BUSINESS PROCESS RE-ENGINEERING

IN SUPPLY CHAINS EXAMINING THE CASE

OF THE EXPANDING HALAL INDUSTRY

Mohammed Belkhatir, Shalini Bala

Faculty of Information Technology, Monash University Sunway Campus, Malaysia

Noureddine Belkhatir

LIG-IMAG Laboratory, CNRS, France

Keywords: Supply Chain, Business Process Re-engineering, Halal Industry, Information Technology Support.

Abstract: Due to several issues arising in the rapidly-expanding Halal industry, among them the production of non-

genuine or contaminated products and meats, there is a need to develop effective solutions for ensuring

authenticity and quality. This paper proposes the specification of a formalized supply chain framework for

the production and monitoring of food and products. The latter enforces high-level quality of automated

monitoring as well as shorter production cycles through enhanced coordination between the actors and

organizations involved. Our proposal is guided by business process support to ensure quality and efficiency

of product development and delivery. It moreover meets the requirements of industrial standards by

adopting the Capability Maturity Model Integration’s highest process maturity level through establishing

quantitative process-improvement objectives, proposing the integrated support of engineering processes,

enforcing synchronization and coordination, drastic monitoring and exception handling. We then delve into

some of the important technologies from the implementation point-of-view and align it with the formalized

Halal framework. An Information Technology support instantiation is proposed leading to a use case

scenario with technology identification.

1 INTRODUCTION

Halal is an Arabic term which means ‘permissible’

or sanctioned by Islamic law. Today, Halal certified

products are products that abide by the Islamic law

and include hygiene, sanitation and safety qualities

(SIRIM, 2004) which are important quality aspects

of food. The consumers of theses products include

Muslims and non-Muslims that hail from many

countries such as Asian countries, Middle East

countries, America, Canada, United Kingdom,

Africa and Europe. According to (AAP, 2007), the

average global Halal food trade or market is

estimated at 560 billion US dollars a year.

For manufacturers and service providers, the

Halal standard means a larger market share to be

tapped, which will simultaneously bring in more

profits. As quality is associated with the standard, it

is of utmost importance that the products and meat

sold comply with it, but many times it has been

found that this is not the case in several countries

(Halal Journal, 2006).

In the USA, Europe (including the UK), Canada

and Singapore, manufacturers and distribution

outlets such as food sellers are using fake certificates

or labels on products and meat; e.g. (IFANCA,

2002), (MUIS, 2000)… Also, there is cross-

contamination in the production of Halal and non-

Halal food at the manufacturers. As far as animal

welfare is concerned, there is clumsy slaughtering

with dull knives (PETA, 2002) which does not

comply with the MS1500:2004 standard accepted by

the United Nations. Animals are moreover reported

to be starved before the slaughtering according to

slaughterhouse officials as well as cruelly

transported by traders such as from the supplier to

the abattoir (PETA, 2002). However, ‘animals

subjected to cruelties in their breeding, transport,

slaughter, or in general welfare, meat from them is

considered impure’, in other words not Halal

77

Belkhatir M., Bala S. and Belkhatir N. (2009).

BUSINESS PROCESS RE-ENGINEERING IN SUPPLY CHAINS EXAMINING THE CASE OF THE EXPANDING HALAL INDUSTRY.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Information Systems Analysis and Specification, pages 77-82

DOI: 10.5220/0001955800770082

Copyright

c

SciTePress

(MUIS, 2000). All of these issues have caused the

consumers to be concerned about the quality of the

Halal food and products they purchase and eat on a

daily basis.

Today, authorized certification organizations

have been set up in many countries to monitor and

inspect the abattoirs, manufacturers and distribution

outlets in their handling of the animals and products,

and to issue the Halal certificates to them once the

inspections are approved. These certification

organizations have been successful to a certain

extent in reducing the quality problem associated

with the products delivered, but there is room for

improvement. Currently, these organizations are

carrying out their inspections manually. Some

require companies to manually submit the

application to their offices and liaise with third party

organizations/labs to test the products, which delay

the certification process and ultimately delay the

genuine products from reaching the consumers’

hands quickly.

