BIODEVICES BASED ON SHAPE-MEMORY POLYMERS

Current Capabilities and Challenges

Andrés Díaz Lantada, Pilar Lafont Morgado, Héctor Lorenzo-Yustos, Vicente Lorenzo Esteban

Julio Muñoz-García, José Luis Muñoz Sanz, Javier Echavarri Otero and Juan Manuel Munoz-Guijosa

Grupo de Investigación en Ingeniería de Máquinas – E.T.S.I. Industriales – Universidad Politécnica de Madrid

Grupo POLímeros, Caracterización y Aplicaciones (POLCA) – Universidad Politécnica de Madrid

C/ José Gutiérrez Abascal, nº 2. 28006 – Madrid, Spain

Keywords: Shape-memory polymers (SMPs), Biodevices, Synthesis, Characterization, Processing, Complete

development.

Abstract: Shape-memory polymers are active materials with thermomechanical coupling and a high capability to

recover from high levels of deformation, which, combined with their low cost and density has favoured the

appearance of numerous applications, particularly those linked to the Medical Industry. In many cases, these

materials are of medical standard, which increases the chances of obtaining biocompatible devices.

In the last decade enormous progress has been made on many areas, regarding these materials, such as

synthesis, characterization, activation and others, aimed at improving their applicability. However, various

spheres of action still remain that require more in depth research to promote the production start-up of

various shape-memory polymer-based devices that have had laboratory validation.

This work sets out the potential these materials provide for developing biodevices and the main advances

achieved. Also shown are various medical devices just being developed, as well current study needs and

trends.

1 INTRODUCTION TO

SHAPE-MEMORY POLYMERS

(SMPS)

Shape-memory polymers (SMPs) are materials that

show a mechanical response to external stimuli,

usually to changes of temperature. When these

materials are heated above their “activation”

temperature, there is a radical change from rigid

polymer to an elastic state that will allow

deformations of up to 400%. If the material is cooled

down after manipulation it retains the shape

imposed; the said structure is “frozen” and returns to

a rigid but “non-equilibrium” state. If the material is

again heated above its vitreous transition

temperature or “activation temperature” it recovers

its initial non-deformed state. The cycle can be

repeated numerous times without degrading the

polymer and most suppliers can formulate different

materials with activation temperatures ranging from

–30 ºC to 260 ºC, depending on the application

required. Of

They are therefore active materials that present

thermomechanical coupling and a high capability for

recovery from deformation, (much greater than that

shown by shape-memory metal alloys), which

combined with their lower density and cost has

favoured the appearance of numerous applications.

Their properties permit applications for

manufacturing sensing devices or actuators,

especially for the aeronautics, automobile and

medical industry.

2 POTENTIAL FOR BIODEVICES

2.1 Some Advantages

As polymers, SMPs can be easily conformed into

different complex shapes and their properties

designed or adapted to specific applications and can

also be integrated with other microelectromechanical

sensors (MEMS) to produce “intelligent”

bioactuators and biodevices.

137

Díaz Lantada A., Lafont Morgado P., Lorenzo-Yustos H., Lorenzo Esteban V., Muñoz-García J., Luis Muñoz Sanz J., Echavarri Otero J. and

Munoz-Guijosa J. (2009).

BIODEVICES BASED ON SHAPE-MEMORY POLYMERS - Current Capabilities and Challenges.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 137-144

DOI: 10.5220/0001123901370144

Copyright

c

SciTePress

Compared to other shape-memory alloys used in

numerous medical devices, SMPs show a far greater

capability for changing their geometry during

activation.

They are also much cheaper to synthesise and

their large scale mass production costs are reduced

by using technologies such as injection moulding.

All this makes them very versatile active

materials with a high potential for industry, provided

they overcome some of the limitations set out in the

following sections.

2.2 Proposed Devices

Bellow are explained some specific proposals for

developing medical devices based on the use of

shape-memory polymers, most of which have

undergone in vitro laboratory testing. After

undergoing in vitro testing and meeting the

requirements for official approval, in some cases

their commercialisation is subject to their attaining

the goals described at the end of this paper.

