MINIATURIZED ELECTROCHEMICAL SENSING SYSTEMS

FOR IN VITRO AND IN VIVO BIOMEDICAL APPLICATIONS

V. I. Ogurtsov, K. Twomey, N. V. Bakunine, C. Mc Caffrey, J. Doyle, V. Beni and D. W. M. Arrigan

Tyndall National Institute, University College Cork, Ireland

Keywords: Miniaturized, Electrochemical, Sensor, Sensing system, In vitro, In vivo, Potentiostat.

Abstract: Development of miniaturized electrochemical sensing systems for in vitro and in vivo biomedical

applications is discussed. The systems are based on high sensitivity potentiostatic instrumentation, which is

suitable for chemical and biochemical sensors. The in vitro application is an 8 channel hand-held PC-

controlled system with user-friendly interface. This is capable of implementing different electrochemical

potentiodynamic techniques. The in vivo applications are realized using two approaches: a small sized PCB

with commercially available ICs, and a specially developed on-chip system. The performance of the

systems is validated through electrochemical characterization of a microarray sensor.

1 INTRODUCTION

Electrochemical sensors play an important role in

biomedical applications, including clinical disease

diagnostics (Peng et al., 2008), (Seo et al., 2008),

(Ndamanisha and Guo, 2008), (Wang and Ha, 2007),

(McLaughlin et al., 2002), drug testing (Abbaspour

and Mirzajani, 2007), microbiological pollutant

determination (Morales et al., 2007), and detecting

and quantifying DNA and proteins (Shiddiky et al.,

2008). These sensors give rapid and sensitive

measurements, and can detect solid, liquid or

gaseous analytes. If we consider the disease

diagnostic applications, this diversity can be

illustrated with the following examples. Nitric oxide

sensors (Peng et al., 2008) have found application in

the monitoring of neural conditions such as stroke,

heart attack and epilepsy, through the link between

elevated nitric oxide levels and these diseases.

Various glucose sensors are available for in vitro or

continuous in vivo monitoring of blood, urine and

saliva to diagnose diabetes (Seo et al., 2008). There

are oxygen sensors (McLaughlin et al., 2002) for

monitoring blood oxygen levels in pathways to

different organs. Recently sensors for uric acid have

been developed which indicate the presence of gout

and Lesch-Nyhan diseases (Ndamanisha and Guo,

2008). Sensors, which measure pH levels within the

gastrointestinal tract, can detect the presence of

intestinal diseases like gastroesophageal reflux

disease (GERD) (Wang and Ha, 2007). Also,

electrochemical sensors for in vivo drug monitoring

are being explored to monitor drugs administered to

treat different diseases e.g. anti-inflammatory drugs

for the treatment of intestinal diseases (Abbaspour

and Mirzajani, 2007).

In the area of clinical diagnosis, there is a

growing emphasis on early–disease detection.

Through this capability, serious diseases such as

heart disease and cancer can be more successfully

treated. To achieve this challenging goal,

developments in three key areas are essential. Firstly

more sensitive and more diverse sensors should be

created. Sensors with a lower limit of detection, for

example, would be crucial for early diagnostics

(before full-scale disease symptoms develop), and an

expansion of the number of available sensors for

analytes or biomarkers linked to the disease is

important to improve accuracy of disease diagnosis.

Secondly these sensors need to move from their

current use in highly specialized clinical laboratories

to areas of point-of-care (POC) such as at the

patient’s bedside. To enable this move,

developmental work in the area of instrumentation is

necessary, which will provide easy access to these

methodologies for the patient and physician, e.g.

user-friendly portable systems or in vivo systems

such as implantable devices that will allow

continuous supervision of the patient with access

close to the source of disease. This ability would

allow for more accurate monitoring of the disease

and provide early disease diagnosis.