Hence, this paper proposes a framework to better

counter the non-genuine products sold in the market

by introducing the automation of inspections, high-

level quality of monitoring, shorter certification

process, shorter production cycles in the supply

chain, enhanced coordination between the actors or

organizations in the industry and drastic exception

handling to manage and control faulty products.

Process support should guide our proposal for the

framework to accelerate quality product

development and delivery. However, development

processes must also meet the requirements of

industrial standards by adopting for example the

highest process maturity level of the Capability

Maturity Model Integration (Chrissis et al, 2006). The

framework in this paper aims to adopt some standard

practices and accomplish its proposal in the following

ways: i) establishing quantitative process-

improvement objectives, ii) integrated support of

engineering processes, iii)

synchronization/coordination, iv) monitoring, v)

exception handling.

Thus, technology is required to accomplish the

above and to enable a better control and monitoring

of the non-genuine products sold in the market,

which is presented in the following sections. In

Section 2, the supply chain framework is presented

along with its actors and business processes. Next is

section 3 which presents the Information

Technology architecture supporting the framework.

In Section 4 there is focus on related works and

Section 5 concludes the paper.

2 THE SUPPLY CHAIN

FRAMEWORK

The Supply Chain Framework has been modeled to

identify the processes that need to be improved and

re-engineered to better counter the problem of non

genuine products sold in the market.

We first provide an outline of the framework and

explain its aim and objectives. We moreover list the

supply chain organizations and detail their role in

regards to the various Halal processes. Business

processes and their quantitative process-

improvement objectives are then listed.

