A FUZZY-GUIDED GENETIC ALGORITHM FOR QUALITY

ENHANCEMENT IN THE SUPPLY CHAIN

Cassandra X. H. Tang and Henry C. W. Lau

Department of Industrial and Systems Engineering, The Hong Kong Polytechnic University

Hung Hom, Kowloon, Hong Kong, China

Keywords: Global optimization, Supply chain management, Advanced manufacturing technologies.

Abstract: To respond to the globalization and fierce competition, manufacturers gradually realize the challenge of

demanding customers who strongly seek for products of high-quality and low-cost, which implicitly calls

for the quality improvement of the products in a cost-effective way. Traditional methods focused on

specified process optimization for quality enhancement instead of emphasizing the organizational

collaboration to ensure qualitative performance. This paper introduces artificial intelligence (AI) approach

to attain quality enhancement by automating the selection of process parameters within the supply chain.

The originality of this research is providing an optimal configuration of process parameters along the supply

chain and delivering qualified outputs to raise customer satisfaction.

1 INTRODUCTION

World has witnessed the increasing use of Artificial

Intelligence (AI) for operations management(OM)

with the purpose of finding optimal solutions to

various problems including quality assurance along

the supply chain (Kobbacy et al., 2007).

Manufacturers therefore face the challenge of

demanding customers who strongly seek for

products of high-quality and low-cost, which

implicitly calls for the quality improvement of the

products in a cost-effective way. One problem is that

different combinations of parameter setting within

diverse processes involved in a supply chain

network may affect the quality of the finished

products to a great extent, whereas the engineers

always keep different views upon these settings by

their personal experiences. Hence it is crucial to find

out the optimal parameter settings for the

manufacturing processes regarding the experts’

knowledge in order to obtain better productivity and

quality. The paper thus presents a fuzzy guided-

genetic algorithm (GA) to identify possible solutions

for quality enhancement in supply chain network.

2 LITERATURE REVIEW

All the organizational activities can be described by

processes and are characterized by a large number of

interdependent sub-processes with assorted factors

that influencing the quality level (Bernardy and

Scherff, 1998). Quality assurance can be attained by

supervision, review of historical data records and the

assignment of domain experts (Heinloth, 2001).

Optimal supply chain performance requires the

overview of individual process parameters on

various functional levels, from the shop floor to the

whole organization. Therefore AI techniques are

raised to complement the conventional techniques in

optimizing the processes involved with better-

finished quality (Yang et al., 2007). The advantage

of knowledge-based systems to assist engineers

solving decision-making problems on manufacturing

activities is gradually realized and developed by

researchers (Bayraktar, 1998; Tana et al., 2006).

GA and Fuzzy theory have been proven to excel

in solving combinatorial optimization problems

(Wang et al, 1998; Yu et al., 2006; Chiang et al.,

2007; Lau et al., 2009). Hwang and He (2006)

suggest that GA makes no limitation on the search

space of optimization problems. Besides, GA

searches for the optimum solutions through a

population of solutions instead of a single solution,

which makes it more possible to obtain the optimum

solutions or near optimum solutions.

Our research is intended to propose a framework

of intelligent system for process knowledge

85

Tang C. and Lau H. (2009).

A FUZZY-GUIDED GENETIC ALGORITHM FOR QUALITY ENHANCEMENT IN THE SUPPLY CHAIN.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Artificial Intelligence and Decision Support Systems, pages

86-90

DOI: 10.5220/0001865100860090

Copyright

c

SciTePress

integration, generating a set of fuzzy-represented

rules for enhancing the finished quality along the

entire workflow.