Self-expanding Stents. Like the stent designed by

Boston Scientific Corporation using the polymer

from CRG Industries known as “Veriflex” under its

trade-name, to treat the problems arising when the

arteries become narrow or obstructed and also for

removing obstructions from other “tube-shaped”

body parts, like the uretheres and the bronchial

tubes. The stent is inserted in its temporary form

(reduced) and the body’s own heat causes it to dilate

and become attached to the artery.

They may be used to replace stents based on

shape-memory alloys such as Nitinol, once the

appropriate biocompatibility studies have been

carried out. Developments of self-expanding stents

have also been carried out by using injected

polyurethane (Wache, 2003).

Intelligent Sutures. Like those developed at the

Forschungszentrum in Karlsruhe by Lendlein’s team

and at the M.I.T. by Langer’s team, which have a

temporary linear shape and a permanent shape in the

form of a knot, with the change in geometry being

activated by the body’s own temperature. They have

numerous applications in minimally invasive surgery

and, as they are biodegradable, they have additional

advantages over the use of textile sutures and metal

clips (Lendlein, Kelch, Langer, 2002, 2005).

Thrombectomy Devices. With the recent discovery

that the thermal effect of shape-memory can be

activated by a laser, part of whose energy is

absorbed by the polymer, devices with special

geometries have been proposed for removing clots

(Wilson, 2006). The polymer is shaped in a spiral

mould and then heated and stretched to give it its

temporary shape. When the laser light passes

through the polymer, the shape-memory effect is

activated and the device recovers its spiral shape

trapping the clot which can then be removed.

Active Catheters. By using shape-memory

polymers for the distal point of catheters together

with a subsequent activation of the memory effect

by laser light or body heat, different drugs and

antitumoral agents can be released. The presence of

an active catheter point can also help reach zones

that are difficult to access in minimally invasive

surgery tasks (Yackaki, 2007).

Drug Release Devices. If biodegradable shape-

memory polymers are used for implantable medical

devices, drug supply reservoirs can be incorporated

into the device itself. After implant, the polymer

begins to be absorbed by the organism and the drug

is released. Patents have been taken out in this

respect for self-expanding coronary stents or intra-

urethral stents (Boston Scientific Co. and Surmodics

Inc.). The possibility of obtaining temporary

geometries with micro-reservoirs for drug storage

has also been studied. The drugs would then be

released on activation of the shape-memory effect by

body heat (Gall, 2004).

Active Annuloplasty Rings. Aimed at obtaining a

progressive postoperative treatment of mitral

insufficiency, they are based on the use of a

polymeric ring with heating resistances distributed

around the inside to activate the shape-memory

effect by Joule effect. This activation must allow the

cross section of the mitral ring to be gradually

reduced and, therefore, the mitral insufficiency

improved.

Figure 1 shows a schematic design of such a

device proposed by our group at Universidad

Politécnica de Madrid. Prototypes of these rings,

with different geometries and materials, have been

developed and tested “in vitro” in pig’s hearts (Díaz

Lantada, Lafont Morgado, 2008).

The different devices explained will provide

considerable therapeutic benefits compared to

conventional devices, due to their capability to act

inside the body thanks to the use of shape-memory

polymers.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

138

Figure 1: Active annuloplasty ring design. SMP with

internal heating resistances. Biodevices 2008.

3 CURRENT CAPABILITIES

Set out below are some of the main advances

achieved in the last decade concerning shape-

memory polymers and the technologies associated

with their use.

3.1 Synthesis

In recent years particular emphasis has been placed

on obtaining new formulations of polymers with

shape-memory properties, by changing the

proportions of monomers, including additives, and

inducing multiple crosslinkings and working on

previously known formulations whose shape-

memory properties have been boosted. (Lendlein,

2002, Liu, 2007).

Different prestigious laboratories have conducted

exhaustive work on synthesis and subsequent

classification in accordance with the molecular

structure of the polymers.

