ISSUES IN IS BASED ENGINEERING ASSET MANAGEMENT

An Australian Perspective

Abrar Haider

School of Computer and Infomatin Science, University of South Australia, Australia

Keywords: Information systems, implementation, asset management.

Abstract: Asset managing eengineering organisations traditionally take a deterministic view of information systems

(IS) adoption. Iinvestments in IS, thus, carry the expectations of high returns in terms of process efficiency

and quality of manufacturing/production/service provision output. In theory, IS serve two major benefits to

asset managing organisations, i.e. by allowing for real time updated asset related information to stakeholders

to assist smooth asset operation; and by providing a broad base of consistent and logically organised

information relating to asset lifecycle for informed choices on effectuating asset management regimes.

However, the case presented in this paper illustrates that when IS are deployed without accounting for the

organisational, social and cultural dimensions of their context , there are little gains. This paper highlights

that physically adopted technology needs to be socially composed, which develops organisation-wide

consensus about what technology is supposed to accomplish and how it is to be utilised.

1 INTRODUCTION

Infrastructure assets maintain the lifeline of any

economy. Continuously changing economic

conditions, increased competition, and stricter

regulatory and environment protection controls

demand asset managing engineering organisations to

ensure availability of these assets though effective

management of their lifecycle. In doing so, they are

embracing an enhanced level of informationalisation

so as to enable informed choices at operational,

tactical, and strategic levels of the asset lifecycle.

This trend is particularly getting popular in capital

intensive industries, such as petroleum (Yusof et al.

2006; Liyanage and Kumar 2003). Information

systems (IS), thus, are becoming an integral part of

asset lifecycle management and facilitate various

tasks at each stage of the lifecycle through data

acquisition, processing and manipulation operations.

In actual effect scope of IS in engineering asset

management extends well beyond the usual data

processing and reaches out to business intelligence,

value chain integration, and transformation of

patterns of business relationships (Haider and

Koronios 2005).

Asset managing organisations relate a diverse set of

expectations from IS adoption, such as operational

efficiency, reduction in operating expenses, and

enhanced competitiveness (Rondeau et al. 2006;

Markeset and Kumar 2005; Leibs 2002; Anderson et

al. 2002). However, engineering organisations

traditionally take a deterministic of IS adoption and

emphasis is on actual installation of technology

aimed at increase quality and quantity of output as

well as substitution of human effort through process

automation (Karlsson and Gennas 2005), rather than

facilitating its institutionalisation in the

organisations through effective transition and change

management strategies. Haider et al. (2006)

conclude that during asset lifecycle planning,

technical aspects of the asset configuration and

operation command most resources and factors like

choice of IS to support asset lifecycle as well as

skills, process maturity, infrastructure maturity, and

organisational culture are seldom given due

consideration. A recent study by Australian

Government’s Department of Communications

Information Technology and the Arts concluded that

less than a third of all respondents had any post or

pre IS implantation evaluation mechanism for

investments in IT. Well over half the respondents

reported that they never had such an agenda on their

strategic map (DCITA 2005).

The main purpose of this paper is to explore issues

and challenges posed to asset managing

94

Haider A. (2008).

ISSUES IN IS BASED ENGINEERING ASSET MANAGEMENT - An Australian Perspective.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - HCI, pages 94-101

DOI: 10.5220/0001718800940101

Copyright

c

SciTePress

organisations in wake of maximising value from IS

adoption. This paper focuses on a case study of an

Australian rail asset managing organisation, which

was completed in 2007. This paper contributes to the

literature by focusing on and describing in-depth the

issues associated with IS adoption to support asset

lifecycle management. The impediments to effective

utilisation of IS for asset lifecycle management in

this case highlight the need for understanding of the

social nature of IS adoption and the ways in which

engineering enterprises can address the complex

activities of asset lifecycle. This paper first reviews

asset management and role of IS in asset

management, followed by discussion of a case study

in a rail asset managing organisation.