3 THE KNOWLEDGE-BASED

FUZZY-GA FRAMEWORK

3.1 Chromosome Encoding

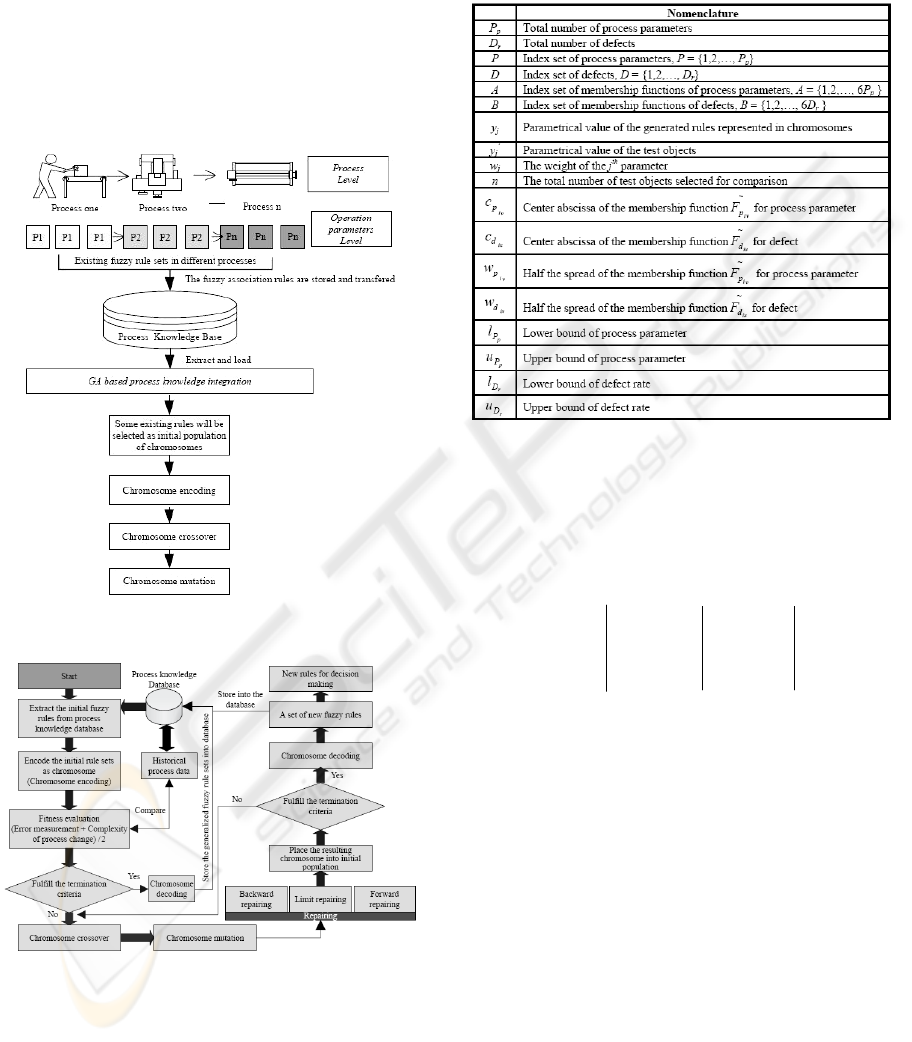

Figure 1: The proposed framework.

Figure 2: Information flow of the proposed algorithm

(Reference: Ho et al, 2008).

Fig. 1 depicts the overview of the entire proposed

knowledge-based framework, while Fig. 2 shows the

corresponding information flow.

The initial rules extracted from process

knowledge base are used to form the initial

population of the GA. The first issue is chromosome

encoding.

Table 1: Relevant Notations.

Definition 1.

{

}

MC

h

,...,2,1

=

represents the index set

of chromosomes where M is the total number of

chromosomes in the population.

Definition 2.

mt

G

×

represents a gene matrix generated

for the population where

()

11 12 1 11 12 1 11 12 1 11 12 1

21 22 2 21 22 2 21 22 2 21 22 2

12 12 12 12

()()()()

abcd

abcd

mw

m m ma m m mb m m mc m m md

iu m a ix m b iy m c iv m z

pp pdd dkk kqq q

pp pdd dkk kqq q

G

pp pdd dkk kqq q

pdkq

×

××××

⎡

⎤

⎢

⎥

⎢

⎥

=

⎢

⎥

⎢

⎥

⎢

⎥

⎣

⎦

=

…………

…………

…………

,, ,,

,, ,,

,,,

pp r r

iv

iv P P ix D D

i piv i p i d ix i d ix

p random l u d random l u

kckwqcqw

τλτλ

⎡⎤

⎡⎤

==

⎣⎦

⎣⎦

====

, , , , , 1,3,5,......;

