Real-Time Traceability and Intelligent Product

Management in the Supply Chain

Taxiarchis Belis, Stelios Tsafarakis and Anastasios Doulamis

Dept. of Production and Management Engineering

Technical University of Crete

Chania, Polytechnioupolis Campus, Greece

Abstract. In this paper we present an architecture that provides enterprises with

the opportunity to apply a low cost traceability system which allows for the

complete transparency of products in the supply chain. The proposed traceabil-

ity system uses the RSS 2.0 format, while a product classification ontology is

developed in order to enable intelligent product management. The above tech-

nologies are incorporated into an RFID architecture. The deployment of RFID

technology in the supply chain is expected to increase significantly the amount

of product data, raising the need of adoption of an effective ontology-based

model for intelligent product information management.

1 Introduction

According to the European Community regulation (EC regulation 178/2002) from the

1/1/2005 all enterprises that deal in any way with the foods and drinks industry are

compelled to implement reliable track and trace systems.

Traceability can be defined as “The ability to follow (in real time) or reconstruct

(off-line) the logistic route of singular or compound products” [10].

The benefits of traceability concern the consumer’s safety as well as the complete

transparency and automation of the supply chain, which cannot be adequately ad-

dresed with existing technology. In our study we focus mainly in the foods and drinks

sector, since this sector appears to be more complex in implementing track and trace

systems, due to the several complex procedures involved [11].

The supply chain can be defined as “A web of autonomous enterprises collectively

responsible for satisfying the customer, by creating an extended enterprise that con-

ducts all phases of design, procurement, manufacturing, and distribution of products”

[2]. Supply chain can be considered as a collaboration among different enterprises.

Critical factors for an effective collaboration constitute the coordination and synchro-

nization between the processes and operations of all the actors along the chain. Tech-

nology limitations may put in danger the success of the above synchronization.

Several years ago, it was common to encounter problems of tracking certain items

as they physically moved from one point to another in the supply chain. Some did not

originally get shipped out due to a back order, an order cancellation, or a failure to

pass quality inspection. Others got lost, stolen, or misplaced during the transport.

Belis T., Tsafarakis S. and Doulamis A. (2009).

Real-Time Traceability and Intelligent Product Management in the Supply Chain.

In Proceedings of the 3rd International Workshop on RFID Technology - Concepts, Applications, Challenges , pages 91-102

DOI: 10.5220/0001996300910102

Copyright

c

SciTePress

Some were found improperly configured or packaged, or to have missing parts or

inadequate data sensitivity labels when they arrived at a distribution center. Others

got damaged, recalled or spoiled during their transport to final destinations. Items that

were cannibalized, discontinued, or returned were not properly recorded into the

system. Under these circumstances, excess, idle, and duplicate items piled up in the

warehouse. Problems of tracking over-shipped, under-shipped, user-dissatisfied, and

wrong items occur almost on a daily basis.

In this work we propose RFID (Radio Frequency IDentification) as an efficient so-

lution to the above problems. This technology enables the complete real-time tracea-

bility in each point of the supply chain. Unlike bar-coded labels, RFID tags can in-

clude information on where in the supply chain the packages, items, and pallets were

physically moved, how they were tracked, and when the tracking took place at each

point of the chain. RFID tags for a case hold a wider range of data about the product

and the manufacturer than the tags for individual items. This saves the time and cost

required for opening the case, taking out each product to read its label, putting back

the products, and repacking the case, as the pallets move from one end to another in

the supply chain.

As mentioned before, systems like this handle enormous amounts of information.

This requires the incorporation of an ontology that will provide the user with useful

feedback. For example if there is lack of stock in a certain product category in the

warehouse, the system should have the ability to know all the products that are un-

available without the use of the product database.

2 Related Work

The authors of [13] have proposed a RFID-based Material Tracking Information

System. However their research specializes in internal traceability (factory bounded).

In addition the system doesn’t work with bar-code data. The system that we propose

works with bar-code data as well as RFID. In this case real-time traceability is really

impractical due to bar-code technology limitations, but the proposed system is still

functional.

Only one extended research is directly related to the ontology-based products and

services classification. The UNSPSC [9] is an open, global, multi-sector standard for

efficient, accurate classification of products and services, available for use free of

charge. However UNSPSC is a broad general purpose ontology. The ontology we

have developed specializes in particular brands in a certain supply chain. Thus it can

be directly incorporated into a particular management information system.

