DECISION SUPPORT SYSTEM FOR CLASSIFICATION OF

NATURAL RISK IN MARITIME CONSTRUCTION

Marco Antonio García Tamargo, Alfredo S. Alguero García, Víctor Castro Amigo

Department of Information Technology, University of Oviedo, Campus de Viesques, 33204 Gijón, Spain

Amelia Bilbao Terol

Department of Quantitative Economics, University of Oviedo, Campus del Cristo, 33006 Oviedo, Spain

Andrés Alonso Quintanilla

Fomento de Construcciones y Contratas, (FCC), Oviedo, Spain

Keywords: Decision-making support, Artificial intelligence, Data mining, Risk prevention, Building of maritime works.

Abstract: The objective of this paper is the prevention of workplace hazards in maritime works – ports, drilling and

others – that may arise from the natural surroundings: tides, wind, visibility, rain and so on. On the basis of

both historical and predicted data in certain variables, a system has been designed that uses data mining

techniques to provide prior decision-making support as to whether to execute given work on a particular

day. The system also yields a numerical evaluation of the risk of performing the activity according to the

additional circumstances affecting it: the number of workers and the machinery involved, the estimated

monetary cost of an accident and so on.

1 INTRODUCTION

Prevention of workplace risks seeks to prevent

accidents that might entail injury or even loss of

human lives, or monetary losses. Assessment of risk

of a natural origin – wind, rain or tide – often tends

to be intuitive, and thus bears a substantial degree of

subjectivity.

The natural surroundings in construction works,

particular maritime works, entail a series of special

features that make it quite changeable in terms of the

risk they may suppose to the performance of certain

types of work (Inst. Seguridad e Higiene en el

Trabajo, 2003). This can be due to meteorological

conditions, the state of the sea and, in most cases,

the continuous change in the scenario caused by the

progress of work; hence, determination of risk must

have a predictive nature.

The company Fomento de Construcciones y

Contratas, Construcción (FCCC hereinafter), a

section of the parent company FCC, one of the

leading building companies in Spain with an

international projection, is carrying out a large

number of works in maritime settings where sea

conditions and climate determine the temporal and

physical progress of each work and the potential risk

to workers performing them. This paper constitutes

part of a pilot project in this line that is being carried

out in 2007-2008 in the framework of the Spanish

National Plan 2004-2007 for Scientific Research,

Development and Technological Research in the

section of Promotion of Technical Research. To

execute the project, FCCC contracted the research

group at the University of Oviedo, the authors of this

paper. The objective was to develop an intelligent

risk prevention system that operated semi-

autonomously. Based on forecasts of certain climate

variables and the accumulated experience of safety

experts in similar situations, the system would

induce prior classifications in times and days as to

whether the risk of performing a given activity was

acceptable or not; it would also provide a numerical

evaluation of the expected risk according to

seriousness of the risk and the number of people and

machines involved. The aim would be twofold: first,

138

Antonio García Tamargo M., S. Alguero García A., Castro Amigo V., Bilbao Terol A. and Alonso Quintanilla A. (2009).

DECISION SUPPORT SYSTEM FOR CLASSIFICATION OF NATURAL RISK IN MARITIME CONSTRUCTION.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Artificial Intelligence and Decision Support Systems, pages

138-143

DOI: 10.5220/0001983201380143

Copyright

c

SciTePress

to protect the physical safety of workers and,

second, to minimize costs incurred in the under-use

of resources by means of a their preventive

relocation in tasks that are not dangerous on a given

date.

2 BACKGROUND

The firm FCCC has already developed a work

methodology, Metodología de Trabajo de Control

del Oleaje (FCCC, 2007) that can yield a daily

forecast of working conditions for a number of the

activities entailed in the building of a port:

anchoring of blocks, unloading of aggregates and so

on.

This methodology is based on a calculation of

the freeboard – or maximum level a wave could

reach above the working level, using the latter as the

zero – in an explicit way of meteorological

variables: significant wave, tide index and the type

of terrain: the slope, the working level and so on.

The methodology was implemented in a

rudimentary manner in a complex spreadsheet that

ultimately generates a recommendation as to

whether work can be performed in a certain working

area, with reference to each of the times of day

examined.

However, a series of known limitations have

been found in this methodology, which are

quantitatively summarized in the error percentages

in the period under study, from June to October

2007. In this period, it had an average error rate of

35.45%; with the lowest accuracy rates in the

months that were the fairest meteorological sense,

and thus the least hazardous.

