Implementing EPCIS with DEPCAS RFID Middleware

Carlos Cerrada, Ismael Abad, José Antonio Cerrada and Ruben Heradio

Departamento de Ingeniería de Software y Sistemas Informáticos

Escuela Técnica Superior de Ingeniería Informática, UNED

C/ Juan del rosal 16, 28040 Madrid, Spain

Abstract. RFID middleware is a new breed of software acquisition system that

allows transfer data between device readers and business applications. RFID

middleware has been structured in facto with several layers: infrastructure

layer, event processor, tag data translator, rules and composite process, and ap-

plication integration or EPCIS. EPCIS term is a generalization to refer the up-

per layer that link RFID middleware with external systems like SCMs, ERPs,

WMSs or any user application that use auto identification data. In this paper we

want to present the EPCIS DEPCAS layer. DEPCAS (Data EPC Acquisition

System) is a RFID middleware proposal based on an extension of control and

data acquisition systems (SCADAs). We examine the elements that compound

EPCIS in DEPCAS based on SOA (Service-Oriented Architecture) and pub-

lish/subscribe message technologies implemented with JMS (Java Message

Service). EPCIS in DEPCAS solves the two-way communication: it receives

the configuration back-end information to increase the RFID semantic process

defined with scenarios and offers the services to exploit the RFID acquisition

results.

1 Introduction

As part of the optimization effort, companies of diverse application areas are

exploring the use of RFID technology [1]. The noncontact identification applied

to control, to supervise or to acquire any kind of information holds the promise to

provide real time visibility for the most heterogeneous activities [2]. These activi-

ties which are so different as supply chain management, inventory control, asset

management, medical survey, access restriction, individual or animal identifica-

tion, codification and food traceability, etc., manage the same source information

but with very different purposes and objectives.

In traditional RFID applications there was a reduced middleware needed be-

cause the RFID infrastructure was much compact (even there was not networked

RFID readers) and the RFID information was used directly in the business proc-

ess [3]. But nowadays we can start to use a huge variety of RFID infrastructure

and a very complex ubiquitous information network with redundancy, backup

acquisition system or hierarchical organizations [4]. Now, the objective is how to

encompass current and future technology at the same time, and how this informa-

tion could be combined with current capabilities.

Cerrada C., Abad I., Antonio Cerrada J. and Heradio R. (2008).

Implementing EPCIS with DEPCAS RFID Middleware.

In Proceedings of the 2nd International Workshop on RFID Technology - Concepts, Applications, Challenges, pages 167-174

DOI: 10.5220/0001740001670174

Copyright

c

SciTePress

Of course, we cannot forget the real migration environment that we are going

to solve. There are thousands of applications that are using identification through

codes, bar codes, plates, badges, 2D codes, etc. [5] that in a mid-time will change

to RFID auto identification. From the little applications that we can find in any

little market wherever you look in the world, to the large and more complex in-

formation system of a big and global company, the change from identification to

auto identification will arrive.

This state of the art in the integration of RFID in the existing and real systems

provide a research prospect to propose a general middleware architecture that

process and consolidate RFID information solving the pending questions and

helping efficiently to migrate from identification to auto identification systems.

To leverage the RFID data sharing between RFID acquisition software and

disparate business applications the EPCGlobal [6], an organization that develops

world-wide standards for RFID technology proposed the EPC Information Ser-

vice [7] a data repository that covers most issues related to RFID data manage-

ment and uniform programming interfaces for data acquisition and sharing. In a

general meaning, EPCIS is the upper middleware layer of any RFID middleware

that interconnect business process to RFID data.

This paper is organized as follows. Section 2 introduces the EPCIS standard

proposal and compares some existing EPCIS implementations. Section 3 de-

scribes the general DEPCAS architecture and the main ideas introduced in these

middleware architecture. Section 4 describes the EPCIS DEPCAS implementa-

tion using JMS technology. And section 5 concludes our paper.

