ON-DETECTOR ELECTRONICS

OF THE CLEAR PEM SCANNER

E. Albuquerque

1

, V. Bexiga

1

, R. Bugalho

2

, B. Carriço

2

, C. S. Ferreira

2

, M. Ferreira

2

, J. Godinho

3

F. Gonçalves

1

, C. Leong

1

, P. Lousã

3

, P. Machado

1

, R. Moura

2

, P. Neves

3

, C. Ortigão

2

, F. Piedade

3

J. F. Pinheiro

2

, P. Relvas

3

, A. Rivetti

4

, P. Rodrigues

2

, J. C. Silva

2,6

, M. M. Silva

1

, I. C. Teixeira

1,5

J. P. Teixeira

1,5

, A. Trindade

2

and J. Varela

2,5,6

1

INESC-ID - Inst. de Engª de Sistemas e Computação, Investigação e Desenvolvimento, Lisboa, Portugal

2

LIP - Lab. de Instrumentação e Física Experimental de Partículas, Lisboa, Portugal

3

INOV – Inst. de Novas Tecnologias, Lisboa, Portugal

4

INFN - Istituto Nazionale di Fisica Nucleare, Torino, Italia

5

also with Inst. Superior Técnico, Univ. Técnica de Lisboa, Portugal

6

also with CERN, Geneva, Switzerland

Keywords: PET, Scanner, Breast, Cancer, SPECT.

Abstract: A Portuguese consortium has developed a PET scanner dedicated to breast cancer detection (Clear-PEM

scanner) within the framework of the international Crystal Clear Collaboration at CERN. In the construction

of this scanner several challenges have been addressed, from the design of the photon’s detector, front-end

electronics and data acquisition systems up to the image reconstruction algorithms. In this paper we describe

the development of the electronics in the detector heads needed to read-out and filter the data from 12288

detector channels, as well as to provide regulated high-voltages, low voltage power and control signals, and

also to monitor the environment in the detector heads. The scanner is currently in its final phase of

integration and will soon be installed in the department of Nuclear Medicine of Hospital Garcia de Orta and

Instituto Português de Oncologia (Porto) were clinical trials will be conducted.

1 INTRODUCTION

The Clear-PEM detector is a Positron Emission

Mammography scanner that was developed by

several Portuguese institutions within the framework

of the international Crystal Clear Collaboration at

CERN (

Abreu, 2006).

The detector assembly is based on two detecting

planar heads. The detection heads are mounted on a

robotized mechanical system, enabling the exam of

both breasts, one at a time, as well as the axillary

lymph nodes.