2, 4,6,......; , , , 6 , 6

h

p

rp r

iC vPxDyAzB

mMaPbDc Pd D

τ

λ

∀∈ ∀ ∈ ∀ ∈ ∀ ∈ ∀∈ =

======

Note that the decoding method of an element in the

first sub-matrix

(

)

bm

iv

p

×

or second sub-matrix

(

)

sm

ix

d

×

of

wm

G

×

to a linguistic variable is given by

(i) 0: ignore, (ii) 1: low, (iii) 2: medium, and (iv) 3:

high. For any row of the third sub-matrix

()

iy

me

k

×

of

wm

G

×

, a group of six consecutive values

(6 5), (6 4), (6 3), (6 2), (6 1), (6 )iiiiii

kkkkkk

ρρρρρρ

−−−−−

in the matrix

forms a single set

{}

~

,,,, ,

iv iv iv iv iv iv iv iv iv

ppppppppp

Fcwwcwcww=− + for

ICEIS 2009 - International Conference on Enterprise Information Systems

86

process parameter p

v

where

,......3,2,1=

ρ

. Also, for

any row of the fourth sub-matrix

()

nm

iz

q

×

of

wm

G

×

, a group of six consecutive values

)6(),16(),26(),36(),46(),56(

ρρρρρρ

iiiiii

qqqqqq

−−−−−

in the

matrix forms a single set

{}

ixix

x

iix

x

iix

ix

x

ix

i

ddddddddd

wwcwcwwcF ,,,,,

~

+−= for

defect rate d

x

where

,......3,2,1

=

ρ

. For both two

cases, there are totally 6 genes in the sets of

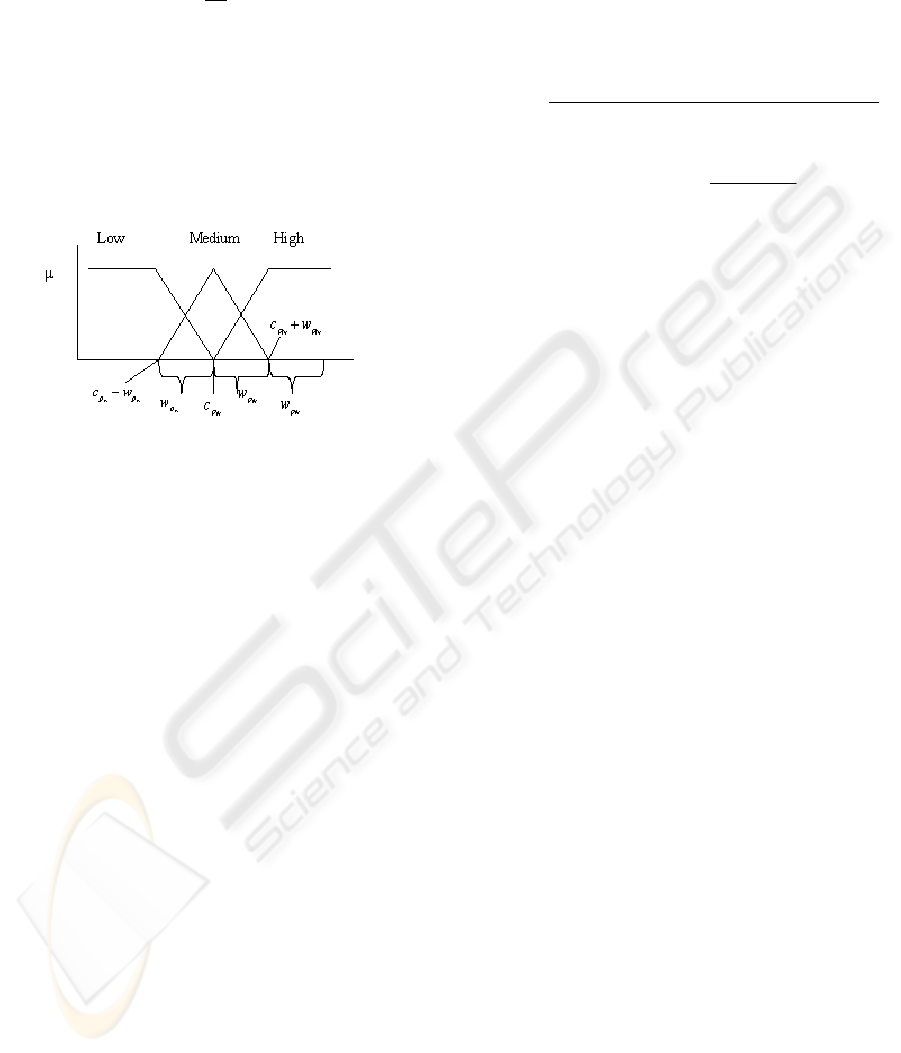

membership functions shown in Fig. 3.