The recent synthesis of polymers capable of

remembering two pre-set shapes using two

programming stages (triple shape effect) has brought

new possibilities for future medical devices, due to

the fact that two postoperative changes can be made

to the geometry (Bellin, 2006).

In spite of the numerous formulations for the

shape-memory polymers that have been synthesised

recently, the main problems for obtaining

commercial biodevices based on these materials are:

the small number of commercial formulations, the

toxicity of many of them and problems regarding

thermomechanical properties, as will be explained in

the following sections.

3.2 Characterization

During the last decade most experiments linked to

characterizing different shape-memory polymer

properties have attempted to compare the

thermomechanical response of different

formulations.

At the Langley Research Centre the results of

tests using thermomechanical analysers (TMA) has

been compared with those obtained by using

differential scan calorimeters (DSC) to obtain

precisely the vitreous transition temperature in

shape-memory polymers (Volk, 2005). This research

also explains deformation recovery tests conduced

by heating under constant deformation and under

constant stress, for which MTS Alliance RT1

traction machines and a heating chamber are used.

Three-point bending tests have also been used in

heated chambers in order to evaluate the geometric

recovery capability of these materials subjected to

different levels of stress and deformation (Lendlein,

2002, Tobushi, 2008).

Dynamic mechanical analyses (DMTA) have

been used basically to evaluate the elastic modulus

of these materials according to temperature. They

also enable the vitreous transition temperatures of

the materials to be found (Mather, 2002, Liu, 2003,

2006, Huang, 2006, Yakacki, 2007). This is a

supplementary technique to DSC tests (which are

usually used for the study of vitreous transitions,

polymorphisms, crystallisations and aging).

All these experiments and many others have

helped to provide basic knowledge concerning the

thermomechanical behaviour of these materials,

which is decisive for future developments.

3.3 Processing Technologies

3.3.1 CAD-CAE-CAM Tools

Computer-aided design, calculation and

manufacturing technologies (CAD-CAE-CAM),

have become essential tools for product

development. They let 3D geometries and alternative

designs be obtained rapidly. Calculations on stress,

deformations, ergonomics, dynamic response and

other aspects including material comparison and

design can also be performed for design

optimization.

The numerous benefits of these technologies for

developing conventional products can also be

applied to the development of shape-memory

polymer-based medical devices.

The recent use of programs such as MIMICS for

processing medical image technique files (TAC,

RMN and others) enables biodevices to be made-to-

measure (Harrysson, 2007). With these programs

three-dimensional geometries of parts of the human

body can be obtained and exported to other CAD-

BIODEVICES BASED ON SHAPE-MEMORY POLYMERS - Current Capabilities and Challenges

139

CAE-CAM programs to perform the customised

designs and obtain prototypes by using techniques

that we will now explain. They also contribute new

possibilities to the design of customised implants

that benefit from the use of SMPs.

3.3.2 Rapid Prototyping Technologies

These new technologies mean that physical parts can

be obtained in a short time (days) directly from the

computer-aided designs. They are of great help in

optimising design iterations, improving end quality

and speeding up production.

Rapid prototyping systems first appeared in 1987

with the American company, 3D Systems’

stereolithography, currently the most widespread

technology. It is based on being able to activate a

polymerisation reaction in a liquid state epoxy resin

by means of laser beam projection with a power and

frequency suited to the type of resin, which “draws”

the required geometry layer by layer. By using this

technology, epoxy resin prototypes with shape-

memory properties can be obtained directly.

Several results of our investigations at Product

Development Laboratory – Universidad Politécnica

de Madrid related with the application of these

technologies to the development of SMP-based

devices are shown below.

Figure 2 shows how a pincer-shaped end for an

active catheter can be obtained from its 3D geometry

in a CAD file. An SLA-3500 machine was used to

polymerise a 3D Systems epoxy resin sold under the

trade name of Accura 60.

The pincer can be made to open by hot

deformation during the shape-memory “training”

process. By then heating it, the pincer closes, as

Figure 3 shows.

