PERSPECTIVES OF ELECTROCOAGULATION IN

WATER DISINFECTION

C. Ricordel

1,2

, D. Hadjiev

2

and A. Darchen

3

1

Ecole des Métiers de l’Environnement, Campus de Ker Lann, 35170 Bruz, France

2

Laboratoire de Biotechnologie et Chimie Marine, Université de Bretagne Sud

Centre de Recherche, rue Saint Maudé, 56132 Lorient, France

3

UMR CNRS Sciences Chimiques de Rennes, ENSCR, avenue du Général Leclerc, 35700 Rennes, France

Keywords: Water disinfection, E. Coli, Electrocoagulation, Aluminum, Kinetic.

Abstract: Today effective electrochemical disinfection system seems to be an alternative to conventional chlorination,

ozone or UV processes. This paper reports on a series of experiments evaluating the disinfection efficiency

of electrocoagulation cell using Al electrodes. Solutions contaminated by E. coli and surface waters were

used as test media. The process significantly outperformed chemical coagulation reducing the amount of

aluminum used. In all cases, the treated solutions were effectively disinfected and almost total removal of

coliforms and algae were rapidly performed. A relationship for the disinfection rate of E. coli cells has been

proposed. This equation takes into account the electrophoretic migration of the cells and the subsequent

release of discharged cells into the bulk.

1 INTRODUCTION

Nowadays water quality and available quantity are

being challenged by increased pollution from

various sources such as industry and agriculture.

Innovative, cheap and efficient methods of purifying

water as well as to clean wastewaters from industrial

effluents are needed. Electrochemical techniques

such as electroflotation, electrodecantation or

electrocoagulation offer the possibility to be easily

installed and they require few chemicals. According

to Rajeshwar et al. (Rajeshwar 1994) benefits from

using electrochemical techniques include:

environmental compatibility, versatility, energy

efficiency, safety, selectivity and cost effectiveness.

In addition to these, the systems employ only

electrons to facilitate water treatment. Of the known

techniques, there is a considerable interest in using

electrocoagulation. The process is well known for

the treatment of suspended particles (

Domini 1994,

Abuzaid 2002), phosphates (Idermez 2006a, Idermez

2006b) and oil-in-water emulsions (Canizares 2008 ,

Asselin 2008

, Un 2006). Another approach of the

electrocoagulation is water disinfection where this

technique can reduce notably the amount of chlorine

used. It has been reported that electrochemical and

magnetic fields can destroy a wide variety of

microorganisms from viruses (

Zhu 2005) to bacteria

(

Dao 2004, Li 2004).

In this study, Escherichia coli cells were used to

show the disinfection effect of electrocoagulation

using aluminum electrodes. The technique was then

used to treat total coliforms and algae.

2 THEORETICAL

Electrocoagulation is a process involving many

chemical and physical phenomena that use soluble

(“sacrificial”) anode to supply ions into the treated

water. In the electrocoagulation process the

coagulation ions are produced in situ. The process

involves three successive stages: coagulant

formation by electrolytic oxidation of the soluble

anode; contaminants destabilization and emulsion

breaking; aggregation of the destabilized phases

leading to floc formation.

In the case of an electrocoagulation, the reactor

contains one cathode and one anode (Figure. 1).

When a potential is applied with a current generator,

the anode material undergoes oxidation, while water

254

Ricordel C., Hadjiev D. and Darchen A. (2009).

PERSPECTIVES OF ELECTROCOAGULATION IN WATER DISINFECTION .