Figure 3: Membership functions of process parameters.

~

v

i

p

F consists of aggregated membership functions

which relate to a fuzzy rule set is assumed to be

isosceles-triangle functions.

v

i

p

c is the center abscissa of

~

v

i

p

F .

v

i

p

w represents half the spread of

~

v

i

p

F .

In “

v

i

p

c

”, “p

iv

” indicates that the v-th feature test is

included, while i specifies the order of all the

condition levels of each feature test. For instance,

1i

p

c stands for the center abscissa of the 1st process

test, within the whole membership function matrix.

Definition 3.

1×m

B denotes a random number

matrix generated for selection and crossover where

11 ()mmiBb×× =

[]

MmCirandomb

hi

=∈∀= ,,1,0

.

Definition 4.

{

}

SC

ch

,.....,2,1

_

= denotes the

index set of the chosen chromosomes in the

crossover where S is the total number of chosen

chromosomes

Definition 5.

wm

G

×

′

indicates the gene matrix in

which the Q chromosomes chosen in crossover are

stored where

()

'(')(')(')(')

m w iu m a ix m b iy m c iv m z

G pdkq

×××××

=

3.2 Fitness Evaluation

To have a good set of process parameters, the

genetic algorithm selects the best chromosome for

mating according to the fitness function suggested

below.

Fitness Funtion accuracy with error rate

=

objects correctly matched within error range

total number of objects

Accuracy =

where

n

yy

w

jj

m

j

j

2

)'(

)( rateError

2

1

−

=

∑

=

ε

Each chromosome is evaluated by calculating its

mean-square error for the error measurement. As

each chromosome is represented as the fuzzy rule,

the quality of the chromosome is then validated by

comparing its defuzzified output with the actual

output of the test samples. The centre of gravity

(COG) is used as the defuzzification method to

obtain the crisp values of the finished quality level.

3.3 Chromosome Crossover

Crossover is a genetic operation aiming at producing

new and better offspring from the selected parents,

while the selection is determined by a crossover rate.

The current crossover methods include single-point

crossover, two-point crossover, multi-point

crossover, uniform crossover, random crossover, etc.

In our paper Uniform crossover is selected.

3.4 Chromosome Mutation

Mutation is intended to prevent all solutions in the

population from falling into the local minima. It

does this by preventing the population of

chromosomes from becoming too similar to each

other, which might slow down or even stop

evolution. Mutation operation randomly changes the

offspring resulting from crossover, given that the

value of the mutation rate must range within 0 and 1.

In our paper a bit-flip mutation is used.