2 ASSET MANAGEMENT

The term asset in engineering organisations is taken

as the physical component of a manufacturing,

production or service facility, which has value,

enables services to be provided, and has an

economic life greater than twelve months (IIMM

2006), such as manufacturing plants, roads, bridges,

railway carriages, aircrafts, water pumps, and oil and

gas rigs. Oxford Advanced Learner’s Dictionary

describes an asset as valuable or useful quality, skill

or person; or something of value that could be used

or sold to pay of debts (OALD 2007). These two

definitions imply that an asset could be described as

an entity that has value, creates and maintains that

value through its use, and has the ability to add value

through its future use. This means that the value it

provides is both tangible and intangible in nature

(Amadi-Echendu 2004). A physical asset should,

thus, be defined as an economic entity that provides

quantifiable economic benefits, and has a value

profile (both tangible and intangible) depending

upon the value statement that its stakeholders attach

to it during each stage of its lifecycle. Management

of assets, therefore, entails preserving the value

function of the asset during its lifecycle along with

economic benefits. Asset management processes are

geared at gaining and sustaining value from design,

procurement and installation through operation,

maintenance and retirement of an asset (Blanchard

and Fabrycky 1998).

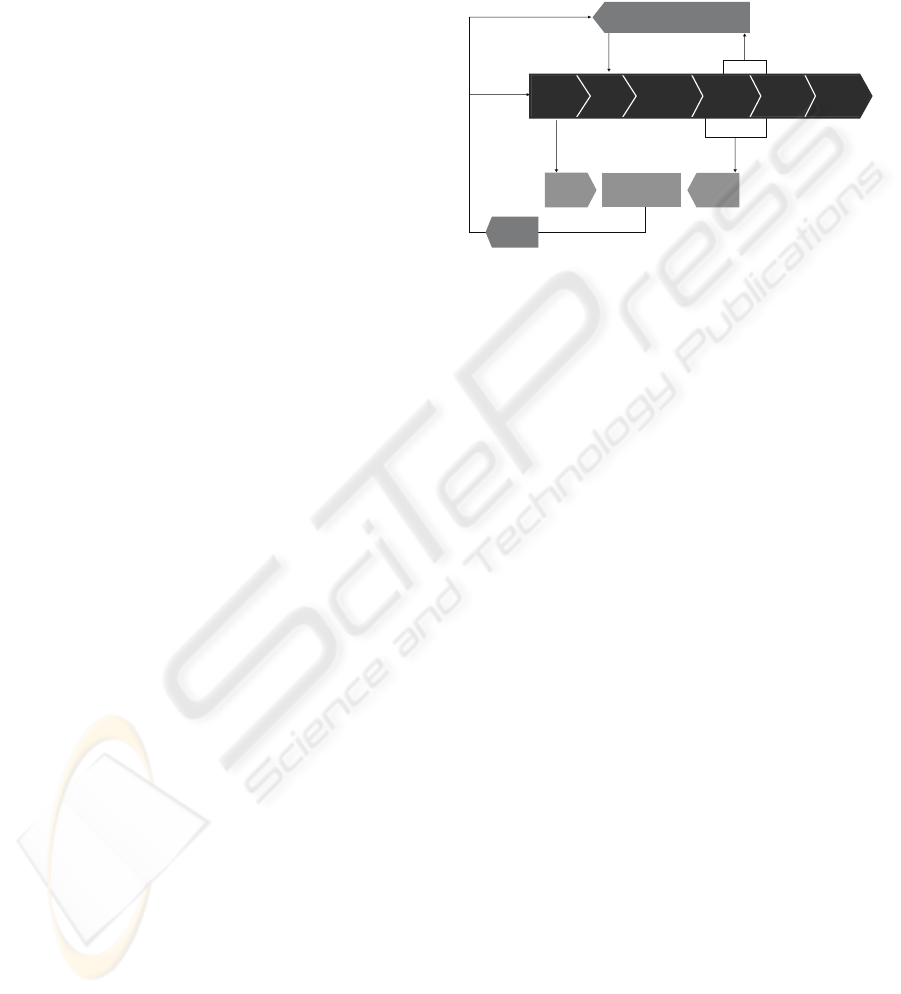

Core asset management processes are derived from

the asset management strategy and are arranged

through operating plans and procedures. These

processes represent the primary asset lifecycle

through stages such as, asset design, acquisition,

construction, and commissioning; operation;

maintenance; refurbishment; decommissioning; and

replacement. An asset lifecycle management

process, thus, consists of three cycles, i.e. primary

asset management cycle, learning and change cycle,

and renewal cycle (figure 1).