In Proceedings of the International Conference on Bio-inspired Systems and Signal Processing, pages 254-258

DOI: 10.5220/0001511602540258

Copyright

c

SciTePress

reduction occurs at the cathode. The reactions can be

presented as follows:

At the anode: M

s

= M

aq

n+

+ ne

-

2H

2

O = 4H

+

+ O

2

+ 4e

-

At the cathode: 2H

2

O +2e

-

= H

2

+ 2OH

-

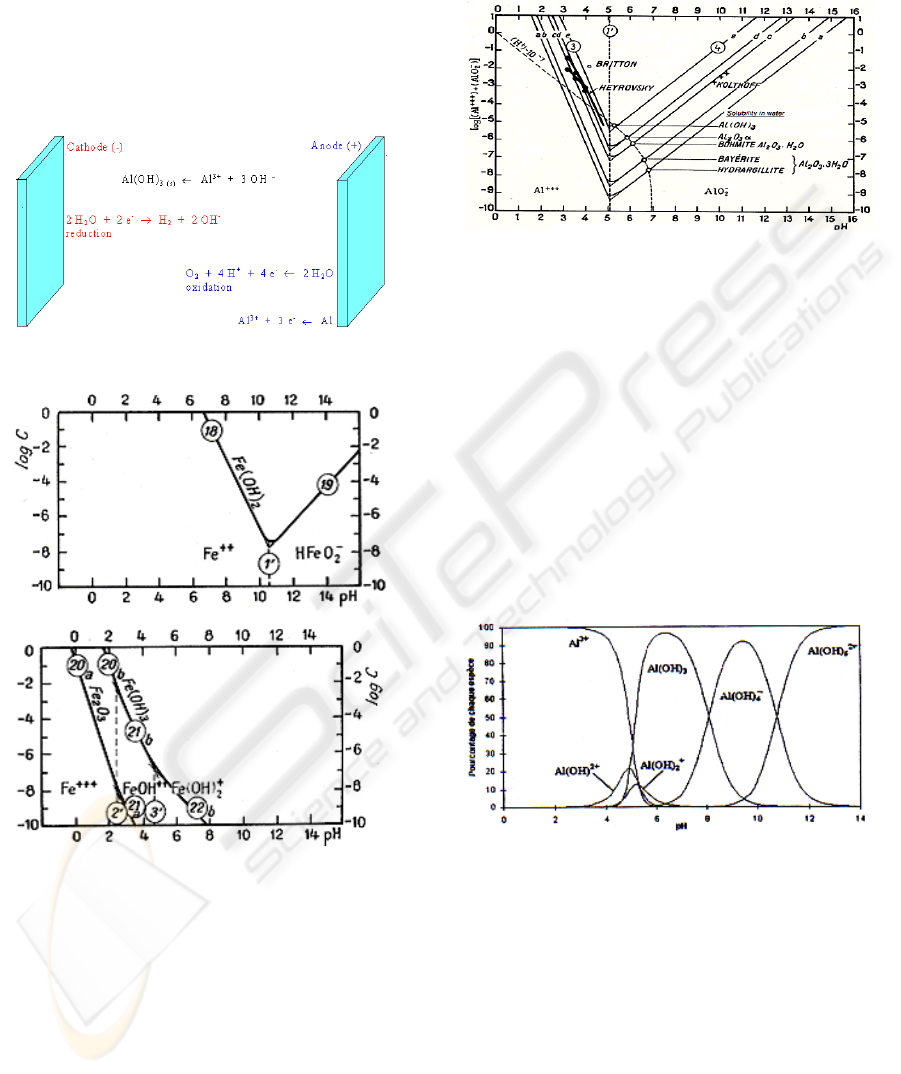

Figure 1: Schematic diagram of an electrocoagulation cell.

Figure 2: Influence of pH on the solubility of iron

hydroxides.

Generally iron or aluminum electrodes are

proposed both allowing good process performance.

These metal ions generated in the solution react in

solution and afford corresponding hydroxide and/or

polyhydroxide compounds. These compounds have

strong affinity for suspended particles, droplets and

eventually bacteria to cause coagulation. In fact, the

choice of the sacrificial electrode is a very important

parameter which depends on the operating

conditions, the goal being to use all the metal

hydroxides dispersed in the solution. The solubility

of these hydroxides depends on the pH of the treated

solution as it can be seen in Figure 2 and Figure 3.

Figure 3: Influence of pH on the solubility of aluminum

hydroxides.

It is clear that aluminum hydroxides have a lower

solubility than ferrous hydroxide, and therefore a

better efficiency in wastewater treatment. This is

why aluminum electrodes have been used in this

study.