2 EPCIS Review

Despite the variety of existing RFID applications, the EPCIS main functionalities

are almost similar. Therefore, the EPCGlobal propose an EPCIS specification

framework designed to be “layered, extensible, and modular”. This framework is

a definition about a minimal set of use cases that the EPCGlobal working group

has identify like basic functionality. Other use cases are projected to be included

in future specification releases. From this initial spec the existing middleware

projects has develop their own EPCIS layer to solve the link between RFID data

models and business applications demands.

2.1 EPCIS Network Specification. From PML to the Abstract Data Model

The EPC Information Service provides a specification framework to solve the

external RFID middleware applications to capture, secure and access RFID data.

The original EPC network architecture was defined from EPCIS White Paper in

October 2003 [8] like an “omniscient entity” to provide relevant information re-

quired from business application to RFID middleware. The main four functions

included in EPCS in this started proposal were: to provide a long term repository

of EPC event data, to supply an access point to higher-level information obtained

168

from EPC process acquisition, to solve the storage and access to detailed business

information associated to EPC process acquisition, and to provide transparent on-

demand access to data attribute held in others systems.

These general functions were so broad that introduces a general confusion

about how to solve and implement it. These pending questions are got pass in the

definite EPCIS specification definition [7][10] including an standard interface to

allow EPC data interchange. This standard interface is characterized by: manag-

ing only historical data (real-time EPC data is decoupled from EPCIS), operating

with cooked EPC related information (raw EPC data is processed in low EPC

Network layers), and dealing only with enterprise systems environment. All this

specific functions are solved using a three layer interface: the abstract data model

layer, the data definition layer and the service layer. The abstract data model is a

closed and defined interface that proposes a specification of general requirements

for creating data definitions in the data definition layer. This data definition is

called core event type. This structural organization in the interface allow to use

standard vocabulary elements used by inter organizations and user specific vo-

cabulary elements defined and meaning inside intra organizations.

2.2 EPCIS Implementations

There are several implementations of generic functions of EPCIS. We want to

include in this comparative point the Sun Java RFID System v3.0 [11], the Web-

Sphere RFID Premises Server [12], the WinRFID middleware [2] and the Accada

EPC Network open source RFID prototyping platform [13]. There exists other

EPCIS implementations from other companies, like RFID Anywhere EPCIS layer

or the BEA WebLogic RFID Enterprise Server.

The EPCIS layer is solved in Sun Java RFID System by the RFID Information

Server a J2EE application that covers the business connection with the Sun Java

infrastructure components. The RFID Information Server uses a permanent re-

pository (in version 3.0, ORACLE 9i, ORACLE 10g or PostgreSQL 8) that allows

defining metadata to be interchanged. The transport mechanism is implemented

using HTTP or JMS of XML messages according to their specific schema. The

WebSphere RFID Premises Server includes the WebSphere RFID Information

Server to support EPCIS functionality. This information server includes a DB2 or

and Oracle as backend database. The WinRFID platform dedicates the two upper

layers: XML framework and the data presentation layer to solve the basic EPCIS

operations and a generic rule engine to manage interface interchange. The Accada

EPC Network prototype includes an EPCIS layer composed itself the same three

standard layers: EPCIS capture application, the EPCIS repository and the EPCIS

query application.

Despite the objective of all these implementations is the same: to connect

business with RFID middleware, there are a set of characteristics that differ be-

tween specific solutions. This analysis introduces the following features:

- Standard compliance, what is the compliance degree in the existing implementa-

tion according to EPC Network standard.

169

- EPCIS permanent data model implementation, what is the existing repository

implementation supported by EPCIS solutions.

- Security EPCIS control. There is a large range of security control levels in EPCIS

data, from general user access to low granular data access.

- Metadata management. The business process defines process data and specific

attributes that are introduced in the EPCIS repository.

- Supply chain support. The EPCIS implementation has specific elements to solve

supply chain questions.

- Reports. The EPCIS includes report facility to data access using XML exporters.