This ability can be used in similar devices, with

different geometries and materials, to extract foreign

bodies and in minimally invasive surgery.

Using silicone mould vacuum casting,

polyurethane prototypes with shape-memory can be

obtained. Figure 4 shows a ring device obtained with

this technology using a type of polyurethane sold

under the trade name of MCP 3115, whose

capability for recovering shape through heating is

also shown. Similar devices can be used to change

soft tissue geometry (annuloplasty, sutures,

cerclages and others).

The main benefits of these technologies are:

designs and functionalities can be efficiently

compared and the associated products more rapidly

developed. Being able to apply these technologies to

SMP-based devices is of great importance to their

becoming widespread in industry.

Figure 2: Active pincer design and prototypes.

Figure 3: Geometric activation in an epoxy resin pincer.

Figure 4: PU geometric cerclage activation.

3.3.3 Microfabrication

Being able to use microfabrication technologies with

SMPs provides a new line of use for these materials

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

140

inside the medical device industry, particularly in

lab-on-a-chip and controlled drug delivery systems.

Typical devices for these applications require

surface channels and microtextures with micrometric

geometries that can be obtained in polymeric

materials by using technologies such as “hot-

embossing”, “micro injection moulding” or “LIGA”.

To be precise, by applying hot-embossing to

SMPs, surface microtextures and microreservoirs

with temporary geometry can be achieved (Gall,

2004).

The possible use of physical or chemical vapour

deposition technologies, combined with the ability to

produce protective masks by applying UV

photolithography, enables surface embossing to be

performed on very different materials (metals, alloys

and ceramics) using shape-memory polymers as

substrate (Paumier, 2008).

Thus, by making connection microtracks, these

can be used to send an order to certain parts of a

device to activate a geometric change by heating an

adjacent resistance. In some cases, the connection

track itself can be used as a heating element if its

cross section is sufficiently small and its electrical

resistance, therefore, high enough.

This ability to manufacture by layers and

combine different materials enormously strengthens

the capability to integrate certain SMP-based active

parts into complex systems (such as implantable

medical devices).

3.4 Shape-memory Effect Training

The shape-memory effect training process is usually

conducted through heat deformation of the device

manufactured in SMP and subsequent cooling to

maintain the deformation, thereby obtaining the

temporary shape.

To increase the length of the temporary shape

devices traction machines with heated chambers are

used. To produce temporary surface marking hot

compression moulding presses are used.

Recently, the use of cone-shaped countershapes

has been proposed to obtain ring devices with a

temporarily enlarged diameter (Díaz Lantada, Lafont

Morgado, 2008).

3.5 Activation

Another aspect where most progress has been made

is the activation of the memory effect by various

methods, especially:

Joule Effect Activation. Based on distributing

heating resistances at the core of the polymer where

the passing of an electric current generates the

necessary heat.

Light or Laser Activation. Based on projecting a

laser through a shape-memory material with a

similar absorption frequency to that of the laser

used, which produces heating (Lendlein, 2005,

Wilson, 2006).

Magnetic Activation. Based on heating by

induction of magnetic or metallic microparticles,

distributed at the core of the polymer while it is

being conformed to its shape (Buckley, 2006).

However, the biocompatibility of the associated

devices needs to be further optimised.

Support Technologies. Progress in the field of

wireless communications means that devices can

now be remotely activated, which is promoting the

appearance of new active implantable biodevices.

3.6 Commercial Formulations

The promising applications of these materials,

particularly in the field of medicine, together with a

growing industrial demand, has led to departments

dedicated to the synthesis of shape-memory

polymers being set up in large companies and the

appearance of some spin-off. The major ones are:

• Mitsubishi Heavy Industries Ltd.

• DIAPLEX.

• mNemoscience GmbH.

• CRG Industries LLC.

Most of these recently set up companies and

departments offer “a la carte” design work and

prototyping applications using SMP. They also

commercialise their developments, both synthesised

materials and products based on those materials.

