HAND-HELD LUMINOMETER WITH ECL-BASED BIOSENSOR

FOR LACTATE DETERMINATION

A. Martinez-Olmos, A. J. Palma

Department of Electronics and Computer Technology, University of Granada, Granada 18071 Spain

J. Ballesta-Claver, M. C. Valencia-Miron and L. F. Capitan-Vallvey

Department of Analytical Chemistry, University of Granada, Granada 18071, Spain

Keywords: Electrochemiluminescence, Portable instrumentation, Potentiostat, Biosensor, Screen-printed device,

Lactate determination, Saliva.

Abstract: A new hand-held luminometer for electrochemiluminescence (ECL)-based one-shot biosensor for lactate is

described. The lactate recognition system is based on lactate oxidase and the transduction system consists of

luminol, all reagents immobilized in a Methocel membrane. The measurement of ECL from a screen-

printed electrode by a portable instrument designed and developed by the authors makes it possible to

determine lactate concentration. The compositions of the membrane and reaction conditions have been

optimized to obtain adequate sensitivity. The one-shot biosensor responds to lactate rapidly, with the typical

ECL acquisition time being 3 min, with a linearized dependence whose dynamic range was from 9·10

-6

to

2·10

-3

M, a detection limit of 2.4·10

-6

M and a sensor-to-sensor reproducibility (relative standard deviation

RSD) around 10 % at the medium level of the range. The performance of the ECL one-shot biosensor and

portable instrument was tested for the non invasive analysis of lactate in saliva, validating the results against

a reference procedure.

1 INTRODUCTION

L(+)-Lactate is produced in the anaerobic

metabolism of glucose and its determination is of

interest in clinical analysis, sports medicine and food

analysis. The measurement of lactate is routinely

performed with liquid chromatography (Ewaschuk,

2002), spectrophotometry (Benthin, 1991) and

amperometry, mainly with enzymatic electrodes

(Compagnone, 1998). Lactate analysis is needed in

different fields such as food, sports medicine and

health. In foodstuffs, lactate is produced by bacterial

fermentation and is an essential component related

to the manufacture of cheese, yoghurt, milk, etc.,

thus monitoring lactate being an important quality

control parameter.

Rapid evaluation of lactate levels can be

performed with one-shot sensors, that mainly are of

electrochemical type (Klonoff, 2003).

Chemiluminescence measurement could be of

interest for one-shot sensor design due to its good

sensitivity and selectivity, although the use of

electrochemiluminescence (ECL) could offer clear

advantages for controlling the chemical system

(Richter, 2004).

The use of screen printing technologies, with

benefits for low cost and mass production, appears

to be interesting to develop ECL one-shot biosensors

next to portable instrumentation.

The presented lactate biosensor is based on its

enzymatically catalyzed oxidation and back ECL

transduction using luminol (L) according to:

Lactate + O

2

⎯⎯→⎯

LOD

Piruvate + H

2

O

2

L – e → L* (electrode)

H

2

O

2

+ L* → 3-aminophthalate + N

2

+ H

2

+ hν

2 MATERIALS

The one-shot biosensor is formed by a screen printed

electrode where the working electrode contains all

343

Martínez-Olmos A., J. Palma A., Ballesta-Claver J., C. Valencia-Miron M. and F. Capitan-Vallvey L. (2009).

HAND-HELD LUMINOMETER WITH ECL-BASED BIOSENSOR FOR LACTATE DETERMINATION.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 343-346

DOI: 10.5220/0001432703430346

Copyright

c

SciTePress

needed reagents immobilized in a Methocel

membrane. The sensing layer was spotted as

solutions of luminol, lactate oxidase (LOD), BSA,

sodium chloride and 8.8 pH phosphate buffer in

aqueous solution of Methocel. The screen-printed

electrode was covered by a thick overlapping plastic

layer with a 40-μl volume hole in the electrode area

to place the sample.

The characterization of the screen-printed

electrodes was investigated through cyclic

voltammetry. The ECL measurements were

performed measuring the light intensity emitted

while triggering the ECL reaction.

3 INSTRUMENTATION

After describing the biosensor, a portable instrument

based in ECL detection and designed and fabricated

for this sensor will be detailed. The prototype has

been applied to lactate concentration determination

in saliva.

