APPLICATION OF KNOWLEDGE HUB AND RFID

TECHNOLOGY IN AUDITING AND TRACKING OF

PLASTERBOARD FOR ENVIRONMENT RECYCLING AND

WASTE DISPOSAL

A. S. Atkins, L. Zhang, H. Yu and B. P Naylor

Faculty of Computing, Engineering and Technology, Staffordshire University

Keywords: Auditing system, CAD, Environmental Recycling, Knowledge Hub, Plasterboard, RFID Technology.

Abstract: The traditional disposal of waste in landfill sites is causing serious environmental concerns due to the

amount of hectares consumed by this method and the waste of resources which results from not being

proactive in effective recycling. The construction industry, for example, contributes approximately 108mt of

the total 335mt of waste annually produced in the United Kingdom of which 50-80% could be reusable or

recyclable. Construction waste is composed of at least 1mt of plasterboard waste which has resulted in

serious problems because of the emission of hydrogen sulphide gas which is odorous and causes a health

hazard to people living near disposal sites. Consequently, this material can only be disposed of in licensed

and special designed sites. Plasterboard can be recycled and some countries, for example Japan, Canada,

United States and, recently, the United Kingdom, are using this technology to obviate the issue of landfill.

This paper outlines knowledge hub using Radio Frequency Identification (RFID) linked to Computer Aided

Design (CAD) systems for providing auditing and monitoring systems for environmental recycling and/or

licensed disposal of plasterboard waste.

1 INTRODUCTION

The disposal of waste has become a sensitive topic

in recent years in terms of environment, health and

economic cost. There are a number of government

initiatives and environmental pressure groups

seeking environmental, socially responsible, and

economical means of future waste disposal.

In general, waste is a combination of many types

of material, and most of them are harmful and

polluting. Waste takes many years to break down,

and can pollute water courses and the land even

when it is carefully disposed of (McDougall and

White,2001).

Waste production is now a serious issue, and the

UK is currently producing around 335mt of waste

annually, including 50mt of industrial waste, 25mt

of commercial waste and 72mt of demolition

waste(ARIC and DEFRA, 2007; DEFRA, 2006b).

Demolition waste and construction waste are

becoming an increasing problem particularly due to

the re-development of urban areas. This requires

appropriate attention in terms of recycling rather

than traditional landfill disposal, which results in

long term environmental problems. Traditional

regeneration of urban areas results in harmful

material from demolition building being mixed in

with general waste. During its decomposition in

landfill sites, building waste such as plasterboard

can break down with organic waste and generate

Hydrogen Sulphide gas (H

2

S) which is odorous and

dangerous to health in high concentration (Granholm

and Chester, 2007).

The disposal of hazardous waste such as

plasterboard needs an auditing system to track and

visually record the correct disposal of the material in

licensed sites and/or its recycling in an

environmentally appropriate way. The advent of

computer and wireless technology can provide a

solution by using a combination of RFID technology

and wireless imagery to integrate data into a

knowledge hub for auditing and procedural

verification.

This paper explains and discusses the necessity

of an auditing system for demolition and

190

S. Atkins A., Zhang L., Yu H. and P Naylor B. (2008).

APPLICATION OF KNOWLEDGE HUB AND RFID TECHNOLOGY IN AUDITING AND TRACKING OF PLASTERBOARD FOR ENVIRONMENT

RECYCLING AND WASTE DISPOSAL.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - SAIC, pages 190-195

DOI: 10.5220/0001723601900195

Copyright

c

SciTePress

construction waste with particular reference to

plasterboard waste. A case study concerning

tracking systems that can be used for domestic waste

will be discussed in relation to a proposed integrated

auditing system concerning the environmental

recycling and disposal of plasterboard waste.

2 UK WASTE INFORMATION

The total amount of waste produced in the UK in

2004 was around 335mt annually(DEFRA,2006a).