4 CHALLENGES

This section deals with the main fields where more

in-depth study is particularly important, in order to

facilitate the industrial expansion of shape-memory

polymers as an integral part of active implantable

medical devices.

BIODEVICES BASED ON SHAPE-MEMORY POLYMERS - Current Capabilities and Challenges

141

4.1 Thermomechanical Response

Unfortunately, the shape-memory polymer materials

developed up to now only let forces of

approximately 3 MPa be withstood during

activation, which is insufficient for certain medical

applications intended for use as actuators, specially

when wishing to change the geometries of biological

tissues.

Enhancing the activation forces requires greater

understanding of the basic physical-chemical

principles of these phenomena. To this end,

computational models can be used that help apply a

combined knowledge of materials science,

thermodynamics, mechanics and heat transmission

(Conti, 2007).

4.2 Modelling and Simulation

Using the data obtained from the characterization

tests, (of materials and specific applications),

behaviour models can be obtained that facilitate the

development of new applications with the same

material or similar applications with other polymers.

The possibility of combining models that are

developed ad hoc and the multivariable simulations

that allow finite element calculation programs will

help simplify the design of training systems and the

heat activation of SMP-based devices.

4.3 Stability of Properties

In general, the variation in the properties of

polymeric materials through aging has major

economic implications as it affects in-service

performance. Particularly in the case of shape-

memory implants, any change in the vitreous

transition temperature (or activation temperature)

can cause problems when activating the necessary

geometric changes.

It is also necessary to study the changes to the

mechanical properties of these polymers (elasticity

modulus, hardness, and resilience), due to their

being implanted in the human body. Figure 5 shows

an example of an study (carried out by our group at

Universidad Politécnica de Madrid) on how the

hardness of an aging shape-memory polyurethane

evolves at 40ºC for 80 days. A Vickers

microhardness tester was used with a 0.98 N load

and a 15 s contact time.

114

116

118

120

122

124

126

128

130

132

-1 -0,5 0 0,5 1 1,5 2

log (time)

Vickers Microhardness MPa

Figure 5: Evolution of hardness in a shape-memory

polyurethane.

Changes in the mechanical properties like that

shown can considerably affect the applicability of

devices based on these materials. The use of

additives and the synthesis of new formulations that

help minimise the changes to properties with the

passage of time will be highly useful for optimising

devices that can be commercialised.

However, the effects of moisture on changes in

the properties of SMPs may be determining factors

for making an application invalid. This effect has

been studied on shape-memory polyurethanes by

conducting DMTA and DSC tests with samples

submerged in water for different lengths of time to

age them (Yang, 2004).

4.4 Activation Temperature

Only on rare occasions, in the polymeric products

industry, have materials with vitreous transitions of

between 0 ºC and 50 ºC been used, as in-service

changes to properties are not usually desirable. For

this reason, it is difficult to find commercial

formulations for polymers with Tg in the 25 to 45 ºC

range.

However, for the development of shape-memory

polymer-based active implantable medical devices,

it is precisely temperatures near to the 37 ºC of body

heat that are sought. SMPs with a Tg of around 30

ºC may give rise to devices that change their

geometry on contact with the patient’s body. SMPs

with a Tg of around 45 ºC can be used to develop

implants intended for postoperative activation

through heating to induce geometric changes.

Some laboratories and companies achieve

noticeable changes in the Tg of dual component

SMPs by modifying the proportion of monomers and

additives for cross-linking that are used to synthesise

them. Most formulations still have activation

temperatures that are too high to be used in

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

142

implantable devices without causing damage to

surrounding tissues.