83

I. Ogurtsov V., Twomey K., V. Bakounine N., Mc Caffrey C., Doyle J., Beni V. and W. M. Arrigan D. (2009).

MINIATURIZED ELECTROCHEMICAL SENSING SYSTEMS FOR IN VITRO AND IN VIVO BIOMEDICAL APPLICATIONS.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 83-87

DOI: 10.5220/0001546300830087

Copyright

c

SciTePress

There have been notable advances in suitable

sensors for early stage disease detection (Peng et al.,

2008), (Seo et al., 2008), (Ndamanisha and Guo,

2008), (Wang and Ha, 2007), (McLaughlin et al.,

2002), (Abbaspour and Mirzajani, 2007), (Morales

et al., 2007), (Shiddiky et al., 2008), However, there

remains a need to address the developments in

appropriate systems to allow progression of these

sensors outside of the lab to POC and to in vivo

applications. Currently, sensing instrumentation is

mostly bench-top based equipment, which is large

and not adapted to work outside of the lab

environment. Therefore, the development of

miniaturized sensing instrumentation is essential.

In this study, we discuss approaches to develop

miniaturized sensing systems for in vitro and in vivo

applications based on a potentiostatic solution,

which is commonly used with different

electrochemical sensors, and different sensing

methods (amperometry, voltammetry,

impedometry). Although, fundamentally the systems

for in vitro and in vivo applications are built on

similar circuitry, they vary significantly due to

different requirements in size, power, sensitivity,

biocompatibility and functionality. For the in vitro

applications, we have developed a portable, hand-

held, miniaturized, multichannel potentiostatic

system, which is optimized for operation with a

sensor array on chip. The system has the appropriate

accuracy and sensitivity required by biomedical

applications, and would be suited for use in a

hospital or at a GP’s office. For the in vivo

applications, we have developed two variants of the

system that are both miniaturized and can operate

over extended periods on low power, again with the

required accuracy and sensitivity. The first solution

is based on commercially available low-power, low-

noise, micro-sized small outline integrated circuit

(SOIC) components and chips. The second device

presents a specialized on-chip system that is

developed in-house. The in vivo systems have

similar performance specification but the PCB-based

system costs less. Both of these systems are

optimized for low-power operation, making them

applicable for implantable devices, where an

appliance is implanted and remains long term in the

body, operating on a continued basis.