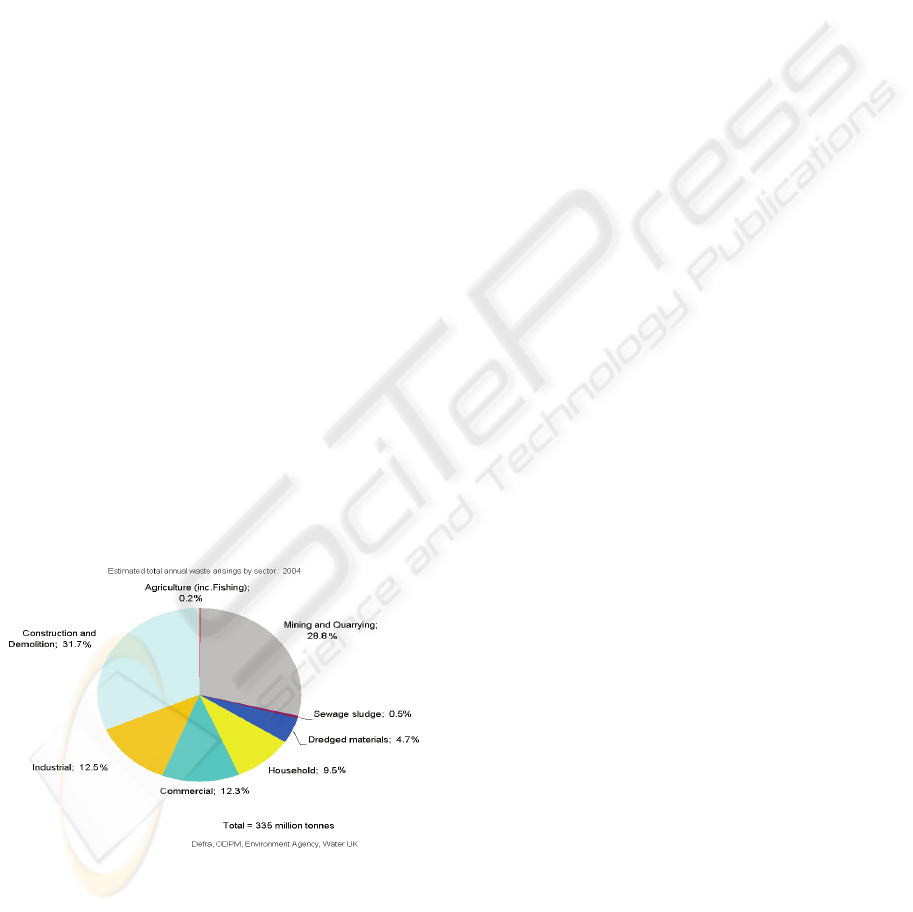

Figure 1 shows that the largest amount of waste is

from the construction and demolition sector which

contributes 106.1mt, and accounts for 32% of the

total UK waste(DEFRA,2006a). The information on

construction and demolition waste also includes

excavated soil, miscellaneous materials and hard

materials, such as brick, concrete and road

infrastructure (DEFRA,2006a).

The construction and demolition (C&D) waste

sector represents a large percentage of the waste

created (32%), and is undoubtedly a significant

aspect of the waste disposal issues in the UK. In

England, there are over 90 million tonnes of

construction and demolition waste (total for UK is

107.5 mt) generated (DEFRA,2006a). The amount

of landfill from the construction and demolition

sector is consequently causing environmental issues

particularly if it contains harmful materials. The

challenge is to ensure that in the future a much

higher percentage of construction and demolition

waste is either recycled and/or disposed of in a safe

manner.

Figure 1: Estimated Total Annual Waste by Sector in the

UK 2004 (DEFRA,2006a) (modified by authors).

3 THE PLASTERBOARD WASTE

3.1 Current Landfill in UK

Plasterboard is a popular material that is usually

used in the interior finishing of buildings, because it

is easy to use, relatively cheap, and provides a high

quality finish. It is widely used in industrial

construction, typically for house building in the

construction of room partitions and ceilings etc.

In the UK, the current disposal method of

plasterboard waste is usually in landfill sites.

Information from DEFRA in 2007 indicates that

more than 1mt of plasterboard from the construction

and demolition sector is being sent to landfill with

only 70,000 tonnes being recycled. It is anticipated

that over next 15 years the volume of plasterboard

waste will increase because of expansion in its use

and the rise in construction projects (DEFRA,2007).

Consequently, plasterboard waste is becoming a

serious concern because of the hazards in disposing

of this type of material in traditional landfill sites.

