COORDINATION OF SELF-OPTIMIZING MECHATRONIC

SYSTEMS

A New Application for Multi-Agent Planning

Benjamin Kl

¨

opper and Wilhelm Dangelmaier

Heinz Nixdorf Instiute, University of Paderborn, F

¨

urstenallee 11, Paderborn, Germany

Keywords:

Self-optimization, Mechatronics, Multi-agent systems, Planning and coordination.

Abstract:

The paradigm of self-optimization introduces flexible and highly adaptive mechatronic systems. During the

exploiation of this flexibility, new problems arise. One of these problems is the coordination of mechatronics

systems and subsystems. This paper introduces the application area self-optimizing mechatronic systems and

identifies the arising coordination problems. Two main scenarios are identified: coordination of autonomous

mechatronic systems and coordination of several subsystems within an autonomous mechatronic system. We

will show that multi-agent technology and in particular multi-agent planning can be applied to solve both

coordination scenarios.

1 INTRODUCTION

Technical systems and machines are designed to ful-

fill tasks for humans. Technological progress continu-

ously extends the spectrum of tasks and improves the

quality of tasks fulfillment. The quality of tasks full-

fillment can be measured in various dimensions, de-

pending on the current area of application. Examples

for such dimensions are: timeliness, resource con-

sumption, processing accuracy (e.g. in case of ma-

chining tools), or comfort and driving pleasure (in

case of vehicles). Mechatronic systems are a rel-

atively new class of technical systems. The term

mechatronics refers to the close integration of elec-

tromechanical systems, electronic and information

technology (Bradley, 1997).

Further advancement in information and commu-

nication technology enables systems to adapt their be-

havior to changing environmental settings and user

preferences. We use the term self-optimization to

characterize such systems. Self-optimizing systems

(Gausemeier et al., 2008) are able to adapt their objec-

tives autonomously. This includes modifying the rel-

ative weighting or ranking of the objectives. Adapt-

ing the objectives results in an adaptation of the sys-

tem behavior. To determine the suitable adaption of

the system behavior, the objectives are used to formu-

late corresponding optimization problems. Their so-

lutions problems indicate the suitable behavior adap-

tations. The adaptations are realized by adapting pa-

rameters (e.g. changing a control parameter) or the

structure of the system (e.g. replacing the current con-

troller).

We understand self-optimization as an iterative se-

quence of three actions:

1. Situation-Analysis – includes the state of the sys-

tem and observations about its environment.

2. Determining the system of objectives.

3. Adapting the system behavior according to the

new objectives.

In this paper we will explore two main theses re-

garding self-optimizing mechatronic systems:

1. Planning extends the steps of self-optimization to

futures states and helps to implement autonomous

determination of objectives

2. The structure of mechatronic systems requires

multi-agent planning

The paper is structured as followed: First it intro-

duces mechatronic systems and their structure in more

details. Then, the following section explains how

planning can be used to implement the determination

of objectives. From classical planning we proceed to

multi-agent planning and show that this discipline has

great potential within the context of self-optimizing

mechatronic systems. Finally we will conclude with

example that illustrates this new application area.

312

Klöpper B. and Dangelmaier W. (2009).

COORDINATION OF SELF-OPTIMIZING MECHATRONIC SYSTEMS - A New Application for Multi-Agent Planning.

In Proceedings of the International Conference on Agents and Artificial Intelligence, pages 312-317