Primary Asset Life

Cycle

Renewal Cycle

Learning,

Optimisation, &

Change Cycle

Review

Need

Monitor

Re-Evaluate

Asset Solution

Change

Renewal

Maintain

AM Strategy Plan Construct/

Acquire

Operate

Retire

Figure 1: Core Asset Management Lifecycle.

The learning, optimisation, and change cycle is

aimed at changing of an asset solution in the existing

asset solution to meet stakeholders’ needs. Therefore

the essential aims of this exercise are, firstly, to

identify enhancements in asset solution design, and

secondly, if the first response to factors such as asset

need redefinition, technology refresh, environmental

and regulatory concerns, and maintenance and other

economic trade offs. However, the crucial factor in

this cycle is the ability of the organisation to have

complete information on asset lifecycle so as to

evaluate and compare its outputs with the business

objectives. The gap analysis provides learnings on

effectiveness of is not possible, to provide

alternatives for asset renewal. Subsequently, the

learning, optimisation, and change cycle has a much

greater impact calls for redefinition of asset strategy,

whereas the renewal cycle does not go as far and

necessitates adjustment to asset management plan.

3 IS FOR ASSET MANAGEMENT

In theory IS in engineering asset lifecycle

management have three major roles; firstly, IS are

utilised in collection, storage, and analysis of

information spanning asset lifecycle processes;

secondly, IS provide decision support capabilities

through the conclusions arrived at from analysis of

information; and thirdly, IS provide an integrated

view of asset lifecycle through integration of asset

lifecycle functions. IS for asset lifecycle, thus, seek

to enhance the outputs of asset management

processes through a bottom up approach. This

ISSUES IN IS BASED ENGINEERING ASSET MANAGEMENT - An Australian Perspective

95

approach gathers and processes operational data for

individual assets at the base level, and on a higher

level provides a consolidated view of entire asset

base.

At the operational and tactical level, IS are required

to provide necessary support for planning and

execution of core asset lifecycle processes. For

example, at the design stage designers capture and

process information such as, asset configuration;

asset and/or site layout design and schematic

diagrams/drawings; asset bill of materials; analysis

of maintainability and reliability design

requirements; and failure modes, effects and

criticality identification for each asset. Planning

choices at this stage drive future asset behaviour,

therefore IS are also required to facilitate in analysis

of information to make informed choices to ensure

availability, reliability and quality of asset operation.

As we move forward in the asset lifecycle, the

complexity of information increases. For example, at

maintenance stage it is important to have historic

information on design, operations and condition

monitoring, as well as previous maintenances carried

out on the asset. This includes financial as well as

non financial information. This information is

required to perform a variety of actions such as

locating and diagnosis of failure condition;

allocating spares and maintenance work requests;

and informing asset shut down schedules. After

maintenance has been carried out, this information

needs to be communicated throughout the asset

lifecycle chain, such as to design function (to design

out errors and faults in asset design, or

enhancements required in asset design); to operation

(in case asset was not being operated according to as

designed specifications); to maintenance planners (to

plan and schedule future routine maintenance); to

decision makers (to identify the financial and non

financial risks posed to asset operation, their impact,

and ways to mitigate those risks); to environment

protection agencies (to assess and define the level of

contamination in case of environmental disaster as a

consequence of asset failure). An important measure

of effectiveness of IS, therefore, is the level of

integration that they provide in bringing together

different functions of asset lifecycle management, as

well as stakeholders, such as business partners,

customers, and regulatory agencies like

environmental and government organisations.

However, realisation of an integrated view of asset

lifecycle through IS requires appropriate hardware

and software applications; quality, standardised, and

interoperable information; appropriate skill set of

employees to process information; and the strategic

fit between the asset lifecycle management

processes and the IS.

4 RESEARCH METHODOLOGY

This exploratory research employs an interpretive

epistemology with a qualitative perspective. It is

obvious that the issues relating to IS investments in

asset lifecycle management are multifaceted and

require a broad and flexible perspective for

comprehensive examination. It include investigation

of technical as well as an assortment of others

dimensions such as organisational, social, and

cultural. The aim of this research is to explore the

issues and impediments to maximising IS value for

asset management from technical, social, and

cultural perspective. The research question framed

for this research is: How do IS facilitate an

integrated view of asset lifecycle and what factors

impede maximising value of IS adoption? In order

to address this question, 17 middle managers

representing various roles associated with asset

lifecycle management were interviewed in a large

rail asset managing organisation during January

2007 – August 2007. These interviews were

conducted over a one - one and half hours period

and included the following job descriptions, asset

designers, maintenance engineers, network access

manager, business development manager,

Operations and Maintenance manager, manager

projects, manager assets management, project officer

assets, finance manager, and IT manager.