When aluminum electrodes are used, the

generated Al

aq

3+

ions undergo spontaneous reactions

to generate:

Mononuclear complexes :

Al(OH)

2

+

,Al(OH)

4

-

, Al (OH)

2+

Polynuclear complexes : Al

2

(OH)

2

4+

, Al

2

(OH)

5

+

,

Al

6

(OH)

15

3+

, Al

13

(OH)

34

5+

Figure 4: Al hydroxides and polyhydroxides species as

function of pH.

For pH between 5 and 8, the predominant specie

is Al(OH)

3

(almost 95% when pH = 6.5) with small

amounts of Al(OH)

2

+

and Al(OH)

2+

. These

compounds show strong affinity for counter ions to

cause coagulation. The gases evolved at the

electrodes may impinge on and cause flotation of the

coagulated material. It can be assumed that the

process may be summarized as follows: charge

neutralization resulting from the production of

counter ions during the electrochemical dissolution

of the sacrificial anode, van der Waals interactions

followed by coagulation and floc formation.

PERSPECTIVES OF ELECTROCOAGULATION IN WATER DISINFECTION

255

In the present study we are presenting results

obtained with artificial and real aqueous solutions

for E. coli and indigenous flora to illustrate the

possibilities offered by an electrochemical

disinfection process using aluminium anode.

3 EXPERIMENTAL

3.1 Artificial Solutions containing E.

Coli

These solutions were prepared by diluting an E. coli

culture in a PCA medium. The E. coli was grown on

a shaker at 37°C for 24 hours and then 100 µl were

used to inoculate the medium.

Surface waters were obtained from local river

and pool.

E. coli, total coliforms and algae were counted in

accordance with standard methods.

3.2 Pilot Plant

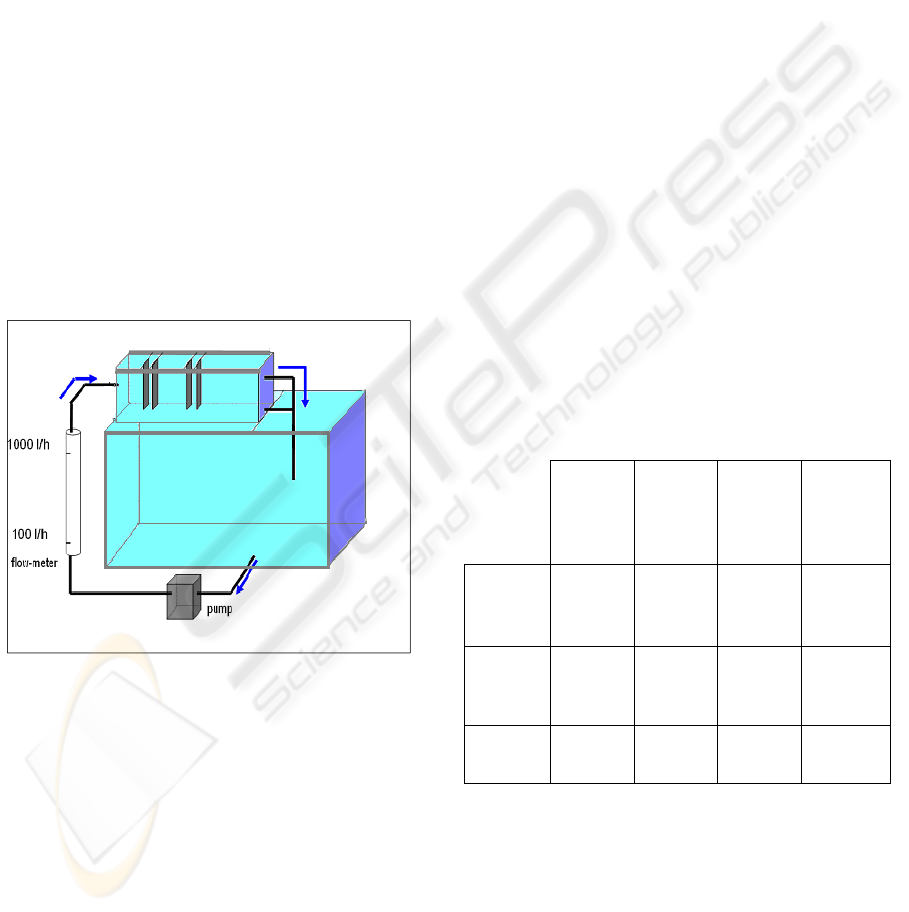

Figure 5: Schematic diagram of the bench-scale reactor

with monopolar electrodes.