2 SENSING SYSTEM

STRUCTURE

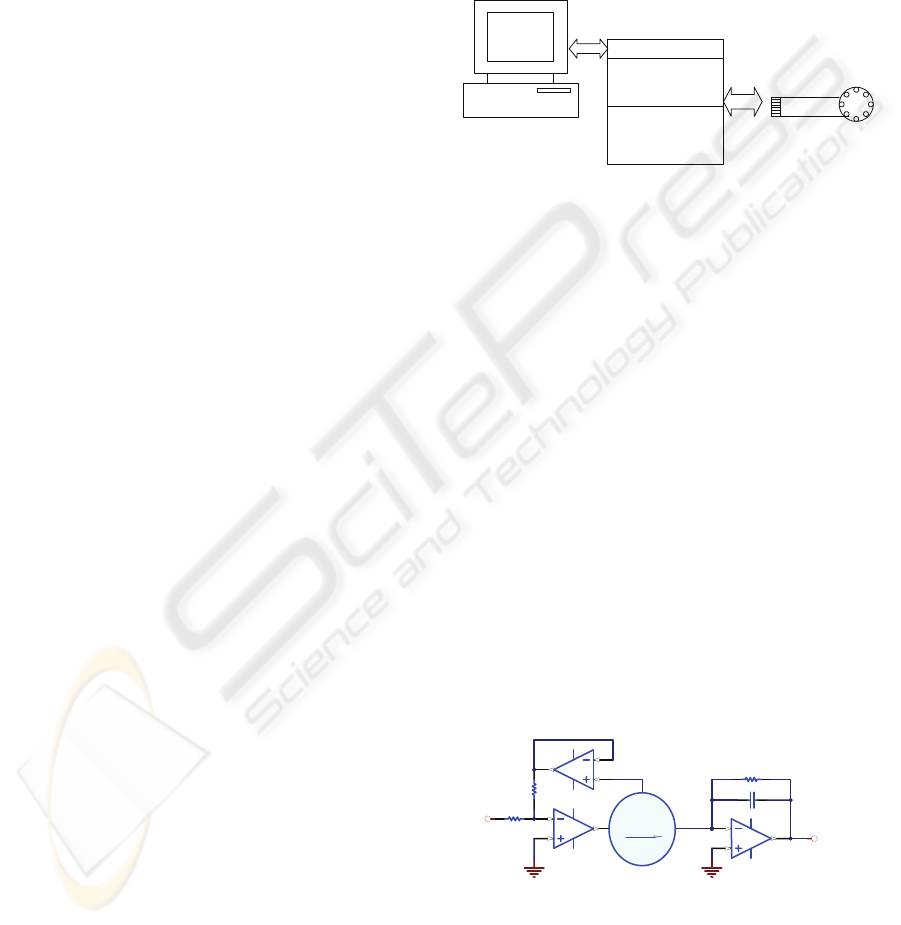

In general, for both system solutions, the

electrochemical potentiostatic sensing system

consists of an electrochemical cell incorporating the

sensor or sensor array, and two main analog

electronic units, the potentiostat and a

transimpedance amplifier, and a microcontroller

unit. These analog units connect to the

microcontroller unit that controls the measurement

process, and provides data acquisition and

connectivity to the personal computer (PC) as shown

in figure 1.

Microcontroller

Multichannel

potentiostat

Transimpedance

amplifier

Microcell

PC

Figure 1: Block diagram of electrochemical sensing

system for in vitro and in vivo applications.

The electrochemical cell is usually a three

electrode structure comprising a counter electrode

(C), reference electrode (R) and working electrode

(W), which is immersed into or covered by sample

solutions to be analyzed. Electrochemical or

biochemical reactions in the cell are detected with

electronics, in particular with a transimpedance

amplifier. The reactions are dependent on the W

potential, therefore, a stable potential at the W

should be provided. The W potential stability is

secured by the R, which supplies a reference

potential independent of the environment, and the

potentiostatic unit, which maintains this W potential,

with respect to the R, to be equal to a stimulation

signal generated by the microcontroller unit. The

shape of the stimulation signal depends on the

sensing methodologies (i.e. DC for amperometry,

staircase for voltametry and so on). A simplified

schematic of the electrochemical potentiostatic

sensing system (without microcontroller unit) is

shown in figure 2

Figure 2: Simplified schematic of the potentiostatic

sensing system.

Implementation of the electrochemical sensing

systems for in vitro and in vivo biomedical

applications is each governed by a different set of

requirements. For in vitro real- time systems, these

2

3

1

Op3

R

W

Vout

2

3

1

Op2

2

3

1

Op1 C

Vin

Current pass

CELL

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

84

requirements are high sensitivity, rapid rate of

measurement and corresponding signal processing,

accurate data interpretation, a multi-functional

instrument and simplicity of its operation by the end

user. For in vivo systems the main challenging

requirement besides sensitivity is the size of device,

which must adhere in some cases to millimeter size

scale, and continuous operation over extended

periods of time (i.e. up to one year, or longer for

some implantable devices). Both of these restrictions

impose a serious limitation on the power and size of

the electronic components which can be used for the

system design.