DOI: 10.5220/0001794903120317

Copyright

c

SciTePress

2 STRUCTURING OF

MECHATRONIC SYSTEMS

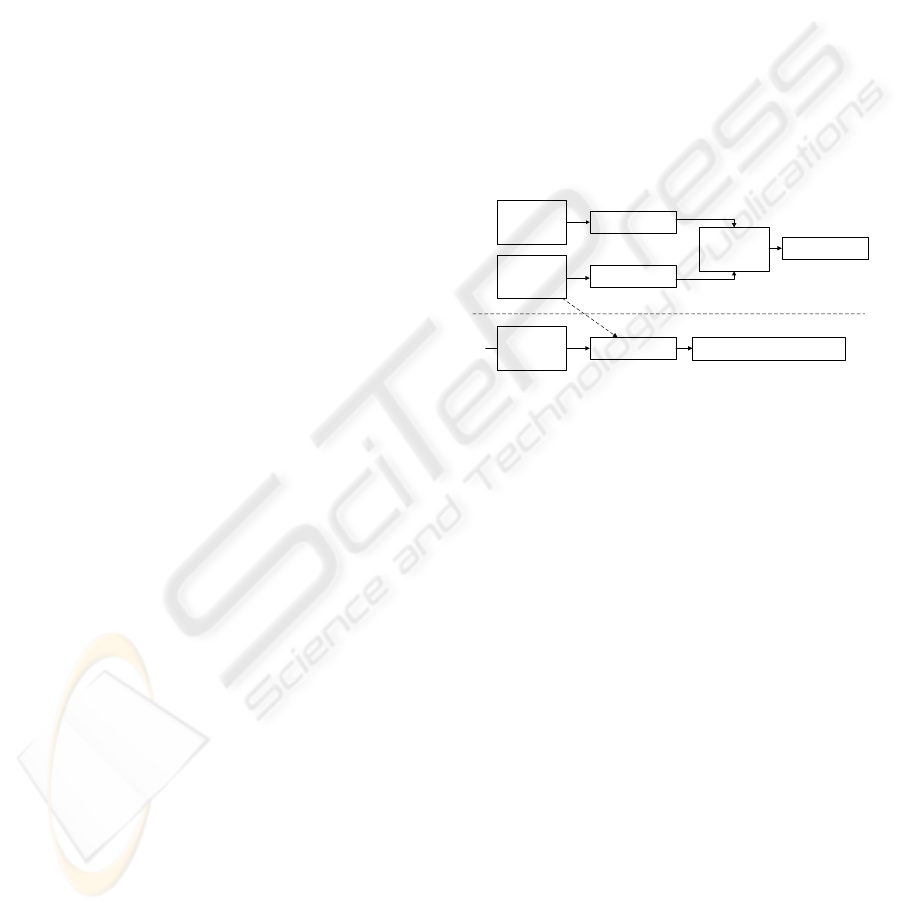

Figure 1 shows an proposal for a hierarchical structur-

ing for mechatronic systems ((VDI), 2004). Mecha-

tronic Function Modules (MFM) are on the lowest

level of the hierarchy. MFM are the elementary type

of mechatronic systems and consist of a mechanic

structure, actuating elements and sensors. The sen-

sors provide information about the environment and

the system for a superimposed information process-

ing, which controls the actuating elements. On the

next level autonomous mechatronic systems (AMS)

integrate several function modules. AMS and MFM

interact by exchange of information. Finally, several

AMS can establish networked mechatronic systems

(NMS). The structuring shows versatile relationships

between mechatronic systems by information, energy

and material flow. These relationships and interac-

tions require coordination.

Figure 1: Structure of a complex mechatronic system.

3 PLANNING FOR

SELF-OPTIMIZATION

Planning in Artificial Intelligence refers to the task

of finding a sequence of actions which lead from a

given initial state to a desired goal state (Russell and

Norvig, 2003). Planning languages are used to for-

malize this problem and enable the algorithmic so-

lution. Planning languages usually consist of two

main elements: state representation and action rep-

resentation. While the states represent snapshots of

the world, actions define the dynamic component of

the planning problem. An action defines which ac-

tivities are applicable in a given state (via precondi-

tion) and which consequences arise from this activ-

ity (via effects). During the last years, the Planning

Domain Definition Language (PDDL) (Gerevini and

Long, 2005) established a de facto standard in aca-

demic research.

In the context of self-optimization planning can

be interpreted in a different way. For each action plan-

ning locally determines (on a time line) the objectives.