2.1 Outline

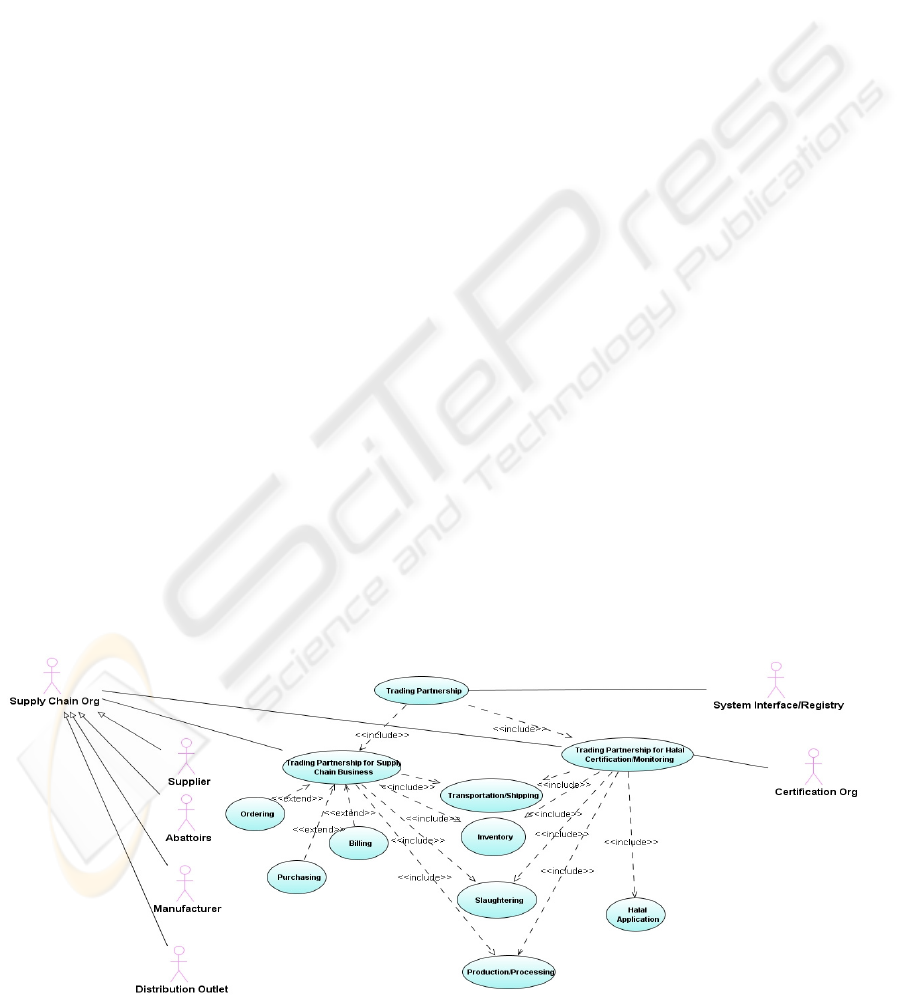

The solution designed in Figure 1 is the general

model of the Halal Supply Chain Framework which

has several objectives to fulfill in order to achieve

this aim, as follows:

Figure 1: General Framework for the Halal Supply Chain.

ICEIS 2009 - International Conference on Enterprise Information Systems

78

• Ensure continuous improvement of the

performance of Halal processes via incremental

and innovative technological improvements

• Enhance synchronization/coordination between

the actors or organizations in the industry

• Achieve high-level quality of monitoring

• Shorten the certification process

• Shorten the production cycles in the supply chain

2.2 Actors

The different actors that have been identified in this

framework are the Supply Chain Organizations, the

Certification Organizations and the System

Interface/Registry. The Supply Chain Organizations

include: the suppliers/breeders who supply the

animals, the abattoirs which buy these animals and

slaughter them, the manufacturers who purchase the

slaughtered meat and processes it for production and

the distribution outlets including retailers, food

sellers and butchers selling the products.

The system Interface/Registry enables the

synchronization/coordination of the organizations in

the supply chain so that they can communicate with

each other and form an electronic trading partnership

in order to better control the non genuine products.

The Certification Organization plays a very

important role in the framework that is to certify and

monitor the organizations to ensure the authenticity

of the products.

2.3 Business Processes

The first business process involved is the main

‘trading partnership’. The framework contributes to

the Halal industry by illustrating that a trading

partnership is necessary before any kind of supply

chain business or monitoring can be executed

between the actors in this diagram. There are two

types of partnership processes that can be formed

between the actors.

First, the ‘trading partnership for supply chain

business’ involves the partnership among the

supplier/breeder, abattoir, manufacturer and

distribution outlet in order to ensure fast production

and counter the non-genuine products sold in the

market. This is accomplished by accelerating the

exchange of information in the processes beginning

with the ordering of products, then their purchase,

transportation/shipping, storing in the inventory,

slaughtering, production/processing and ending with

the billing procedure.

Second is the ‘trading partnership for

certification/monitoring’ which involves the

partnership between the certification organization

and the supplier, abattoir, manufacturer and

distribution outlet to monitor the Halal problem. It

also covers the partnership between the

supplier/breeder, abattoir, manufacturer and

distribution outlet to increase the responsibility,

cooperation and communication of each of these

organizations.

Let us note that among the processes mentioned,

the transportation/shipping, inventory, slaughtering

and production/processing carry an important role

since they are part of both trading partnerships.

Indeed, these core processes are meant to accelerate

product supply and are also necessary to monitor the

several issues identified in the supply chain.

The common quantitative process-improvement

objectives for these core processes are as follows:

• Increase the number of electronic partnerships,

technical communications and documents

between the certification organization with the

supply chain organizations as well as among the

supply chain organizations, to enhance their

coordination.

• Reduce the time it takes for the certification

organizations to inspect or exchange

information.

The specific quantitative process-improvement

objectives for the core processes are related to the

rapid decrease of the number of:

• ‘injured’ or ‘unhealthy’ animals certified by

veterinarians in their health reports for

transported animals as far as transportation

and shipping are concerned.

• ‘starved’ or ‘unhealthy’ animals certified by

veterinarians in their health reports which are

reported just before the animals are slaughtered

when handling the inventory.

• animals that are not slaughtered according to

the MS1500:2004 standard .