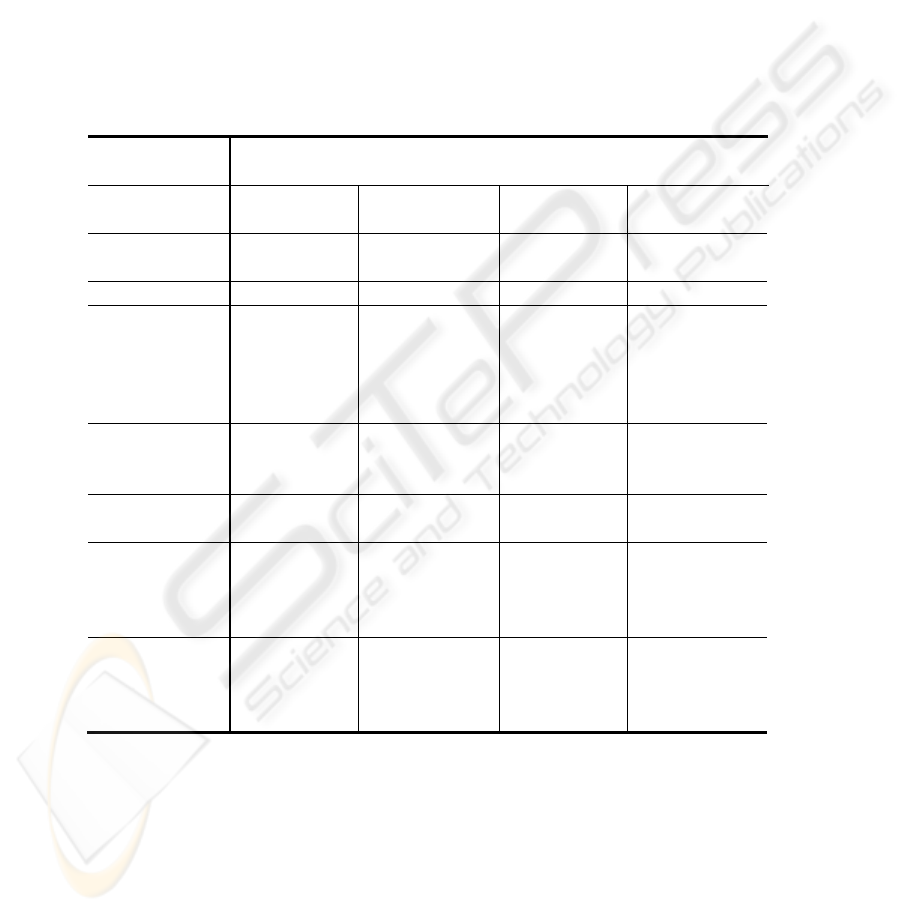

The comparative values for existing implementations are shown in the following

table:

Table 1. EPCIS attributes versus existing implementation.

Sun RFID WebSphere

RFID

WinRFID Accada

Standard com-

pliance

Partial Complete Partial Partial

Datamodel Oracle

PostgreSQL

Oracle

DB2

Oracle

SQLServer

MySQL

Web Server Jini WebSphere Unknown Apache

Security WebServer

security

Proprietary

security in-

fraestructure

Remote

objects

Authentica-

tion and au-

thorization for

query opera-

tions

Metadata Using data in

repository

Specific meta

data model

XML

framework

No support

for new vo-

cabulary type

Supply chain

support

Yes Yes Specific

adaptor

Yes

Reports Not included BIRT: Busi-

ness Intelli-

gence Report-

ing Tool

Not included Not included

EPCIS events Yes, abnor-

mal process

Events and

alerts EPCIS

manager in-

cluded

Rule man-

ager excep-

tions

Yes, abnormal

process

3 DEPCAS Architecture

DEPCAS (Data EPC Acquisition Systems) is a software architecture solution to

solve the RFID acquisition in heterogeneous and real systems. The scheme pro-

170

posed here takes origin in the architecture of modern SCADA systems. This archi-

tecture is applied to solve the RFID middleware requirements previously de-

scribed. In the system that we propose the remote equipment of systems SCADA

are replaced by the systems RFID antenna-readers who receive the auto identifi-

cation information. The communication network can be anyone of supported by

the hardware equipment that is commercialized now: communications via series,

Ethernet... And finally the central software system that in this case is the funda-

mental nucleus. The basic structure of the acquisition system that we propose is

organized in four great subsystems: Middleware Device Manager (MDM), Mid-

dleware Logic Manager (MLM), the graphical user viewer (GUV) and the subsys-

tems of exchange information (EPCIS: EPC Information Services).