Since the planning procedure builds a complete se-

quence of activitivies, this local system of objectives

is coherent with future steps and situations in the plan.

Thus, planning is a powerful mechanism in the con-

text of self-optimization.

To use this powerful mechanism, the planning

models from artificial intelligence must be mapped

onto the abilities and behaviors of mechatronic sys-

tems. Thus, the next section introduces a classical

methodology for the design of mechatronic systems.

Subsequently, the central modeling elements of the

methodology are mapped onto the planning of artifi-

cial intelligence.

3.1 Classic Design of Mechatronic

Systems

A technical system fulfills its tasks by the implemen-

tation of a behavior. During the design of a mecha-

tronic system the behavior is usually modeled as a

black box. The transformation of incoming informa-

tion, energy and material flow into outgoing flows is

focussed. The system’s designer defines a function

hierarchy and splits the main tasks into sub-functions

until a sufficient amount of details is achieved (Pahl

and Beitz, 07). According to the definition of the

function hierarchy, the subfunctions are examined for

relationships, dependencies and conflicts. The de-

signer searches for a feasible sequence of subfunc-

tions to implement the desired behavior. This se-

quence may contain loops and branches. Finally, the

designer identifies possible implementations and so-

lutions of the subfunctions.

3.2 Planning Models for

Self-Optimizing Mechatronic

Systems

Self-optimizing mechatronic systems are able to

adapt their behavior to the current operation condi-

tion and varying external preferences (e.g. defined by

a user or surrounding systems) regarding the possible

quality dimensions of their behavior. For this purpose,

these mechatronic systems feature several implemen-

tations of their sub-functions. We refer to these im-

plementations as operation modes.

To achieve maximum flexibility and adaptability

COORDINATION OF SELF-OPTIMIZING MECHATRONIC SYSTEMS - A New Application for Multi-Agent Planning

313

the mechatronic systems must be able to identify the

sequence of operation modes that provides the best

quality regarding the current external objective and

the current environmental influences. This problem

leads directly to the planning problem in artificial in-

telligence.

If the operation modes of a mechatronic system

are mapped onto the action definition of a planning

language, artificial intelligence planning can be ap-

plied to determine the currently best sequence of op-

eration for a given overall task. An example for such

a task is the transportation of a passenger from a start

station to a destination station by a railway vehicle.

The initial state is the current position of the vehicle,

the goal state is the passenger at his destination. Pos-

sible quality dimension or objectives are travel time,

comfort and energy consumption. The vehicle’s ac-

tive suspension may feature different combinations of

comfort and energy consumption for certain environ-

mental circumstances (e.g. track conditions). The fol-

lowing listing shows an action definition for a driving

on track section with an active suspension:

(:action drive

:parameters

(?v vehicle ?l1 ?12 - location)

:precondition

(and at ?r ?l1)

(>=(energy_storage ?v)

(*distance ?l1 ?l2)

(suspension-active ?v)

:effect

(and (not (at ?v ?l1))

(at r? ?l2)

(increase (total-energy-used)

(*(distance ?l1 ?l2)

(suspension active ?v)))

(decrease (energy_storage ?v)

(*(distance ?l1 ?l2)

(suspension-active *v)))

)

The precondition of the action assures that the ve-

hicle has sufficient energy to travel between the two

locations l1 and l2. In the effects the vehicle moves

from its origin l1 to l2 and the state of charge of the

energy storage is reduced by the energy consumption

of travelling the distance between l1 and l2 with acti-

vated suspension.

Beside fundamentally different implementations

of sub-functions (e.g. active and passive suspension)

the activities can also differ just in certain parame-

ters (e.g. operating pressures). To select appropriate

parameter settings to define actions is difficult. Fig-

ure 2 shows a possible systematic approach to deter-

mine reasonable operation modes. The first steps in

the definition of operation mode is the selection of

characteristic environmental influences and a reason-

able configuration of objectives (e.g. weighting of en-

ergy consumption vs. comfort). The environmental

influences will be part of the precondition of the ac-

tions while the objectives configuration label the ac-

tions. An optimization (e.g. (Witting et al., 2008) is

used to determine continuous parameters of the sys-

tem behavior and to provide information on how good

the objectives can be achieved under the character-

istic environmental influences and with the predeter-

mined weightings. Optimal control (Kirk, 1970) even

offers a way to predetermine optimal continous state

trajectories regarding a cost functions. During oper-

ations the expected environmental influences must be

mapped to a characteristic influence from optimiza-

tion to determine the effects of an action. This prob-

lem is a classification problem.