Plasterboard should be recycled on a much larger

scale than the present 7% to obviate the problem of

landfill disposal.

Currently, landfill facilities that only accept non-

biodegradable waste (gypsum materials should be

disposed in landfill sites which do not accept

biodegradable wastes to avoid the emission of

hydrogen sulphide when mixed with organic waste)

are limited in England and Wales compared to the

total number of waste disposal facilities. In England,

there are only 316 landfill sites (Wales has 16 sites)

which accept non-biodegradable waste out of a total

of 1055 landfill sites in England (DEFRA,2006c).

Consequently, recycling and/or disposal of

plasterboard in a licensed landfill site requires an

auditing and tracking system to provide evidence for

future verification.

3.2 Problem for Landfill Plasterboard

Plasterboards are made from fibre materials and

gypsum. The gypsum (CaSO

4

.

2H

2

O) is usually in the

middle layer of the plasterboard and sandwiched

together by two pieces of fibre material such as

paper or cloth. Plasterboard waste contains a high

proportion of gypsum and once placed in a landfill

site with biodegradable organic waste, will

decompose to produce hydrogen sulphide gas

(H

2

S) (Marvin,2000). This gas is noxious and

extremely malodorous at low concentration levels,

and can be toxic at higher levels resulting in

APPLICATION OF KNOWLEDGE HUB AND RFID TECHNOLOGY IN AUDITING AND TRACKING OF

PLASTERBOARD FOR ENVIRONMENT RECYCLING AND WASTE DISPOSAL

191

pollution of the environment and causing a health

and safety issue (Marvin,2000).

In July 2005, The Landfill Regulations of UK

was amended and now requires that gypsum or other

high sulphate-bearing materials should be disposed

of in landfill sites which do not accept biodegradable

waste, in order to avoid the emission of hydrogen

sulphide (Bradshaw,2005). Plasterboard can now

only be disposed of in specially designed landfill

sites which do not accept normal waste, such as

household, organic, and other types of waste which

can be broken down by living organisms. The

purpose of this regulation was to try and avoid the

plasterboard emitting harmful gas when associated

with organic waste, but waste buried in the ground

can still be problematic. In 2006 WRAP, the UK

DEFRA agency launched a project on the recycling

of gypsum to find alternatives to landfill disposal.

(Recycling Today, 2006).

3.3 Overview of Plasterboard

Recycling Methods

The recycling of plasterboard waste will reduce the

amount of plasterboard entering the waste system to

avoid damaging the environment. There are several

techniques for recycling plasterboard, but in general,

the main method is crushing to release the gypsum

and combining with the plasterboard production

cycle to make a new product(Hamm et al.,2007).

4 CASE REVIEW –

PLASTERBOARD RECYCLING

AND WASTE TRACKING

4.1 Recycling Plasterboard Case

Review

Plasterboard recycling has been used in a number of

countries such as Japan and Canada to make new

products. The difficulty is not the method of

recycling, but how to track and logistically supply

the processing plants to ensure there is sufficient

waste supply delivered on time and dramatically

reduce the amount of tonnage going to landfill

which is currently more than 93% in the UK.

A Japanese company Yoshino Gypsum Ltd is

using recycled plasterboard waste to make new

plasterboard, which they refer to as “Tiger Board”.

Their plasterboard is made from a mixture of raw

gypsum from mining, and a by-product from

generating power plants and waste plasterboard

operations which is collected from construction or

demolition sites (Yoshino-gypsum.com,2007). The

waste plasterboard is crushed twice to produce a

gypsum powder and during the process any paper

material is removed from the gypsum and the

powder is mixed with raw materials. However, only

5% of the gypsum material is from plasterboard

waste and thus the amount of plasterboard actually

recycled is limited.