Interviewees were chosen based on their

responsibilities as they are between senior mangers

(who make decisions) and operational employees

(who act on the decisions made by senior mangers).

They are the actual implementers of IS and,

therefore, are well placed to provide insights into

policy setting and decision making of the senior

management and the issues and challenges posed to

these policies and decisions at the operational level.

The interview questions were open-ended and

interviewees had freedom to describe their

experiences and problems beyond the scope of the

questions. In addition, researchers were provided

access to all documentation concerning asset

lifecycle management, as well as access to sites of

asset operation. The interviews were transcribed and

data from all sources were analysed using typical

case study techniques of themes, descriptions and

assertions as detailed in Creswell (1998). The

interviews were followed up by email and telephone

for further clarifications, where it was deemed

ICEIS 2008 - International Conference on Enterprise Information Systems

96

necessary. The conclusions drawn in the following

case, thus, represent interpretations of the evidence

as understood by the authors.

5 RAIL ASSET MANAGEMENT -

CASE STUDY

Rail infrastructure is a vital component of

Australia’s national transport infrastructure.

Australian railway industry has an annual turnover

in excess of 8 billion Australian dollars and employs

approximately 75000 staff (Austrade 2006).

However, till 1990’s railways in Australia was

publicly owned and had a vertically integrated

operation. Concerns for improving efficiency

necessitated reforms, and thus the industry

underwent major changes through which some state

railways transformed into private/public structures,

separating ownership, operation and regulation

(Australian Infrastructure Report Card 2005). Ozrail

(Pseudonym) owns, operates, and manages rail

assets in one of the largest states of Australia. It’s

nearly 4 billion Australian dollars worth of rail

network stretches throughout the important

industrial and agriculture stretch of Australia. The

company has been in operation for nearly 150 years

and is one of Australia’s largest passenger, coal, and

freight transport provider. In the financial year

2005-06, more than 2600 staff of Ozrail operated

approximately 260000 passenger services, and

carried over 54 million passengers. In all Ozrail

employs more than 13000 staff and provides a broad

range of freight services to a wide customer base in

many industries in Australia, through its 9500 km

rail network. Ozrail’s state based fleet includes over

12300 units of rolling stock, which includes more

than 10200 wagons, 508 diesel and electric

locomotives, 143 three-car electric trains, and 177

passenger carriages. All of which are used to

transport people, coal, bulk or containerised freight.

Ozrail employs in excess of 1400 staff (including

176 apprentices and trainees) at four geographically

dispersed locations all over the state to manage these

units.

5.1 Asset Management at Ozrail

Ozrail manages a number of assets, including rolling

stock, track assets, carriages, godowns, railway

bridges, signals, and engines. However, for this case

study the subject under study is the below train

assets, i.e. track, bridges, and other civil

infrastructure. Ozrail has generally followed a whole

lifecycle approach to managing its assets. In order to

optimise the assets, the company has developed an

asset management framework that has a ten years

time span. However, it is subjected to minor

modifications so as to make it relevant to current

legislations as well as changes in the market.

Nevertheless, the asset management framework is

based on five key elements, which are Ozrail’s

network development plan; Ozrail’s network

maintenance plan; an alliance-style maintenance and

project agreements with specified goals; a detailed

performance monitoring framework; and

independent asset condition and service provision

auditing. Ozrail’s asset management framework also

includes a financial asset corridor model to provide

historical and projected indications of the financial

performance of each asset in company’s rail

network. This model accounts for the revenues,

capital investments, maintenance activities, capital

charges and internal costs and service charges.

Ozrail has a number of systems aimed at enhancing

and maintaining asset management capability, which

encompass range of asset lifecycle management

dimensions. These systems include, procurement

and materials logistics; track and structures

performance management; detailed long and short-

term planning advice; rail infrastructure condition

monitoring; asset inspection and safety auditing;

regulatory and operational compliance assurance;

and property and contract management.