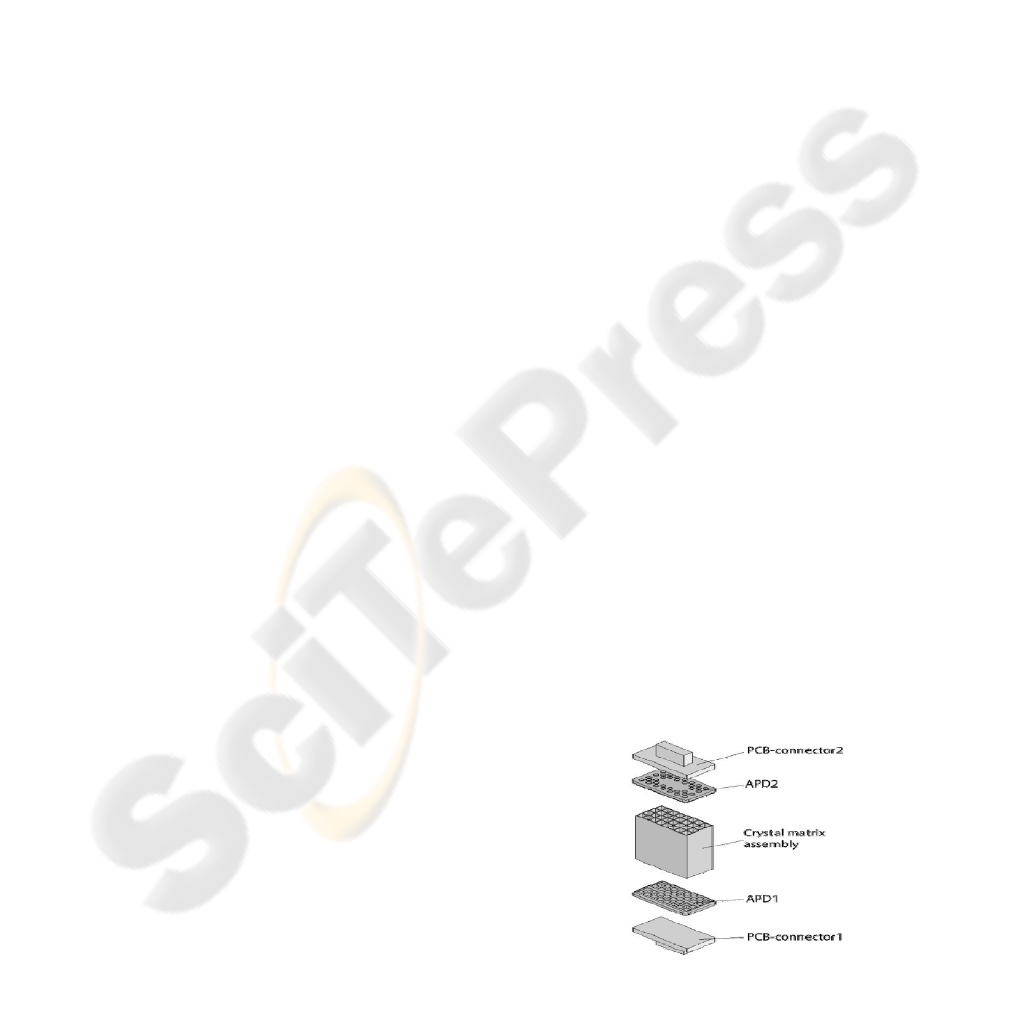

The basic element of the scanner is the detector

module (Fig. 1). Each module has 32 LYSO:Ce

crystals with 2x2x20 mm

3

assembled in a matrix

coupled on both ends to avalanche photo-diodes

(APD) (Amaral, 2007). Twelve of these detector

modules are assembled in a mechanical structure

placed between two Frontend boards forming a

Supermodule (Fig. 2).

355

Albuquerque E., Bexiga V., Bugalho R., Carric¸o B., Ferreira C., Ferreira M., Godinho J., Gonc¸alves F., Leong C., Lous

˜

a P., Machado P., Moura R., Neves

P., Ortig

˜

ao C., Piedade F., Pinheiro J., Relvas P., Rivetti A., Rodrigues P., Silva J., Silva M., Teixeira I., Teixeira J., Trindade A. and Varela J. (2009).

ON-DETECTOR ELECTRONICS OF THE CLEAR PEM SCANNER .

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 355-358

Copyright

c

SciTePress

The traditional readout based on photomultipliers

is replaced by multi-pixel APDs. Due to its

compactness, it is possible to read each single crystal

with one APD pixel on each end, and to use the

relative amplitude of the two signals to estimate the

longitudinal coordinate of the photon interaction.

The individual 1:1 crystal-APD pixel coupling

leads to 12 288 detector channels, with a density at

about 13 channels per centimeter square. The limited

available space in the detector heads demand that all

the processing electronics must have a strict limited

power consumption budget. This and the low gain

(100) of the APDs, has lead to the development, for

the Clear-PEM scanner, of specifically tailored low-

noise Application-Specific Integrated Circuit (ASIC).

Frontend electronics boards based on the Clear-

PEM ASICs provide the first level of signal

processing, including readout, amplification,

sampling and storage in analogue memories of the

APD array signals.

The ASIC’s output pulses are digitized by free-

sampling ADCs in the Frontend boards. LVDS data

links are used to transmit the detector data to the off-

detector electronics system, which implements the

first-level trigger, and data concentration and

transmission to the data acquisition server

(Albuquerque, 2008).

Auxiliary service boards located in the detector

heads are needed to provide regulated high-voltages

for each of the APD arrays and to distribute low

voltage power as well as control and clock signals.

The electronics is also responsible to monitor the

detector heads environment (temperature and

pressure).

Each Clear-PEM detector head has a total 3072

crystals grouped in 96 detector modules and 8

Supermodules. The detector head includes also one

Service Board, one high-voltage connection Matrix

Board and one clock fan-out unit. These electronics

boards are described in the following sections.

2 THE FRONT END

ELECTRONICS SYSTEM

The Frontend electronics system is one of the most

challenging and innovative sub-systems of the

Clear-PEM detector. It is composed by the Frontend

boards which interface directly with the APD arrays

assembled in the detector modules and are connected

to the Auxiliary Boards in the detector head.

The system, physically located on the detector

heads, performs signal amplification, channel

selection and analog multiplexing, analog to digital

conversion and parallel-to-serial translation.

A frontend ASIC has been developed for readout

of the multi-pixel S8550 Hamamatsu APDs.

Themixed-signal ASIC incorporates 192 low-noise

charge pre-amplifiers, shapers, analogue memory

cells and digital control blocks. Pulses are

continuously stored in memory cells at clock

frequency. Channels above a common threshold

voltage are readout for digitization by off-chip free

sampling ADCs. The number of output channels of

the frontend ASIC is two, still allowing for the

readout of two-hit Compton interactions in the

detector. The ASIC has a size of 7.3 mm x 9.8 mm

and was designed in 0.35 µm CMOS technology.

