SURFACE MODIFICATION OF DENTAL DEVICES

Surface Analysis of Plasma-based Fluorine and Silver Ion Implanted & Deposited

Acrylic Resin

Yukari Shinonaga, Kenji Arita and Milanita E. Lucas

Department of Pediatric Dentistry, Institute of Health Biosciences, The University of Tokushima Graduate School

Tokushima, Japan

Keywords: Surface modification, Dual ion implantation & deposition, Dental device, Fluorine, Silver, XPS, Contact

angle, Surface free energy, Abrasion.

Abstract: The aim of this study was to modify acrylic resin (PMMA) with fluorine (F) and silver (Ag) dual ions by a

hybrid process of plasma-based ion implantation & deposition (PBII-D), and to enable the surface of the

devices inhibition of bacterial adhesion. The surface characteristics, hydrophobic property and brushing

abrasion resistance were evaluated by XPS analysis, contact angle measurement and brushing abrasion test.

F and Ag were implanted-deposited and have formed carbon-fluoride and Ag-deposited layer on the surface

of the PMMA plate. The contact angle of F+Ag implanted-deposited PMMA was increased compared with

non-treated control and F only deposited PMMA. After 60,000 brushing strokes, the contact angle of

modified PMMA remained to be higher than that of the control PMMA. This study indicated that F+Ag

implantation-deposition has improved the hydrophobic property of acrylic resin and was sustained even

after routine tooth brushing.

1 INTRODUCTION

Bacterial colonization and subsequent device

infection are common complications of medical and

dental devices (Gristina, 1987). Especially, acrylic

base plates for prosthodontics, orthodontics and

pedodontics are exposed to oral microbial flora to

include bacteria, viruses, and fungi, and are

susceptible to adhesion of bacterial plaque. Oral

bacteria can be released from denture plaque into

salivary secretions and then aspirated into the lower

respiratory tract causing pneumonia (Sumi, 2007).

Among patients, the most general method for the

removal of denture plaque is brushing. However,

effective plaque removal requires a degree of

manual dexterity that is often lacking especially

among elderly and individuals with disabilities.

Therefore, it is important to modify the acrylic resin

denture surface to enable inhibition of oral bacterial

adhesion.

Plasma-based ion implantation (PBII) is a

promising method for the surface modification of

three-dimensional materials (Conrad, 1987). In

particular, the ion deposition with simultaneous ion

implantation (plasma-based ion implantation and

deposition: PBII-D) is desirable for efficient

processing and has an advantage over conventional

methods (Kuze, 2002).

Recently, several researchers have carried out the

surface modification using fluorine (F) ion and

found it to be a useful means of inhibiting bacterial

adhesion (Zhao, 2007 and Nurhaerani, 2007). In

addition, it is well known that silver (Ag) possesses

the antibacterial property without any toxic effects in

comparison to other heavy metal ions. We

developed the new technology to simultaneously

implant and deposit both F and Ag ions into dental

and medical devices using PBII-D. The aim of this

study was to examine the effectiveness of both F and

Ag ions implanted-deposited into acrylic resin by

evaluating the surface characteristics and brushing

abrasion resistance.

2 MATERIALS AND METHODS

2.1 Preparation of Specimens

Poly methyl methacrylate (PMMA) (Clarex 000,

Nitto Jushi Kogyo, Co., Ltd., Tokyo, Japan) plates

157

Shinonaga Y., Arita K. and E. Lucas M. (2009).

SURFACE MODIFICATION OF DENTAL DEVICES - Surface Analysis of Plasma-based Fluorine and Silver Ion Implanted & Deposited Acrylic Resin.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 157-160

DOI: 10.5220/0001424101570160

Copyright

c

SciTePress

with measurements of 10mm×10mm×1mm were

used. The PMMA plates were modified by plasma-

based ion implantation-deposition equipment at

Plasma Ion Assist Co., Ltd., Kyoto, Japan. Fluoride

gas used for F ion implantation-deposition was

perfluoropropane (C

3

F

8

). For Ag ion implantation-

deposition, a 99.8 % Ag mesh cover was set 10mm

above the plates and sputtered by C

3

F

8

gas. The

conditions of plasma-based F and Ag dual ion

implantation-deposition are shown in Table 1.

Table 1: The condition of fluorine and silver ion

implantation-deposition into PMMA plates.