• defect products either cross-contaminated or

with fake labels attributed by manufacturers

during production and processing.

• both fake certificates put up by distribution

outlets such as food sellers and defect products

that are sold with fake labels at the distribution

stage.

BUSINESS PROCESS RE-ENGINEERING IN SUPPLY CHAINS EXAMINING THE CASE OF THE EXPANDING

HALAL INDUSTRY

79

3 INFORMATION

TECHNOLOGY SUPPORT

INSTANTIATION

The Information Technology framework is designed

to model the electronic partnerships in the Halal

industry and highlight the role of the system registry

which enables these partnerships. It furthermore

illustrates how all the components come together to

support the quantitative process-improvement

objectives. This framework is based on the e-

business standard technology and in particular the

ebXML scenario 2 example framework (Webber,

2004). The e-business standard technology both

automates and standardizes business processes so

that different organizations with different systems

and business processes can exchange information or

documents quickly. In addition to this, this

technology enables the organizations in the industry

to monitor and control electronically the several

issues identified, that is from a distance and in a

secure manner. Also, it makes it possible to produce

and certify the products fast in order to reach the

consumers’ hands quickly. The facility to form

electronic partnerships among these organizations

also enables each one of them to take the

responsibility of monitoring at every stage of the

supply chain. As a matter of fact, this role is no

longer specific to the certification organization

alone.

The partnerships, system registry components and

solution to support the quantitative process-

improvement objectives are presented in detail

below.

3.1 Partnerships

In this framework, the supply chain organizations

such as the suppliers/breeders, abattoirs,

manufacturers and distribution outlets as well as the

certification organizations have to first build a

system interface that is compliant with the system

registry, and then register with the latter before

establishing an electronic partnership with each

other. These partnerships can be formed between

organizations known to each other, or new

organizations intending to form partnerships with

one another. Once these organizations have formed a

partnership, they can proceed to communicate and

liaise extensively with each other. The dynamic

aspect of this process which allows new

organizations to find one other in the system registry

enables a vast expansion of partnerships in the

industry, with unlimited geographical boundary, to

better control the highlighted issues.

3.2 System Registry and its Components

The system registry is the system that enables

different organizations in the industry to discover

one another and register to form electronic

partnerships. The components stored in this registry

include the Library and Models, List of Scenarios,

Collaboration Protocol Profiles (CPP), Messaging

Constraints and Security Constraints.

The Library and Models component is based on

the Business Process and Information Meta Model

concept identified in a specific e-business standard

technology. It consists of the definition of business

processes as well as reusable core components that

reflect common business semantics, XML

vocabularies and actual message structures defined.

The latter are reused by organizations in the industry

to ensure sound communication of the standard

terms and formats.

The modeling of the processes and scenarios is

executed via the UN/CEFACT Modeling

Methodology (UMM) which is based on the Unified

Modeling Language (UML). The modeling includes

the class diagram modeling of the core processes.

The general model of the ‘Formalized Supply Chain

Framework’ serves as the foundation to form the

modeling of the class diagrams.

The information from the Library and Models

contributes to the formation of the Collaboration

Protocol Profile (CPP) which is registered in the

system registry. The CPP contains information such

as the industry classification, supported business

processes, requirements for interface and messaging

and service information for contact purposes. Other

registered organizations in the industry can then

discover these CPPs and find out the supported

processes and scenarios and decide to become

partners with each other. The agreement for a

partnership is called the Collaboration Protocol

Agreement (CPA). Included in the CPPs and CPAs,

are the messaging and security constraint details.

3.3 Supporting the Quantitative

Process-Improvement Objectives

The first quantitative process-improvement

objective of increasing the number of electronic

partnerships, technical communications and

documents among the organizations in the industry,

can be achieved through the electronic partnerships

and System Registry components. As more and

ICEIS 2009 - International Conference on Enterprise Information Systems

80

more organizations register in the system registry

and become partners with one another, the number

of CPPs and CPAs increase, which indicates that

more organizations are able to assist the

certification organization to monitor the

highlighted issues in the supply chain.