Objective

Configuration

Characteristical

environmental

influences

Action Precondition

Operation modes /

Actions

Optimization

Action Effects

Current

environmental

influences

Classification

Action with

Current Effects

Run Time Design Time

Figure 2: Action Definition by Offline Optimization.

4 MULTI-AGENT PLANNING

FOR SELF-OPTIMIZATION

The structuring of mechatronic systems clearly shows

that mechatronic systems do not act isolated in their

environment. Instead, there are various interactions

and interdependencies. Thus, the activities and the

planning of mechatronic systems have to be coordi-

nated. Witteveen et. al. define multi-agent plan-

ning as the combination of planning and coordination

(Weerdt et al., 2005).

Multi-agent systems (MAS) and agent based sys-

tems are recognized as a new approach to the control

and coordination of mechatronic systems (cf. (Baum

et al., 2002; Al-Safi and Vyatkin, 2007)). Anyhow,

multi-agent planning is rarely used in mechatronics

today.

In the context of mechatronic systems two funda-

mentally different application scenarios can be distin-

guished:

1. Multi-agent planning for autonomous mecha-

tronic systems

2. Multi-agent planning for function modules within

an autonomous mechatronic systems

ICAART 2009 - International Conference on Agents and Artificial Intelligence

314

4.1 Multi-agent Planning for AMS

Each autonomous mechatronic system possesses an

individual system of objectives. Thus, they act self-

ishly and cooperation is an instrument to improve

their local plan quality. In the context of self-

optimizing mechatronics we distinguish three types of

cooperative actions. In job swapping an AMS trans-

fers a job (e.g. a transport job or machining work-

piece) to another AMS, which is more suitable. Rea-

sons may be the abilities of the systems or their cur-

rent local plans. For instance, a machining center of-

fers better processing accuracy or a vehicle already

passes the start and destination of a transport job.

AMS may also outsource operations. This coopera-

tion action requires extenisve coordination. The plan-

ning system has to embed an externally executed op-

eration into its current local plan. Thus, timing is cru-

cial. The third coordination activity is the alignment

of activities. The alignment of activities changes the

cost-benefit ratio of an activity. Mainly, the alignment

of activities refers to a chronological rearrangement

of activities or a change of the activity’s subject (e.g.

a workpiece). For example such rearrangements help

to avoid set-up cost.

To realize these cooperation actions during the

planning process, a phase model according the

Wooldridge and Jennings (Wooldridge and Jennings,

1998) seems suitable: Recognize cooperation poten-

tial,team formation, plan formation, and team action.

To recognize possible cooperation action, these

actions have to be integrated into the local planning

problem of the AMS. In case of the exchange of jobs

the integration is straight forward. The systems can

compare the quality of a plan with and without a job.

Data clustering can be used to select candidate jobs.

Under the assumption that jobs which differ largely

from the other job cause large costs, small clusters

apart from the residual data set are good candidates.

The external execution of sub-functions is just a spe-

cial type of sub-function. They can be integrated with

expected cost-benefit ration in the local planning pro-

cess. Conditional actions can model the alignment

of activities, with special effects for aligned and un-

aligned actions.

Multi-agent technology offers various methods

to implement team formation and plan formation.

Matchmaking mechanisms like middle agents (Sycara

et al., 1997) or distributed matchmaking (Ogston and

Vassiliadis, 2002) can identify possible cooperation

partners. Negotiations (Faratin et al., 1998), auctions

(David et al., 2002) and voting (Conitzer, 2008) can

be used to provide an agreement about joined plans

and compensations.