2.1 In vitro System

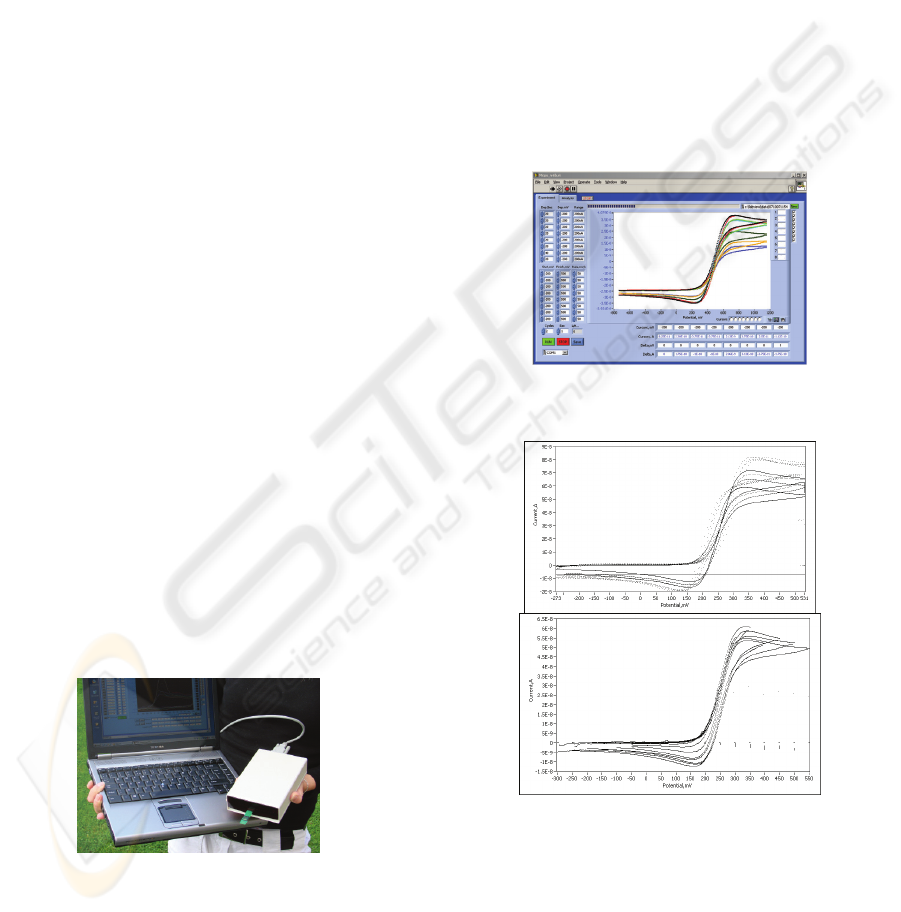

In keeping with these requirements for the in vitro

applications, a multi-channel potentiostatic system,

optimized for operation with an 8 working electrode

on-chip sensing system, has been developed. The

instrument is based on low-noise, high precision,

pico-ampere input current operational amplifiers

AD8602 (leakage current of 200 fA) and Analog

Devices microconverter, ADuC812, which enables

generation of the stimulation signal (via the in-built

DAC), feeds sensing data into the system (via the in-

built 8 channel ADC), and provides preliminary

signal processing and communication with the PC

(via an RS232 communications port). Running on

the PC is dedicated software with user-friendly

graphical interface, which provides final signal

processing and data interpretation. The prototype of

the system, with overall size 170x110x40 mm and

weight 250 g, is shown in figure 3. The associated

user-friendly interface software (developed in

LabVIEW, figure 4) allows the user to specify the

type of voltammetric technique and its setting (start

and finish potential, scan rate for each channel), and

to visualize obtained experimental data.

Figure 3: The multi-channel potentiostatic system suitable

for in vitro applications.

In order to validate and characterize the system,

a microelectrode array was fabricated using CMOS

techniques. It consisted of an array of gold working

electrodes surrounded by a counter electrode. The

final packaged die connects to a PCB dipstick which

allows for easy connection and testing of the sensor

chip. The solutions with analyte can be placed

directly on the sensor, or the dipstick can be

integrated into an associated fluidic system, or it can

be simply immersed into a container with the sample

to be analysed. The performance of the developed

system can be estimated by example of cyclic

voltammetry applied to the 8 Ws in ferrocene

carboxylic acid solution in simultaneous mode. The

measurements that were carried out over different

scan rates are shown in figure 5a, and the

measurements that were carried out over different

start and finish potentials are shown in figure 5b.

These experiments demonstrate that the system’s

current sensitivity is greater than 1nA, with a noise

level less than 50pA p-p.

Figure 4: PC Interface for the multi-channel potentiostatic

system.

a.

b.

Figure 5: Cyclic voltammograms recorded simultaneously

with the instrument for oxidation of Ferrocene carboxylic

acid at an eight microelectrode array: (a) – with different

scan rates set for each channel (from 50mV/s to 400mV/s),

(b) – with different starting and finishing potentials set for

each channel.