There is also only one proposal concerning RSS-based product information [7]

which is not relevant with traceability applications. In this paper we propose an RSS

format that specializes in product tracking. Then we integrate this information into a

RFID architecture in order to track (real-time) and trace (off-line) the product flow.

Finally there is one research in an ontology-based product tracking system [4].

However ontology and agent deployment premises common set of protocols, lan-

guage and common ontology all over the supply chain. Thus there is lack of standar-

dization. Also the above system architecture does not use RFID technology which is

the key for real-time tracking.

92

3 Technologies Used

This section briefly describes the main technologies used in the proposed system.

3.1 RSS (Really Simple Syndication)

For efficient product description we need an XML-type document which will be used

in transmitting product data according to the system architecture. XML gives us an

incentive to describe product information semantically [7]. Any time the product

XML is updated, generated or deleted, the system can log the information, which is

the key for implementing traceability purposes.

Suitable vocabulary for structured representation of product data (XML) can be

used in case of closed systems such as B2B merchandising. A common practice in

these cases is the adoption of EDI protocols, which are quite expensive. However, if

we use the web to transmit the RSS Feeds, the above cost can be minimized. In case

of large-scale systems such as the supply chain, a product cannot be recognized se-

mantically without standardization of vocabulary. The solution is given by RSS.

RSS 2.0 is one of standardized XML. All RSS files must conform to the XML 1.0

specification, as published on the World Wide Web Consortium (W3C) website [1].

The complete RSS 2.0 specification can be found at Harvard Law for internet tech-

nology [12].

3.2 Ontologies

Ontologies are used to capture knowledge about some domain of interest. An ontolo-

gy describes concepts in the domain and also the relationships that hold between

those concepts. Standardized ontologies for many disciplines are now being devel-

oped, which domain experts can use to share and annotate information in their fields.

Ontologies on the Web range from categorizations of products and their features

(such as on Amazon) to large taxonomies categorizing web sites (such as on Yahoo).

Usually the main reason for developing ontologies is for sharing common under-

standing, structured information among software agents. For the purpose of our

project we developed an ontology in order to describe the relationships among differ-

ent products of different classes. This will provide the user with the ability to query

the ontology and receive certain useful responses. For example, assume that we have

a retail-store, and there is lack of stock of a product. With the use of the ontology, the

system is able to propose to the user a variety of similar products of different brands

and classes.

3.3 Radio Frequency IDentification

RFID technology enables the optimization of multiple business processes. This can

be done through the improvement and the automation of existing processes, and the

93

emergence of new processes called intelligent or smart processes, which are automat-

ically triggering actions or events.

A RFID system consists of three parts: radio frequency (RF) tags, RF tag readers

and the middleware which in most cases is a savant server. RF tags consist of a mi-

crocontroller and an antenna (either wire or printed using conductive carbon ink).

Readers interrogate tags for their contents through the RF antenna and pass the data

to the servers net for further filtering and processing. Most RFID devices work in

Industrial-Medical-Scientific bands which are freely available for use by low power,

short-range systems [6], [8].

Barcode-based identification mechanisms are being replaced all over the world by

RFID, as communication between a reader and a tag is not limited by the requirement

of ‘‘line-of-sight’’ reading. In addition, unlike barcode, each RFID tag has a unique

ID called EPC (Electronic Product Code).

3.4 Savant Servers

Savants are servers running Savant software in a Unix-type operating system or, if the

RFID data streaming is not too overwhelming, a Windows platform server. This kind

of server can control all the readers at one, or all the mini savant servers which

process and filter information from a particular area in the supply chain. Savant serv-

ers allow customized filters to fix incorrect or duplicate data, monitor for event

changes, log data into a database or remote servers, and send alerts to the intended

recipients [5].

Protocols such as RS-232, RS-485, TCP-IP, need some sort of data management

system in order to effectively cooperate. Unified servers are savants customized to

receive all the different data between readers. Those servers can convert all data sig-

nals to Ethernet. We chose Ethernet because it offers the ability to multiplex up to

900 readers at a time, whereas protocols such as RS-232 allow only one. Further-

more, Ethernet can travel 100m, whereas RS-232 fails after about 5-10m.

