SYNCHRONIZING AN X-RAY AND

ANESTHESIA MACHINE VENTILATOR

A Medical Device Interoperability Case Study

∗

David Arney

†

, Julian M. Goldman

‡

, Susan F. Whitehead

‡

and Insup Lee

†

†

University of Pennsylvania, Philadelphia, PA, U.S.A.

‡

MD PnP Program, CIMIT, Cambridge, MA, U.S.A.

Keywords:

MDPnP interoperability, Plug-and-play, Interoperable interconnected medical devices, X-ray ventilator, For-

mal methods, Verification model, Checking apnea, Patient safety.

Abstract:

When a x-ray image is needed during surgery, clinicians may stop the anesthesia machine ventilator while the

exposure is made. If the ventilator is not restarted promptly, the patient may experience severe complications.

This paper explores the interconnection of a ventilator and simulated x-ray into a prototype plug-and-play

medical device system. This work assists ongoing interoperability framework development standards efforts

to develop functional and non-functional requirements and illustrates the potential patient safety benefits of

interoperable medical device systems by implementing a solution to a clinical use case requiring interoper-

ability.

1 INTRODUCTION

Medical devices are a key element in the modern

health care environment. They assist medical staff by

automatically measuring physiologic parameters such

as blood pressure, oxygen level, and heart rate, or ac-

tively influence these parameters by means of infu-

sion pumps for analgesia and insulin or ventilators for

breathing support. Almost all modern medical care

rely on electronic medical devices.

Despite the pervasive use of medical devices

throughout modern health care, most devices work

on their own and in isolation. In contrast, interop-

erable devices would allow connections for sharing

patient data, device status, and enabling external con-

trol, even between devices from different manufactur-

ers. Such interoperability would lead to clear bene-

fits for the care provider and the patient such as more

accurate assessment of the patient’s health and error-

resilient systems through safety interlocks, closed-

loop control, and automatic hot swappable backups.

To realize these benefits, the MD PnP program

at the Center for Integration of Medicine & Innova-

∗

This research was supported in part by NSF CNS-

0509327, NSF-CNS-0610297, NSF CNS-0720703, and

NSF CNS-0834524.

tive Technology at the Massachusetts General Hospi-

tal (CIMIT.org) has been developing techniques and

standards to facilitate medical device interoperability

via MD PnP (Medical Device Plug-and-Play), similar

to the plug-and-play of PC devices.

This paper describes a prototype MD PnP case

study that was conducted for two purposes: (1) for

the MD PnP program to extrapolate functional and

non-functional requirements for the interoperability

standards in progress, and more importantly, (2) to

develop a demo interoperable medical device system

which would illustrate the benefits of the work by im-

plementing a solution to a clinical use case requiring

interoperability.

The rest of the paper is organized as follows. Sec-

tion 2 describes the clinical use case which motivated

this case study. Our problemstatement and challenges

are in Section 3. Section 4 describes the details of our

system implementation, and Section 5 tells how we

modeled and verified the system and generated code

from the model. Finally, our conclusions are in Sec-

tion 6.

52

Arney D., M. Goldman J., F. Whitehead S. and Lee I. (2009).

SYNCHRONIZING AN X-RAY AND ANESTHESIA MACHINE VENTILATOR - A Medical Device Interoperability Case Study.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 52-60

DOI: 10.5220/0001537100520060

Copyright

c

SciTePress

2 CLINICAL USE CASE

This project was driven by a specific clinical use case.

This use case was documented by the Anesthesia Pa-

tient Safety Foundation to illustrate a potential safety

problem with the way x-ray images are usually taken

during surgery.

A 32-year-old woman had a laparoscopic

cholecystectomy [gall bladder removal] per-

formed under general anesthesia. At the sur-

geons request, a plane film x-ray was shot dur-

ing a cholangiogram [bile duct image]. The

anesthesiologist stopped the ventilator for the

film. The x-ray technician was unable to re-

move the film because of its position beneath

the table. The anesthesiologist attempted to

help her, but found it difficult because the

gears on the table had jammed. Finally, the

x-ray was removed, and the surgical proce-

dure recommenced. At some point, the anes-

thesiologist glanced at the EKG and noticed

severe bradycardia. He realized he had never

restarted the ventilator. This patient ultimately

expired. (Lofsky, 2004)

It is common practice to stop the anesthesia ma-

chine ventilator for a short time during surgery when

this type of x-ray is performed. This ensures that the

patient’s chest and abdomen are not moving when the

exposure is made, thus providing a sharper image.

This does not harm the patient provided that the ven-

tilator is restarted promptly. Difficulties arise only if

the ventilator is not restarted for some reason. This

kind of problem can be mitigated by using intercon-

nected devices. If the anesthesia machine ventilator

can synchronize with the x-ray, then it is no longer

necessary to manually stop the ventilator to make the

exposure.

Synchronization between a camera and external

devices like a flash is not new. Typically, the cam-

era sends a trigger signal to the flash at the right time.