In view of the criticisms and defects found in the

previous tool by the workplace safety expert who

was using it, the alternative system we present

herein, conceived as a decision-making support

system (Ríos Insua, S., Bielza Lozoya, C., 2002)

should meet the following requirements:

a) It should be risk classification system that

is more accurate than the present one, and, due to

the particularly subjective nature of risk

assessment, should be grounded in the

experience of the technical director in assessing

similar situations of risk.

b) It should assist experts in deciding whether

or not to perform a given activity sufficiently in

advance so as to allow for optimal use of human

and material resources.

c) It should provide a numerical quantification

of risk that encompasses both human and

material risks. Such quantification would be

provided with the prediction outlook allowed by

available prognoses.

d) It should automate to the extent possible

both the acquisition of the data required and the

generation of daily reports with the prediction.

3 METHODOLOGY USED

The maritime work is defined as a set of units. In

each unit, a series of activities such as block

anchoring or aggregate dumping are performed over

time.

The risk of performing an activity is determined

by a set of naturally generated variables that are

considered by expert user to be determinative for the

risk conditions of that activity: wind speed, the

height of the significant wave, rainfall and so forth

for maritime work; therefore, activity in a maritime

work at a given time is identifiable by a state vector

comprised of the values of all those variables at the

time.

Initially, the risk for a given moment is to be

determined with a Boolean method: true, which

entails a prognosis of don't work, and false (table 1),

which entails of recommendation of work.

Transferred to a state vector framework, the

problem might arise of making a prediction for a

state vector such as classifying the vector in one of

two values for risk: true or false. A simplified

geometric model of the solution to this problem

would be to obtain a hyperplane that separated the

two types of state vectors: those classified as true

and those classified as false. But the real world is

somewhat more complex.

Table 1: State vectors with the Boolean risk classification.

Date Time Hso Tp K … Risk

4/6/08 00:00 0.8 11 1.05 … TRUE

… … … … … … …

4/6/08 23:00 0.8 9 1.05 … FALSE

… … … … … … …

In the state vector space of an activity, nearly all

the variables have a maximum or minimum; the very

fact of exceeding them would be a determination of

extreme risk and, therefore, a decision to not work in

the given activity, regardless of the values of the

other variables. Thus, instead of a single hyperplane,

there is a series of hyperplanes perpendicular to the

axes of the n-dimensional space, which, as a whole,

would constitute a polyhedral frontier between the

vectors of the two categories we have mentioned,

DECISION SUPPORT SYSTEM FOR CLASSIFICATION OF NATURAL RISK IN MARITIME CONSTRUCTION

139

namely true and false. The inner zone adjacent to

that frontier, specifically that of the edges and

vertices of the polyhedral surface, is the risk

decision zone or the caution zone, and here is where

the frontier must be redefined. An accumulation in

single vector of several variables with values that do

not exceed the hazard maximums but which are near

them, as would be the case with state vectors in the

caution zone, may belong – in principle, at the

judgment of the expert – to a category other than the

one it would be found owing to its position with

respect to the polyhedral frontier (figure 1).

Figure 1: 2-dimensional depiction of natural frontier.

Having modelled the problem in this way,

consideration was given to the method that should

be used to solve it, and we decided to rule out

conventional models based on analytic mathematical

models – i.e., a formula to determine risk – due

mainly to the large degree of subjectivity used by

experts in assessing risk.

Consequently, we decided to use one of the

existing systems with the capacity for supervised

inductive learning. The system should learn from

state vectors that reflect past situations that have

been classified by an expert according to the risk

they entailed. The classification model provided by

the system would induce classification for state

vectors that were not necessarily included in the

learning process; that is, it would neatly trace the

new frontier in the caution zone based on the expert

decisions for the state vectors in the past.

An activity in a given instant in the maritime

work will be identified with a state vector to which a

Boolean class variable will be added with the

possible values of true or false. The new state vector

shall be n-dimensional, where n-1 is the number of

variables that have been defined to assess the risk in

that activity y la n-th the special class variable. An

example or case will be a specific state vector.

Measurements generated by examples are commonly

made at one-hour intervals. Examples that will be

used to train the system will have a special variable

value that classifies each as: true, a situation of high

risk, or false, when the risk is low or at least

acceptable. Classification of these examples will

have been performed – or at least supervised – by an

expert. With a database with this vector type as

entries, learning systems extract models that enable

subsequent classification of new cases. Models are

abstractions of structural patterns that present

vectors classified in one class against those

classified with another: that is, systems will learn to

distinguish high-risk situations from low-risk ones

by using the knowledge accumulated in the learning

process and retained as a model.