The system is based on a solid-state photodiode

detector, which generates an electric current

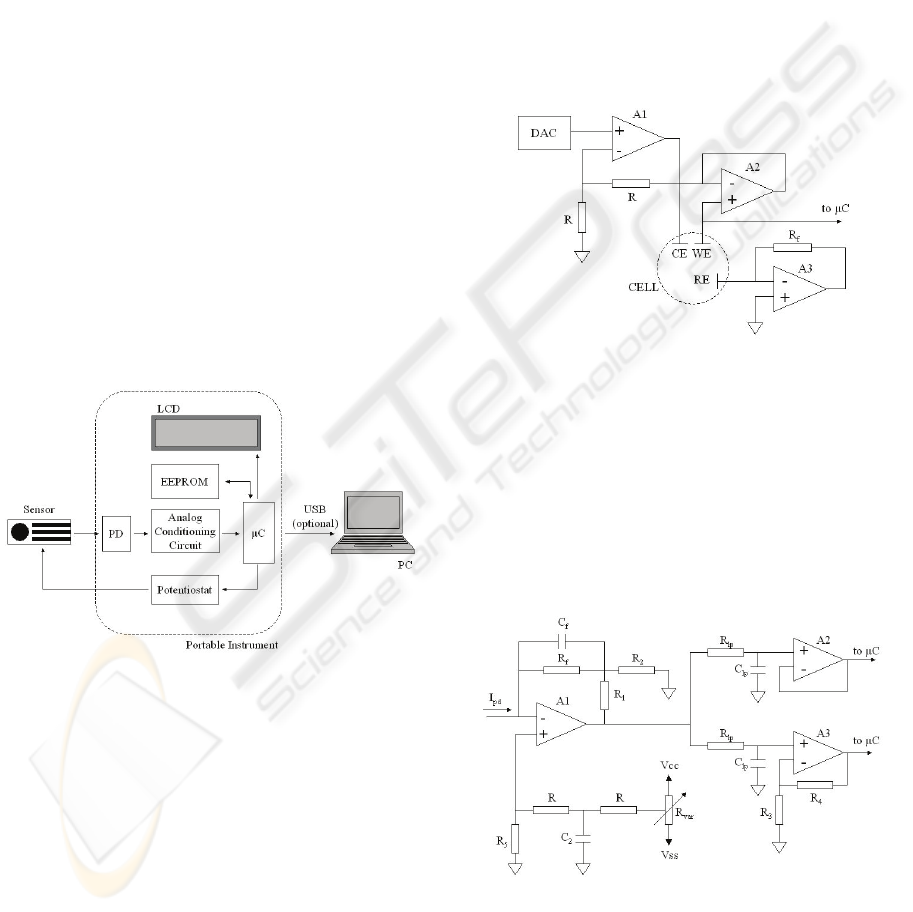

proportional to the ECL being measured. In Figure 1

the general scheme of the system is presented.

Figure 1: Block diagram of the instrument.

The light resulting from the ECL reaction on the

sensor excites the photodiode detector (PD) (S1227-

66BR, Hamamatsu Photonics) which generates an

electric current in response. The analog circuit for

measuring this current is shown in Figure 3. ECL

is

produced when a voltage difference of 0.5V is

applied between the reference and the working

electrodes in the biosensor. This polarization of the

sensor is carried out using a programmable built-in

potentiostat, which is designed to apply variable

voltage steps between the sensor electrodes.