Similarly, the ventilator could synchronize with the

x-ray machine. Since ventilators are not built to send

synchronized signals to x-ray machines, we designed

our system to have a third device which sits between

the ventilator and x-ray, reads status messages from

the ventilator, and makes the decision about when to

trigger the x-ray. This third component is called the

supervisor and is described in detail in Section 4. Sys-

tems which synchronize x-rays and ventilators have

been built in the past, see for instance (Langevin et al.,

1999), but these systems must be built one at a time

for specific devices and are limited to experimental

use. Ventilators and x-ray machines are manufac-

tured by many companies. Cross-manufacturer inter-

operability would allow synchronized systems to be

built from any combination of devices that support

the functionality. The aim of the MD PnP program

is to develop techniques and standards that facilitate

medical device interoperability in order to allow such

systems to be easily assembled and used clinically.

3 PROBLEM STATEMENT AND

CHALLENGES

Our goal was to explore the safety and engineering

issues involved in building a system that would al-

low the x-ray machine to take a clear image of the

patient without the need to turn off the ventilator. Fur-

thermore, we wanted to build a system which would

illustrate the benefits of interoperability in the med-

ical domain. Interoperable medical devices are de-

vices which are capable of connecting to each other

to share data or to allow external control. Such de-

vices must have an external interface, and the design

of these interfaces is the subject of several ongoing

standards processes such as ISO/IEC 11073, Health

Level 7 (HL7), and others. The use case we addressed

specifically requires interoperability supporting exter-

nal control. The implementation we developed is not

intended to be used clinically. This project is essen-

tially a research platform for understanding the core

issues with interfacing these devices in this particular

use case.

Most medical devices currently manufactured are

not designed to be interoperable. The challenges we

faced in building this system are generally faced by

anyone trying to connect medical devices and are a

major reason such interconnection is not more com-

mon. Medical devices generally have proprietary in-

terfaces which are only documented in technical man-

uals or other material not openly available. We were

fortunate to have the cooperation of Dr¨ager, the man-

ufacturer of the ventilator we used. The interface of

the ventilator was designed to be used for diagnosis

of machine faults and to send data to the electronic

medical record, not as a source of real-time status in-

formation. Thus, it runs at a relatively slow rate, and

the low maximum sample rate (5 - 10 samples per sec-

ond) was the limiting factor in designing our control

algorithm.

A further challenge in interconnecting medical

systems is proving the safety of the resultant system.

Safety is defined as freedom from unnecessary risk,

where risks are unmitigated hazards. FDA provides

guidance on risk minimization for medical devices.

(U.S. Department of Health and Human Services,

Food and Drug Administration, Center for Drug Eval-

SYNCHRONIZING AN X-RAY AND ANESTHESIA MACHINE VENTILATOR - A Medical Device Interoperability

Case Study

53

uation and Research (CDER), Center for Biologics

Evaluation and Research (CBER), 2005) The risk as-

sessment process starts with a hazards analysis or fail-

ure modes and effects analysis (FMEA). These docu-

ments gather potential hazards and their mitigations,

that are used in writing requirements and safety prop-

erties. The risk analysis process and how we used

hazards to derive safety properties with which to ver-

ify the system is described in Section 5.

Our development process started with informal

system requirements which were used to build a state

machine model of the desired system behavior. We

checked this model for safety properties using model

checking software and then generated code from the

model to produce the supervisor.