The experiments were performed with two types of

reactor. The first one was composed of two

electrodes which were plunged in a beaker (V = 1

L). Different distances between the electrodes have

been tested (1, 2 and 4 cm). The electrodes ware

connected to a direct current power supply able to

furnish a controlled tension or current up to 30 V or

10 A, respectively. Applied tension, current,

temperature, conductivity and pH were measured.

After each run, the electrodes were dried and

weighted.

The obtained results have been used to build the

pilot plant shown in Figure 5. It consists of an

electrocoagulation reactor (V = 2 L) having two

pairs of monopolar aluminum electrodes and a

decantation chamber with V = 10 L. The flow in the

pilot is controlled with a centrifugal pump (Prolabo,

France). All tests were performed at a constant flow

rate of 100 L.h

-1

(flow velocity of 1.85 x 10

-3

m.s

-1

).

4 RESULTS AND DISCUSSION

4.1 Comparison between Coagulation

and Electrocoagulation

In order to illustrate the interest of the technique, a

comparison between the chemical coagulation and

the electrocoagulation is presented in Table 1. The

chemical coagulation was performed using the same

amount of aluminum as in the electrocoagulation. It

can be seen that the electrocoagulation improves

considerably thee bacteria removal. Using the same

amount of aluminium a 3-log (99.9%) reduction can

be achieved in this case, while only 1-log bacteria

reduction was reached with the chemical coagulation

in the same Al dosage range.

Table 1: Comparison between chemical and electro-

coagulation (Coa = coagulation).

Coa 1 Coa 2 Coa 3 Electo

coagulation

T0

(CFU/mL)

5.75E+04 2.38E+04 8.30E+04 3.00E+05

Tf

(CFU/mL)

9.75E+03 1.12E+04 1.40E+04 5.40E+02

E (%) 83 53 83 99.9

The fact that the electrocoagulation significantly

outperformed chemical coagulation deserves

explanation. According to Oss (Oss 1994) bacterial

adhesion to surfaces results from the Lifshitz-Van

der Waals interaction free energy and the Lewis

acid-base interaction free energy. Bacteria either

donate or accept electrons to the surface of the

substrate (in this case the gas bubbles). Adhering

bacteria may decrease electrostatic repulsion

BIOSIGNALS 2009 - International Conference on Bio-inspired Systems and Signal Processing

256

Table 2: Reduction of the cellular concentration of E.coli as function of the gap between the electrodes.

Distance 1 c

m

2 c

m

4 c

m

Run N° 1 2 3 1 2 3 1 2

T

0

(CFU/mL) 6.60E+04 1.20E+04 3.95E+04 1.60E+04 5.35E+04 2.48E+04 2.50E+04 5.00E+04

T

f

(CFU/mL) 3.50E+02 9.30E+02 6.35E+02 7.70E+01 2.85E+03 4.45E+02 8.30E+01 1.70E+01

E (%) 99.5 92 98 99.6 95 98 99 99

N/N

0

0.0053 0.0775 0.0161 0.0048 0.0518 0.0179 0.0033 0.0003

allowing floc formation. The charge transfer,

however, takes place over a range shorter than 0.5

nm, so close contact is needed. This contact is

realized easily in electrocoagulation process where

the negatively charged bacteria could

electrophoretically move resulting in higher bacteria

concentrations near the positively charged anode. At

the same time, the coagulation (chemical or

electrochemical) creates a sludge blanket that

entraps and can bridge colloidal particles as well as

bacteria still remaining in the aqueous solution.

At the same time, aluminum cation is generated

continuously over the extended area of the anode in

electrocoagulation compared with the point addition

in chemical coagulation. So aluminum is more

effectively used. Thus, locally higher coagulant and

bacteria concentrations might have been one reason

of the better performance of electrocoagulation

compared to chemical coagulation.