Fig. 1. Functional architecture of DEPCAS.

The Middleware Device Manager (MDM) main functions are three. The main

purpose is to establish the communication management of one or several devices

hiding their particularities. Another function is to solve the communication proto-

col with the readers and the event processing implementation. The last MDM

main function is to support the topological acquisition network configurations

formed by the antennas and the reading equipment.

The Middleware Logic Manager (MLM) objective is to implement the logical

processes for the auto identification in different scenarios. The “scenario” concept

is the key idea in DEPCAS objective. In the same way that analog and status

processing are the basic process in SCADA systems, one particular scenario in

DEPCAS is associated to an specific purpose and abstract scenario, The logical

processing to solve will depend on each particular scenario. This process will

generate the permanent and non permanent information that results in each situa-

tion. The basic scenarios on which we are working are: operations of tracking,

aggregation of items information to generate new information, operations of items

classification, conversion of information formats and execution of states ma-

chines. Each one of these scenarios generates a set of processed information that

could be used by other systems though the EPCSIS systems or exploited with the

user interface of DEPCAS.

171

The Graphical User Viewer (GUV) will allow having a graphical interface to

the configuration components of DEPCAS, for example, the management of de-

vices, the scenarios configuration, etc. Also it will include the possibility to access

to the information that has being processed in some scenarios or the information

already consolidated. Also it must present/display the corresponding result of

alarms and events that middleware generates.

Finally, services EPCIS will solve the bridge of information between the data

consolidated by the MDM and the MLMs, and the external applications of busi-

ness to DEPCAS. These services will allow to receive as to send information

from system DEPCAS to other systems.

The scenario concept is equivalent to the logical process that with general ap-

plication it is possible to be used in a set of situations where the information takes

advantage of auto identification. In each scenario there are information that is

received, processed, summarized and accumulated, according to their own logic.

4 EPCIS DEPCAS Implementation

The main functionalities of EPCIS in DEPCAS are: to solve publish/subscription

manager, to manage permanent historical data information, to transfer in/out data

between DEPCAS and business applications, to establish a security distribution of

DEPCAS information, a XML data mapping, and to define specific application con-

nector with DEPCAS.

This general functions are implemented using a four subsystem development (fig. 4):

the publish and subscription manager, the data converter manager or metadata man-

ager, the EPCIS feeder and the EPCIS server.

Fig. 2. EPCIS DEPCAS subsystems.

The Publish/Subscription Manager supports two kinds of relationships: relation-

ships that are simple data representations of some actual relationship that exists be-

tween business atomic data and DEPCAS data, and relationships between tables that

have their own properties. Data representations of relationships can contain a Web

172

service reference to access the relationship Web service. The EPCIS implementation

defines interfaces to query a manageable resource about the relationships it partici-

pates in directly, such as a containment relationship. The Publish/Subscription man-

ager also defines an interface for a service that offers relationship information for

many manageable resources enabling a relationship registry. Manageable resources

do not have to be aware that they are participating in relationships.

The metadata or converter manager implements a global repository that captures

the relationships between the RFID product-process data, that we call scenario in

DEPCAS terminology, and existing business data. The converter manager layer offers

the possibility to control the level of aggregation by customized combination of sev-

eral built-in filters as well as those developed by specific environments. Hence a wide

range of variation is at hand. Attaching meta-data from backend-systems to DEPCAS

scenarios is requires connecting specific existing external data to DEPCAS scenarios

tables.