4 SYSTEM DESCRIPTION

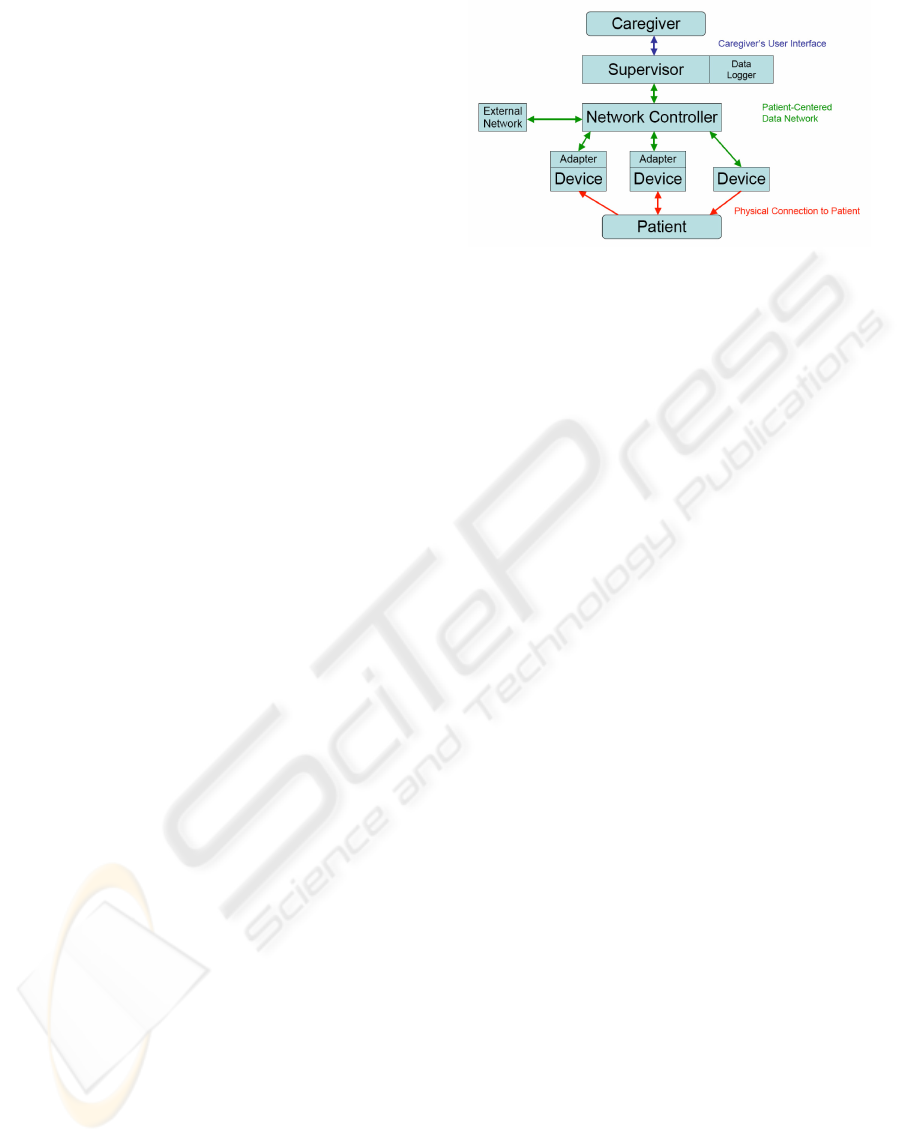

Figure 1 shows the overall architecture of our ap-

proach. This architecture follows closely that of the

draft standard for integrating the clinical environment

(hereafter referred to as ICE) (ASTM F29 WK19878,

2008). The major components are a set of medical

devices, a network controller, a supervisor, the pa-

tient, and a caregiver. Medical devices connect to

each other and the supervisor through the network

controller. The devices’ connections to the network

controller may go through physical adapters and data

format converters if their connectors and formats are

not directly compatible. The network controller may

also connect to an external network such as a hospital

information system. The supervisor runs the control

software for the system. Supervisor software for our

system is the subject of Section 4.2. The supervisor

hosts the user interface for the caregiver and may also

contain a data logger, which records network activity

and information from the devices.

MD PnP requires three phases of operations each

with its own safety, security, and functional require-

ments. The first phase is device discovery and con-

nection establishment, when devices are first con-

nected to a MD PnP network. When a new device

is connected to the network, the device’s capabilities

need to be communicated to the rest of the system.

The second phase is normal operation of the plug-

and-play system. During this phase, the devices trans-

mit data they produce and receive commands or data

from other parts of the system. The final phase is

disconnection. When devices are removed from the

system, the supervisor must decide how to respond.

If the device was necessary for continued operation

of the supervisor program, then the supervisor might

notify the user and shut down. If the device was not

Figure 1: Conceptual Architecture Overview.

necessary, the supervisor might be able to continue

operating in a limited manner.

Our system implementation, which follows the

conceptual architecture, is shown in Figure 2. The

devices we used were a Dr¨ager anesthesia machine

ventilator and a simulated x-ray machine. The role of

network controller and adapter is filled by the Live-

Data RTI software program. LiveData Inc. is a com-

pany which produces software to integrate medical

devices for common display data. We worked with

LiveData to connect the ventilator and simulated x-

ray. Their software translates the proprietary medical

device formats and makes the data available through

a single interface.

The supervisor program runs on the same com-

puter as the LiveData RTI software. Finally, the pa-

tient was represented with a physical lung simulator

consisting of a bellows and spring. While a simple

lung simulator does not capture all the nuances of a

real patient, it is sufficient for this application. Lung

movement is the factor we can control in taking a

clear x-ray, and a supervisor which can synchronize

with a simulated lung can be expected to do the same

with a real patient.

Our demo is not a full MD PnP system. It is

an interconnected medical device system rather than

an interoperable system. An interconnected system

is one in which devices are functionally connected

through an interface. It differs from an interoperable

system in that the devices are hard-coded. The sys-

tem is built around specific devices and will not oper-

ate with other, similar devices. It also does not fully

implement the three phases described above. The

demo is designed to illustrate the possibilities of in-

terconnected systems and show the kinds of systems

which interoperability would permit. It is not pos-

sible at this time to build a fully interoperable MD

PnP system, since the standards are still under de-

velopment. We believe that limited systems such as

this demo still have value in identifying functional

and non-functional requirements for the standards in

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

54

Supervisor

Server

ModBus /

Ethernet

Logitech IF /

USB

SOAP /

Ethernet

MediBus /

Serial

PLC

Light Button

Webcam

Simulated X−Ray

Ventilator

LiveData

Figure 2: Overview of the System.

progress and illustrating the benefits of the interoper-

ability work.

4.1 Hardware

The system consists of three major hardware compo-

nents. These are an anesthesia machine ventilator, an

x-ray machine, and a supervisor computer. The venti-

lator breathes for the patient by pumpinggas into their

lungs and allowing them to exhale on their own. The

x-ray machine takes radiographs, and the supervisor

coordinates the actions of the other components. Each

of these devices has its own physical interface and

communication protocol, all of which are different.