The Frontend Board (FEB) integrates two 192

channels ASICs and two dual free-sampling 10-bit

ADC chips working at frequencies up to 100 MHz.

The digitized data is transmitted to the off-detector

data acquisition system by LVDS serial links at 600

MHz.

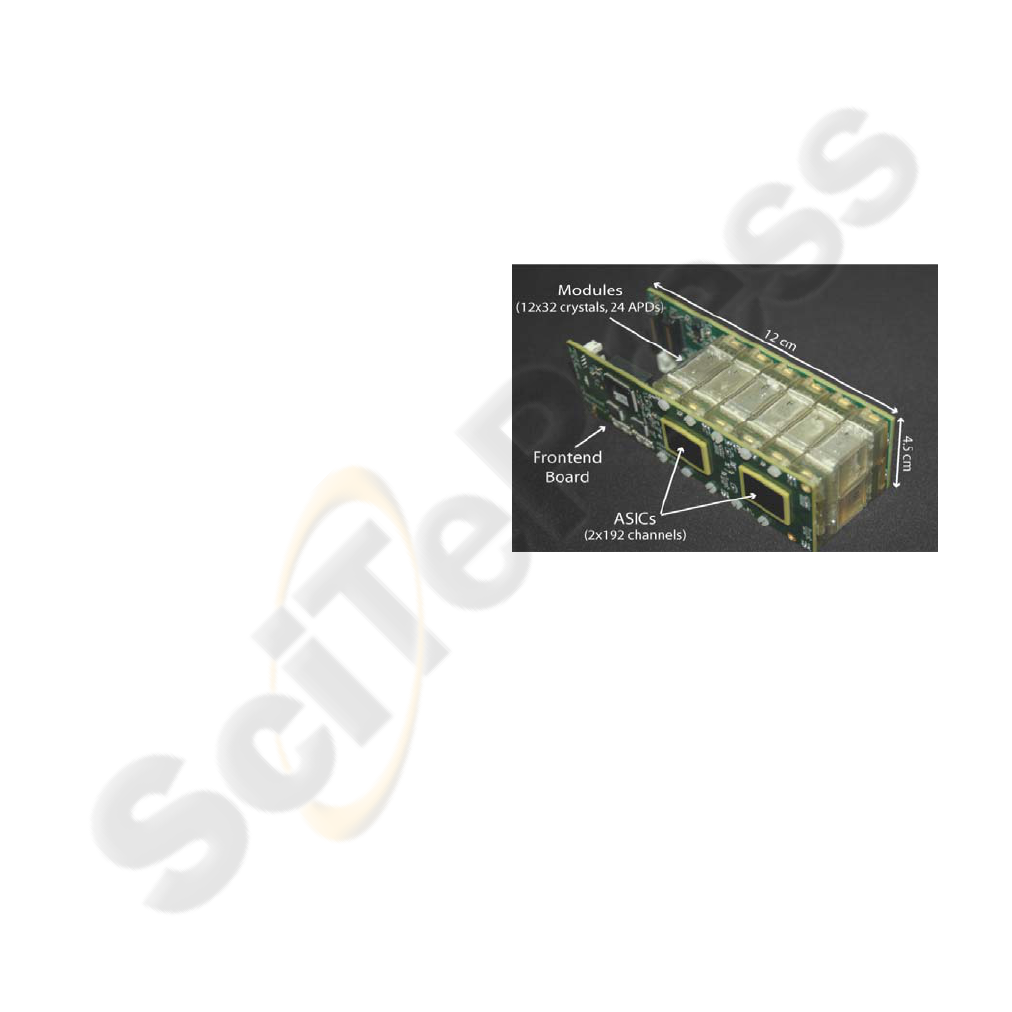

Figure 2: Supermodule structure assembling 12 modules,

each with 32 LYSO:Ce crystals and two 32-pixel APD

arrays in double readout. Each Frontend board has two

ASICs with 192 input channels.

Two FEBs are used to mount one supermodule

structure with a total of 768 electronic channels and

dimensions of 12x4.5 cm

2

as illustrated in Fig. 2.

The frontend electronics must have low-noise

due to the initial reduced charge at the amplifier

input, which for a 511 keV photon energy deposit is

around 30fC (maximum value). The frontend ASIC

amplifies this charge by about three orders of

magnitude, while complying with the low-power

dissipation requirements (5 mW/channel),

compatible with a compact water based cooling

system that allows to operate the detector at 18

o

C. A

temperature stability of the order of 0.1

o

C

is

required since the LYSO:Ce light yield and APD

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

356

gain are inversely dependent on the temperature (2-

3%/

o

C).