The abundance of learning systems means that

multiple solutions or models are possible; usually

more than one per system, as these offer parameters

that, according to their settings, make the system

produce different solutions. An important task shall

be to decide what system of learning and what set of

parameters to use, in addition to studying the

suitability of the variables used and perhaps

reducing or increasing the number of them; in short,

a good job of data mining is needed, (Wittten et al.,

2005).

Following these considerations, discussions and

the pertinent tests, we decided to pre-select two

systems of supervised inductive learning for trials

and a more thorough comparison in our problem:

these were C4.5 (Quinlan, 1993) and Support Vector

Machines (SVMs, hereinafter) (Cortés, Vapnik,

1995), (Cristianini, Shawe-Taylor, 2004).

Conceptually, these systems are quite different:

while the first is based on a heuristic approach, the

second is grounded in a whole mathematical theory

to explain its method. We will now provide a brief

description of each.

3.1 The C4.5 System

C4.5 is a traditional automatic learning system that,

however, remains fully valid (Jaudet et al., 2005),

and needs no introduction. For this paper, its main

feature is that it produces the knowledge learned in

an explicit form, by means of a decision tree or

classification rules; in both cases, these are

comparable to the experience of an expert in the

field, an aspect of the utmost interest to us. C4.5

works with both qualitative and quantitative

variables and is powerful when faced with noise.

C4.5 incrementally generates a decision tree; each

new level is originated by a variable that is selected

for its importance in determining class.

O

X-safety

margin

Polyhedral

frontier

Natural

frontier

Y-safety

margin

X

Y

ICEIS 2009 - International Conference on Enterprise Information Systems

140

3.2 SVMs

SVMS obtain an optimal separating hyperplane from

examples from each of the two classes, which are

usually transformed into a new space.

SVMs include, as a quite efficient strategy, the

transformation of the example space into another,

larger one, which is called a feature space, in which

examples transformed will likely prove to be linearly

separable. The scalar product between vectors of the

transformed space is achieved according to the

scalar product defined in the initial space and the

transformation between spaces or kernel function,

which makes calculation of the hyperplane in the

feature space computationally feasible.

One SVMs drawback lies in its sensitivity to

parameters that adjust its operations, and another,

the most important one for our purposes, is the

implicit form of knowledge they produce, as a

function, which corresponds to that of an optimal

separating hyperplane of the examples of each class.

Because of this weakness, which safety experts from

the contracting firm criticized, and the results the

SVMs yielded in the trials, they were ultimately

ruled out in our choice in favor of C4.5.

4 EXPERIMENTS PERFORMED

For experiments to evaluate the two systems, we

began with a set of 20 variables related to the risk of

performing an activity. For these variables we had

historical data accumulated since the start of the

maritime work. Each state vector consisted of the

values of these variables at a specific instant, plus

the class variable, which represents the decision

taken by the expert at that time on risk: true risk or

false risk; the risk value provided by the prediction

model used by FCCC was also available.

We thus had a set of 2296 entries similar to that

shown in table 1, comprised of state vectors in

instants that were all from the past; further, the risk

value provided by the prediction model presently

used by FCC was also available for each entry.

4.1 Experiments with SVMs

We performed work with the SVMs most commonly

used in classification problems: C-SVC and nu-SVC.

For each of these, tests were conducted for the most

commonly used general purpose kernel functions:

linear, polynomic, Gaussian (rbf), sigmoidal, inverse

multiquadratic.

A cross validation was performed on each type

of SVM and kernel function, with experiments with

different learning option values, and different

parameters of the kernel functions.

As shown in table 2, the best result of 86.80% of

accuracy, was achieved for the nu-SVC and the

Gaussian kernel (rbf) with parameters of nu=0.3 and

C=0.1. This result represents an improvement of

22.35% in risk prediction over the model presently

used by FCC.

Table 2: Results of cross validation with SVMs and

different parameters.

4.2 Experiments with C4.5

The C4.5 system was subjected to a size 10 cross

validation, with different sets of parameters for both

trees and rules.