Medical devices are not generally developed with the

intention of interconnection. Any external interfaces

which are present are usually used for logging sta-

tus information or debugging. There is presently lit-

tle incentive for manufacturers to follow standards in

building these interfaces, and few standards for them

to follow. Thus, a wide range of interfaces are found

on various devices.

A fourth component is the LiveData server, which

translates formats between the other devices. The

LiveData server communicates with the anesthesia

machine ventilator using Dr¨ager’s MediBus protocol

over a 9600 baud serial line, with the x-ray machine

using the Modbus protocol over ethernet, and with the

supervisor using SOAP on HTTP on TCP/IP over eth-

ernet.

The x-ray machine is simulated using a PLC con-

troller, a webcam, a small red light, and a pushbut-

ton. The PLC allows the light to be turned on and

off and the pushbutton’s status to be read over ether-

net. The webcam is a standard USB webcam which is

controlled using proprietary software.

The supervisor computer, LiveData server, and

PLC are connected with a standard ethernet switch.

In our demo, the supervisor software and LiveData

server were usually run on the same computer.

4.2 Software

The system’s software is divided between the supervi-

sor and the LiveData server. The supervisor controls

the other devices in the system - it correlates infor-

mation from the other devices and makes the deci-

sion when to trigger the x-ray. Supervisors in gen-

eral are responsible for implementing the parts of the

system which are specific to a particular clinical sce-

nario. The supervisor checks to see whether the re-

quired devices are present, collects data from the var-

ious connected devices, and sends commands to the

devices according to the particular scenario. For this

demo, the supervisor gathers data from the ventilator

and sends the signal to trigger an x-ray exposure.

The LiveData server receives SOAP requests from

the supervisor and translates them into requests to

individual devices in their proprietary formats, then

takes the replies from the devices and formats them

as SOAP responses.

The development of the supervisor software is de-

scribed in more detail in Section 5.

4.3 SOAP

The SOAP interface is used for communication be-

tween the supervisor and the LiveData server. A typi-

cal SOAP transaction goes as follows:

1. the user requests the list of variables from the

LiveData server

2. they use the generic get or set methods to do op-

erations on those variables

3. the server receives the command, translates it to

the Dr¨ager MediBus protocol used for the ventila-

tor, and sends the command along

4. the ventilator sends its response to the server,

which translates it and passes the response to the

user

5. the response is returned in an XML wrapper

which contains typing information for the re-

turned values

SOAP is a standard protocol for web services. We

used it here primarily because it was supported by the

LiveData program. It worked well enough for this

application, which had relatively slow data rates and

small amounts of data being passed, but it does have

appreciable overhead. All queries and responses are

SYNCHRONIZING AN X-RAY AND ANESTHESIA MACHINE VENTILATOR - A Medical Device Interoperability

Case Study

55

passed as XML messages which need to be generated

on the sending side and parsed when received.

Another issue was the latency of the SOAP server.

Some of the latency is inherent in encoding and de-

coding XML messages and in passing the messages

through a translator instead of directly sending them

from one device to another. Additional latency in our

demo system resulted from a commonly used conges-

tion control method. When many small packets are

sent over a TCP/IP network, the data being sent is a

small portion of the transmitted packet - most of the

packet is taken up with headers. This can lead to the

network becoming congested when small packets are

sent quickly.

Nagle’s algorithm (Nagle, 1984) is used to con-

catenate these small packets together to reduce over-

all network overhead at the expense of delayed mes-

sage delivery. The data in many small packets can

be bundled into one large packet, reducing the over-

head but increasing the transmission time of the early

packets. In this context, we had plenty of bandwidth

and were much more concerned about the timely de-

livery of messages, so turning off this feature greatly

reduced the latency of the SOAP server.

4.4 Synchronization Algorithms

The supervisor uses information from the ventilator to

decide when to trigger the x-ray. The synchronization

algorithm defines exactly how this decision is made.