4.2 Waste Tracking Case Review

Tracking systems are not a new concept, but their

application to construction and demolition waste is

novel, especially for plasterboard waste. Some case

studies of tracking confidential or domestic wastes

are outlined as follows:

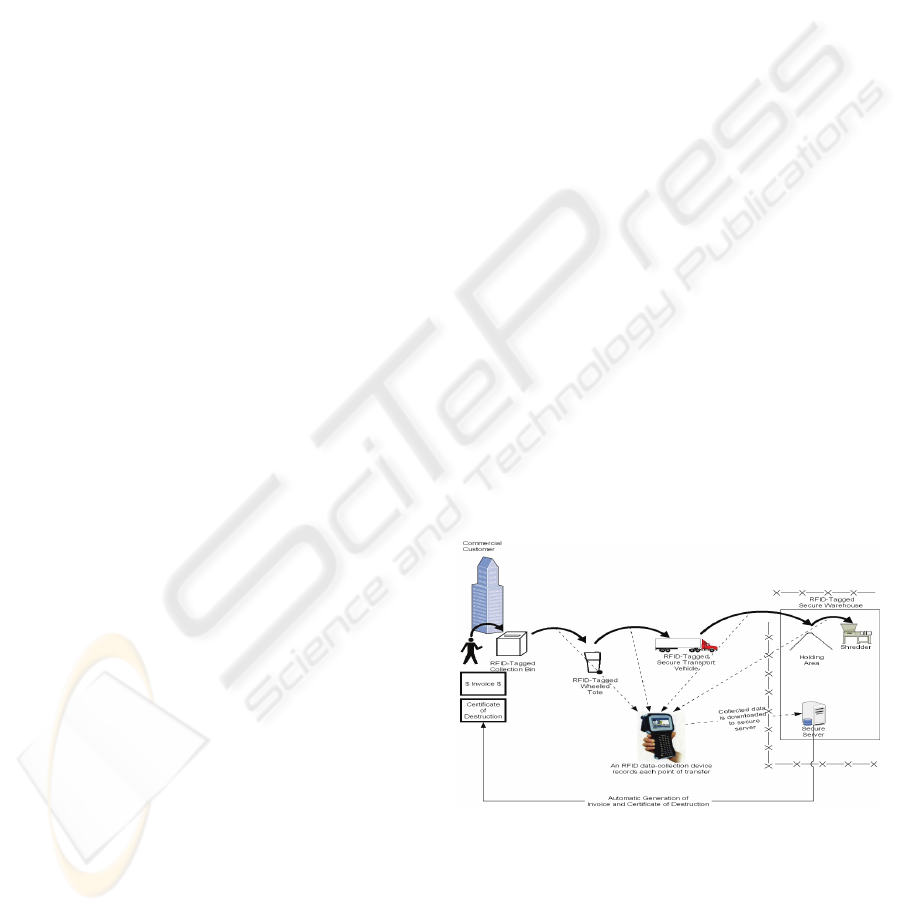

A Canadian company called NJE Consulting

provides an RFID solution for the secure destruction

of confidential paper records. They use a tracking

and auditing system for auditing confidential waste,

such as the paper waste from some government

departments, and provide evidence to prove that the

confidential material is promptly and completely

destroyed. Figure 2 outlines the process. Firstly, the

containers are all RFID-tagged, and the staffs record

each transfer using a hand-held RFID data-collecting

device. Once this confidential waste arrives at the

destroying facility, it is promptly destroyed, and the

data from the RFID data-collection device is

securely downloaded to a central server over an

encrypted network (NJE,2007). Customers then can

check the status of their confidential waste.

Figure 2: RFID-based Information to Automatically

Generate Customer Invoices and Certificates of

Destruction(NJE,2007).

ICEIS 2008 - International Conference on Enterprise Information Systems

192

5 PROPOSED SOLUTION USING

KNOWLEDGE HUB AND RFID

TECHNOLOGY FOR

AUDITING AND TRACKING

An outline and description of a proposed solution

using a knowledge technology system (knowledge

hub) to audit and track the plasterboard waste from

its source to recycling and/ or disposal location is

discussed.

The aim of the proposal can be viewed from 3

aspects: firstly, the auditing of plasterboard waste

removed from the construction site during

refurbishment and/or demolition of the building

(including off-cut plasterboard waste); secondly the

monitoring of plasterboard supplies during

construction and refurbishment; and finally the

auditing and tracking facilities for predicting the

amount of plasterboard waste and the logistics of

inward and outward movement.