This monitoring will be executed via XML

documents that are exchanged between the supply

chain organizations and the certification

organization as well as among themselves. The

increase of XML documents designed and

exchanged would indicate extensive communication,

cooperation and coordination between these actors.

By communicating via XML, the second

quantitative process-improvement objective can be

supported which is reducing the time it takes for the

certification organizations to inspect or exchange

information. The Partnerships and System Registry

components, together, provide real-time information

access, faster information exchange and query

resolution as well as improved information flow.

They furthermore enable mutual use of the

information that has been exchanged between the

organizations in the supply chain. The monitoring is

assisted as certain aspects of the inspections are

automated and executed from a distance with speed

and security. For instance, the health reports by

veterinarians who check the animals after their

transportation from the supplier/breeder to the

abattoir can be transmitted to the certification

organization electronically, eliminating the need for

physical inspectors to look through the health

reports. Also, the submission of applications and

documents to the certification organization, and the

liaising between the latter and third party

organizations/labs to test the products can also be

achieved via XML technology. The fast exchange of

information in turn assists to shorten the certification

process and the production cycle.

The above stated solution also supports the

specific quantitative process-improvement

objectives of rapidly decreasing the number of

‘unhealthy’ animals in the transportation and

inventory process. This is because after the animals

are transported and before they are slaughtered,

health reports by veterinarians are transmitted to the

certification organization and these reports would be

recording the number of animals that are certified

‘unhealthy’. In this way, the number of ‘unhealthy’

animals can be monitored at a closer interval of

inspection due to the utilization of technology and

can be decreased at a faster pace. With the Halal

Partnerships and System Registry, the transportation

process can also be inspected by the supplier/breeder

and abattoir, not only by the certification

organization. This is because either the

supplier/breeder will engage the transportation

service or the abattoir will engage the service for

transporting the animals. Since the process involves

two different organizations in the supply chain, these

can help the certification organization by monitoring

each other via the e-business technology and

documents, and inform the certification organization

whether there is a problem in the transportation

service such as lack of room which can harm the

animals.

As for the rest of the specific quantitative

process-improvement objective in the slaughtering,

production/processing and distribution process, the

certification organization will need to physically

inspect these processes to ensure that all

requirements are met, but unlike before, all the

inspection reports will be transmitted via the e-

business system immediately after the inspection to

speed up the resolution of issues encountered.

4 RELATED WORKS

According to Kok (Kok, 2003) and Kotinurmi et al.

(Kotinumi et al, 2003), ebXML and RosettaNet

(RosettaNet, 2007) are among prominent standards

that provide key business and technology benefits

for e-business integration (Webber, 2004) and have

a high level of general adoption across the globe.

Both standards focus on integrating different

systems and business processes in several

organizations to execute business easily with each

other. Nevertheless, the two standards differ from

one another as the RosettaNet standard specifically

targets the high-tech industry whereas ebXML does

not target any industry. In addition to the ebXML

and RosettaNet standards, OAGIS and xCBL are

also known to be among the prominent XML-based

e-business standards (Numilaakso et al, 2006) that

have high likelihood of general adoption due to their

suitability for industrial procurement, design,

production or distribution. xCBL is however

migrating in phases to UBL which has now taken a

prominent role.

To address the issues in the Halal supply chain,

we have selected the ebXML standard technology.

Following are the reasons discussed.

OAGIS and UBL (since xCBL is migrating in

phases to UBL, we will restrict ourselves to

discussing the latter) are non-proprietary and open

standards, which are major advantages. Furthermore,

they have been implemented in food industries

BUSINESS PROCESS RE-ENGINEERING IN SUPPLY CHAINS EXAMINING THE CASE OF THE EXPANDING

HALAL INDUSTRY

81

where they provide reasonable cost and support.

They also provide processes which are particularly

suited for the Halal industry such as the certification

of origin process which can assist in verifying

imported products. However, these technologies are

not complete and have therefore to be instantiated

along with other e-business technologies such as

ebXML messaging, registry and security

mechanisms.