The Frontend Boards have a mixed analog-digital

environment and therefore special care is needed

regarding the correct conditioning of the digital,

large amplitude, high-frequency clock and other

periodic signals. Noise pickup in the PCB traces that

connect the APD outputs to the frontend chips must

also be minimized.

The performance of the Supermodules was

evaluated in a setup that integrates all the electronics

and data acquisition sub-systems as it will operate in

the final detector. A cooling system based on

controlled flux of cold water was build to cope with

the power dissipation from the Frontend Boards

during the qualification tests.

Acquisition runs with

22

Na and

137

Cs radioactive

sources, as well as background acquisitions from the

176

Lu natural radioactivity of the LYSO:Ce crystals

have been performed

(R. Bugalho, 2008).

The energy and time resolutions, energy linearity

of detector readout chain and output channels

occupancy are the parameters under evaluation for

each supermodule.

The noise of the detector channels, defined as the

equivalent noise charge (ENC) at the amplifier

inputs, is around 1300 e

-

RMS. This noise

contributes less than 2% to the energy resolution,

which at 511 keV is dominated by the fluctuations of

the scintillating light signal in the crystals. This

noise level implies a RMS time resolution of

individual 511 keV photons of the order of 1 ns.

3 THE AUXILIARY BOARDS

Several auxiliary boards have been designed to

provide regulated high-voltages, low voltage power,

as well as clock and control signals to the

Supermodules, and also to monitor the temperature

and pressure inside the detector heads.

These boards are placed in the back side of the

detector head, leaving the front side free of obstacles

for the detection of the PET photons.

The main auxiliary board is the Service Board

(SB) shown in figure 3.

Dedicated circuits in the SB including remotely

controlled Digital to Analog Converters (DAC) are

used to regulate the high-voltage (HV) lines (350-

500V) needed for the polarization of the APDs.

Plugging directly on the SB, the HV Matrix is

another auxiliary board that provides the

connections of the HV lines to the APD arrays

(figure 4).

Figure 3: View of the Service Board.

The connection matrix distributes 32 different

high-voltage references to the 384 APDs sub-arrays

(16 pixels) in the detector head. The APD gain

variation is of the order of 6%/V which requires a

stability of the biasing voltages better that 0.1 V.

The ripple of the high-voltage lines is less than 0.02

V. Before assembly each HV channel is calibrated in

order to guarantee that the gain of the APDs is

100.External power supplies provide independent

low-voltages for the analog and digital sections of

the detector electronics. The SB organizes the

distribution of these voltages to the Frontend Boards.

The control of the ASICs reset sequence uses an

Altera FPGA in the Service Board, and the setting of

the voltage thresholds of signal detection in the

ASICs is done by DACs controlled remotely via I2C.

The measurement of the temperature in the

detector modules uses PT100 sensors placed in

contact with the APD arrays, coupled to dedicated

signal conditioning circuits followed by ADCs

accessed remotely by the I2C control lines. The

pressure inside the detector head is also measured to

assure that slightly over-pressured nitrogen fills the

detector heads avoiding water condensation.

The system clock and a synchronization signal

are distributed to the frontend electronics. To avoid

interferences of the clock with the high-voltage lines,

a dedicated board is used to fan-out the clock and

sync signals.

Finally the detector head are closed using a

specifically designed patch panel board equipped

with vacuum tight connectors to insure the detector

box hermeticity (fig 4).

ON-DETECTOR ELECTRONICS OF THE CLEAR PEM SCANNER

357

Figure 4: View of a detector head, with the hermetic patch

panel on bottom, during the cabling phase.

4 CONCLUSIONS

In this paper, the detector electronics of the Clear-

PEM scanner, composed of the Frontend Boards

connecting directly with the detector modules and of

the Auxiliary Boards in the detector heads, was

presented. The detector electronics system is one of

the most challenging and innovative sub-systems of

the Clear-PEM scanner.

This electronics was validated in an experimental

setup that includes detector supermodules and all the

external sub-systems developed for the Clear-PEM

scanner, including the data acquisition electronics

and computing systems. The measured electronic

noise levels in the detector are below the

requirements set by the Clear-PEM specifications.

REFERENCES

Abreu et al. “Design and Evaluation of the ClearPEM

Scanner for Positron Emission Mammography”,

IEEE Trans. Nucl. Sci. (2006), Vol.53(1), pp 71-7.

Amaral et al. “Performance and quality control of Clear–

PEM detector modules”, Nucl. Instrum. And Meth. In

Phys. Res. (2007) A580, 1123-1126.

R. Bugalho et al. “Validation of Clear-PEM Data

Acquisition Electronics and Operation Software” sub.

IEEE NSS-MIC 2008.

Albuquerque et al. “Performance Evaluation of a Highly

Integrated APD/ASIC Double-Readout Supermodule

with 768 Channels for Clear-PEM” sub. IEEE NSS-

MIC 2008.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

358