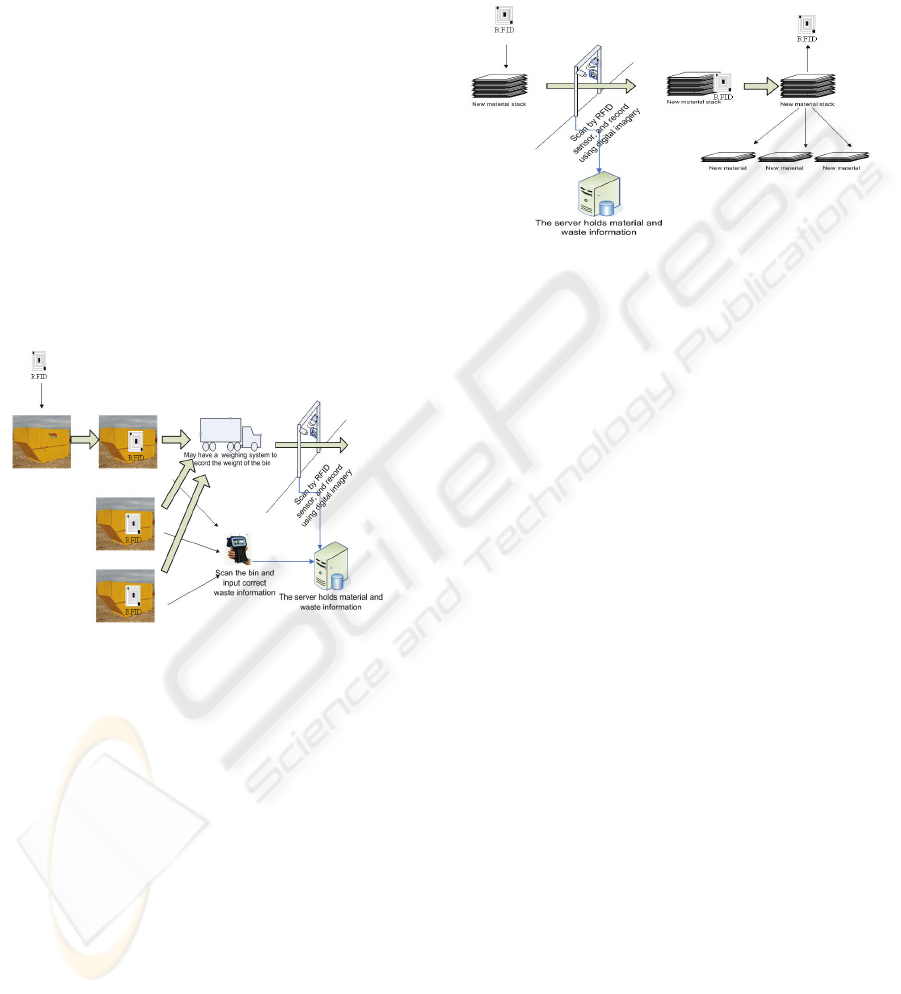

Figure 3: The Outward Material Handling System for

Waste Plasterboard.

Figure 3 shows that each plasterboard waste

container (skip or compactor skip) is marked with a

unique ID and RFID tag in the demolition or

construction site. The ID relates the information of

the waste container, such as the total load, unloaded

weight, location etc. This information is located in

the central information server, and can be checked or

updated by a hand-held RFID device. The operator

can input real time information about the waste as

appropriate; this system could also be used for other

kinds of waste such as asbestos, timber and glass etc.

When the waste containers are fully loaded, they are

transported through a special gate to the recycling

company or appropriate licensed landfill site. The

gate is equipped with RFID sensors and digital

imagery to create records which could be

supplemented with mobile imagery and logging

devices on site. The record is uploaded to the central

information server and shows the logistics of the

containers and the appropriate tonnages of

plasterboard waste being transported or delivered to

recycling and/or landfill sites (Atkins et al. 2003;

Zheng et al. 2006; Zheng et al. 2007).

Figure 4: Inward Material Handling System.

Figure 4 shows the inward logistics of the

proposal for new plasterboard material stacks which

are marked with a unique ID and RFID tag at the

construction site or before being transported. The

construction site is equipped with imaging

equipment (static picture and/or video) and an RFID

sensor connected to a central server (Information

Hub) which contains the material information. The

sensor will trigger the imaging equipment to start

recording this information, which is then sent to the

central server with date, time, and ID number. These

records can be checked to show how much

plasterboard is delivered to the site. Figure 4 also

shows that as plasterboard is used in a construction

the RFID tags are then removed from the stack, to

ensure that the plasterboard is not recorded again.