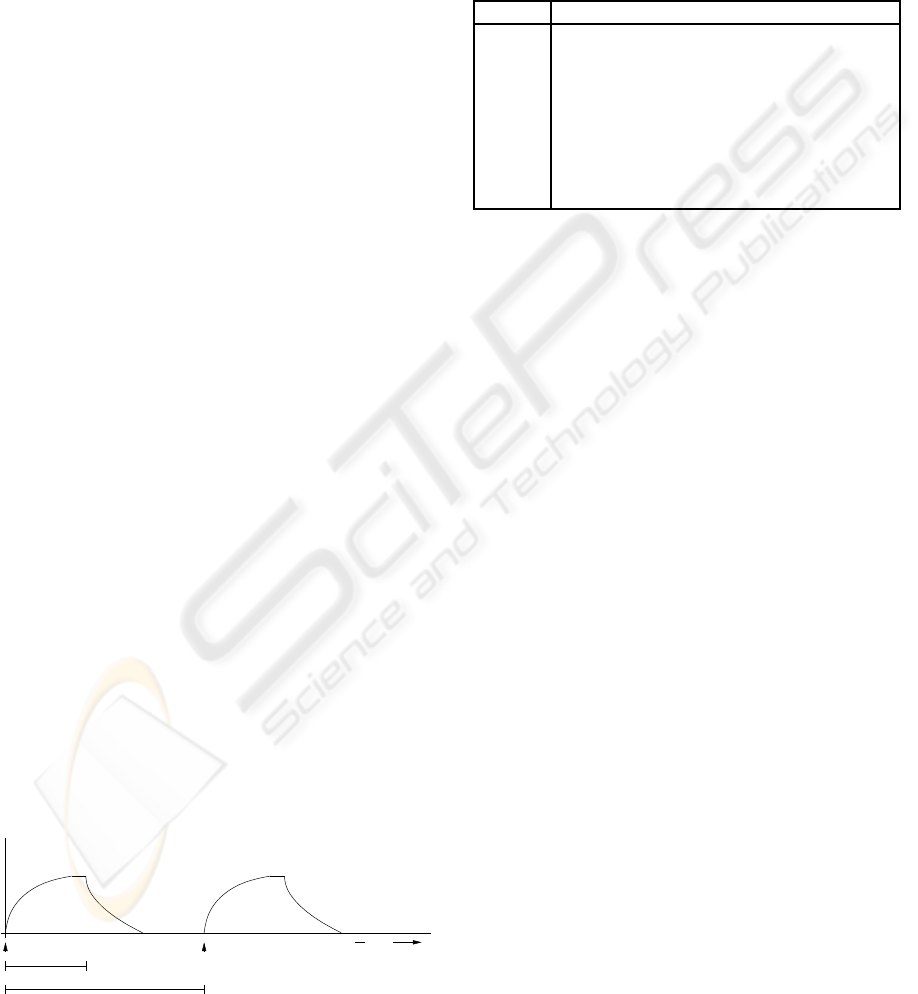

Figure 3 shows the respiratory cycle graphed as pres-

sure over time. The pressure increases until the end

of inspiration (at time Tinsp after start of breath), at

which point it drops off quickly through expiration.

There is usually a pause between the end of exhalation

and the start of the next breath. For this case study,

we want to support taking an x-ray when the ’lung’

was not moving significantly. This occurs when the

patient is relatively still at the peak of inspiration or

between the end of expiration and the start of the next

breath. An exposure is possible if the time the patient

is still exceeds the time needed for the exposure plus

the latency between triggering the x-ray and the actual

exposure.

Pressure

Start of Breath Start of Breath

Tinsp

1 / Frequency

Time

Figure 3: Respiratory Cycle.

4.4.1 Synchronization Method 1: Dead

Reckoning

The first method used to determine when to trigger

the x-ray is simple dead reckoning using the time of

last breath, time of inspiration, and frequency. The

variables used for this method are shown in Figure 4.

All times are in seconds.

name description

T

now

current time

T

lb

time of last breath

T

nb

time of next breath

T

δ

a small offset time to accommodate jitter

T

trigger

time to send trigger signal to the X-ray

T

exp

time of X-ray exposure

freq frequency, breaths / minute

flow instantaneous flow rate

Figure 4: Variables for dead reckoning.

If we know the time of the start of the last breath

and the frequency of breathing, then it is trivial to cal-

culate the time of the start of the next breath.

T

nb

= T

lb

+ 60/ freq (1)

There is probably time to trigger the x-ray just be-

fore start of the next breath, as long as the patient has

finished exhaling before the start of the next inhala-

tion.

T

trig

= T

nb

− T

exp

− T

delta

(2)

We can check whether the patient has actually fin-

ished exhaling by sampling the instantaneous flow

rate just before the start of the next breath. If it is

close to zero, then the patient is not inhaling or exhal-

ing and is still enough to allow taking the x-ray.

1. Get values of the variables T

now

, T

lb

, freq

2. Calculate T

trig

3. Sleep for T

trig

− T

now

seconds

4. Wake up and sample flow

5. If flow = 0, trigger X-ray

else, start over

This method of synchronization makes many as-

sumptions. The most critical assumption is that the

respiratory frequency is not going to change between

the last breath and the next one. If it does, or if the

system setup changes in other ways, this method of

synchronization will not work. The check of instanta-

neous flow rate should prevent the system from trig-

gering the x-ray when the patient is moving, but the

system may not be able to take an image in situations

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

56

where a different synchronization method would al-

low an exposure.