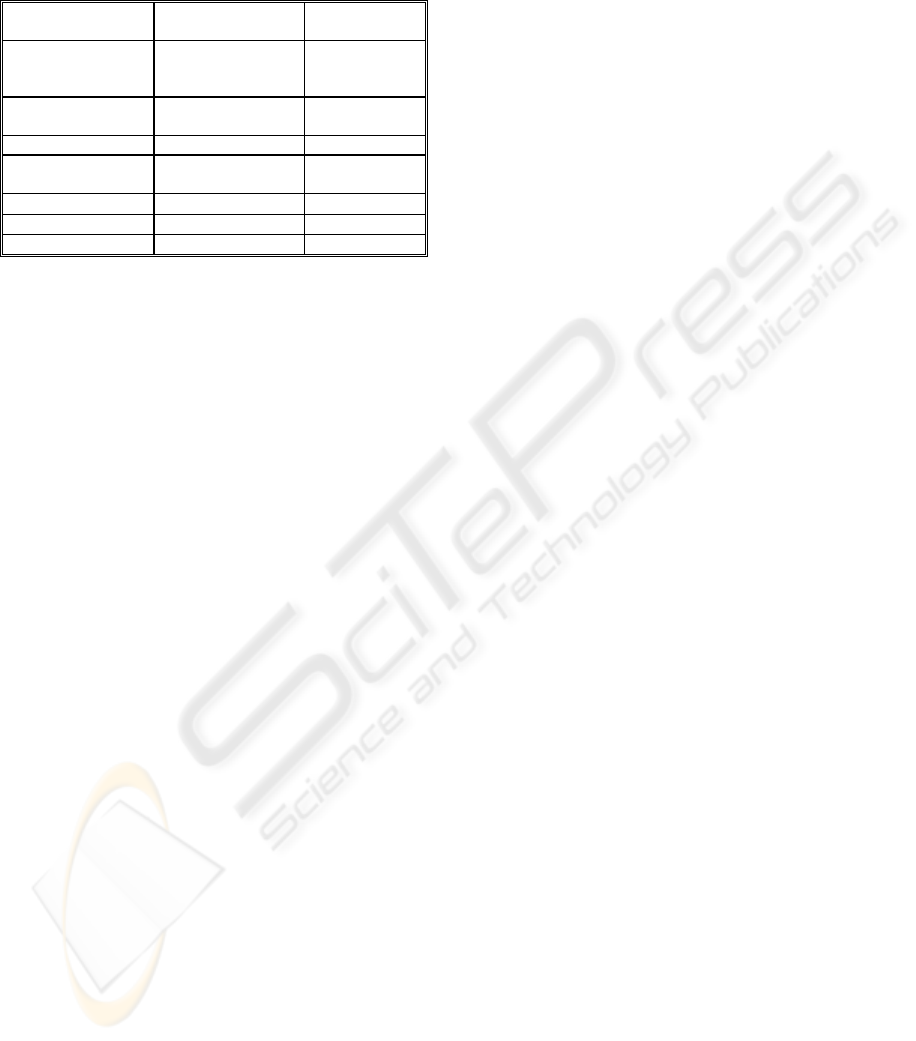

Table 1: Materials and acceptable Tg for biodevices.

Material

Vitreous transition

temperature

Reference

tBA-co-PEGDMA

40 - 52 ºC

(according to % of

cross-linking)

(Yakacki, 2008)

Polynorbornene

(Norsorex

®

)

Around 40 ºC

(Liu, Mather,

2003, 2007)

Polyurethane Room Temp. ±50 ºC (Tobushi, 2008)

Polyurethane Diaplex

MM5520

55 ºC

DIAPLEX Ltd.

(Small, 2005)

Poly(ε-caprolactone)

40 – 59 ºC (Lendlein, 2002)

Epoxy-based 35 – 105 ºC CRG Industries

Styrene-based 45 – 95 ºC CRG Industries

Fortunately, in the last 5 years new SMPs with a

Tg closer to body temperature have been synthesised

and could be used in conjunction with appropriate

protective coatings to develop percutaneous

implants. Table 1 shows some prime examples.

In addition, some considerations, which are set out

below, must be taken into account concerning the

feasibility of using these materials.

4.5 Security Issues

4.5.1 Biocompatibility Improvements

Starting up production of shape-memory-based

polymers is closer than ever as more emphasis is

being placed on improving the biocompatibility of

these devices.