Consequently, after building is completed, the

information contained in the central server could

show how much plasterboard was used in the

buildings, determine the wastage, and assist in

auditing disposal and identifying and rectifying

inefficiency through the waste produced. This

information can be used in the refurbishment and

demolition of buildings in the future.

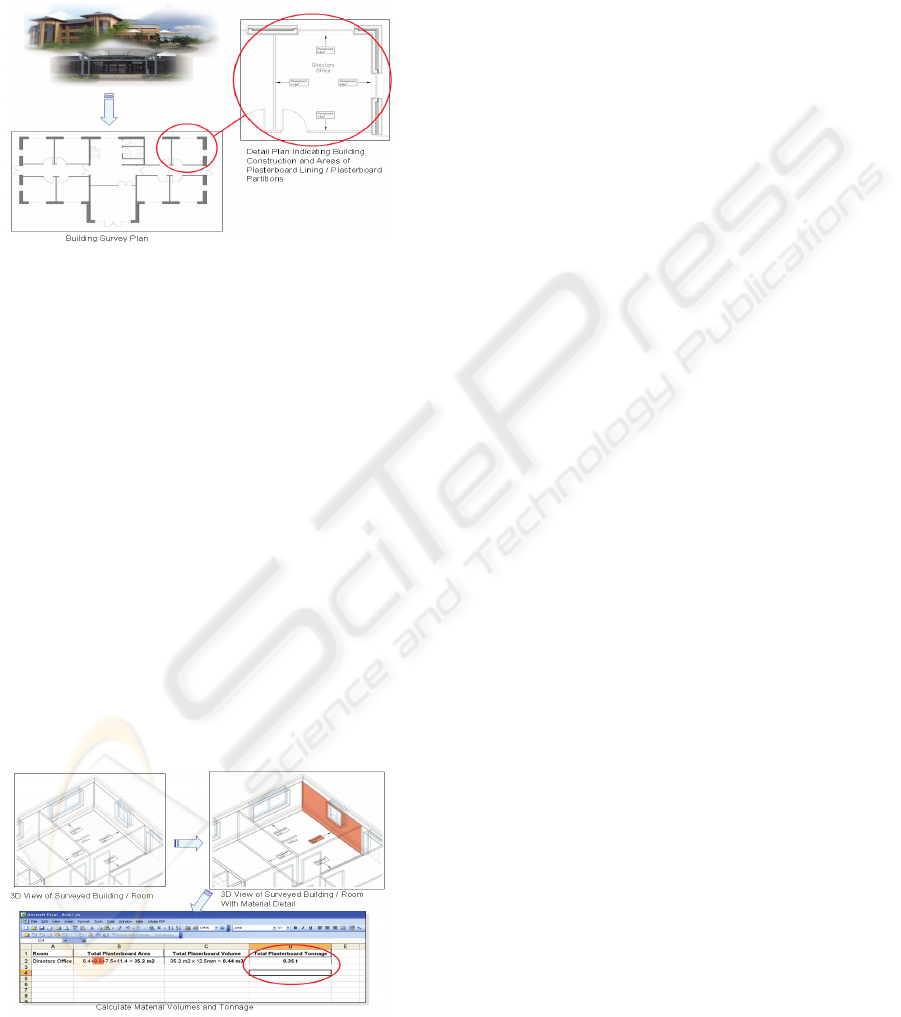

Using Computer Aided Design (CAD), tools

such as AutoCAD Architecture 2008 can be used to

estimate plasterboard waste by integrating the

information into a repository with digital imagery

(Autodesk.co.uk,2007). Figure 5 shows that after the

existing building has been surveyed, the building

plan can then be drawn in AutoCAD Architecture

2008. AutoCAD Architecture 2008 allows the user

to draw the plan in a 2D environment but at the same

time automatically generates 3D building

components. The user can determine the

APPLICATION OF KNOWLEDGE HUB AND RFID TECHNOLOGY IN AUDITING AND TRACKING OF

PLASTERBOARD FOR ENVIRONMENT RECYCLING AND WASTE DISPOSAL

193

construction of the build as identified in the survey

and apply the information to the relevant wall and

ceiling type of the waste material that needs to be

disposed. This allows 'Tags' to be attached to the

walls that can automatically generate the area of

specified materials, i.e. plasterboard.