Group Conditions

Implantation

process

Deposition

process

Control

Voltage (keV)

Time (min)

Ag mesh

0

0

unused

0

0

unused

F deposited

Voltage (keV)

Time (min)

Ag mesh

0

0

unused

-0.5

60

unused

F+Ag

implanted-

deposited

Voltage (keV)

Time (min)

Ag mesh

-5

30

used

-0.5

60

used

2.2 Surface Shemical Analysis by XPS

The surfaces of the control, F deposited and F+Ag

implanted-deposited PMMA were characterized by

X-ray photoelectron spectroscopy (XPS). XPS

spectra were obtained using an X-ray photoelectron

spectrometer (ESCA-850, Shimadzu Co., Kyoto,

Japan) with Al-Kα radiation operated at 30 mA

current and 7 kV accelerating voltage. Specifically,

depth profile analysis for the F+Ag implanted-

deposited PMMA was performed using Ar etching

under the pressure of 5×10

-4

Pa. The Ar etching rate

was approximately 6 nm/min on Ag.

2.3 Contact Angle Measurements

Specimens were ultrasonically cleaned in distilled

water for 10 minutes, and then dried at room

temperature before contact angle measurement.

Static contact angle measurements were conducted

by the sessile drop technique using a contact angle

meter (CA-DT, Kyowa Kaimenkagaku Co. Ltd.,

Saitama, Japan) with three test liquids: distilled

water, diiodomethane and ethylene glycol at room

temperature. One point per specimen was measured

(N=5/group, i.e. 5 points/group). The surface free

energies of specimens were calculated from the

contact angles with the three test liquids (Liu, 2005).

2.4 Brushing Abrasion Test

The brushing abrasion test machine (MANA-63S,

MASUDA Co., Osaka, Japan) was used. A

commercial toothbrush (Dr. Bee Young ⅡS, Bee

Brand Medico Dental Co., Ltd., Osaka, Japan) was

attached to the toothbrush holder in contact with the

F deposited and F+Ag implanted-deposited PMMA

set on the sample holder. Distilled water without

dentifrice was then poured into the vessel, and the

machine was run at 80 rpm with a 200 g load. The

water contact angle measurements of the F deposited

and F+Ag implanted-deposited PMMA were done

every 10,000 strokes up to 60,000 strokes. In the

control PMMA, the contact angle was measured

without brushing. Five points per specimen were

measured.

2.5 Statistical Analysis

The results of the contact angle measurements

before and after the brushing abrasion test were

expressed as the mean ± standard deviation. The

data were analyzed using one-way ANOVA and

Scheffe’s multiple comparison tests (α = 0.05).