5.2 Information Systems at Ozrail

Ozrail is also participating in two federal

government funded cooperative research centres to

enhance its IS platforms. The scope of these

technologies ranges from standalone process

facilitating tools to integrated decision and planning

systems. The company has recently set up a

scheduling optimisation tool to increase the speed

and effectiveness of train, crew and maintenance

scheduling on track, and its business intelligence

technical infrastructure. However, major

technologies employed by Ozrail are SAP R/3;

CAD; CMMS; and a variety of industry specific

asset lifecycle management softwares such as

RailFrame, TRIM, PST, V0, RIMS, and RDMS.

Ozrail does not conform to a common information

model for asset management. It is for the same

reason that traditionally IS adoption is driven by

need of individuals or departments, rather than the

process or organisational need. Consequently, there

are numerous isolated islands of useful data in the

ISSUES IN IS BASED ENGINEERING ASSET MANAGEMENT - An Australian Perspective

97

organisation. Ozrail’s IT manager summarises the

technology adoption approach and states, “we are

not early adopters, and we are not explorers and we

are not easily influenced or driven by whatever the

latest thing on the market is. Its need driven and

business case driven. Basically in past our

motivating factors have been tactical needs of

individual areas, so it hasn’t been strategic at all but

its moving towards being more strategic mainly for

information integration. We now have stronger

governance and cost focus, since we are now

viewing ourselves as a market player as we are

expanding nationally and are moving into more

commercial roles” - IT Manager (Ozrail)

5.3 IS at Operational Level

Ozrail is a representative case of semi government

public sector organisations. It has a hierarchical

structure, bureaucratic culture, and centralised

decision making. There is no culture of process or

technology audit, which could highlight the needs of

business processes, such as information needs, skills

level, and maturity of existing technology to

accommodate new technology. For example,

investment in SAP was made due to pressure from

regulatory agencies, rather than as a response to

needs of asset management regime. Consequently,

asset lifecycle management stakeholders saw it as a

necessary evil and its adoption was not taken

seriously. Being an engineering organisation,

functional level employees are more interested in

executing the workflow than recording data and

information on what they do. As a result Ozrail has

struggled to develop a culture that values

information, and staff struggle with primary and

secondary job quandaries. General feeling among

the staff is that “their performance will be judged on

the execution of their primary roles such as asset

maintainer, designers, and monitors and not on how

much and how good they enter data into a system” –

Maintenance Manager Ozrail. It was only around

the year 2004 that the change of guards at the senior

management saw more technology savvy

management and efforts have since been made to

think laterally on how these technologies could

benefit asset lifecycle management. However, there

is a long way to go before IS could be

institutionlised in the organisation, as one of the

design engineer notes that “from the outset when the

decision was made for SAP as the core asset

management tool its adoption should have initiated.

This project started in Sept 05 and we are still (May

2007) umming and ooing about SAP as the core

technology for asset lifecycle management. We

should sit down and work through all the cobwebs,

recruitment issues, training, and a smooth transition

to use this technology. My SAP training was left up

to me to book in and when you hear so many

negative things about it its not something you rush to

do”. A corollary to this issue is the varying quality

of information that exists within the IS in Ozrail. For

example, in asset design the quality of information is

restricted to the drawings, since the same have been

subjected to a number of reviews. However, quality

of the financial and administrative information

cannot be guaranteed since it is not audited. In the

words of the civil works reviewer, “we probably can

ensure that the checks and balances that we can put

in the systems are operating properly. But in terms

of the type of information that gets entered, well, you

can’t check everything. You can check certain things

that give a certain level of assurance that things are

doing OK”. Although the intent of business change

has been communicated and well publicised within

the organisation, change initiatives to achieve the

same have been far and few between. Instead of

building around the core IS technologies of the

organisation, such as SAP and CMMS, different

asset lifecycle functions prefer to use simple

spreadsheet and database applications. The use of

these technologies is justified as ‘they are easy to

use’, and that ‘they can be customised to meet

changing needs’. This lack of control and disregard

of quality culture had led to islands of data

throughout the organisation, without being put to

effective use.

Ozrail caters for metropolitan as well as countryside

track assets, and therefore is not only concerned with

the traffic on the tracks but also the weight borne by

these tracks. Traffic is managed by state of the art

software that manages as well as allocates traffic on

the tracks; whereas, the condition of the track is

monitored through sensors and manual inspections.