Figure 5: Surveying the Target Building and Indicating

Plasterboard Materials.

The final stage is to calculate the volume of

plasterboard used in the buildings. Figure 6 shows

that AutoCAD can be used to estimate and identify

the individual rooms together with the area of

material used and generate a schedule of the waste

plasterboard information. This schedule can then be

exported into a repository and using spreadsheet

applications can be programmed to generate the total

volume of the material from different aspects of the

building construction. This information can be used

to determine the volume and tonnage of plasterboard

waste (or of other materials as appropriate for

recycling) that will be generated during the

refurbishment and/ or demolition. This information

can then be imputed to the central server and

compared to the information from the RFID sensor

to provide specifications of the material to be

disposed of, and assist in the logistics of supplying

recycling or disposal sites.

Figure 6: Predicting the Correct Volume and Tonnage of

Plasterboard in Advance.

Ensuring that the plasterboard waste goes to the

correct destination requires the co-operation of

construction firms and recycling and waste disposal

companies (recycling company or landfill site). At

the destination sites, sensors and imagery (cameras)

need to be used to record the transport information

in real time. The function and mechanism of the

sensor and the imagery would be similar to those

used at the construction sites, but on a smaller scale

and using fixed and mobile devices to give more

mobility for easier operations.

This system can be used to support construction

companies in determining the amount of

plasterboard waste produced in refurbishment or

demolition as well as appropriate construction

quantities to obviate unnecessary waste (Atkins et

al.,1986; Atkins et al.,1987). The system can be used

to provide the verification and tracking of waste

disposal required for auditing and complying with

government and/or public scrutiny. This proposed

system can also be used within recycling companies,

to help them maintain adequate supplies and

coordinate their inbound logistics of deliveries using

simulation to improve their efficiency and process

plant control for more efficient environmental

solutions to hazardous waste as well as other

construction material such as wood and glass etc

(Atkins et al.,1996; Atkins et al.,1985).

6 CONCLUSIONS

This paper reviews current waste production and the

increasing trend of certain waste categories in the

UK, particularly construction and demolition waste

which accounts for 335mt per annum, and

noticeably increased between 1998 and 2005. In

particular, plasterboard waste is causing a significant

problem for landfill sites as it has a high gypsum

content, which can result in the emission of

hydrogen sulphide (H

2

S) gas when it decomposes

with organic waste. Currently, there are two ways to

avoid this hazardous emission: either dispose of the

plasterboard in special landfill sites which only

accept non-biodegradable wastes, and/or recycle the

plasterboard waste which would be the preferred

environmental solution. However, the amount of

plasterboard waste currently recycled is extremely

low: only 70,000 tonnes which is about 7% of the

total UK waste. Recent information from DEFRA

(SweeneyII,2005), anticipates that plasterboard

waste will continue to increase in the next 15 years.

In the plasterboard application outlined in this paper,

an auditing and tracking system is necessary to solve

ICEIS 2008 - International Conference on Enterprise Information Systems

194

and provide verification and logistic support to this

environmental problem (AK and Atkins,2007). This

system is being designed to use RFID technology

and digital imagery to integrate records including

construction material, location, volumes and weight,

container movement and delivery tracking

inventories and scheduling etc. It will be integrated

into a knowledge hub that can be used to predict the

scheduled logistics of plasterboard waste to

recycling plants using simulation techniques to

improve processing operations. This system can

ensure that containers of plasterboard waste go to

the correct destination and provide verifiable

evidence of each stage of the operation for auditing

purposes and independent scrutiny. This can also be

used by waste disposal or recycling companies to

provide improved logistical support to the recycling

of other materials such as wood and glass to improve

recycling capability.

ACKNOWLEDGEMENTS

The authors would like to thank Dr. Emma Price for the

technical support in producing this paper.

REFERENCES

ARIC and DEFRA. "Waste Arisings in the UK."

Available from: www.ace.mmu.ac.uk/ Cited: 03-Oct-

2007.