4.4.2 Synchronization Method 2: Dynamic

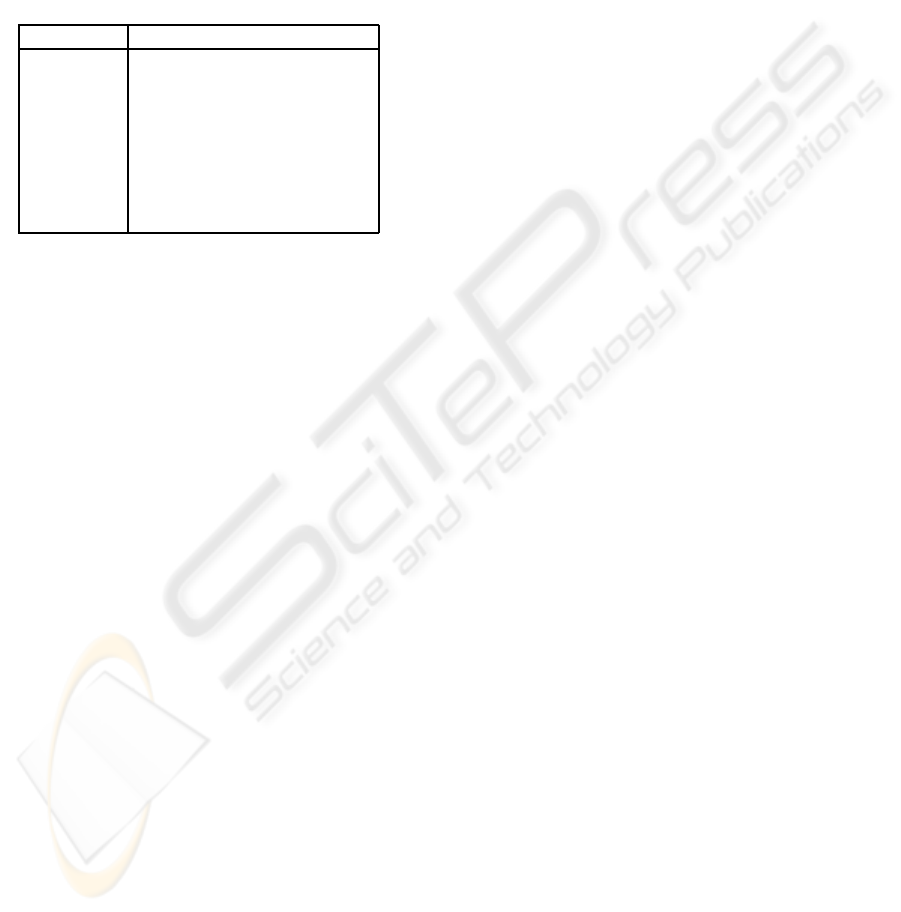

Another way to calculate the trigger time is to sam-

ple the real-time flow rate rapidly enough to build a

picture of the flow graph. We experimented with two

techniques for doing this. The variables used in the

following descriptions are listed in Table 5.

name description

flow instantaneous flow rate

T

flow

time of last flow sample

S

current

value of current flow sample

T

current

time of current flow sample

S

last

value of last flow sample

T

last

time of last flow sample

slope calculated slope value

Threshold slope threshold

Figure 5: Variables for dynamic synchronization.

We originally envisioned sampling at a high

enough rate to be able to integrate the total flow vol-

ume by multiplying the sampled flow rate by the time

interval of the samples. This would allow the supervi-

sor to trigger the x-ray at the right time no matter what

changes were made to the ventilator’s programming

or how the patient reacted. However, the ventilator

was not able to provide samples at a high enough rate

to enable this method to be used. The SOAP server

and interface introduced additional latency and jitter

into the samples, which further reduced their useful-

ness for this purpose.

Our second idea was to use the slope of the flow

signal to find when inspiration is about to end. This

meant taking two or more samples, calculating the

rate of change of the flow rate between them, and

triggering when this rate of change was low enough.

The problem we ran into here is that the flow graph

tails off very rapidly, making it unlikely that we would

get even a pair of samples in the short time when the

breath is about to end. The low sample rate made this

problem worse.

1. prime S

last

, T

last

, S

current

, T

current

with two consec-

utive samples

2. S

last

= S

current

3. T

last

= T

current

4. S

current

= flow

5. T

current

= T

flow

6. slope = S

current

− S

last

/T

current

− T

last

7. if slope < Threshold and flow is near 0, trigger

x-ray

else loop back to 2.

In the end, we found that dynamic synchroniza-

tion is possible only at relatively low respiratory rates

- under 8 to 10 breaths per minute. The dead reck-

oning method functions at much higher rates, up to

approximately 25 to 30 bpm depending on the other

ventilator settings. The supervisor program for our

demo checks the respiratory rate and chooses whether

to use the dynamic or dead reckoning method accord-

ingly.

4.5 Alarms

The system should not trigger the x-ray if the venti-

lator has active alarms. The ventilator will take care

of displaying the alarm condition to the caregiver and

sounding alarms, so the supervisor just has to detect

that the ventilator has active alarms and not trigger the

x-ray on that respiratory cycle. It does this by getting

a summary of all active alarms and warnings from the

ventilator. If the list of active alarms is not empty,

then the supervisor will not trigger the x-ray. This

technique is easy to implement and covers the most

common situation where the alarm sounds sometime

before the supervisor decides to trigger the x-ray. This

is sufficient for the demo, but an implementation with

a real x-ray machine and a real patient would have

to take into account factors such as the alarm being

raised after the supervisor checks the alarm status but

before the exposure is made.