3 RESULT

3.1 XPS Analysis

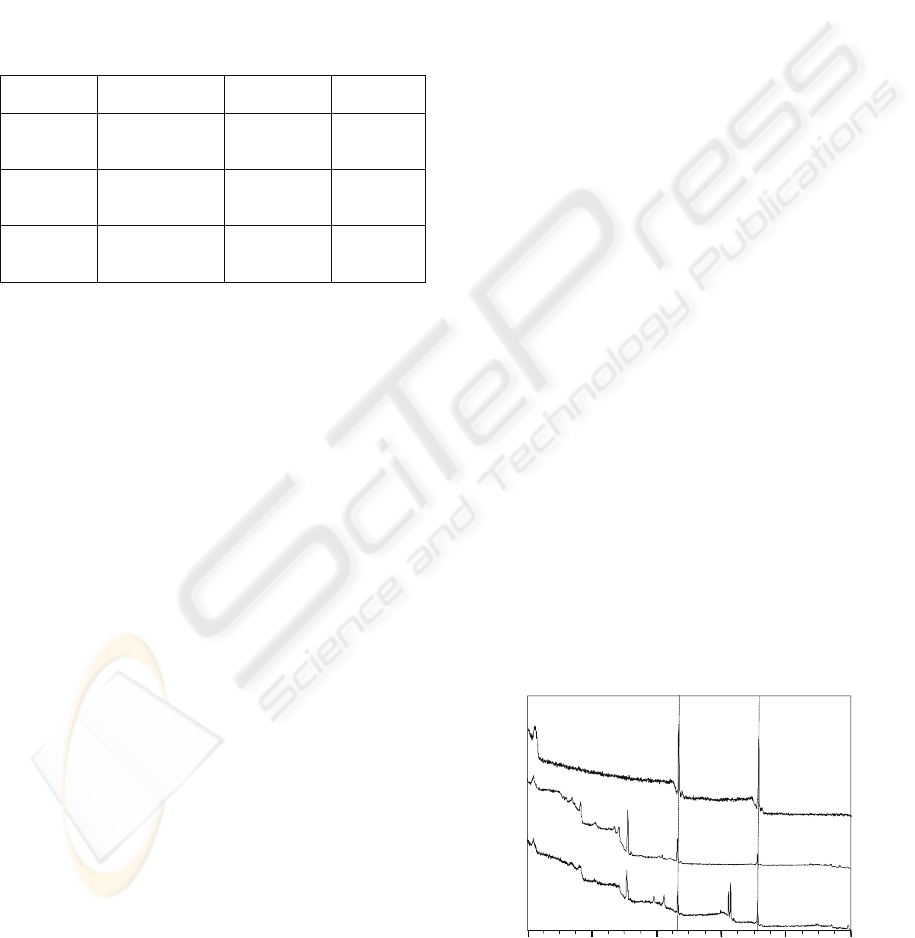

XPS wide-scan spectra of the control, F deposited

and F+Ag implanted-deposited PMMA are shown in

Figure 1. The peaks of C1s and O1s were detected in

the wide-scan spectrum of the control PMMA.

Moreover, F1s peak appeared on the F deposited

PMMA surface; and F1s, Ag3d and Ag3p peaks

appeared on the F+Ag implanted-deposited PMMA

surface. The F1s and Ag3d XPS depth profiles of the

800 600 400 200 0

Binding Energy (eV)

1000

F+Ag

Implanted/deposited

F dposited

Control

F1s

F1s

Ag3p

Ag3d

O1s

C1s

Count (arbitrary unit)

Figure 1: XPS wide-scan spectra of PMMA specimens.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

158

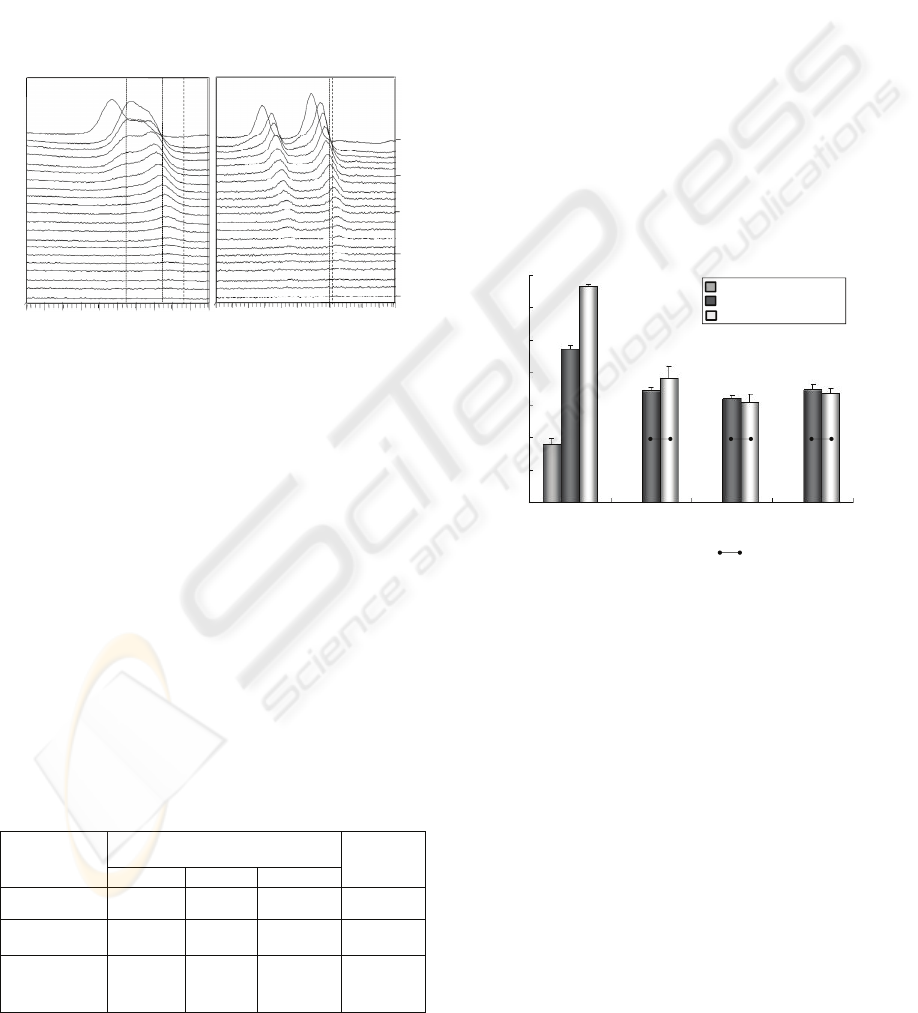

F+Ag implanted-deposited PMMA are shown in

Figure 2. The chemically shifted peaks of F1s from

surface to 7 minutes Ar etching depth are observed

in the higher binding energy region (689-690 eV).