3.5 Chromosome Repairing

If the membership function is not in ascending order,

the new offspring should be modified by exchanging

the gene order in accordance with the definition of

{}

~

,,,, ,

iv iv iv iv iv iv iv iv iv

ppppppppp

Fcwwcwcww=− +

A FUZZY-GUIDED GENETIC ALGORITHM FOR QUALITY ENHANCEMENT IN THE SUPPLY CHAIN

87

4 CASE EXAMPLE AND

DISCUSSION OF RESULTS

ABC Co. Ltd. is one of the leading manufacturers of

sliders for computer disk drives. ABC offers a wide

range of magnetic head-gimbal assembly, head-stack

assembly and small spindle motors to different

magnetic recording media industries. The workflow

starts from receiving the order; and the wafer is the

raw material to be processed to the slider under

different processes. When the integrated workflow is

finished, the specifications of the finished products

in term of quality features are also recorded in order

to investigate the correlation between process

parameters and finished quality. The modifications

of the process parameters along the logistics

workflow will be suggested to minimize the defects

in every stage within the workflow based on the

generalized fuzzy rules in proposed system. In order

to illustrate the effectiveness of the proposed fuzzy–

Genetic algorithm for knowledge processing, the

algorithm has been applied for setting the parameters

for the reactive ion etching process. The process

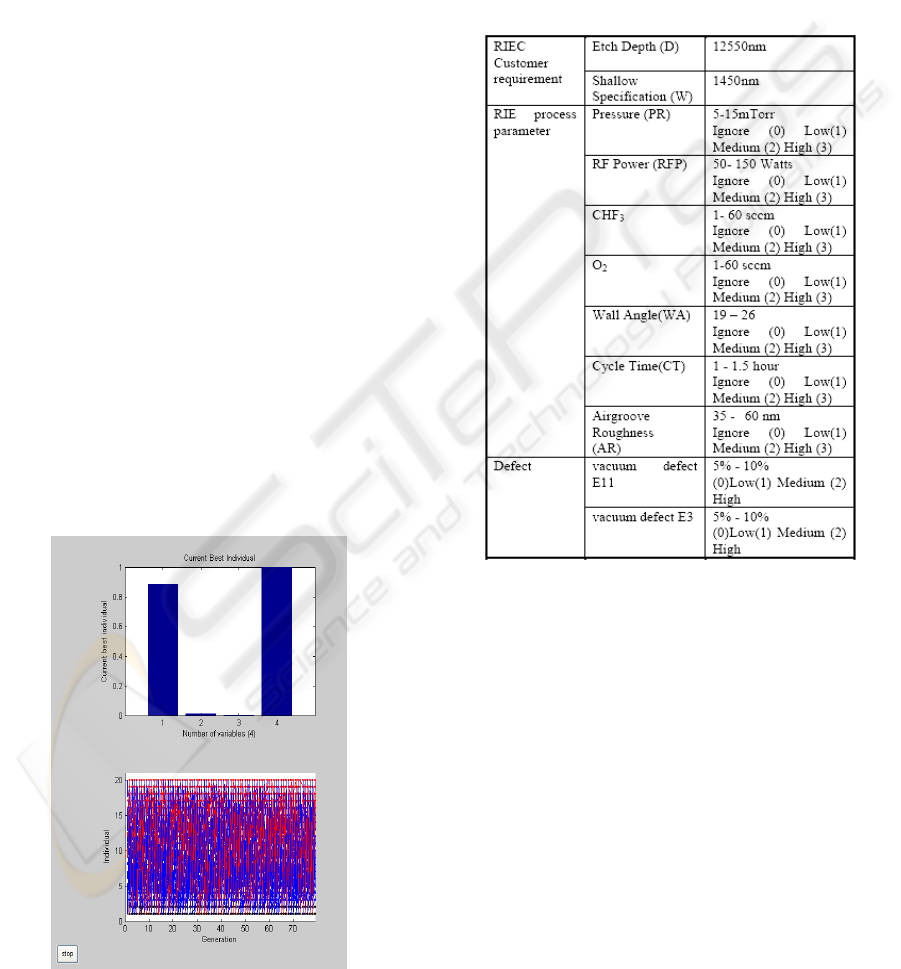

parameter domain (listed in Table 2) contains 65

cases from a manufacturer of magnetic hard disks.

The proposed approach was implemented in MatLab

2007, and the code is executed by a regular PC. GA

will be deployed to find out the optimal process

parameter settings. In the experiments, the operation

frequency for uniform crossover and mutation was

set at 0.8 and 0.01 respectively. The stopping

criterion is set as 100 generations.

Figure 4: Numbers of generations with respect to best

individual and genealogy.

The top left graph of Fig. 4 plots the expected

number of children versus the raw scores at each

generation and the genealogy of individuals. The

best individual is obtained by plotting the vector

entries of the individual with the best fitness

function value in each generation. It is found that RF

Power (variable 1) and O

2

(variable 4) are the best

individuals. Bottom left graph of Fig. 4 plots the

genealogy of individuals.

Table 2: Fuzzy terms of the case parameters.

The process parameter generated by Fuzzy-GA is

above 95% matched with the experiment done by

Winnall and Winderbaum (2000) and it shows that

the result is promising.

5 CONCLUSIONS

In this paper, the design and implementation of a

process knowledge integration system, incorporating

the fuzzy theory and GA to attain quality

improvement in industrial processes, is introduced.