The best mean accuracy percentage, 90.9%, was

obtained with rules, which was 3.6% better than the

best result achieved by the SVMs, and 25.95% better

than the average accuracy of the present analytical

model. The parameters used in this case, which

differed from the default values used by the system,

were those from the pruning, c= 35, compared to the

default c=25, which involved a larger pruning, and

the relative to the redundancy of attributes or

variables, r=1.5 compared to the default r=1, which

meant that there was a certain redundancy of

variables or attributes among those used. The

redundancy had been detected by the principal

components method, but given the fact that reducing

the number of variables failed to improve results, the

possibility was ruled out.

SVM Kernel Test

parameter

Best

performance

Precision

class

nu-SVC rbf

C C=0.03125

0.824

nu-SVC poly

Degree

C

degree=2.5

C=0.1

0.810

nu-SVC rbf

Nu

C

nu=0.3

C=0.1

0.868

nu-SVC rbf

Gamma

C

gamma=0.1

C=0.1

0.861

C-SVC linear

C C=2

0.801

C-SVC rbf

C C=2

0.854

C-SVC poly

Degree

C

degree=3.0

C=0.1

0.834

C-SVC rbf

Gamma

C

gamma=0.1

C=0.1

0.834

nu-SVC rbf

C

gamma

nu

C=0.5

gamma=0.01

nu=0.4

0.862

DECISION SUPPORT SYSTEM FOR CLASSIFICATION OF NATURAL RISK IN MARITIME CONSTRUCTION

141

In view of the excellent results yielded by this

system in the validation, we decided that the

classification model to be used to detect situations of

risk would be the rules produced by C4.5 with the

parameters seen.

5 RISK INDEX

C4.5 induces a classification model that can

subsequently classify state vectors not seen in that

phase, for which the value of the attribute class

(risk) is unknown. Values of the other attributes of

these vectors shall consist of the values predicted for

variables that influence the activity to be performed

up to the prediction horizon available, which can

range from one day to a week. By applying the

mining model to these vectors, we will obtain a

classification for each of them. If we have 24 state

vectors for every working day (1 day = 3 work shifts

of 8 hours per shift), the mining model will yield 24

values of risk class for each working day. These 24

values have to be summarized in a risk index (RI)

for each working day that will enable an expert to

decide whether or not to work in that activity on that

day. This RI will be calculated as a linear

combination that is adjusted by the user with the

weights (hrw+mrw=1) of two components: human

risk (HR) and machine risk (MR):

RI=HR*hrw+MR*mrw

HR is 0 if there is no potential affect to any

worker. In case a worker could potentially be

affected, we define HR as follows:

HR=(persistence+scope)/2*aif

where aif (aif∈(0.1]) is a weighting factor supplied

by the expert of the severity that might be involved

in an accident among workers.

Persistence is the proportion of the working day

in which the situation of risk persists, and this is

defined as follows:

Persistence=

HoursExistenceRisk/HoursWorkingday.

Calculating persistence involves predictions

obtained from the data mining model for the variable

risk class.

Scope includes the potential number of workers,

out of the total involved in the activity, which would

be directly exposed to the risk.

Scope= PotentialWorkersAffected/TotalWorkers

It remains to be defined how the term RM, or

risk to facilities and machinery, will be defined.

RM=DCPAM*ND/ATC*mif

Where, DCPAM is an estimate of the daily cost

of the machines potentially affected by the accident.

ND is an estimate of the number of days in which

machines may be out of service if affected by the

accident. ATC is the total cost of the activity

performed and mif (mif∈[0,1]) is a weighting factor

of the severity of an accident on working machinery.