Ozrail has an extensive network of track inspectors,

which includes a substantial number of indigenous

Australians who are well known for their knowledge

and familiarity with outback terrain and geography.

Ozrail relies heavily on their tacit knowledge, and

these track inspectors have also proven to be

extremely reliable sources of track information.

However, there has been no effort made to record

information collected through these manual

inspections, while there are certain aspects of asset

operation that seem to be over automated, as

described by the Operations Manager of Ozrail. He

states, “for a case of a broken rail, essentially it’s

about train coming off. One system records broken

ICEIS 2008 - International Conference on Enterprise Information Systems

98

rail, which goes to the network controller who can

stop trains from going on the track. Another system

records the same incident the same information in a

track incidence system to raise signal alarms. Yet

another one of the systems records the same incident

in the rail defect management system, such that a

request could be generated to fix it. Now you have

the same information available in three different

systems. There is not only duplication, in fact

triplication of information. Information in each

system is biased towards a particular function, so

which version is more credible?”.

This symbolises the typical behaviour of an

organisation where each function trusts its own

information and does not believe in sharing the

same. As a result there is significant wastage of

effort and finances, and quality of information is

undermined due to lack of integration. According to

a design engineer at Ozrail, “a piece of track looks

the same today, looked the same five years ago, and

will look the same in five years from now. However,

it’s the formation that keeps on

changing…………Although we have got fair bit of

say over what software applications we use, we miss

the old system where we had somebody that was sort

of monitoring what was happening in the market

with regards to design software from across Ozrail.

At the moment where I see some degree of

connectivity with civil engineering design, there is

little connectivity when we go across other areas

like electrical design”.

5.4 IS at Tactical Level

Ozrail has an old set of asset infrastructure as

majority of these assets were laid in 1920s and 30s,

with some even earlier. Design information for most

of these assets is not available in digital format.

There are, therefore, significant issues in managing

these assets and most of decisions have to rely on

the tacit knowledge of middle to senior mangers.

While designing assets, design engineers are

required to take into consideration asset workload

and work out the asset need profile. However, it is

all done manually or with support from simple Excel

based spreadsheets. Traditionally, design engineers

surveyed the area and identified particular routs,

they would then design the asset accordingly. In so

doing, there has been heavy reliance on the

knowledge of filed staff in designing or refurbishing

sections of asset, since they are closest to assets.

However, times have changed and for the up-

gradation of assets Ozrail utilises a range of

technologies to aid design and designing workflow.

Now Ozrail utilises design technologies such as

AutoCAD, Microstations, and 12D civil design

software. However, design information is held

locally in the regional offices and is not exchanged

between regional offices or with other functions of

asset lifecycle management. In addition,

recommendations on asset lifecycle supportability

design form a part of the design feasibility study,

however the actual information remains with the

designers and is not exchanged or transferred to a

system where it could be reused. Although Ozrail is

aware of these issues, there has been no effort made

to improve the situation. Business development

manager of Ozrail summarises the quandary and

argues that, “Ozaril needs to capture, manage, and

maintain knowledge for future generation of Ozrail,

so we don’t have to reinvent the wheel every time.

We are long away from that. In terms of information

we have proliferation of tactically disparate

databases and spreadsheets. We have got the

information but it stays with designers. It is not

exchanged and even if it were exchanged it could not

be merged with other information”.

