A GENERAL SYSTEM FOR MONITORING AND

CONTROLLING VIA INTERNET

Adrián Peñate Sánchez, Ignacio Solinis Camalich

Alexis Quesada Arencibia and José Carlos Rodríguez Rodríguez

Instituto de Ciencias y Tecnologías Cibernéticas, Universidad de Las Palmas de Gran Canaria

E35017, Las Palmas, Spain

Keywords: J2EE, Java, Web Monitoring and Controlling, Automation, Mobile Technologies, Internet Computing.

Abstract: The main aim of the project, presented in this paper, is to create a system that will give a solution to the

variety of situations we can encounter in industrial plants control; to achieve this goal we have given the

system different automation, remote control and remote monitoring functionalities. Industrial installations

can be composed of several plants; for this reason we offer a solution capable of defining a central office

that is in control of all plants, each plant with its own controller. Apart from the problem of geographically

disperse locations, it is also of the essence to offer automation for the tasks that take place in the plants. In

order to achieve an automation system capable of giving answer to a range of situations, as wide as possible,

we have designed an engine so that the user may create its own rule based system, defining himself the rules

by means of an interface that abstracts the user from the formal definition of the rules.

1 INTRODUCTION

This application sprung up from the approach of

several companies interested in having an

application capable of surveying their plants and

being able to do those tasks automatically. These

approaches gave place to the development of two

consecutive projects that gave birth to the system

that we will outline in this paper.

1.1 Final Objective

The challenge was to create a system by means of

which an industrial plant could be controlled

remotely and its processes automated; all this

without being tied to a specific kind of industrial

plant or process.

For this we understand that any industrial

process, generally, is composed by three factors:

- Sensors.

- Actuators.

- Decision making.

By intending to control these factors we have

settled the basis on which to build the system.

1.2 System Structure

The system’s structure is composed by two

subsystems: the plant and the office; each one of

them will be managed by a different application. The

different plants will be connected to the office, from

where the surveillance of the plants functioning state

will be made.

The office will be managed by an application

that will take care of the visualization of the plants

state, store the historical data of each plant, allow the

user to make simple statistical studies of the

historical data, etc.

Each plant’s application will take care of the

usual tasks of monitoring and automation, as well as

communicating with the office. The information

flow between the office and the plants is

bidirectional, being established under the following

circumstances.

- The office starts the communication in order to

obtain real time data about the plant

- The plant sends warnings about the activation

or deactivation of alarms. We indistinctively

refer to rules or alarms in the same way.

267

Peñate Sánchez A., Solinis Camalich I., Quesada Arencibia A. and Carlos Rodríguez Rodríguez J. (2008).

A GENERAL SYSTEM FOR MONITORING AND CONTROLLING VIA INTERNET.

In Proceedings of the Tenth International Conference on Enterprise Information Systems - SAIC, pages 267-270