4.2 Influence of the Gap between the

Electrodes

The tests were performed at an initial pH = 7.2 at

15.6°C. The initial conductivity of the medium was

0.4 mS/cm. The applied tension was 30 V and the

current 0.22 A. The electrocoagulation time was

estimated according to the well-known sterilization

chart assuming a first order reaction for the cell

elimination and an imposed efficiency of

disinfection of N/N

0

= 0.001. The experiment

duration was 30 min. Three distances between the

electrodes have been tested: 1, 2 and 4 cm. The

obtained results are presented in Table 2.

As it can be seen, the best results have been

obtained with the distance of 4 cm where a 3-log

reduction was always obtained so this distance was

used in the experiments with real effluents. These

results show that electrical phenomena occurring in

the solution, and particularly the ion

electromigration, are involved in the disinfection

process, may be thanks to an electroporation

mechanism.

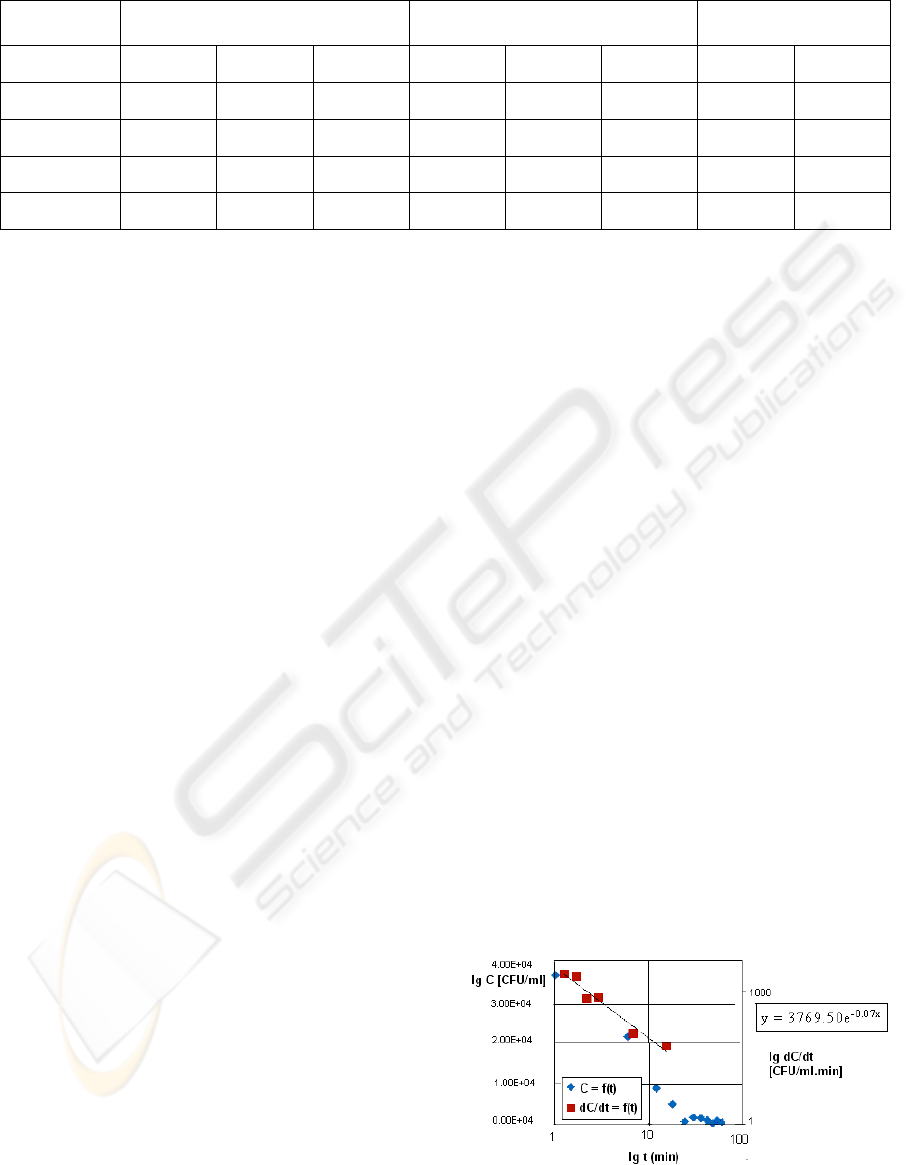

4.3 Coagulation Rate in a Batch

Electrocoagulation

The electrocoagulation of E. coli cells in a batch

continuously flowing system consisting of two cells

in series has been studied using the pilot plant shown