4.2 Multi-agent Planning for Function

Modules

The coordination of function modules differs largely

from the coordination of AMSs. The composition of

the systems is already known, no method for the iden-

tification of cooperation partners is required. Further-

more all function modules are committed to the sys-

tem of objectives of the AMS. Thus, the purpose of

the coordination of function modules is to achieve a

behavior that optimizes the system of objectives of

the overall system.

For this problem, centralized planning could be a

feasible approach. However, this approach has sev-

eral disadvantages. First, the definition of complex

centralized planning models is more time-consuming

than the definition lean localized planning models.

Secondly, the centralized approach is less flexible.

Every change in the composition of the function mod-

ules requires a redesign of the planning models. Fi-

nally, the paradigm of divide-and-conquer offers bet-

ter performance. In distributed planning, paralleliza-

tion speeds-up the processing and splitting up a cen-

tralized planning problem into several smaller local

problems reduces the complexity. For an example, we

consider a system with two function modules. Each

function module can carry out different modes of op-

erations. In a decentralized formulation two state-

action trees with 2

d

nodes can be constructed. In a

centralized 4

d

state-action combinations have to be

considered. The better performance of localized and

distributed planning has to be balanced with the coor-

dination efforts.

In (Kl

¨

opper et al., 2008a) we introduced a for-

mal framework, which enables the function mod-

ules to consider the social consequences of their

activities. The basic model element in this for-

mal framework are conditional evaluation functions:

eval

ω

∆

(om

f m

|om

0

f m

0

, e) defines how good an operation

mode of function module f m achieves an objective

ω under the environmental influences e if function

module f m

0

carries out an operation mode om’. In

(Kl

¨

opper et al., 2008b) we introduced a systematic

approach to map the objectives of the AMS to the

objectives of the function modules and thus provided

(in combination with the formal framework) planning

metrics for local planning processes.

We suggest a planning process that resembles the

popular Generalized Partial Global Planning (GPGP)

(Lesser et al., 2004). The conditional evaluation func-

tions are equivalent to the relationships of GPGP. In

difference to GPGP, the conditional evaluation func-

tions are already considered during the local plan-

ning based on the expected behavior of other function

COORDINATION OF SELF-OPTIMIZING MECHATRONIC SYSTEMS - A New Application for Multi-Agent Planning

315

modules. The seamless integration of the interaction

into the local planning requires no special coordina-

tion strategies like in GPGP. The GPGP coordination

strategies work only on single actions, while the con-

ditional evaluation functions in combination with re-

planning and full knowledge of all local plans, en-

ables simultaneous coordination of all actions within

a plan horizon. The feasibility of each local plan can

also be assured.

Another problem is to assure feasibility over all

local problems. This problem occurs, if the function

modules share some resources like energy. Here we

suggest a central coordination agent which governs

the shared resources. If the coordination agent detects

a shortage, it asks the function module agents for a

modification of their behavior. The conditional eval-

uation functions enable the comparison of the sug-

gested behaviors. Thus, the coordination agent selects

the behavior modifications, which have the smallest

negative effect on the overall system performance.

5 APPLICATION SCENARIO

Figure 3 shows how the two multi-agent planning

problems in the context of the RailCab-system can

be coupled in a hierarchical process. The RailCab-

system is an innovative railway system. Autonomous

vehicles – RailCabs – fulfill transportation jobs with a

demand oriented transport disposition. Thus, no fixed

schedule exists. The RailCabs feature a number of

innovative function modules: an active suspension,

an air gap adjustment systems (AGAS) and a linear

drive.