In the case where this happens, many conditions

which would cause a ventilator alarm will not affect

the synchronization algorithm. These include alarms

like low gas levels, overpressure, some sensor fail-

ures, etc. Any alarm that does not indicate an unex-

pected change in ventilator settings will not stop the

supervisor from being able to synchronize. Alarms

for major mechanical malfunctions are very rare, but

would indicate conditions where we would not want

an exposure to be made - though any failure which

stopped the ventilator from operating would mean

that the patient’s chest was not moving. The prob-

lem with taking an exposure during an alarm is not

that the image would be blurred, but that the safety of

any caregivers responding to the alarm could be com-

promised. Caregivers are also protected by the use of

a ’dead man switch’ that the x-ray technician holds

during the exposure. If the switch is released, the x-

ray will not be taken. The time interval where there

was an active alarm and the exposure was being made

would be a fraction of a second, but this should be

taken into account in the risk management process.

SYNCHRONIZING AN X-RAY AND ANESTHESIA MACHINE VENTILATOR - A Medical Device Interoperability

Case Study

57

Any system using a real x-ray machine would also

need to take into account alarms from the x-ray, and

any system using medical devices which are capable

of pushing alarms rather than having them polled (as

we did with this ventilator) would also need to con-

sider possible race conditions between the alarm han-

dling and synchronization parts of the supervisor.

5 MODELING, VERIFICATION

AND CODE GENERATION

The software for the supervisor is the key element of

the system. The supervisor is the new piece which

facilitates communication between the other devices.

As was described in Section 4.2, the supervisor’s role

in this demo is to gather data from the ventilator, de-

cide when to trigger the x-ray, and send the signal to

the x-ray machine at the correct time. The supervi-

sor interacts with the caregiver to get input such as

whether to make the exposure during inspiration or

expiration and to provide the caregiver with status in-

formation and, ultimately, with the x-ray image.

The functioning of the supervisor program is crit-

ical to the safety of the system, so we devoted a sig-

nificant amount of time and effort to ensuring its cor-

rectness.

The supervisor software development process

started with gathering informal requirements. These

requirements were collected during discussions with

caregivers and biomedical engineers and included

functional requirements such as “when the exposure

is made, the red light on the x-ray box should light

up” and safety requirements like “the caregiver’s x-

ray trigger button must be held down for the x-ray ex-

posure to be made”. These requirements were refined

and expanded upon throughout the development pro-

cess. For instance, when we started development we

did not know that we would need a dead-reckoning

synchronization algorithm in addition to the dynamic

method and thus did not include any requirements

about when the supervisor should use one or the other

of these techniques.

A state machine model of the supervisor was built

and then verified to meet essential safety properties.

We used the model to generate Java code which then

ran the demo. This development process is described

in more detail in the following sections.

We began by modeling the supervisor program as

an extended finite state machine (EFSM). This format

was chosen because it is expressive enough to capture

the behavior of the program and tools are available

to automatically translate the EFSM specification into

the input languages of a number of tools.

Verification. Once the system was modeled as a

state machine, we used a tool to translate it into the

input format for the model checker UPPAAL. The

model checker was used to simulate the system, to

test the system for general properties like deadlock,

and to test more specific properties. These activities

suggested changes to the EFSM specification, and the

process went though several iterations. Eventually,

we produced an EFSM specification which satisfied

all the safety requirements.

The safety requirements for the system were gath-

ered by talking with clinicians and working though

an informal hazard analysis process. For a device in-

tended for use with patients, this process would be

much more thorough.

The primary hazard introduced by this system is

triggering the x-ray at the wrong time. This could po-

tentially endanger the x-ray technician or other clini-

cians. Triggering the x-ray when the patient is mov-

ing will result in a blurred x-ray and the need to take

another exposure, meaning additional radiation expo-

sure for the patient. Another hazard is that an image

might not be taken even though it is possible. This is

less significant, since the system will inform the clin-

ician that the exposure was not possible and try again

on the next breath. The exposure is delayed slightly,

but this is a small cost compared to that of a failed ex-

posure. The EFSM model of the system was checked

for structural properties like deadlock (that the sys-

tem can’t get ’stuck’) and for specific safety proper-

ties. These focused on when the x-ray is triggered,

since this is the single safety-critical action the sys-

tem takes. We checked that the trigger signal was sent

only at the correct time (as described in the algorithms

in 4.4.1 and 4.4.2) and that the system would not trig-

ger unless the flow rate reported by the ventilator was

near zero.

AG xray = exposing implies T

now

= T

nb

− Texp− T

δ

(3)

Formula 3 is used for checking the system when

it is being used to make an exposure at the peak

of expiration (the lung is empty) in dead reckoning

mode. This specification is in linear temporal logic

(LTL) and it says that whenever the x-ray machine

is in a state where it is exposing (AG xray = expos-

ing) the current time must be the time of the next

breath minus the exposure time minus a small offset

(T

now

= T

nb

− Texp − T

δ

). This means that if there

is any possible way that the EFSM could have the x-

ray in the state ’exposing’ when it is not that time, the

model checker will show it as a counterexample. Sim-

ilar formulas are used for checking exposure times for

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

58

inspiration.

AG xray=exposing implies flow <= flow threshold

(4)

Formula 4 states that when the x-ray is exposing,

the instantaneous flow rate must be less than the flow

threshold. This threshold is defined to be low enough

that the lung will not be moving enough to blur the

image, but also high enough to allow an exposure

when there are very small movements.

Implementation Generation. The final EFSM

specification was used to automatically generate Java

code which was used in the demo implementation.

