with

one SC Entity and one Performance Attribute. In

order to prescribe which attribute and which SC

Entity can be appraised with a given metric, the

generic concept of metric should be specialized in

particular metrics that assess the SC performance.

The values assigned to a certain Performance

Attribute of a SC Entity in relation to a given Metric

are represented in the ontology by the Measure class.

These values can be obtained by actually doing a

measurement, by benchmarking, or can be set as part

of a SC design process; nevertheless, each value is

always associated with a Metric.

The Performance Attribute concept is specialized

in the following classes: Reliability, Flexibility,

Responsiveness, Costs and Assets, following the

guidelines of the SCOR model. In turn, performance

attributes are categorized through the Performance

Dimension concept, which characterizes them

according to their scope. The SCOR model identifies

two, the Internal Facing and the Customer Facing

perspectives, which are focused on short-term

assessment issues. The Long Term Facing

perspective has been added to SCOntology to

include a performance perspective concerned with

the evaluation of actions performed to achieve future

results, related with strategic and tactical issues.

Additionally, this proposal acknowledges that

some performance evaluation frameworks, like the

one proposed by Brewer and Speh (2000), based on

the Balanced Scorecard idea (Kaplan and Norton

1992), identify links between pairs of different

Performance Dimensions. These relationships

indicate, in a qualitative manner, that if changes take

place in a given performance dimension, they are

expected to entail modifications in another one. This

notion is included in the ontology as an Influence

association between Performance Dimensions. For

instance, the Long Term Facing dimension

influences both the Internal and Customer Facing

ones, whereas the Customer Facing dimension

affects the Internal Facing one.

2.3.5 Application Example

With the purpose of illustrating the main concepts of

the ontology, a simple case study is presented.

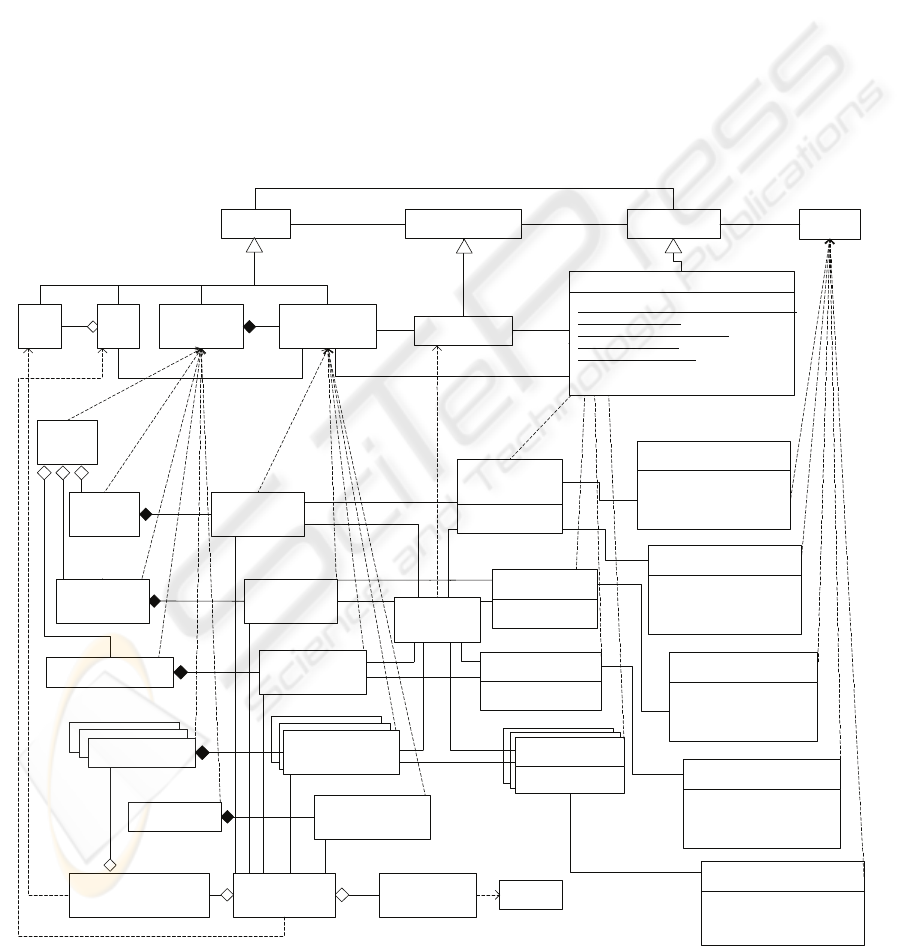

Figure 2 shows a partial view of SCOntology,

capturing some of the notions under analysis along

with the instantiation of these concepts in order to

represent a SC associated with a furniture enterprise

and its corresponding evaluation. The constituents of

this SC are the ‘Oak Wonders’ enterprise, the

‘InWay Trucking’ company and various retailers.