Many SMP formulations are toxic; however,

some of them have been shown to be compatible

with human tissues (Cabanlit, 2007, Sokolowsky,

2007), which is hopeful for future developments. In

whatever case, the use of protecting coatings (using

PVD or CVD) may be of considerable help in

improving this aspect.

4.5.2 Sterilization

Before in vivo implantation the devices need to be

sterilised using some of the methods that are usually

applied to polymers (steam, ethylene oxide, gamma

radiation, low temperature plasma “LTP” or the

Noxilizer process).

In spite of the numerous methods that can be

used, it is preferable to choose low temperature

sterilisation (LTP, ethylene oxide or the Noxilizer

method) to avoid activating the memory effect

before implanting the devices.

The influence of these methods on toxicity and

thermomechanical response of these materials has

recently begun to be studied with promising results

(Yakacki, 2008).

4.5.3 Regulations

In order to optimise the safety of devices based on

these materials they must be in compliance with the

guidelines of the “European Directive on Medical

Devices – 93/42/EEC” and the “European Directive

on Active Implantable Medical Devices –

90/385/EEC”. It is also advisable to follow the

recommendations of Standard ISO 13485 on quality

in medical devices as well as specific legislation

concerning materials characterization tests (ISO and

ASTM Standards especially).

4.6 Structured Development Process

If the development of commercial medical

applications based on these devices is to be

promoted, it is important to increase the connection

between all the actors taking part in the different

development stages.

In this way, they could collaborate to establish a

structured design process to combine the tasks of:

synthesis, materials characterization and processing,

mechanical design, prototype manufacture, “in

vitro” and “in vivo” trials, official approval and

subsequent production start-up.

Similar proposals are being successfully applied

to promote developments based on other active

materials, such as electroactive polymers (EAPs),

(Bar-Cohen, 2002, 2006).

5 IMPROVING RESULTS AND

CONCLUSIONS

Shape-memory polymers have emerged with

enormous potential allowing the development of

medical devices with special features and

capabilities for activation hitherto unachievable.

The development of bioactuators based on these

materials at present requires progress in various

scientific-technological aspects to optimise their

possibilities. It will then be possible to obtain

commercialisable medical devices (diagnostic and

therapeutic) that fulfil all the mechanical,

therapeutic, stability and safety requirements.

Recent advances in issues of international co-

operation concerning active materials with the

setting up of specific forums like Scientific.net,

Biomat.net and others, are helping to disseminate

results and exchange opinions. However, it would be

BIODEVICES BASED ON SHAPE-MEMORY POLYMERS - Current Capabilities and Challenges

143

of great interest to create a specific forum on shape-

memory polymers and their applications, where

researchers, universities and enterprises could make

contact in order to fit technological supply with

market requirements, which is of particular

importance for the Medical Industry.

While the new capabilities brought by these

materials give rise to expectations that many medical

devices will become more effective, considerably

more effort still needs to be put into research and

development, so as to obtain robust and effective

actuators based on these materials.

REFERENCES

Lendlein, A., Kelch, S., 2002. Shape-Memory Polymers.

Angewandte Chemie International.

Lendlein, A., Kelch, S., 2005. Shape-Memory Polymers.

Encyclopedia of Materials: Science and Technology.

Liu, C., Mather, P., 2007. Review of progress in Shape-

Memory Polymers. Journal of Materials Chemistry.

Wache, H., 2003. Development of a polymer stent with

shape-memory effect as a drug delivery system.

Journal of Materials Science – Materials in Medicine.

Lendlein, A., Kelch, S., 2005. Shape-Memory Polymers as

Stimuli-sensitive Implant Materials. Clinical

Hemorheology and Microcirculation.

Lendlein, A., Langer, R., 2002. Biodegradable, Elastic

Shape-Memory Polymers for Potential Biomedical

Applications. Science.

Wilson,T., et al., 2006. Shape-memory Polymer

Therapeutic Devices for Stroke. Lawrence Livermore

National Laboratory.