The process hierarchy follows the structuring of

mechatronic systems. On the top level (networked

mechatronics systems) the RailCabs perform the co-

operative actions transportation job swapping and

convoy formation. In the decentralized job swapping

each vehicle constantly analyzes it’s local plan. It

searches for jobs that cause inappropriate costs, e.g.

jobs that cause large detours for picking up and/or de-

livering a single passenger. This kind of job is ad-

vertised for bids of other vehicles. An implemen-

tation of the job swapping reduces the cost of track

utilization by 15% in average during simulation ex-

periments. Details about job swapping can be found

in (Danne et al., 2006). The formation of convoys

reduces energy costs for non-leading vehicles in the

convoy. Assuming a cost reduction of 50%

1

, a plan-

ning procedure reduces travelling costs from 15% up

to 20% over all vehicles in the convoy, considering

1

on perfect flat tracks the reduction is 80% due to slip-

stream effect

costs for necessary detours in order to join the convoy

(D

¨

urksen et al., 2008).

N

M

S

etworked

echatronic

ystem

A

M

S

utonomous

echatronic

ystem

M

F

M

echatronic

unction-

odules

Cooperative Planning for AMS:

- Job Swapping

- Convoy Formation

Route Planning

Cooperative Planning for

Function Modules

Mandatory

Stops

Current

Route

Track Sequence

Figure 3: Hierarchical Planning Process in the RailCab Sce-

nario.

The cooperative planning process for AMS cre-

ates a number of mandatory stops for each vehicle (to

pick-up and disembark passengers). A conventional

route planning process creates a route to connect the

mandatory stops. The resulting sequence of tracks

is input for the cooperative planning process for the

function modules. Each function module locally con-

structs a plan for the activities on this track sequence

with respect to the expected behavior of its fellow

modules. An example of a planning process on this

level is the linear drive, which has to select an accel-

eration profile for each track section. The propulsion

module may take the effects on the active suspension

(high velocity implies high energy consumption) into

consideration. When each local plan is constructed,

the coordination after planning takes places.

6 CONCLUSIONS

In this paper we introduced a new application area

for multi-agent planning: self-optimizing mecha-

tronic systems. The new application area was struc-

tured and first results of multi-agent planning in self-

optimizing mechatronic systems were introduced. In

our opinion the application of multi-agent technology

to mechatronic systems enables the full potential of

the paradigm self-optimization. Two different appli-

cation scenarios for multi-agent planning were intro-

duced and first results were presented. With the com-

bination of self-optimization and multi-agent plan-

ning a new class of technical products with new levels

of utility becomes possible.

ICAART 2009 - International Conference on Agents and Artificial Intelligence

316

ACKNOWLEDGEMENTS

This contribution was developed in the course

of the Collaborative Research Centre 614 Self-

Optimizing Concepts and Structures in Mechanical

Engineering funded by the German Research Foun-

dation (DFG). Further information can be found at

www.sfb614.de/en.

REFERENCES

Al-Safi, Y. and Vyatkin, V. (2007). An ontology-based

reconfiguration agent for intelligent mechatronic sys-

tems. In Holonic and Multi-Agent Systems for Manu-

facturing, number 4569 in Lecture Notes In Artificial

Intelligence, Berlin. Springer Verlag.

Baum, W., Bredenfeld, A., Hans, M., Hertzberg, J., Rit-

ter, A., Schonherr, F., Christaller, T., and Schraft, R.

(2002). Integrating heterogeneous robot and software

components by agent technology. In Robotik 2002,

volume 1679 of VDI-Berichte. VDI Verlag GmbH.

Bradley, D. (1997). The what, why and how of mecha-

tronics. Engineering Science and Education Journal,

6(2):81–88.

Conitzer, V. (2008). Comparing multiagent systems re-

search in combinatorial auctions and voting. In

10th International Symposium on Artificial Intelli-

gence and Mathematics (ISAIM-08).

Danne, C., D

¨

uck, V., and Kl

¨

opper, B. (2006). Selfish moti-

vated cooperative planning in cross networked mecha-

tronic system. International Transactions on Systems

Science and Applications, 2(2):221–225.

David, E., Azoulay-Schwartz, R., and Kraus, S. (2002).