Oak Wonders (OW) produces and distributes oak

home furniture: tables, beds, sofas, cabinets,

wardrobes, etc., both in a standard format and in a

tailored made one. It has outsourced the delivery

transportation business and made a long-term

contract with InWay Trucking (IWT), which is a

3PL that specializes in the haulage of different types

of products, such as apparel, footwear and furniture.

IWT is the linkage between OW and the retailers.

The business process configuration of this

furniture SC and its associated evaluation methods,

depend on the product line that is managed. Thus,

from an OW viewpoint, the processes involved in

supplying standard furniture to retailers include the

storage of final products. On the contrary, no stock

is kept for tailor made furniture. Similarly, metrics

used to evaluate the performance of business units

and processes are not the same for standard and

custom built furniture. Due to these reasons, it is

important to distinguish SCs according to their

associated product and service.

This example focuses on one particular SC

whose objective is to furnish small and medium size

national retailers with standard wardrobes. This

information is represented in Fig. 2 by the ‘Standard

Wardrobes SC’ instance as well as by its links to the

‘Standard Wardrobes Family’ and to the ‘Middle

and Small Size National Furniture Retailers’ objects.

All of the previously described companies are

modelled by instantiating the Organizational Unit

concept. Additionally, but limiting the analysis to

only those elements associated with the standard

wardrobes family of products, OW is composed of

three OUs: one manufacturing plant and two

distribution centers (the north and the south ones).

Each of these OUs has a perspective involved in the

standard wardrobes SC which is linked to the

‘Standard Wardrobes SC’ object.

With the purpose of exemplifying the application

of the ontology to the evaluation of this particular

SC, the ’Number of Monthly Stockouts’ metric is

proposed as a specialization of the Metric concept.

This metric is an adaptation of the ‘Number of

stockouts’ one, which was described in the first

section of this contribution. The metric is

appropriate for appraising an environment where

A SUPPLY CHAIN ONTOLOGY CONCEPTUALIZATION WITH FOCUS ON PERFORMANCE EVALUATION

407

standard products are sold from stock. It is defined

as the ‘Number of requested items that are out of

stock per month’ and represents a method that

allows evaluating the responsiveness of an

organizational perspective, as indicated by its

associations.

The ‘Number of Monthly Stockouts’ metric is

instantiated, resulting in the following objects:

‘Wardrobes Manufacturing Plant Metric’, ‘North

Distribution Center Metric’, ‘South Distribution

Center Metric’ and ‘Retailer Metric’. As seen, these

metrics are involved in the evaluation of the

responsiveness of specific OPs. Each of them has its

own target value and an allowed tolerance.

Moreover, each metric shown in this example is

related to one or more measures that represent the

values of the responsiveness attribute for the

different OPs being evaluated. Additionally, the

measure instances capture further data about the

measurement: the time point when the assessment

was done and the period that was appraised. Thus, it

is possible to trace how a performance attribute was

evaluated, which metric was used, which were its

values in diverse occasions and, in turn, which SC

entity each measure evaluates. For example, it can

be seen that the standard wardrobes manufacturing

OP was evaluated twice, according to the

‘Wardrobes Manufacturing Plant Metric’, to assess

its responsiveness. Its values were 30 and 25

items/month for the October and November periods,

respectively.

Oak

Wonders

Plant November Stockouts

Middle and Small Size

National Furniture Retailers

Standard

W ardrobes Famil y

Wardrobes

Manuf ac t uri n g

Plant

val ue: 5

timepoint: 8/11/2007

period: 01/10/2007 - 31/10/2007

normalized value: "-"

Retailer October Stockouts

value: 25

timepoint: 7/12/2007

period: 01/11/2007 - 30/11/2007

normalized value: "-"

Responsiveness

Instance

Plant October Stockouts

val u e: 30

timepoint: 5/11/2007

period: 01/10/2007 - 31/10/2007

normalized value: "-"

North Dis tri bu ti on Center

October Stockouts

val u e: 8

timepoint: 3/11/2007

period: 01/10/2007 - 31/10/2007

normalized value: "-"

South Distribution Center October

Stockouts

value: 16

timepoint: 4/11/2007

period: 01/10/2007 - 31/10/2007

normalized value: "-"

target= 0

allowed tolerance= 25

Wardrobes

Manufacturing Plant

Metri c

target= 0

allowed tolerance= 10

target= 0

allowed tolerance= 12

South Distribution

Center Metric

target= 0

allowed tolerance= 10

Retailer Metric

0..n

1

Performanc e Attribute

1

0..n

0..n

0..n

Number of Monthly Stockouts

10..n

Organizational

Unit

0..1

0..n

1

0..1

1

SC Entity Metric

Standard

W ardrobes North

Distribution OP

Standard W ardrobes

South Distribution OP

Furniture Retai ler

S tandard W ardrob es

Commercialization OP

InWay Trucking

Standard

Wardrobes SC

definition ="Number of requested items that are

out of stock per month" {readonly}

unit of measure = "Items/month"

{readonly}

frequency = "monthly"

{readonly}

normalization criteria= "-"

{readonly}

target

allowed tolerance

North Distribution

Center Metric

Responsiveness

North Dis tri bu ti on

Center

Standard W ardrobes

Transportation OP

Meas ure

0..n

1

Standard

W ardro bes

Manufacturing OP

SC

Ma rke t

Orga ni zati onal

Perspective

1..n

1..n

1

Supply

Chain

Product

South Distribution Center

Figure 2: Metric specialization and instantiation example.