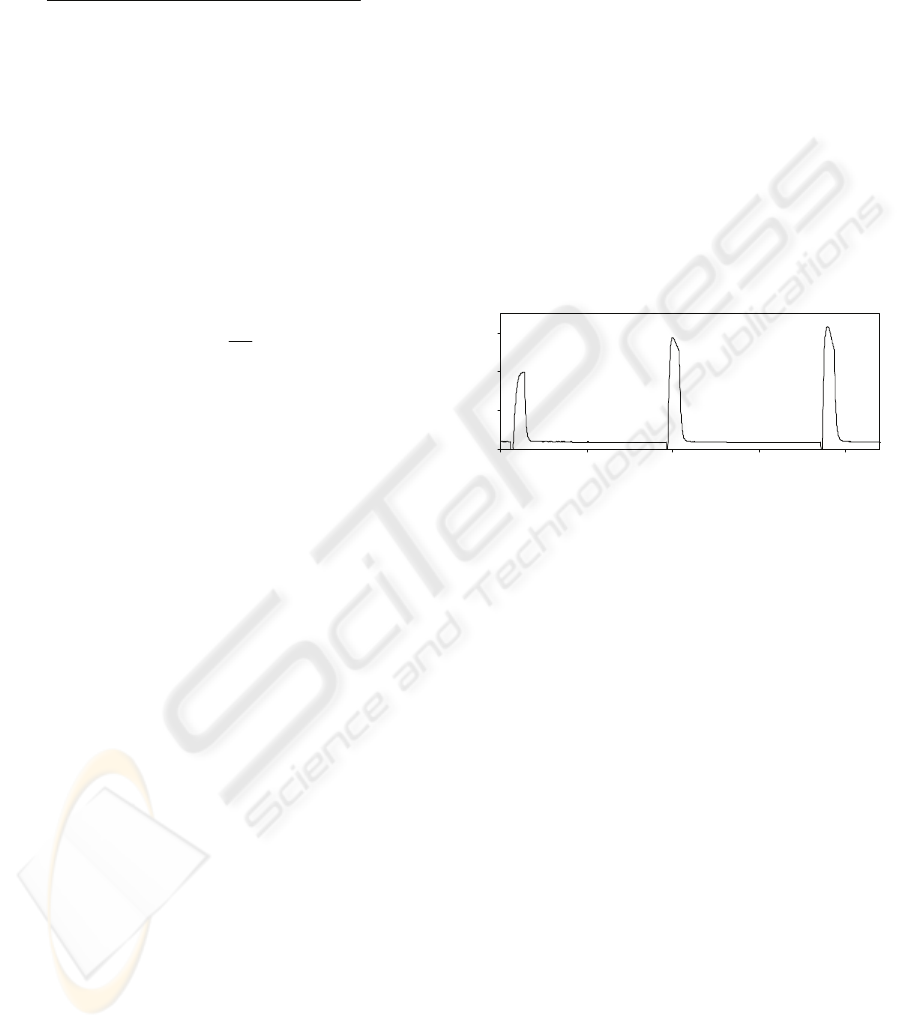

A detailed schematic of the potentiostat is

presented in Figure 2. In this circuit, a serial digital-

to-analog converter (DAC) (DAC8574, from Texas

Instruments) generates an analog voltage from a 16-

bit digital word sent by the microcontroller, which is

the input value to the potentiostat. If the

electrochemical cell is full of a conductive liquid,

the operational amplifiers A1 and A2 form a non-

inverting amplifier stage with gain 2. This

establishes a voltage at the working electrode that is

double than the input voltage value. The voltage at

the reference electrode is forced to virtual ground

because of the negative feedback of the operational

amplifier A3. Thus, the voltage difference between

the working and the reference electrodes is simply

twice the analog value generated by the DAC.

Figure 2: Potentiostat circuit.

The voltage at the working electrode is

monitored directly by the microcontroller, since its

function is to detect when the test drop is deposited

on the biosensor. This event causes the start of a

time count, thus allowing a precise determination of

the time elapsed between the drop deposition and the

beginning of the measurements. Therefore, a perfect

timing control of the measurement procedure can be

achieved.

Figure 3: Measurement circuit.

The current is converted into voltage trough the

current-to-voltage converter formed by the

operational amplifier A1 (TLC277, from Texas

Instruments). This device has a feedback network

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

344

compounded by the resistors R

f

, R

1

and R

2

, which

results in a high gain conversion, being the output

voltage of A1:

(

)

12 12 2

2

() ( )

pd f f

o

VR R I RR R RR

V

R

+

+− ++

=

(1)

where V

+

is the voltage at the non-inverting input of

the operational amplifier A1, and I

pd

is the current

generated by the photodiode. The voltage V

+

takes a

value of few mV and can be changed through the

variable resistor R

var

. The effect of this parameter is

to compensate the input offset voltage of the

operational amplifier, which can have a high

influence on the output because of the great gain of

this stage.

Under ideal conditions (V

+

=0) and assuming

R

f

>> R

2

, Equation (1) can be rewritten as:

1

2

1

opdf

R

VIR

R

⎛⎞

=+

⎜⎟

⎝⎠

(2)

Selecting a high value for R

f

and making R

1

>R

2

,

a gain factor of 10

11

– 10

13

V/A can be achieved.