Protocols and strategies for automated multi-attribute

auctions. In Proc. First Joint Conf. on Autonomous

Agents and Multiagent Systems, pages 77–85.

D

¨

urksen, D., Kl

¨

opper, B., Ruth, D., and Thonemann, C.

(2008). Combining distributed matchmaking and

clustering to prune the solution space in distributed

optimization problems – demonstrated in the railcab

system. In Eighth International Conference on Hybrid

Intelligent Systems, pages 108–113,, Barcelona. IEEE

Computer Society, IEEE Computer Society Press.

Faratin, P., Sierra, C., and Jennings, N. R. (1998). Nego-

tiation decision functions for autonomous agents. In-

ternational Journal of Robotics and Autonomous Sys-

tems, 24:3–4.

Gausemeier, J., Kahl, S., and Pook, S. (2008). From

mechatronics to self-optimizing systems. In 7. Inter-

nationales Heinz Nixdorf Symposium, volume 223 of

HNI-Verlagsschriftenreihe, Paderborn. Heinz Nixdorf

Institut, HNI Verlagsschriftenreihe, Paderborn.

Gerevini, A. and Long, D. (2005). Plan constraints and

preferences in pddl3. Technical report, Department

of Electronics for Automation, University of Brescia.

Kirk, D. E. (1970). Optimal control theory. Prentice-Hall,

Englewood Cliffs, NJ.

Kl

¨

opper, B., Romaus, C., Schmidt, A., and V

¨

ocking, H.

(2008a). A multi-agent planning problem for the co-

ordination of functions modules. In Self-Optimizing

Mechatronic Systems: Design the Future.

Kl

¨

opper, B., Romaus, C., Schmidt, A., V

¨

ocking, H., and

Donoth, J. (2008b). Defining a system of objec-

tives for multi-agent coordination of function mod-

ules within mechatronic systems. In : Proceedings

of IDETC/CIE 2008 ASME 2008 International Design

Engineering Technical Conferences & Computers and

Information in Engineering Conference, volume . uk,

uk.

Lesser, V., Decker, K., Wagner, T., Carver, N., Garvey, A.,

Neimann, D., Prassad, M. N., Raja, A., Vincent, R.,

Xuan, P., and Zhang, X. (2004). Evolution of the

gpgp/taems domain-independent coordination frame-

work. Autonomous Agents and Multi-Agent Systems,

9:87–143.

Ogston, E. and Vassiliadis, S. (2002). Unstructured

agent matchmaking: experiments in timing and fuzzy

matching. In SAC ’02: Proceedings of the 2002 ACM

symposium on Applied computing, pages 300–305,

New York, NY, USA. ACM.

Pahl, G. and Beitz, W. (07). Engineering Design: A Sys-

tematic Approach. Springer.

Russell, S. J. and Norvig, P. (2003). Artificial Intelligence:

A Modern Approach. Pearson Education.

Sycara, K., Decker, K., and Williamson, M. (1997).

Middle-agents for the internet. In Proceedings of

IJCAI-97.

(VDI), V. D. I. (2004). Vdi-guideline 2206 - design method-

ology for mechatronic systems. Technical report,

Verein Deutscher Ingenieure (VDI), Beuth-Verlag,

Berlin.

Weerdt, M., Mors, A., and Witteveen, C. (2005). Multi-

agent planning - an introduction to planning and co-

ordination. Technical report, Dept. of Software Tech-

nology, Delft University of Technology.

Witting, K., Schulz, B., Dellnitz, M., Bcker, J., and

Frhlecke, N. (2008). A new approach for online mul-

tiobjective optimization of mechatronic systems. In-

ternational Journal on Software Tools for Technology

Transfer STTT, 10:223–231.

Wooldridge, M. and Jennings, N. R. (1998). Formalizing

the cooperative problem solving process, pages 430–

440. Morgan Kaufmann Publishers Inc., San Fran-

cisco, CA, USA.

COORDINATION OF SELF-OPTIMIZING MECHATRONIC SYSTEMS - A New Application for Multi-Agent Planning

317