MINIATURIZED ELECTROCHEMICAL SENSING SYSTEMS FOR IN VITRO AND IN VIVO BIOMEDICAL

APPLICATIONS

85

2.2 In vivo System

In keeping with requirements for the in vivo

applications, a potentiostatic system based on a PIC

microcontroller, has been developed. This

microcontroller family contains a number of

microcontroller models including those which are

available in a smaller size, consumes less power and

has more RAM memory than the ADuC, making

them more suitable for this application. The

PIC18F2520 has been chosen which features

6x6mm, 1256 bytes RAM and current consumption

of 2.6mA during normal operation. This is in

contrast to the ADuC812 features of 8x8mm, 256

bytes RAM and 6.2mA during normal operation. In

the programming of the microcontroller, close

attention has been given to reduce the power

consumed during device operation by using

appropriate electronic components with power

switch on/off mode and inbuilt microcontroller

possibilities. There are two realizations of this

system. The first one is a PCB-based device with

separate commercially-available low power and

small size ICs forming a one-channel potentiostatic

system in accordance with figure 1. The size of the

system prototype is 12x24 mm, which is suitable for

a variety of in vivo applications. To validate the

performance of the system, cyclic voltammetry was

carried out in 0.5M sulfuric acid solution at a gold

macroelectrode, figure 6.

Figure 6: Cyclic voltammogram for in vivo PCB-based

system at the macro gold electrode in 0.5M sulphuric acid

solution

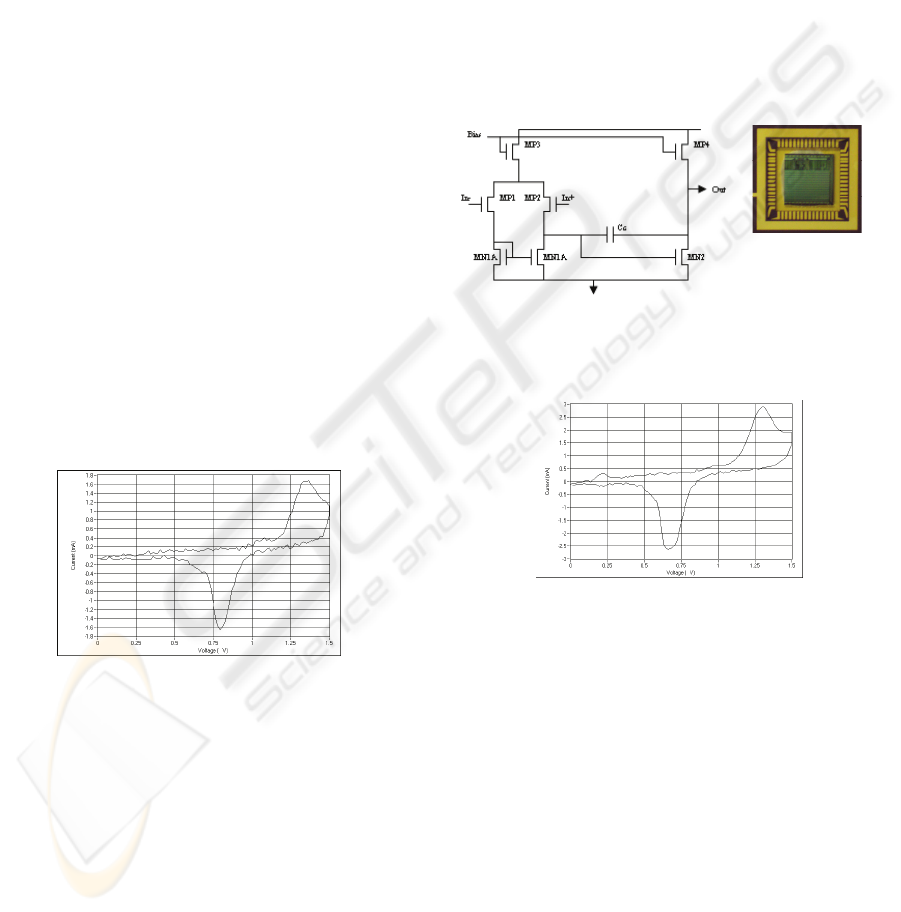

The second in vivo system is a specially

developed on-chip system, which is a realization of

the PCB in vivo device in an integrated single die.