DOI: 10.5220/0001725902670270

Copyright

c

SciTePress

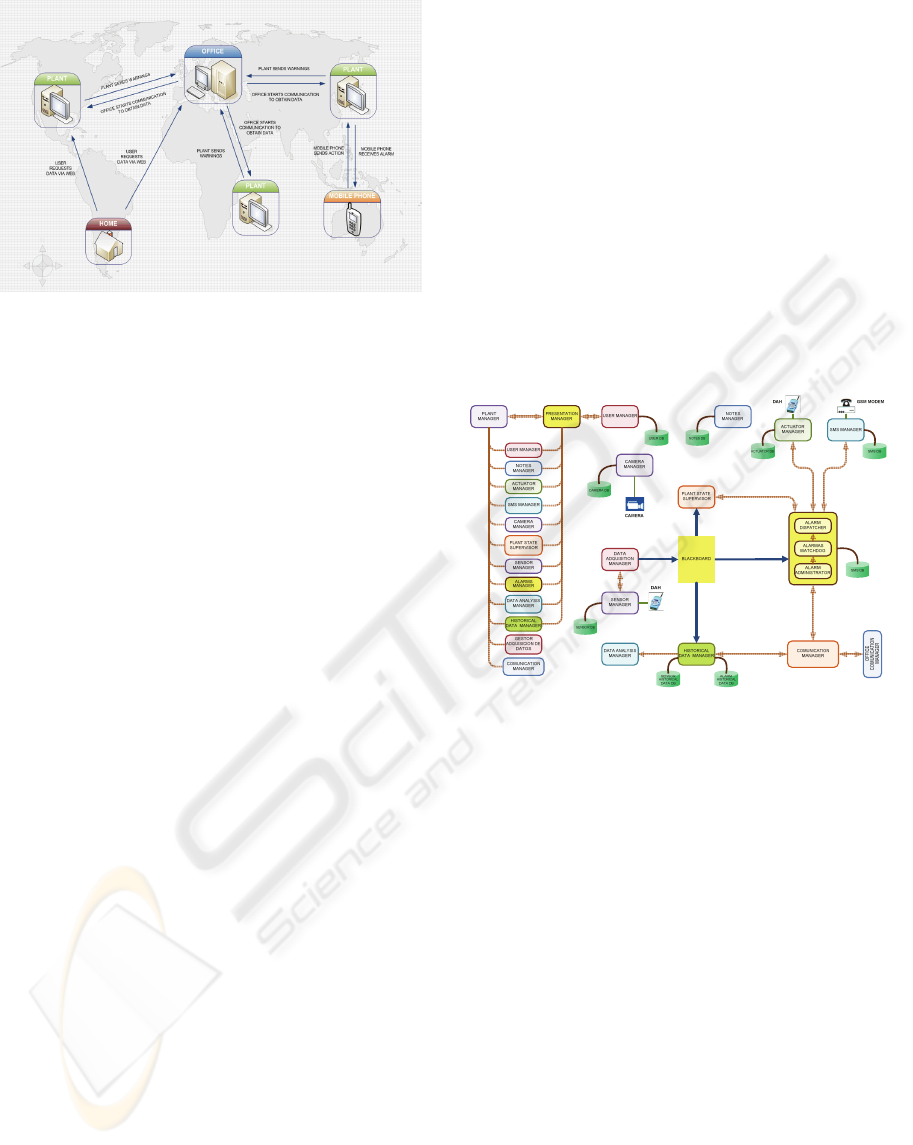

Figure 1: Topology of the system. In this picture both

subsystems can be seen in a centralized topology where

plants act as peripheral nodes and the office as the central

node.

In the image we can appreciate how the system’s

different actors start communicating in order to

perform the tasks that are required. It can be seen

how the office asks the plants for data and how the

plants send the historical data to the office. It can

also be seen how the mobile phone starts the

communication, when it sends an action to the plant,

and how the plant starts the communication, when it

sends an SMS in the event of an alarm. Another

possible communication process can be established

in any computer with access to the internet, you can

ask both the plants and the office for information

about the actual state of the installations.

1.3 Development with Open Source

Tools

One of our main concerns was to develop this

system with Open Source tools. For this reason we

defined several requirements in order to use the most

suitable tools for the purpose of the project.

After the process of studying and selecting

different languages, frameworks and development

software, we chose the following ones:

- The developed system is based on a Java EE 5

platform. The J2EE platform consists of a set

of services, APIs, and protocols that provide

the functionality for developing multitier

Web-based applications.

- Open Source software: Linux, Specific software

(application server, databases, etc.),

Integrated development environment

(Eclipse, DBdesigner, etc.).

2 SYSTEM ARCHITECTURE

In this section we will introduce the system´s

architecture. We are going to show its modular

design as well as the most relevant modules.

2.1 A Modular Approach to the

Problem

This system was conceived as one that was going to

be made and evolved in several issues, so, as for the

architecture, a modular approach was of essence.

Introducing a modular design would make the

system capable of adding new modules without

other parts needing to be changed or adapted to

assemble with the new ones.