ICEIS 2008 - International Conference on Enterprise Information Systems

408

3 CONCLUSIONS

This paper presents advances in the development of

an ontology, named SCOntology, that contributes

towards the formalization of the SC domain and its

associated evaluation system. SCOntology provides

the basis for the description of the supply chain

structure, its associated processes and evaluation

system. In this way, it could lay the foundation for

the development of a computational performance

evaluation system. It adopts the process hierarchical

decomposition structure of the SCOR reference

model, which is nowadays a de facto standard.

However, it enlarges it with additional concepts that

allow to (i) render a more comprehensive enterprise

model, and (ii) formally describe information

composition or decomposition processes.

Regarding the evaluation system, SCOntology

incorporates several performance evaluation

management tools in a single framework. It allows

the definition of different metrics and performance

related concepts, including the measurement of

performance attributes of distinct types of SC

entities. Besides, classifications of metrics and

performance attributes, relations with the SC’s goals

and their control, as well as important relationships

between metrics and performance dimensions are

some of the features that are incorporated in the

ontology.

Future work entails representing SCOntology in

OWL or in a closely related language. Once the

ontology is fully defined, new defies will be tackled.

One refers to the identification of mechanisms for

collecting and managing the data needed to operate

an assessment system in an actual dynamic

environment. Another is related to the analysis and

handling of performance information from a

temporal perspective. One of the possible solutions

to these challenges is the use of agent technology.

ACKNOWLEDGEMENTS

This work has been supported by CONICET (PIP

5915), UTN, UNL and ANPCyT (PICT 12628).

REFERENCES

Beamon, B.M., 1998, ‘Supply Chain Design and Analysis:

Models and Method's’, In International Journal of

Production Economics, vol. 55, no. 3, pp. 281-294.

Beamon B.M., 1999, ‘Measuring supply chain

performance’ In International Journal of Operations

and Production Management, vol. 19, no. 3, pp. 275-292.

Bhagwat R., Sharma M.K., 2007, ‘Performance

measurement of supply chain management: a balanced

scorecard approach’, In Computers & Industrial

Engineering, vol. 53, no 1, pp. 43-62.

Brewer P.C., Speh T.W., 2000, ‘Using the balanced

scorecard to measure supply chain performance’, In

Journal of Business Logistics, vol. 21, no. 1, pp. 75-

93.

Fernández-López M., Gómez-Pérez A., Pazos-Sierra A.,

Pazos-Sierra J., 1999, ‘Building a Chemical Ontology

Using METHONTOLOGY and the Ontology Design

Environment’, IEEE Intelligent Systems & their

applications, vol. 14, no. 1, 37-46.

Gaiardelli P., Saccani N., Songini L., 2007, ‘Performance

measurement of the after-sales service network—

Evidence from the automotive industry’, In Computers

in Industry, vol. 58, no 7, pp. 698-708.

Gunasekaran A., Williams H.J., McGaughey R.E., 2005,

‘Performance measurement and costing system in new

enterprise’, In Technovation, vol. 25, no.5, pp. 523–533.

Hausman W.H., 2002, ‘Supply chain performance

metrics’, In Billington C., Harrison T., Lee H. and

Neale J. (eds), The Practice of Supply Chain

Management, Kluwer: Boston.

Kaplan R.S., Norton D.P., 1992, ‘The balanced scorecard -

Measures that drive performance’, In Harvard

Business Review, vol. 70, no 1, pp. 71-79.

Kim H.M., Fox M.S., 2002 ‘Towards a Data Model for

Quality Management Web Services: An Ontology of

Measurement for Enterprise Modeling’, In:

Proceedings of the 14th International Conference on

Advanced Information Systems Engineering, p.230-244.

Kleijnen J., Smits M., 2003, ‘Performance metrics in

supply chain management’, In Journal of the

Operational Research Society, vol. 54, no 5, pp. 507–514.

Lambert D.M., Pohlen T.L., 2001, ‘Supply Chain

Metrics’, In International Journal of Logistics

Management, vol 12, no. 1, pp 1-19.

Lambert D.M., Cooper M.C., Pagh J.D., 1998, ‘Supply

chain management: implementation issues and

research opportunities’, In The International Journal

of Logistics Management, vol. 9, no. 2, pp. 9-11.

Mannarino, G. S., 2001, Coordinates, Un lenguaje para el

modelado de empresas, Ph.D. Thesis, Universidad de

Buenos Aires, Argentina.

SCOR, 2007, www.supply-chain.org/page.ww?section=

SCOR+Model&name=SCOR+Model

A SUPPLY CHAIN ONTOLOGY CONCEPTUALIZATION WITH FOCUS ON PERFORMANCE EVALUATION

409