The implementation of the developed system on a

silicon substrate was made by using a C5P0 CMOS

5 micron silicon breadboard. There is a digital core

of 1248 gates and an analog oriented section

containing 32 operational amplifier blocks, 1500

units of poly-poly capacitor, approximately 2MΩ of

resistance in 40 sticks of 6 segments each, and a

range of more specialized components. The

schematic of the breadboard operational amplifier

unit and final chip appearance, are shown in figures

7 and 8 correspondingly. The performance of the on-

chip system can be seen from the example of cyclic

voltammetry of a macro gold W in 0.5M sulphuric

acid solution, figure 9, which substantiates its

operability. At present both of the in vivo systems

have similar performance specification but due to

the initial small batch size, the PCB-based system

costs less. The potential advantages of the on-chip

system over PCB based device (a smaller size, a

reduction in noise and power, a decrease of leakage

current, which leads to an improvement of the

system performance) will be realized when complete

integration of sensor and electronics on one chip is

developed.

Figure 7: P-input CMOS OPAMP. Figure 8: Fabricate

d

on-chip potentiosta

t

die, 8x10mm.

Figure 9: Cyclic voltammogram for in vivo on-chip system

at the macro gold electrode in 0.5M sulphuric acid

solution

3 CONCLUSIONS

Miniaturized sensing systems for in vitro and in vivo

biomedical applications suitable for point-of-care

applications have been presented that will facilitate

early-stage disease diagnosis. The systems are based

on potentiostatic instrumentation, which is

commonly employed with different electrochemical

sensors. For in vitro requirements, an 8 channel PC-

controlled system has been developed, capable of

carrying out a number of sensing methods. For the in

vivo applications, two systems have been realized,

both based on the PIC microntroller. The first is a

PCB with separate commercially-available low

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

86

power and low size ICs forming a one-channel

potentiostatic system. The second is a specially

developed integrated on-chip system. Future work

will include optimization of the developed systems

for specific biomedical application according to end-

user requirements. Additionally for the on-chip

system the chip will be redesigned to improve its

characteristics and reduce the fabrication cost.

ACKNOWLEDGEMENTS

Financial support of this work by CFTD/04/112,

CFTD /05 /122 Enterprise Ireland and National

Access Programme NAP68 projects is gratefully

acknowledged.

REFERENCES

Peng, Y., Hu, C., Zheng, D., & Hu, S. (2008). A sensitive

nitric oxide microsensor based on PBPB composite

film-modified carbon fiber microelectrode. Sensors

and Actuators B-Chemical, in press.

Seo, H., Park, D., Park, J. (2008). Fabrication and

characterization of platinum black and mesoporous

platinum electrodes for in-vivo and continuously

monitoring electrochemical sensor applications. Thin

Solid Films, 516(16), 5227-5230.

Ndamanisha, J. C., & Guo, L. P. (2008). Electrochemical

determination of uric acid at ordered mesoporous

carbon functionalized with ferrocenecarboxylic acid-

modified electrode. Biosensors & Bioelectronics,

23(11), 1680-1685.

Wang, M., & Ha, Y. (2007). An electrochemical approach

to monitor pH change in agar media during plant

tissue culture. Biosensors & Bioelectronics, 22(11),

2718-2723.

McLaughlin, G. W., Braden, K., Franc, B., & Kovacs, G.

T. A. (2002). Microfabricated solid-state dissolved

oxygen sensor. Sensors and Actuators B-Chemical,

83(1-3), 138-148.

Abbaspour, A., & Mirzajani, R. (2007). Electrochemical

monitoring of piroxicam in different pharmaceutical

forms with multi-walled carbon nanotubes paste

electrode. Journal of Pharmaceutical and Biomedical

Analysis, 44(1), 41-48.

Morales, M. D., Serra, B., de Prada, A. G. V., Reviejo, A.

J., & Pingarron, J. M. (2007). An electrochemical

method for simultaneous detection and identification

of Escherichia coli, Staphylococcus aureus and

Salmonella choleraesuis using a glucose oxidase-

peroxidase composite biosensor. Analyst, 132(6), 572-

578.

Shiddiky, M.J.A., Rahman, M.A., Choel, C.S., Shim, Y.

(2008). Fabrication of disposable sensors for

biomolecule detection using hydrazine electrocatalyst.

Analytical Biochemistry, 379(2), 170-175.

MINIATURIZED ELECTROCHEMICAL SENSING SYSTEMS FOR IN VITRO AND IN VIVO BIOMEDICAL

APPLICATIONS

87