The demo includes a handwritten GUI frontend which

is the user interface and the supervisor application,

which is largely generated code. The generated code

interacts with some handwritten functions which per-

form low-level actions. For instance, the model sim-

ply uses values like flow, while the generated code

replaces references to such variables with calls to

handwritten library functions which actually provide

the values.

Demo. The demo starts with a screen describing the

clinical use case. This is followed by giving the user

a choice of taking an image at the peak of inspira-

tion (when the lungs are full) or the peak of expira-

tion (when the lungs are empty). The user is asked to

confirm their choice and taken to a screen describing

the image-taking process. The user is asked to play

the role of an x-ray technician and to pick up a physi-

cal button which they will hold while the exposure is

made. In a non-synchronized x-ray, this button would

trigger the x-ray directly. In our system, the button is

held down to give the system permission to make the

exposure. The clinician holds the button for several

seconds while the system waits for the lung to reach

the proper phase of respiration and the system checks

to make sure the button is held before taking an im-

age. If the clinician decides that it is not safe to make

an exposure (e.g., if someone walks into the room),

they can simply release the button and no exposure

will occur. This allows us to keep a human in the loop

as an additional safety precaution. Assuming the but-

ton is held down, when the lung reaches the proper

phase the exposure is made and the webcam image is

displayed on the screen.

The system consisted of many components from a

variety of sources, written in several languages. The

main difficulty in implementing the demo was inte-

grating these diverse components into a single, func-

tional system. As was described in Section 4, the

system was tied together using LiveData and SOAP.

While there were significant disadvantages to this

approach (especially in terms of latency), we were

successful in making a working demo. This demo

was shown at the CIMIT Innovation Congress and

as a Scientific Exhibit at the American Society of

Anesthesiologists annual meeting and presented at the

High Confidence Medical Devices, Software and Sys-

tems and Medical Device Plug-and-Play Interoper-

ability workshop (Arney et al., 2007).

6 CONCLUSIONS

We successfully built a system which was able to syn-

chronize the ventilator with a simulated x-ray ma-

chine, demonstrating that the approach is feasible. In

the process, we learned lessons for building more gen-

eral systems. These include the importance of recog-

nizing the limitations of device interfaces in the su-

pervisor algorithm design and the need to have super-

visors which can respond to the changing settings of

the devices. We had two synchronization algorithms,

one which was more accurate but only usable at low

breath rates and a less accurate but faster algorithm

for high breath rates. We used formal methods in the

development of the supervisor and have presented a

methodology for ensuring that the integrated device

systems meet their specified safety properties.

This work started with an unfortunate use case,

resulting from the lack of a respiratory pause feature

on the ventilator and the ventilator’s inability to syn-

chronize with the x-ray machine. The exposure that

our demos brought to this problem has led to a pro-

posed change to the international anesthesia worksta-

tion standard. Hopefully in the future such changes

and the introduction of safe, inter-connected systems

will help to improve patient safety.

ACKNOWLEDGEMENTS

We would like to thank the following people who

were involved in creating the x-ray ventilator syn-

chronization demo. Without their contributions, this

work would not have been possible.

Steve Boutrus, Tufts Medical School

Philippe Cortes, Compiegne Univ. of Technology,

France

Jennifer Jackson, BWH Biomedical Engineering

Shankar Krishnan, MGH Biomedical Engineering

Ersel Llukacej, LiveData, Inc.

Heidi Perry, Draper Laboratory

Tracy Rausch, DocBox, Inc.

SYNCHRONIZING AN X-RAY AND ANESTHESIA MACHINE VENTILATOR - A Medical Device Interoperability

Case Study

59

Jeff Robbins, LiveData Inc.

Rick Schrenker, Biomedical Engineering

Dan Traviglia, Draper Laboratory

Sandy Weininger, U.S. Food and Drug Administra-

tion

REFERENCES

Arney, D., Goldman, J., Lee, I., Llukacej, E., and White-

head, S. (2007). Use Case Demonstration: X-Ray /

Ventilator. In High Confidence Medical Devices, Soft-

ware, and Systems and Medical Device Plug-and-Play

Interoperability, 2007, page 160.

ASTM F29 WK19878 (2008). New Specification for

Equipment in the Integrated Clinical Environment -

Part I: General Requirements for Integration.

Langevin, P. B., Hellein, V., Harms, S. M., Tharp, W. K.,

Cheung-Seekit, C., and Lampotang, S. (1999). Syn-

chronization of Radiograph Film Exposure with the

Inspiratory Pause. Am. J. Respir. Crit. Care Med.,

160(6):2067–2071.

Lofsky, A. S. (2004). Turn Your Alarms On! APSF

Newsletter, 19(4):41–60.

Nagle, J. (1984). Request for Comments: 896, Congestion

Control in IP/TCP Internetworks. Technical report,

Ford Aerospace and Communications Corporation.

U.S. Department of Health and Human Services, Food and

Drug Administration, Center for Drug Evaluation and

Research (CDER), Center for Biologics Evaluation

and Research (CBER) (2005). Guidance for Indus-

try Development and Use of Risk Minimization Ac-

tion Plans. Technical report, Office of Training and

Communication, Division of Drug Information.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

60