The output voltage of A1 is conditioned using

two parallel stages , formed by the operational

amplifiers A2 and A3. In each stage, the signal is

firstly filtered through a RC low-pass filter. The

operational amplifier A2 acts as a buffer, whereas

A3 amplifies the output voltage of the I/V converter

before sending it to the microcontroller. In this way,

the μC receives two signals, one corresponding to

the filtered output of the first stage, and another that

is an amplification of this last one. The purpose of

having two different channels for measuring the

same signal is to expand the range of lactate that can

be analysed.

The outputs of A2 and A3 are connected directly

to the microcontroller (μC) (PIC18F2550,from

Microchip Inc.), which uses an internal 10-bit

analog-to-digital converter to alternatively sample

these signals at high frequency. A serial EEPROM

module (24LC512, from Microchip Inc.) of 512kbit

is used to store the sampled data. Finally, once the

calibration function (see next section) programmed

in the microcontroller is applied, results are sent to

the LCD display (Figure 1). All electronic circuitry

is included in an enclosure with optical, magnetic

and electrical shielding.

Moreover, control software written in Visual

Basic allows the user to optionally communicate the

instrument with a computer via an USB port to

receive the data for further analysis.

Main advantages of our design lie on portability,

low cost because of the use of a photodiode instead

of a costly or bulky photomultiplier, and the use of

non invasive samples. Most commercial portable

lactate meters use blood or serum for lactate analysis

(www.lactate.com, Poscia, 2005).

4 BIOSENSOR COMPOSITION

AND MEASUREMENT

CONDITIONS

Composition of sensing membrane was optimized in

terms of type and concentration of membrane

polymer, supporting electrolyte, pH and buffer,

luminol concentration, enzyme units, and BSA

concentration.

0

200

400

600

0 5 10 15 20

t / s

ECL relative sign

a

Figure 4: Relative ECL lactate signals.

Different types of ECL analytical signals were

studied using the instrument described in the

previous section in order to obtain an analytical

parameter for lactate concentration. The intensity of

the collected light, resulting from the reaction on the

sensor, did not show a direct relationship with the

lactate concentration, as can be seen in Figure 4,

where three steps at fixed potential were applied to

the same problem drop. The intensity of the light is

increased with successive potential steps. From these

current pulses, a kinetic signal derived from the

relative increase of the signal was chosen for the

measurement of the lactate concentration, since it

remains stable for different excitation pulses. The

measurement conditions studied were: a) applied

potential (0.5 V); b) waiting time before the first

pulse (3 min); c) time between pulses, being 10 s for

better sensitivity; d) pulse time with 1 s as best for

sensitivity and time of analysis.

The sample volume in the screen-printed device

was spotted with a micropipette. From the influence

of sample volume, studied between 20 and 40 µL.

Low volumes have high ECL signals but poor

repeatability. The signal and the standard deviation

decrease when the volume increases. The reason of

this behaviour is that low volumes don’t cover the

HAND-HELD LUMINOMETER WITH ECL-BASED BIOSENSOR FOR LACTATE DETERMINATION

345

three electrodes totally, specially the reference

electrode, making then oscillating potentials.

Therefore a volume of 35 uL for the test drop has

been selected, wich provides a good precision (5-8

% RSD).