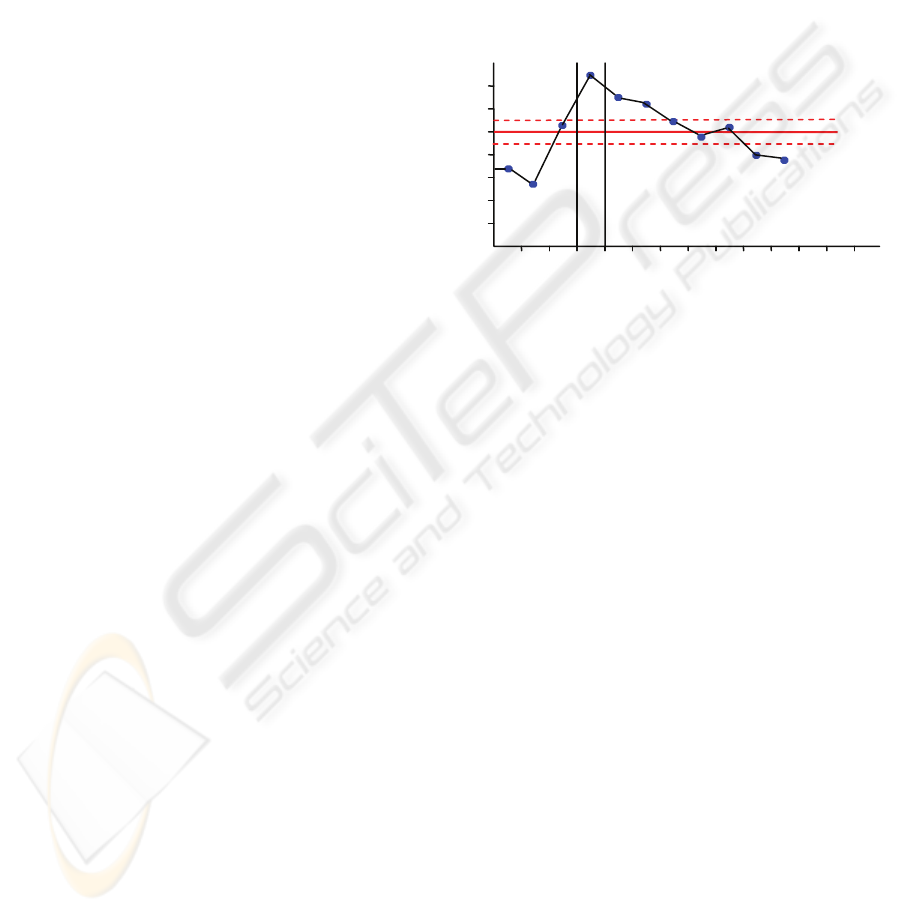

Figure 2: RI evolution chart from -3 day to +7 day.

The RI can be predicted for any activity as far in

advance as values are available for the state vector

variables. The chart trend of the RI variable will

enable an expert to make decisions sufficiently in

advance (figure 2).

6 CONCLUSIONS AND FUTURE

WORK

A system has been created for predicting risk of a

natural origin in a maritime environment.

Predictions are made with a classification model

obtained by C4.5 trained in the previous decisions of

a safety expert in past meteorological conditions of a

similar nature. The entire process is integrated into a

powerful and versatile software tool that automates

most tasks; everything from data capture to report

generation and including publication on a server

through an FTP protocol, in addition to training of

the automatic learning system. The tool is modular,

thus allowing the future addition of other automatic

learning systems or its extension, such as publication

of its reports on a website. We would highlight the

following:

• The capacity to simultaneously implement

nearly any analytical model of risk calculation

based on an explicit function.