All maintenance in Ozrail is carried out in house,

and no part is sublet to a third party. It follows a

periodic preventive maintenance schedule and since

the company maintains a number of different assets

this schedule varies for each type of assets. Though

track assets are fairly stable and do not develop

failure conditions too frequently, the inspection of

track assets is held frequently. Information on

condition of an asset as well as the treatments

carried out are kept with the regional offices and

only a summarised version of this information

(chiefly financial) is communicated to the corporate

head offices, unless the track requires a major

overhaul or relaying. Major software tools used in

maintenance function are the Rail Infrastructure

Maintenance System, and Royal Defects

Management System. These systems help in

condition monitoring, defect detection, and

maintenance scheduling and execution; however

these systems are not integrated. Therefore, more or

less each activity has a separate IS, but the

information thus captured cannot be used for any

strategic advantage. Ozrail’s Maintenance Manager

describes this trends and states that “for asset life

cycle decision support we generally rely on historic

data. There is not a huge amount of data available

though. It (decision making process) is a lot based

on engineering knowledge, lot of our people have

been involved in operational management of the

ISSUES IN IS BASED ENGINEERING ASSET MANAGEMENT - An Australian Perspective

99

assets. So they know how the asset performs and

behaves. They know the discreet life cycle of the

asset components, and by putting those things

together we can come up with the forward

projection of asset. There is no rocket science there,

its based on personal knowledge of particular

engineers involved”. Heavy reliance on tacit

knowledge and the inability of the organisation to

preserve this knowledge is resulting in significant

intellectual capital drain from the organisation. With

nearly 35% of employees due to retire in the next 10

years, Ozrail will lose significant business

knowledge. However, to sieve out learnings from the

execution of routine business, integration and

interoperability of information is as important and

facilitative as developing the culture of information

sharing and exchange to achieve higher levels of

coordination and cooperation. However, with more

information technology savvy staff moving into

senior management, these issues are being

understood and acknowledged. Infrastructure

Group Manager, thus, notes that “when we talk

about the big picture, you may have one piece of

information and someone else can have the other

piece. He doesn’t necessarily see the other piece of

information which together can actually point you to

a totally new area. For continuous improvement we

have to change technology and also have to change

the way we do daily business”.

5.5 IS at Strategic Level

Being a public sector organisation, Ozrail has

traditionally been insulated from competition.

However, with deregulation business environment is

changing and the company is expanding its

operations to other geographic location in Australia.

At the same time, with programs like Auslink

(Federal government’s initiative to improve roads)

Ozrail is facing increased competition from

alternative service providers. Nevertheless, it has

been only recently that the top management has

started considering itself as a market player rather

than a monopoly. This change is forcing Ozrail to

view information and IS in a different way, as is

evident from the business manager’s response, who

argues, “we are going beyond total (asset) life

(profiling), we are going to total community benefit

and trying to financially quantify some of those

things such as enhanced access stations and the sort

of benefits of integrated bus-train interchange to the

community”. However, a transition to this vision

requires quality support from IS in terms decision

support for effective asset lifecycle management;

whereas lifecycle management functions in the

organisation are struggling with the basic questions

whether the technology has the depth or detail and

elegance required to manage assets. In the words of

Group manger infrastructure services, “SAP doesn’t

provide engineering state of lifecycle, since our data

is not integrated. For example, we may know how

much we are spending on track maintenance overall,

but we cannot straight away find out how much was

spent where. Furthermore, this information is not

integrated with maintenance or design or operation.

We are in the process of building some systems now

and our group is also reviewing several different life

cycle scenarios, costing and planning tools for our

track. But at this point, we haven’t got an integrated

life cycle asset management”.

6 DISCUSSION AND

CONCLUSIONS

Ozrail has reactive rather than proactive approach to

asset management, which is the major hurdle in

effective long term planning for an effective asset

management enabling IS infrastructure. Most of IS

adoptions have been in response to foreign

influences and not due to the need pull of the asset

lifecycle processes. The lack of vision and the

unavailability of an enterprise wide information or

IS architecture has led to a plethora of ad hoc

solutions throughout the organisation. These

solutions symbolise a number of organisations

within the organisation, as the information collected

and processed by each asset lifecycle function is

geared at fulfilling its own demands rather than

contributing to the overall objectives of an integrated

asset lifecycle view. IS in Ozrail could best be

described as disparate sets of data dumps reflect

history of business execution with varying degree of

credibility and in no way are near enabling or

informing strategic asset management objectives.

Ozrail needs to ascertain both hard as well as soft

benefits that IS adoption brings to the organisation

and their connection to organizational development.

This can only be attained if process and

organisational maturity is evaluated and compared

with the technical maturity such that the evaluation

provides a roadmap in terms of alternatives and

choices for IS investments. This then becomes a

strategic advisory mechanism that supports

planning, decision making, and management

processes. Such evaluations provide feedback that

facilitates organizational learning and indicate the

ICEIS 2008 - International Conference on Enterprise Information Systems

100

fundamental reasons, factors, and causes for

investment in technology.