in Figure 5. The results given in Figure 6 show the

reduction in cell concentration in time as well as the

coagulation rate. The coagulation rate can be

described by a first order rate equation (1):

dC/dt = k

1

e

-k2t

(1)

where C is the concentration at time t, k

2

=

4kT/3µ (k is the Boltzman’s constant and µ the

viscosity of the aqueous medium), k

1

depending on

the electrophoretic velocity of the cells and the

geometric parameter of the electrode size. This

equation takes into account the electrophoretic

migration of the cells and the subsequent release of

discharged cells into the bulk. According to

Matteson et al. (Matteson 1995), the constant terms

in this equation derive from the basic electrophoretic

and coagulation phenomena, which are depending

on the zeta potential of the cells, the applied voltage,

the initial concentration and the electrode geometry.

Figure 6: Cell reduction and coagulation rate for E. coli

cells.

PERSPECTIVES OF ELECTROCOAGULATION IN WATER DISINFECTION

257

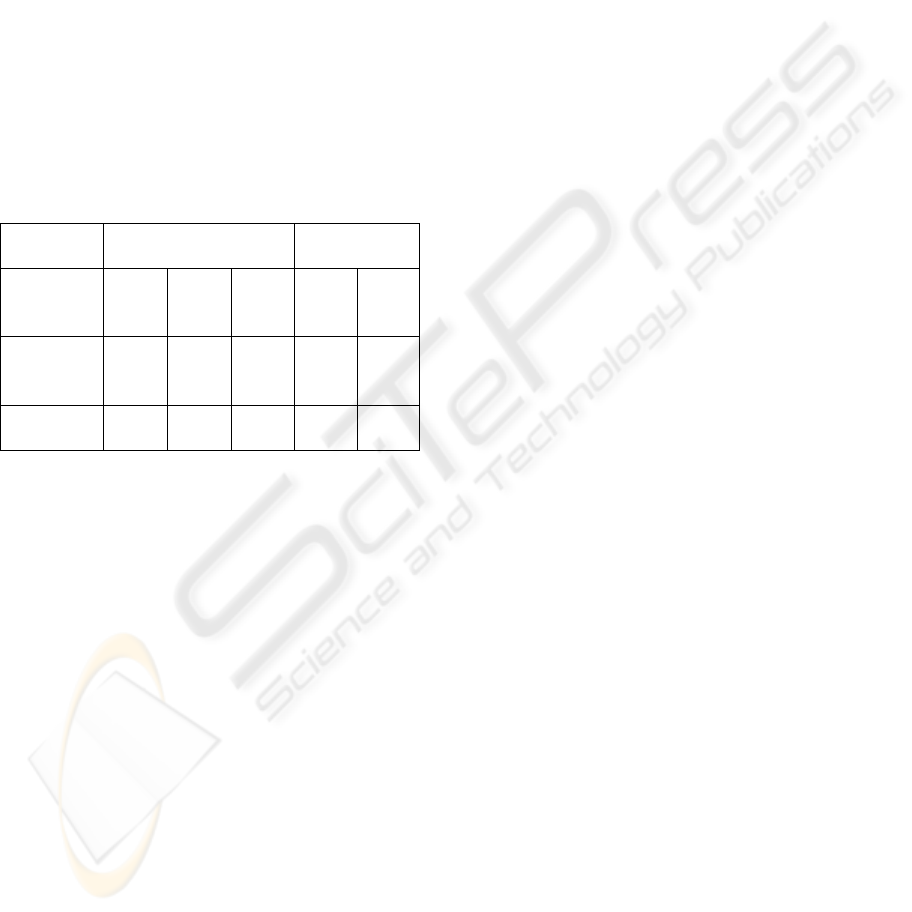

4.4 Electrocoagulation of Surface

Waters

In order to confirm the electrocoagulation

performances, two surface waters were studied. A

river water (conductivity 0.4 mS/cm, pH = 7.2)