5 ANALYTICAL

CHARACTERIZATION

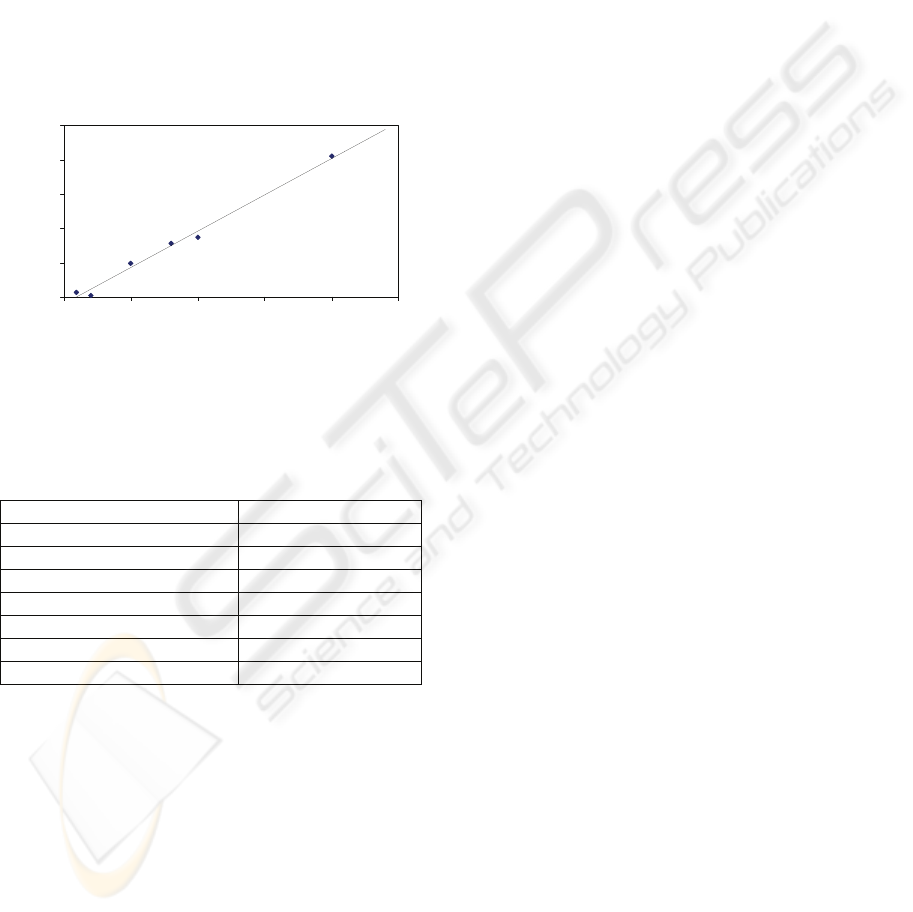

The dependence of ECL signal with lactate

concentration was studied between 10

-7

and 10

-3

M

obtaining a linear relationship between 10

-6

M and

2·10

-4

M (Figure 6).

0

200

400

600

800

1000

0.00 0.50 1.00 1.50 2.00 2.50

lactate·10

4

M

CL relative signal

Figure 6: Linear calibration of lactate biosensor.

Table 1 shows some analytical parameters of

biosensor for lactate.

Table 1: Analytical characteristics.

Parameter Value

Linear ran

g

e (M) 9·10

-

6

–

2·10

-

4

Inte

r

cep

t

1.87

Slope 786150

r

2

0.9956

Detection limit (M) 2.4·10

-

6

RSD blank (%) 8.2 %

RSD lactate (%) 8·10

-

4

M 10.3 %

This biosensor was applied to lactate

determination in saliva obtaining good preliminary

results.

6 CONCLUSIONS

A new hand-held luminometer for

electrochemiluminescence (ECL)-based one-shot

biosensor for lactate is described. Exciting the

sample volume with consecutive steps of 0.5V and

measuring the light resulting from the reaction on

the sensor provides a method for the evaluation of

the lactate concentration. A good linear calibration

in the range of 9·10

-6

to 2·10

-4

M has been achieved,

what indicates that lactate in saliva, rather than

lactate in blood can be measured. This fact results in

a better behaviour of the prototype than the existing

commercial instruments, because of its minimal

invasive requirements for the measurement of lactate

in humans. The use of a solid-state photodiode as

optical detector, instead of a photomultiplier, which

is the usual technique in available commercial ECL

systems, as well as the integration of the potentiostat

and the measurement electronics in the same design

has allowed a low cost and compact instrument.

ACKNOWLEDGEMENTS

This work is supported by the Ministerio de

Educación y Ciencia, Dirección General de

Investigación (Spain), under projects CTQ2005-

09060-C02-01 and CTQ2005-09060-C02-02, and by

the Junta de Andalucía under project P06-FQM-

01467.

REFERENCES

J. B. Ewaschuk, G. A. Zello, J. M. Naylor, and D. R.

Brocks, J. Chromatog. B, 781 (2002) 39-56.

S. Benthin, J. Nielsen, and J. Villadsen, Anal. Chim. Acta,

247 (1991) 45-50.

D. Compagnone, D. Moscone, and G. Palleschi, Recent

Res. Devel. in Pure & Applied Anal. Chem., 1 (1998)

73-86.

D. C. Klonoff, Diabetes Tech. Therapeut., 5 (2003) 929-

931.

M. M. Richter, Chemical Rev., 104 (2004) 3003-3036.

www.lactate.com

A. Poscia, D. Messeri, D. Moscone, F. Ricci, and F.

Valgimigli, Biosensors and Bioelectronics 20 (2005)

2244-2250

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

346