Small, W., et al., 2005. Laser-activated Shape-Memory

Polymer Intravascular Thrombectomy Device. Optics

Express.

Yakacki, C.M. et al., 2007. Unconstrained Recovery of

Shape-Memory Polymers Networks for

Cardiovascular Applications. Biomaterials.

Yakacki, C.M. et al., 2008. Deformation Limits in Shape-

Memory Polymers. Advance Engineering Materials.

Gall, K.; Kreiner, P. et al., 2004. Shape-memory Polymers

for MEMS Systems. Journal of

Microelechtromechanical Systems.

Díaz Lantada, A., Lafont, P. et al., 2008. Treatment of

Mitral Valve Insufficiency by Shape-Memory Polymer

Based Active Annuloplasty. Biodevices 2008 –

International Conference onBiomedical Electronics

and Devices. INSTICC Press.

Lafont, P., Díaz Lantada et al., 2006. Patent Document

P200603149: Sistema activo de anuloplastia para

tratamiento de la insuficiencia mitral y otras patologías

cardiovasculares. Oficina Española de Patentes y

Marcas.

Bellin, I., et al., 2006. Polymeric Triple-Shape Materials.

Proceedings of the National Academy of Sciences.

Volk, B. et al., 2005. Characterization of Shape-memory

Polymers. NASA Langley Research Centre. Texas

A&M University.

Tobushi, H. et al., 2008. Shape Recovery and

Irrecoverable Strain Control in Polyurethane Shape-

Memory Polymer. Science and Technology of

Advanced Materials.

Liu, C. and Mather, P., 2002. Thermomechanical

Characterization of a Tailored Series of Shape-

memory Polymers. Journal of Applied Medical

Polymers.

Liu, Y. et al., 2003. Thermomechanical Recovery

Couplings of Shape-memory Polymers in Flexure.

Smart Materials and Structures.

Huang, W. and Lee, C., 2006. Thermomechanical

Behaviour of a Polyurethane Shape-memory Polymer

Foam. Journal of Intelligent Material Systems and

Structures.

Liu, Y. et al., 2006. Thermomechanics of shape-memory

polymers: Uniaxial experiments and constitutive

modelling. Int. Journal of Plasticity.

Yakacki, C.M. et al., 2007. Unconstrained recovery of

shape-memory polymer networks for cardiovascular

applications. Biomaterials.

Harrysson, O., et al., 2007, Custom-designed orthopaedic

implants evaluated using FEM analysis of patient

computed tomography data. BMC Musculoskeletal

Disorders.

Paumier, G., et al., 2008. Thermoresponsive Polymer-

Based Microdevice for Nano-Liquid Chromatography.

Biodevices 2008 – Int. Conference on Biomedical

Electronics and Devices. INSTICC Press.

Lendlein, A., et al., 2005. Light-induced shape-memory

polymers. Nature.

Buckley, P., et al., 2006. Inductively Heated Shape-

memory Polymer for the Magnetic Actuation of

Medical Devices. IEEE Transactions on Biomedical

Engineering.

Conti, S., et al., 2007. Modelling and Simulation of

Magnetic Shape-Memory Polymer Composites.

Journal of Mechanics and Physics of Solids.

Yang, B., et al., 2004. On the effects of moisture in a

polyurethane shape-memory polymer. Smart Materials

and Structures.

Yakacki, C.M. et al., 2008. Cytoxicity and

Thermomechanical Behaviour of Biomedical Shape-

Memory Polymer Networks Post-sterilization.

Biomedical Materials.

Cabanlit, M., et al., 2007, Polyurethane Shape-Memory

Polymers Demonstrate Functional Biocompatibility In

Vitro. Macromolecular Bioscience.

Sokolowsky, W., et al., 2007, Medical Applications of

Shape-memory Polymers. Biomedical Materials.

Bar-Cohen, Y., 2006. Artificial Muscles using

Electroactive Polymers (EAP): Capabilities,

Challenges and Potential. SPIE Press.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

144