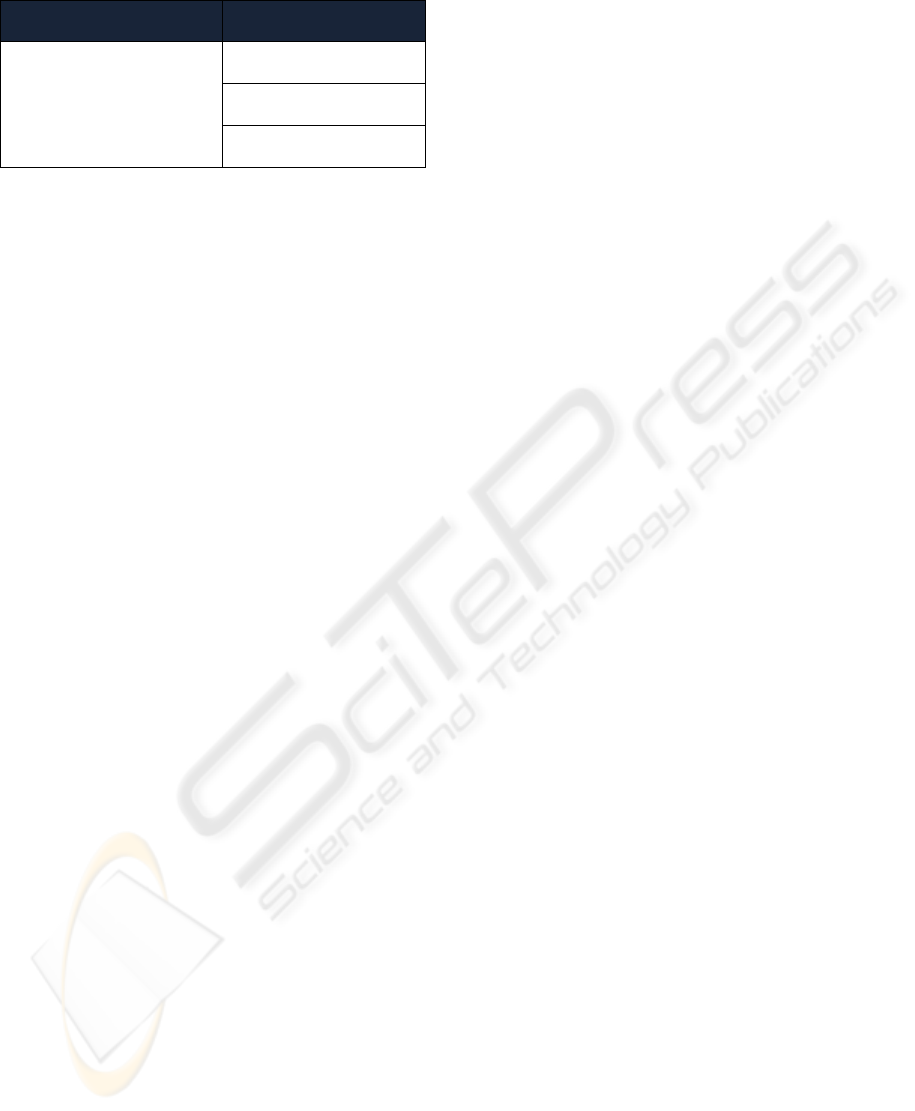

Figure 2: Modular architecture. It can be seen in this

picture the different modules of the plant architecture, the

interaction with each other and their access to their

specific databases.

2.2 Data Acquisition Manager

This module takes care of receiving the sensor

readings from the sensor manager and transmitting

them to the blackboard, from where the other

modules take their data as in a consumer/producer

classic concurrent problem, which in fact it is. In this

case the data acquisition manager will be the

producer and the consumers will be the plant state

supervisor, the alarm manager and the historical data

manager.

ICEIS 2008 - International Conference on Enterprise Information Systems

268

Table 1: Consumer/Producer role distribution.

PRODUCER CONSUMER

Data acquisition manager

Alarm manager

Historical data manager

Plant state supervisor

2.3 Sensor Manager

This module is in charge of introducing, updating

and eliminating the sensors from the system; so this

module needs to have access to the Data Acquisition

Hardware (DAH). The DAH carries out the signals

from the sensors to the final computer. Then these

signals can be processed by the computer in order to

get the readings in real time.

2.4 Actuator Manager

The actuation control is done by this module; it will

take care of including, modifying and deleting the

actuators from the system, and it will also define in

which entry of the DAH it is connected. This

module offers an interface so that the user or the

rules can activate the different actuators that are

installed in the system.

The actuator manager offers digital and

analogical outputs in order to control different kinds

of switches, motors, etc. This is the part of the

system that will enable us with the capacity of

automation.

The actuator manager offers us the ability of

activating and deactivating the different components

of each plant over the distance. We can connect

ourselves to the plant via web or via mobile phone

and give orders to it. This will prove useful in

various situations like shutting down a plant if

desired, or a part of a plant (e.g. Water pumps), or

activating a plant that was idle.

2.5 Alarm Manager

This is one of the most important parts of the system

because it is here where we will be able to define the

behavior of the control that we want for our plants.

With the intention of creating a system capable of

giving a solution to a range of situations, as wide as

possible, we couldn’t define a specific control;

therefore, we decided to create an engine so the user

could define its own control.

We decided to use a rule-based-system (RBS)

where the user would define his own rule set.

Besides, we also had to make a special effort to

create a solution that could be used by users lacking

any knowledge of algorithms; this was achieved by

creating an interface that would guide the user

through, asking questions and offering different

possibilities, and translating them into an algorithm.

Each alarm can have as many conditions for

activation as desired. These conditions can be: a

sensor’s readings are over or under a certain value,

this value can either be a constant or another sensor,

or how long the condition has to be active to raise

the alarm. It is also possible to include a difference

between two different sensors, controlling these way

possible undesired fluctuations.