The higher values was close to the reported binding

energy of p-(CF

2

=CF

2

) (689 eV) (Briggs and Seah,

1990).The F1s peak decreased as the Ar etching

increased and was not detected after 15 minutes of

Ar etching. Ag3d peak was also detected after Ar

etching for about 15 minutes in Ag3d depth profile.

In F1s and Ag 3d depth profiles, the peaks of AgF

were not detected.

700 696 692

688

684

680

Binding Energy (eV)

380

376

372

368

364

360

Ar etching time (min)

0

5

10

15

20

Binding Energy (eV)

(A) F1s

(B) Ag3d

p-(CF

2

=CF

2

)F

Ag

AgF

AgF

Count (arbitrary unit)

Figure 2: F1s (A) and Ag3d (B) XPS depth profiles of the

F+Ag implanted-deposited PMMA. Dashed lines show the

binding energy value of p-(CF

2

=CF

2

): 689.0 eV, F: 685

eV and AgF: 682.7 eV in the F1s depth profile (A), and

Ag: 368.2 eV and AgF: 367.7 eV in the Ag3d depth

profile (B). The values were based from Briggs and Seah,

(1990).

3.2 Surface Energy Analysis

The contact angles of three test liquids: distilled

water (W), diiodomethane (Di) and ethylene glycol

(EG) and the calculated surface free energy values

of control, F deposited and F+Ag implanted-

deposited PMMA are shown in Table 2. The contact

angles of all test liquids on the F deposited and

F+Ag implanted-deposited PMMA were

significantly higher than that of the control PMMA

Table 2: Contact angle and surface free energy of PMMA

specimens.

(p<0.01). Moreover, the contact angle of all test

liquids on the F+Ag implanted-deposited PMMA

was higher than that of the F deposited PMMA

(p<0.001). The surface free energy of the F+Ag

implanted-deposited PMMA was lower than that of

the control and F deposited PMMA.

3.3 Brushing Abrasion Test

In the F deposited and F+Ag deposited PMMA, the

contact angles after 10000, 30000 and 60000

brushing strokes were significantly lower than

before brushing (p<0.001). The contact angle of the

F+Ag implanted-deposited PMMA was not

significantly different compared with that of the F

deposited PMMA for the same number of brush

strokes. However, the contact angles of the F

deposited and F+Ag implanted-deposited PMMA

after the brushing abrasion test resulted in a

significantly higher contact angle compared to that

of the control PMMA (p<0.001).

0 10000 30000

60000

Number of brush strokes

50

60

70

80

90

100

110

Contact angle (degree)

120

Control

F deposited

F+Ag implanted/deposited

:not significant

ANOVA/Scheffe, α=0.05

Figure 3: Contact angles of distilled water on the F

deposited and F+Ag implanted-deposited PMMA

before/after the brushing abrasion test. Horizontal lines

indicate no significant differences (ANOVA/ Scheffe,

α=0.05).

4 DISCUSSIONS

In this study, we have attempted to modify the

surface of PMMA by the simultaneous F and Ag ion

implantation-deposition by PBII-D process.

The results have shown that F and Ag were

detected on the surface of the F+Ag implanted-

deposited PMMA by XPS analysis (Figure 1). The

existence of carbon-fluoride complexes, such as p-

(CF

2

=CF

2

), and Ag were also detected on the F+Ag

implanted-deposited PMMA surface. Moreover, F

and Ag were deposited on the surface and implanted

Group

Contact angle θ (degree)

Surface free

energy

(mJ/m

2

)

θ

W

θ

Di

θ

EG

Control 64.4° 36.3° 50.8° 44.05

F deposited 100.0° 52.2° 62.7° 33.77

F+Ag

implanted/

deposited

123.9° 82.3° 95.2° 20.65

SURFACE MODIFICATION OF DENTAL DEVICES - Surface Analysis of Plasma-based Fluorine and Silver Ion

Implanted & Deposited Acrylic Resin

159

to about 90 nm depth (Figure 2). All these suggested

that both F and Ag ion implantation-deposition

method by PBII-D was applicable to PMMA. In ion

implantation-deposition of insulating materials such

as PMMA, electric charge-up could be a serious

problem, which damages the specimens. In this

study, it was thought that Ag mesh was used not

only for providing Ag ions but also for decreasing

the electric charge-up on the specimens by providing

electrons.