Atkins, A S, J C Atkin, R N Singh and A M H Zadeh.

1986. "An Alternative Method of Surface Disposal

and Stabilization of Coal Mine Tailings." In

Geotechnical and Geohydrological of Waste

Management. Fort Collins: Rotterdam Boston.

Atkins, A S, N I Aziz and Rao B S. 1996. "Applications of

Multimedia in Strategic Management in Engineering

Design Associated with Occupational Hazards of

Dust." In 96 International Symposium on Mining

Science and Technology. Xuzhou, Jiangsu , China:

Balkema , Guo & Golosinski.

Atkins, A S, R N Singh, A Barkhordarian and A H Zadeh.

1987. "Pumpability of Coal Mine Tailings for

Underground Disposal and Regional Support." In 2nd

International Symposium on the Reclamation,

Treatment and Utilization of Coal Mine Wastes.

University of Nottingham, Nottingham NG7 2RD.

Atkins, A. S., R. N. Singh and Hughes D. 1985. "Settable

Composition and Methods of use thereof ", patent by

Coal Industry (patents) Ltd. Hobart House, London.

Autodesk.co.uk. 2007. "Autodesk AutoCAD Architecture

2008." Autodesk Inc.Available from:

www.autodesk.co.uk, cited: 14-Oct-2007.

Bradshaw, Ben. 2005. "The Landfill (England and Wales)

(Amendment) Regulations 2005 " In Statutory

Instrument 2005 No. 1640, ed. DEFRA.

DEFRA. 2006a. "Estimated Total Annual Waste Arising

by Sector: 2004 ": Department for Environment, Food

and Rural Affairs, Available

from:http://www.defra.gov.uk/environment/statistics/

waste/download/xls/wrfg02.xls, Cited: 02-Oct-2007.

DEFRA. 2006b. "Estimated Total Annual Waste Arisings

by Sector in United Kingdom: 1997-2003 ":

Department for Environment, Food and Rural Affairs,

Available from:

http://www.defra.gov.uk/environment/statistics/waste/

download/xls/wrfg02.xls, Cited: 02-Oct-2007.

DEFRA. 2006c. "Operational Waste Facilities in England

and ales at the end of June 2006." Environment

Agency and Department for Environment, Food and

Rural Affairs.

DEFRA. 2007. "Waste Strategy for England 2007."

Department for Environment, Food and Rural Affairs.

Granholm, Jennifer M. and Steven E. Chester. 2007.

"Drywall Recycling." Michigan, US: Michigan

Department of Environment Quality.

Hamm, H., R. Huller and J. Demmich. 2007. "Recycling

of plasterboard." Zkg International 60(5):68-74.

Marvin, Emma. 2000. "Gypsum Wallboard Recycling and

Reuse Opportunities in the State of Vermont."

Vermont Agency of Natural Resources.

McDougall, F. and P. White. 2001. Integrated solid waste

management a life cycle inventory. Oxford: Blackwell

Sciences.

AK, Awangku PG HJ Ali A. H. and A. S. Atkins. 2007.

"A Strategic Business Tool for Mobile Infrastructure –

Wireless Ubiquitous Computing." In Institute for

Systems and Technologies of Information, Control and

Communication Funchal, Portugal.

NJE. "NJE Consulting ": Available from:www.nje.ca,

cited: 28-Sep-2007.

Recycling Today. 2006. "UK Agency Offering Money for

Gypsum Recycling Projects." Available from:

http://www.recyclingtoday.com/news/news.asp?ID=10

242 Cited: 8-Oct-2007.

Sweeney II, Patrick J. 2005. "Chapter2 Auto-ID

Technologies: Why RFID Is King of the Hill." In

RFID for Dummies. Hoboken: Wiley Publishing.

Yoshino-gypsum.com. "YOSHINO GYPSUM CO.,

LTD." Available from:http://www.yoshino-

gypsum.com/en/sekkou/what/what04.html, cited: 28-

Sep-2007.

APPLICATION OF KNOWLEDGE HUB AND RFID TECHNOLOGY IN AUDITING AND TRACKING OF

PLASTERBOARD FOR ENVIRONMENT RECYCLING AND WASTE DISPOSAL

195