containing indigenous coliforms and a pool water

(conductivity 0.55 mS/cm, pH = 6.8) containing

algae were used. The former was disinfected at I =

0.35 A, the latter at I = 0.22 A. In both cases the

applied tension was 30 V. In both cases after 10 min

a froth layer appears at the surface increasing in time

with flocs floating on the surface. The obtained

results after 30 min of electrocoagulation are given

in Table 3. They show a total coliform removal and

a good disinfection efficiency for the algae

population.

Table 3: Coliform and algae reduction in surface waters.

River water Pool water

T

0

(CFU/mL)

1.12

E+02

1.12

E+02

1.12

E+02

4.15

E+04

6.05

E+05

T

f

(CFU/mL)

0 0 0

2.50

E+02

2.20

E+02

E (%)

99.99 99.99 99.99

99.4 99.6

It can be assumed that the applied current

originate potential difference from an extremity to

the other of the cellular membrane on account of its

electrical resistance. This potential difference

modifies consequently the trans-membrane potential

producing destruction of the cellular membrane (Li

2004). The cell membrane is constituted essentially

by layers of phospholipids and proteins can be

included allowing ionic change with the cell

environment. Proteins are easily destroyed by direct

effect of an electric field while the phospholipidic

membrane is not easily oxidable. So, some cells can

be reactivated in a favorable medium. This is

probably the case of the algae present in the

solution.

5 CONCLUSIONS

The effects of disinfection of E. coli cultures,

coliforms and algae using aluminum

electrocoagulation were studied. The process

significantly outperformed chemical coagulation

reducing the amount of aluminum used. In many

cases, E. coli cells in the treated model solutions

were effectively disinfected and almost total

removal of coliforms and algae were rapidly

reached. A relationship for the coagulation rate of E.

coli cells has been proposed. This equation takes

into account the electrophoretic migration of the

cells and the subsequent release of discharged cells

into the bulk.

REFERENCES

Abuzaid N.S., Bukhari A.A., Al-Hamouz Z.M., Adv.

Environ. Res., 6 (2002) 325.

Asselin M., Drogui P., Brar S.K., Benmoussa H., J.F.

Blais, J. Haz. Mat., 151 (2008) 446.

Canizares .P, Martinez F, Jimenez C., Saez C., Rodrigo

M., J. Haz. Mat., 151 (2008) 44.

Dao H.F., Li X.Y., Gu J.D., Shi H.C., Xie Z.M., Proc.

Bioc., 39 (2004) 1421.

Domini J.C, Kan J, Hassan T.A., Kar K.L, Can. J., Chem.

Eng., 72 (1994) 667.

Idermez S., Yildiz Y., Tasunoglu V. , Sep. Purif. Technol.,

52 (2006a) 394.

Idermez S., Demircioglu N., Yildiz Y., Bingül Z., Sep.

Purif. Technol., 52 (2006b) 218.

Li M., Qu J.H., Peng Y.Z., J. Environ. Sci, 16 (2004) 348.

Matteson M.J., Dobson R.L., Glenn Jr R.W., Kukunoor

N.S., Colloids Surf. A.: Physicochem. Eng. Aspects,

104 (1995) 101.

Oss C.J.V., Interfacial Forces in Aqueous Media, Marcel

Decker Inc, New York (1994) p 440.

Rajeshwar K., Ibanez J., Swain G.M., J. Appl.

Electrochem., 24 (1994) 1077.

Un U.T., Koparal A.S., Ogutveren U.B., J. Environ. Man.,

(2008) 1.

Zhu B., Clifford D.A., Chellam S., Wat. Res., 39 (2005)

3098.

BIOSIGNALS 2009 - International Conference on Bio-inspired Systems and Signal Processing

258