Feeder EPCIS interface works using a JMS structure to exchange data from

DEPCAS real time processing scenarios to EPCIS process. This capturing interface

distribute the information to the consolidate database and to synchronous ECPIS

connectors. The message structure is defined using an XML schema. This schema

structures the general data field of any message according to specific scenario. For

example, the JMSType for a tracking scenario includes: general position, specific

place, building, area, reader used, department, auto id read.

The Query EPCIS server supports the DEPCAS servers/clients connections. It

solves the different data interchange (HTTP, web services or XML ) between

DEPCAS and external business applications. In the same way, EPCIS server is de-

signed as a platform with a uniform query and update interface to applications, while

the actual implementation solves the details and data binding to existing databases

and information systems. EPCIS server supports simultaneous binding to multiple

databases and information systems from multiple vendors, as well as EPCIS as a

managed application service. In order to accommodate various types of data relation-

ships such as routes, predictions, reader points, associations with particular transac-

tions, EPCIS server is being is implemented as a modular framework, with a very

lightweight core functionality, which merely described which ‘profiles’ or relation-

ship types are implemented on any particular instantiation providing an EPCIS inter-

face.

5 Conclusions

The RFID middleware research is oriented to find new alternatives to solve the better

way to include auto identification in productive processes. The new topological read-

ers network and the heterogeneous business application must be connected though

RFID middleware solving all the established requirements.

This paper shows how EPCIS is included in DEPCAS architecture and the main im-

plemented possibilities. The prototype system of the introduced middleware software

suite is ready to be applied to the field test in order to apply to many business do-

mains.

173

The existing DEPCAS implementation represents a prototype limited by the read-

er protocols, the scenarios solved, and the EPCIS functions. Future versions of EPCIS

DEPCAS will include specific connector to external applications and EPCIS exten-

sions to connect with thin clients and wireless external demands.

Acknowledgements

This research has been carried out under contract with the Spanish CICYT through

the DPI2005-03769 and DPI2007-61287 projects.

References

1. Frontline-Sep, 2004, RFID benefits will come in phases. Frontline Solutions 5, 9, Septem-

ber.

2. Prabhu, B.S., Su, X., Ramamurthy, H., Chu, G., Gadh, R..: WinRFID: A midddleware for

the enablement of Radio Frequency Identification (RFID) based Applications. (2005).

3. Russell, R.: Manufacturing Execution Systems: Moving to the Next Level, Pharmaceutical

Technology, January 2004, pp 38-5.

4. Ramamurthy, H., Lal, D., Prabhu, B.S., Gadh, R.: ReWINS: A Distributed Multi-RF Sen-

sor Control Network for Industrial Automation, IEEE Wireless Telecommunications Sym-

posium (WTS 2005), pp 24-33, April 28-30, 2005, Pomona, California.

5. Brewer, A., Sloan, N., Landers T.L.: Intelligent Tracking in Manufacturing, Journal of

Intelligent Manufacturing, Vol. 10, 1999, pp245-250.

6. EPCGlobal Inc., http://www.epcglobal.com/

7. EPCglobal, EPC Information Service (EPCIS) Version 1.0 Specification, Mar. 2006.

8. Harrison, M.: EPC Information Service – Data Model and Queries. WhitePaper. Auto-ID

MIT. October 2003.

9. EPCglobal, PML Core Specification 1.0, September 2003.

10. EPCglobal, EPC Information Service (EPCIS) Version 1.0.1 Specification, Sept. 2007.

11. “Sun RFID and Sensor Community”, http://sun.java.net/rfid-sensors/

12. “Web Sphere RFID Premises Server”, http://www-306.ibm.com/software/integration

/ws_rfid_premises_server/

13. Floerkemeier, C., Lampe, M.: RFID middleware design – addressing application require-

ments and RFID constraints. In Proceedings of SOC’2005 (Smart Objects Conference),

pages 219–224, Grenoble, France, October 2005.

174