The RosettaNet technology provides many

advantages as ebXML, but is too focused on the

Electronics industry and its processes and

documents would require extensive modifications to

suit the Halal scenario. Thus, it is concluded that the

ebXML technology would be selected to address the

highlighted issues in the Halal supply chain. It is

furthermore deemed not necessary for ebXML to

work in combination with other technologies as it

has enough facilities, materials and support to work

on its own.

5 CONCLUSIONS

This paper has discussed various opportunities and

issues related to Halal industry and Halal product

process. Even though a lot of work is going on in the

business world related to Halal industry in general,

not much work has been done to formalize the

business processes.

The overall contribution of this paper is a

process-oriented framework for managing the

production of Halal products, which in particular

addresses the issue of the production and

commercialization of non-genuine or faulty

products. We have identified the main activities at

the core of the framework as well as the data and

control flows linking them.

We have moreover proposed the technological

solutions for its instantiation and in particular the

XML-based data flow allowing the unified

description of documents through a generic

formalism. After the study of the related works on

process engine, we have directed our choice towards

the use of open-source software in order to instantiate

the proposed framework and to make the highlighted

processes enactable and executable.

In future works, we will work on the modeling

aspects, i.e. the definition of a language allowing

process specification and characterization. This

language of high-level abstraction shall be

independent from any particular implementation

architecture. We will carry on a large experimental

study based on a real-world scenario, for which we

will study the feasibility of its deployment in a

distributed environment.

REFERENCES

Chrissis, M.B., Konrad, M., Shrum, S. 2006. CMMI:

Guidelines for Process Integration and Product

Improvement (2nd Edition), Addison-Wesley

Professional

Kok, A., 2003. B2B Standards Convergence Between

RosettaNet and ebXML. In XML Conference

Proceedings, USA

Kotinurmi, P., Nurmilaakso, J. and Laesvuori, H., 2003.

Standardization of XML-Based E-Business

Frameworks. Proceedings from the MIS Quarterly

Special Issue Workshop. Seattle, USA.

SIRIM 2004. Standardisation for Halal Food. Standards &

Quality News, SIRIM Berhad Quality Standards web

site, vol. 11, no. 4, www.sirim.my/f_corp/july04.pdf

Halal Journal 2006. Somerset Couple Launch First

Organic Halal Meat Business for Muslims. Global

News-Europe, www.halaljournal.com/artman/

publish_php/article_1036.php

Islamic Food and Nutrition Council of America

(IFANCA) 2002. Current and Future Issues in Halal,

Halal Digest Newsletter, Halal Food Conference

2002. ifanca.org/newsletter/2002_05.htm

Islamic Religious Council Singapore (MUIS) 2000. Halal food

for thought. WaritaKita, Bilangan 126.

www.muis.gov.sg/webpub/warita/warita3-

2000/page22.html

Nurmilaakso, J., Kotinurmi, P. and Laesvuori, H. 2006.

XML-based e-business frameworks and

standardization. Computer Standards & Interfaces,

Vol 28, pp 585-599

OASIS, 2006. Members Approve Universal Business

Language (UBL) 2.0 as OASIS Standard. OASIS

International Standards Consortium web site.

www.oasis-open.org/news/oasis-news-2006-12-19-

pdf.pdf

PETA INDIA 2002. Maharashtra Officials, Animal

Dealers, Slaughterers Call for Central Government

Crackdown on Cruelty, www.petaindia.com/1102

maharashtra.html

RosettaNet, 2007. Overview: Clusters, Segments and PIPs.

Version 02.01.00. RosettaNet Program Office.

Vic: Halal global trade could boost Australian

economy. 2007. AAP General News Wire October 22

Webber, D., 2004. The Benefits of ebXML for e-Business.

ebXML Web Site. www.ebxml.org/news/

ebXMLclippings.htm

ICEIS 2009 - International Conference on Enterprise Information Systems

82