At the moment technology adoption in Ozrail has

fundamental issues. There is disconnect between the

nature of IS and the form of the organisation. As a

hierarchical organisation, Ozrail needs to stability

whereas IS adoption induces change. This change is

geared at various levels and in various forms and

calls for adjustments such as job redesign, cross

functional communication, and informed and

proactive management. Conceptually, staff in Ozrail

is fearful of change and finding it hard to match the

capabilities of technology with organisational

success as well as to adapt to it. Operationally,

technology requires changing the way Ozrail has

traditionally been doing business, such as the need

for information exchange and cross functional

communication. Technology therefore has different

meanings for different departments and stakeholders

within Ozrail under different socio technical

environments. There is need to reinterpret use of

technology according to changes in the broader

context of asset management through change

management strategies that that would render the

current interpretation of technology use obsolete. In

this way when IS are physically adopted and socially

composed, there is the possibility of a general

consensus on accepted reality about what the

technology is supposed to accomplish and how it is

to be utilized.

REFERENCES

Amadi-Echendu, JE 2004, ‘The paradigm shift from

maintenance to physical asset management’, in

Proceedings of 2004 IEEE International Engineering

Management Conference, IEEE, Austin TX, Volume

3, pp. 1156-1160.

Anderson, M, Banker, RD, & Hu, N 2002, ‘Estimating the

business value of investments in information

technology, in Proceedings of the Eighth Americas

Conference on Information Systems, AMCIS 2002,

Dallas, TX. pp. 1195-1197.

Austrade 2006, ‘Railways overview’, The Australian

Trade Commission, accessed online on November 12,

2007 at http://www.austrade.gov.au/Railways-

Overview/default.aspx.

Australian Infrastructure Report Card 2005, ‘Australian

Infrastructure Report Card’, Engineers Australia,

Barton, ACT.

Blanchard, BS, & Fabrycky, WJ 1998, System

Engineering and Analysis, 3

rd

edition, Prentice Hall,

Upper Saddle River, New Jersey.

Creswell JW 1998, Qualitative inquiry and research

design: choosing among five traditions, Sage

Publications, UK

DCITA 2005, ‘Achieving Value from ICT: Key

Management strategies’ ICT research study’,

Department of Communications Information

Technology and the Arts, Commonwealth of Australia

Australian Government, April 2005, Opticon and

Australian National University; Australian ICT

Research Study, Canberra

Haider, A, & Koronios, A 2005, ‘ICT Based Asset

Management Framework’, in Proceedings of 8

th

International Conference on Enterprise Information

Systems, ICEIS, Paphos, Cyprus, vol. 3, pp. 312-322.

Haider, A, Koronios, A, & Quirchmayr, G 2006, ‘You

Cannot Manage What You Cannot Measure: An

Information Systems Based Asset Management

Perspective’, in Proceedings of Proceedings of

Inaugural World Congress on Engineering Asset

Management, 11-14 July 2006, Gold Coast, Australia.

IIMM 2006, ‘International Infrastructure Management

Manual’, Association of Local Government

Engineering NZ Inc, National Asset Management

Steering Group, New Zealand, Thames.

Karlsson, T, & Gennas, JB 2005, ‘Content Management

Systems – Business effects of an implementation’,

Master Thesis in Informatics, Department of

Informatics, Goteborg University and Chalmers

University of Technology, Goteborg, Sweden.

Leibs, S 2002, ‘A step ahead: Economist Erik

Brynjolfsson leads the charge toward a greater

appreciation of IT’, CFO Magazine, NY, pp.38-41.

Liyanage, JP, & Kumar, U 2003, ‘Towards a value-based

view on operations and maintenance performance

management’, Journal of Quality in Maintenance

Engineering, vol. 9, no. 4, pp. 333-350

Markeset, T, & Kumar, U 2005, ‘Product support strategy:

conventional versus functional products’, Journal of

Quality in Maintenance Engineering, Vol. 11, No. 1,

pp. 53-67.

OALD 2007, ‘The Oxford Advanced Learner's

Dictionary’, 7

th

revised edition, OXf. Uni. Press.

Rondeau, EP, Brown, RK, & Lapides, PD 2006, Facility

Management, John Wiley & Sons, Hoboken, NJ.

Yusof, MM, Paul, RJ, & Stergioulas, LK 2006, ‘Towards

a Framework for Health Information Systems

Evaluation’, in Proceedings of the 39th Annual Hawaii

International Conference on System Sciences, HICSS

’06, vol. 5, Hawaii..

ISSUES IN IS BASED ENGINEERING ASSET MANAGEMENT - An Australian Perspective

101