RI

+7 +6

days

+5 +4 +3 +2

+1

-3 -2 -1 0

0,7

0,6

0,5

0,4

0,3

0,2

0,1

ICEIS 2009 - International Conference on Enterprise Information Systems

142

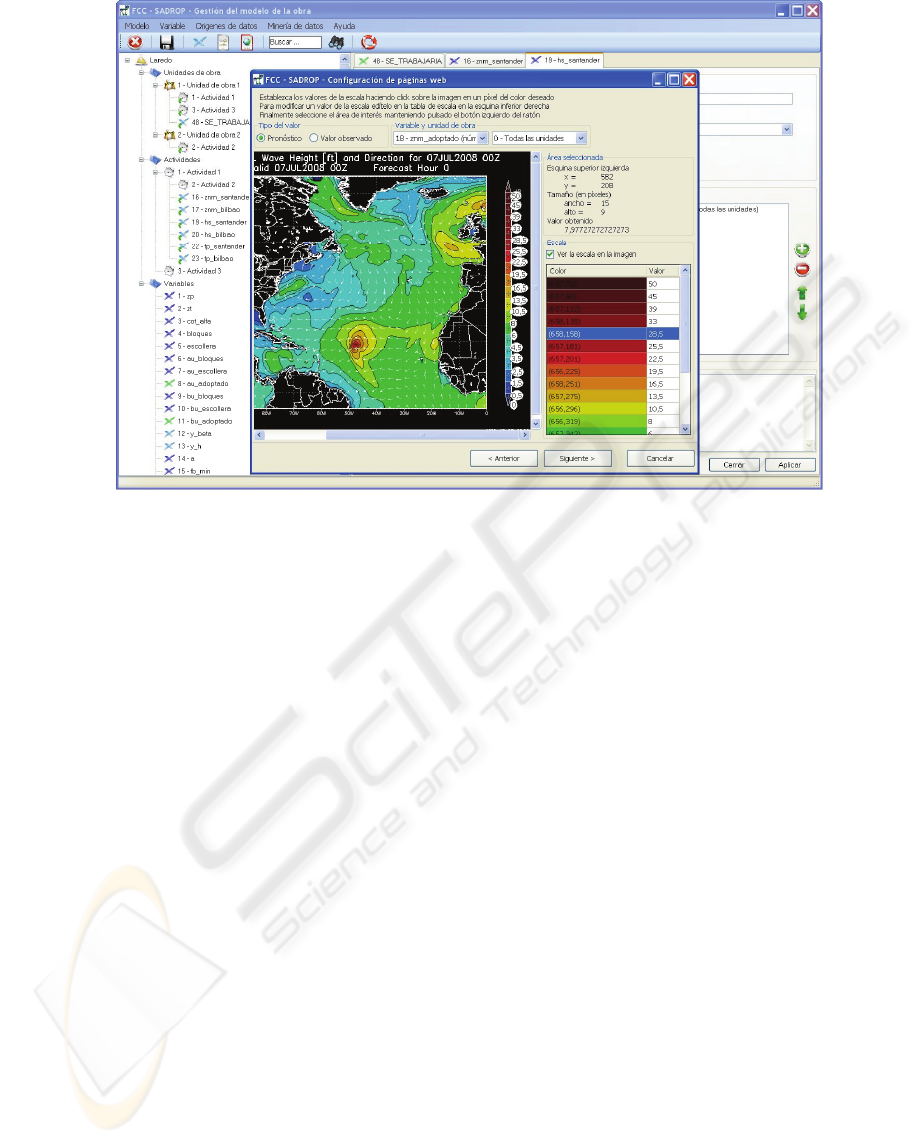

Figure 3: Configuration to retrieve data provide on the Internet by means of chromatic codes.

• The ability to retrieve data provided on the

Internet by means of chromatic codes (figure 3).

• The ability to functionally define new variables

that depend on others previously defined.

The tool has been in use on a trial basis in work on

the Laredo marina in Cantabria, Spain for a short

time. The results it is providing in classification of

state vectors, now with predicted data in their

components, is being evaluated, as their reliability

depend on the reliability of the predictions, and an

extensive period of testing is necessary in order to

reach a sound judgment; nevertheless, our

impression is quite positive, and consistent with the

results yielded with historical data in the laboratory.

At present, work is under way to redefine the state

vectors, with a view to integrating into a single

vector a concatenation of present vectors that

correspond to several consecutive hours both

beforehand and afterwards; thus, each new vector

will cover a time interval that contextualizes the

meteorological data. Therefore, a few specific hours

of meteorological bonanza on one or more rainy

days will not lead to mistakes. The initial trials with

these vectors are yielding encouraging results that

are superior to those of present state vectors.

REFERENCES

Cortés, C., Vapnik, V., 1995. Support Vector Networks.

In Machine Learning, 20: 237-297.

Cristianini, N., Shawe-Taylor, J., 2004. An Introduction to

Support Vector Machines and other kernel-based

learning methods. Cambridge University Press 2004,

2

st

edition.

FCCC, Fomento de Construcciones y Contratas,

Construcción 2007. Metodología de Trabajo de

Control del Oleaje. Informe técnico interno, Laredo

Spain.

Inst. Seguridad e Higiene en el Trabajo, 2003. Guía

Técnica, para la Evaluación y Prevención de los

Riesgos Relativos a las Obras de Construcción. 2003.

Madrid, Spain.

Jaudet, M., Iqbal, N., Hussain A., Sharif, K., 2005.

Temporal Classification for Fault-prediction in a real-

world Telecommunications Network. In ICET 2005,

IEEE-2005 International Conference on Emerging

Technologies.

Quinlan, J.R., 1993. Programs for Machine Learning.

Morgan Kaufmann Publishers, San Mateo, California

USA.

Ríos Insua, S., Bielza Lozoya, C., 2002. Mateos Caballero,

A. Fundamentos de los Sistemas de Ayuda a la

Decisión. Editorial Ra-Ma, Madrid.

Witten, I.H., Frank, E., 2005. Data Mining. Practical

Machine Learning Tools and Techniques. Elsevier,

Morgan Kaufman Publishers, San Francisco, USA, 2

nd

edition.

DECISION SUPPORT SYSTEM FOR CLASSIFICATION OF NATURAL RISK IN MARITIME CONSTRUCTION

143