It was reported that some properties are specific

to the inert surface, such as the surface free energy,

surface charge, hydrophobic property, surface

roughness and surface chemistry (Perini, 2006). One

approach in the attempt to reduce the bacterial

colonization is to modify the surface free energy and

chemistry. The contact angle is characteristic of the

surface energy of a solid surface, and has been used

for determining the wettability and hydrophobic

property of various solid materials. Bacterial

adhesion is energetically unfavourable, if the solid

surface free energy is less than 50 mJ/m

2

(Busscher,

1984). In this study, the surface free energy of the

F+Ag implanted-deposited PMMA was 20.65 mJ/m

2

(< 50mJ/m

2

), which may imply potential inhibition

of bacterial adhesion by hydrophobic mechanism. In

addition, the negative relationship between the

contact angle and the bacterial adhesion property

was reported (Zhao, 2007, and Nurhaerani, 2007). In

the present study, the contact angle of the F+Ag

implanted-deposited PMMA after 60,000 brushing

strokes was significantly higher than that of the

control PMMA. Kanter et al. (1982) estimated that

20,000 brushing strokes were the equivalent to

approximately 5 years of brushing. The present

study confirmed that the high contact angle of the

F+Ag implanted- deposited PMMA could remain

after the equivalent of 15 years of brushing with a

toothbrush. These results suggested that dual F and

Ag implantation-deposition could possibly inhibit

the bacterial adhesion to the PMMA devices by

increasing the contact angle and decreasing the

surface free energy.

These results suggested that both F and Ag ion

implantation-deposition by PBII-D process was the

superior surface modification method for acrylic

materials to inhibit bacterial adhesion.

5 CONCLUSIONS

In this study, PMMA plates were simultaneously

implanted-deposited with both F and Ag ions by a

hybrid process of PBII-D. The F+Ag implanted-

deposited PMMA surface has obtained low surface

free energy (20.65 mJ/m

2

) and the presence of

carbon-fluoride complexes and Ag on the surface

was indicated. Moreover, due to the presence of both

F and Ag ions, the hydrophobic properties remained

after brushing with a toothbrush. These results

suggested that both F and Ag ion implantation-

deposition by PBII-D has the potential to give the

medical and dental devices antibacterial qualities.

ACKNOWLEDGEMENTS

This study was supported by a Grant-in-Aid for

Scientific Research (C) (No. 20592300) from Japan

Society for the Promotion of Science (JSPS).

REFERENCES

Briggs, D., Seah, MP., 1990. Practical surface analysis 2

nd

edition., Volume 1 Auger and X-ray Photoelectron

spectroscopy, 595-634.

Busscher, HJ., Weerkamp, AH., Mei, HC., Pelt, AWJ.,

Jong, HP., 1984. Appl. Environ. Microbiol. 980-983.

Conrad, JR., Radtke, JL., Worzala, FJ., 1987. J. Appl.

Phys. 62, 4591-4596.

Grastina, A. G., 1987. Science.237, 1588-1595.

Kanter, J., Koski, RE., Martin, D., 1982. J. Prosthet. Dent.,

47, 505-513.

Kuze, E., Teramoto, T., Yukimura, K., Maruyama, T.,

2002. Surf. Coat. Technol, 577-581.

Liu, Y., Zhao, Q., 2005. Biophys. Chem. 39-45.

Nurhaerani., Arita, K., Shinonaga, Y., Nishino, M., 2007.

Dent.Mater. J, 684-692.

Perini, CI., Zhao, Q., Liu, Y., Abel, E., 2006. Colloids.

Surf. B: Biointerfaces., 143-147.

Sumi, Y., Miura, H., Michiwaki, Y., Nagaosa, S., Nagaya,

M., 2007.. Arch. Gerontol. Geriatr. 44, 119-124.

Zhao, Q., Liu, Y., Wang, C., Wang, S., Peng, N., Jeynes,

C., 2007. Appl. Surf. Sci, 8674-8681.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

160