The alarm manager is composed of three

subsystems which deliver complementary but

different functionalities. The subsystems that

compose the alarm manager are the following ones:

- Alarm administrator. This subsystem takes

care of creating, modifying and deleting the

rules from the system. This will be the

subsystem that takes care of the alarm

database in which the characteristics,

conditions and actions will be stored.

- Alarm watchdog. The watchdog evaluates the

activation conditions of the rules in order to

detect the activation and deactivation of each

and every one of them; when it detects an

event it informs of it to the alarm dispatcher.

- Alarm dispatcher. This subsystem will give

instructions to other modules in order for the

actions to take place; such actions can

involve sending an SMS to a user to inform

of the alarm, activating an actuator so that it

can put the plant back in order, or both.

2.6 SMS Manager

This component introduces the functionality of

sending SMS to the users so they can know in every

moment if something is going wrong, and if it comes

to that, they can send an SMS to the plant to activate

or deactivate any actuators. This way we introduce a

lot of possibilities of remote controlling the plant.

The SMS sent by the user must be written

according to the specifications of the system so the

SMS manager can interpret the object of its action.

We have chosen to make the remote control over

mobile phone because it enables us to communicate

in places where an internet connection might not be

possible and because it is a cheap technology.

A GENERAL SYSTEM FOR MONITORING AND CONTROLLING VIA INTERNET

269

3 REAL EXAMPLES OF

INDUSTRIAL PLANTS

ALREADY USING THE

SYSTEM

We are going to outline several examples where the

system is already in use, in order to obtain a real

source of data that will help us to decide whether the

goals of the project have been achieved, or whether

changes have to be made.

3.1 Desalination Plant

Several desalination plants are working with this

system at the moment. There is a company that

builds desalination plants offering this system to all

their new clients, so they are selling not only the

final product, the desalination plant, but also it

maintenance. The principal use of the system in this

case is to control pressures, flow and temperatures of

the water during the process of water desalination; it

has been introduced in different kinds of contexts as

airports, golf courses, etc. They have found that,

because of the remote locations of most plants, their

capability of detecting problems and failures has

been increased substantially. Now they can make a

much more efficient use of their human resources

and they can give support to their clients in a shorter

period of time.

3.2 Student Residence

Due to the request of the manager of the residential

service of the University of Las Palmas de Gran

Canaria for modernizing the installations of the

different buildings belonging to the university, the

system was offered as an alternative which has been

accepted by the manager as a quite promising

possibility.

In the different buildings the control required

was mainly of temperature, flow level of water

tanks, actuation over the water pumps and the

valves, control over the gas tanks, etc. it was also a

project that needed a system able to control

buildings that were situated in different parts of the

city.

At the moment this project has been installed and

it is facing different tests of performance, in order to

know whether more sensors or actuators are required

and if any adjustments are (required) to be

implemented to the installations.

4 CONCLUSIONS AND FUTURE

WORK

As we have observed by the feedback of the final

users of the system and our studies of the real cases,

we think that the system has developed into broad

use software capable of adapting to the needs of

most of the industrial plants we have dealt with. This

is also because the project has been developed in

two phases; in the first one the system had less

features and possibilities of control, this was the

system placed at the desalination plants, whereas in

the second phase the user’s requirements were

brought into consideration.

As result of the second phase the actual system

was developed as an evolution adding the features

that were suggested by the user and thought through

by us. As future work further versions of the system

could be made, for example an expert system could

be integrated as an alternative to rule based system,

in the same way further features of

telecommunication could be included in order to

enhance communication with the plant from places

as remote as possible, etc.

In conclusion, this system will give answer to

systems that will need control and automation for

industrial plants without the need to create specific

software to control it and with numerous features,

such as control over mobile phone, a rule system

that automates processes, etc, and that will give

answer to the possible needs that it could encounter.

REFERENCES

Deepak Alur, John Crupi, Dan Walks. Core j2ee patterns.

Best practices and design strategies. Sun Microsystems.

Nadir Gulzar. Practical j2ee application architecture. Mc

Graw Hill, Osborne.

Chuck Cavaness. Jakarta Struts. O’REILLY.

Rima Patel Sriganesh, Gerald Brose, Micah Silverman.

Mastering Enterprise JavaBeans 3.0. Wiley Publishing.

Roger S. Pressman. Software Engineering: A Practitioner's

Approach. Mc Graw Hill.

Ian Sommerville. Software engineering. Addison Wesley.

Solinis Camalich I., Quesada Arencibia A., Rodríguez

Rodríguez J. C., Moreno Díaz jr R. An open modular

system for monitoring remote sensors. EUROCAST

2007. Lecture Notes in computer science Vol-4739, pp:

82-89. 2007.

ICEIS 2008 - International Conference on Enterprise Information Systems

270