Implementing the proposed decision support model

in the slider manufacturer through the demonstration

in the case study has been successful. The

significance of this paper is related to the

introduction of a knowledge discovery approach to

support the optimization process based on expert

advice derived from past experience, capitalizing on

ICEIS 2009 - International Conference on Enterprise Information Systems

88

the essential features and capabilities of the essential

features of a knowledge representation technique

and optimization technology. The principles and

techniques can be extended to different industries

with modifications to the fitness function and

structure of chromosome. By incorporating the error

measurement and complexity of process change into

the fitness evaluation, the generalized fuzzy rule sets

can be less complexity and higher accuracy. An

extension of different measures can also be

incorporated in order to improve the quality of

generalized rules. Future work will entail other

fuzzy learning methods to dynamically adjust the

membership functions of various process parameters

for enhancing the accuracy of the system.

ACKNOWLEDGEMENTS

The authors wish to thank the Research Committee

of The Hong Kong Polytechnic University for the

support of this research.

REFERENCES

Bayraktar, D. (1998), A knowledge-based expert system

approach for the auditing process of some elements in

the quality assurance system, Int. J. Production

Economics, vol. 5657, pp. 37-46.

Bernardy, G. and Scherff, B. (1998), SPOC – process

modelling provides on-line quality control and

predictive process control in particle and fibreboard

production, Proceedings of the 24th Annual

Conference of IEEE Industrial Electronics Society,

IECON’98, 31.08.-04.09., Aachen.

Heinloth, S. (2001), Measuring quality’s return on

investment, Quality Yearbook 2001, McGraw-Hill,

New York, NY.

Yang, J.B., Liu, J. , Xu, D.L., Wang, J. and Wang, H.W.

(2007), Optimization Models for Training Belief-

Rule-Based Systems, IEEE Trans. Syst., Man Cybern.

A, Syst., Humans, vol. 37, no. 4, pp. 569-585.

Kobbacy, K., Vadera, S. and Rasmy, M.H. (2007), AI and

OR in management of operations: history and trends,

Journal of the Operational Research Society, vol.58,

pp. 10-28.

Tana, K.H., Limb, C.P., Plattsc, K. and Koay, H.S. (2006),

An intelligent decision support system for

manufacturing technology investments, Int. J.

Production Economics, vol. 104, pp. 179-90.

Yu, F., Tu, F. and Pattipati, K.R. (2006), A novel

congruent organizational design methodology using

group technology and a nested genetic algorithm,

IEEE Trans. Syst., Man Cybern. A, Syst., Humans, vol.

36, no. 1, pp. 5-18.

Chiang, T.C., Huang, A.C. and Fu, L.C. (2007), Modeling,

scheduling, and performance evaluation for wafer

fabrication: a queueing colored Petri-net and GA-

based approach, IEEE Transactions on Automation

Science and Engineering, vol. 3, no. 3, pp. 912-918.

Wang, C.H., Hong, T.P. and Tseng, S.S. (1998),

Integrating fuzzy knowledge by genetic algorithms,

IEEE Transactions on Evolutionary Computation,

vol.2, no. 4, pp. 138-149.

Lau, H.C.W., Ho, G.T.S., Chu, K.F., Ho, W. and Lee,

C.K.M. (2009), Development of an intelligent quality

management system using fuzzy association rules,

Expert Systems with Application, vol.36, no. 2, pp.

1801-1815.

Hwang, S.F. and He, R.S. (2006), Improving real-

parameter genetic algorithm with simulated annealing

for engineering problems, Advances in Engineering

Software, vol. 37, pp. 406-18.

Ho, G.T.S., Lau, H.C.W., Chung S.H., Fung R.Y.K., Chan,

T.M. and Lee, C.K.M (2008), Development of an

intelligent quality management system using fuzzy

association rules, Industrial Management & Data

Systems, vol.108, no. 7, pp. 947-972.

Winnall, S., and Winderbaum, S, (2000), Lithium Niobate

Reactive Ion Etching Electronic Warfare Division,

DSTO Electronics and Surveillance Research

Laboratory, DSTO-TN-0291.

A FUZZY-GUIDED GENETIC ALGORITHM FOR QUALITY ENHANCEMENT IN THE SUPPLY CHAIN

89