4 Implementation Model

4.1 System Architecture

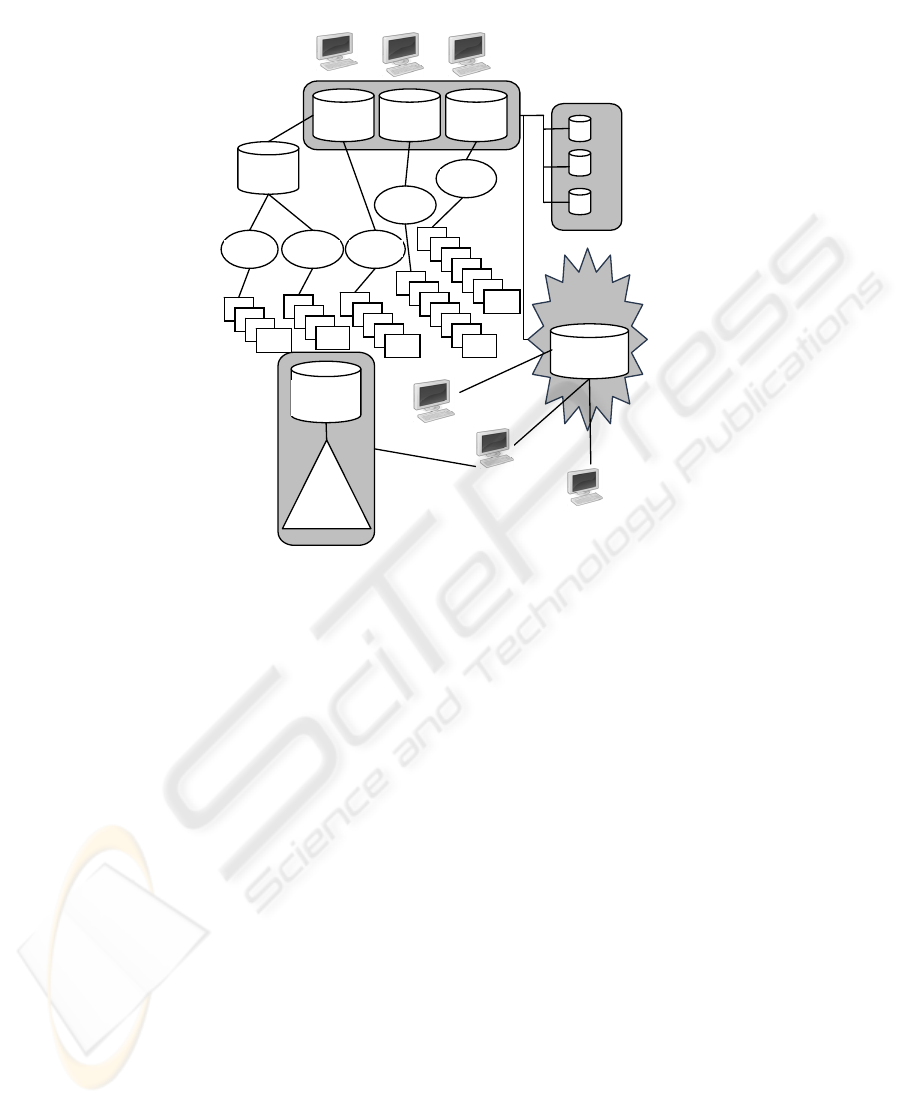

To deal with the product information management and real-time traceability we de-

signed a system which consists of a typical RFID architecture integrated with the

main product management system (Figure 1).

94

Ta

g

Ta

g

Ta

g

Ta

g

Tag

Ta

g

Ta

g

Tag

Ta

g

Ta

g

Ta

g

Ta

g

Tag

Reader Reader Reader

Unified

Server

Savant

Server

Savant

Server

Savant

Server

Ta

g

Ta

g

Ta

g

Ta

g

Ta

g

Ta

g

Tag

Reader

Ta

g

Ta

g

Ta

g

Ta

g

Ta

g

Ta

g

Tag

Reader

Actor #1

EPC IS

Actor # 2

EPC IS

Actor # 3

EPC IS

EPC Global

Database

Web

interface

RSS

RSS

RSS

Client #1

Client #2

Client #3

Local

Database

Product

classification

ontolo

gy

Query

Fig. 1. RFID system architecture for real time traceability and intelligent product management

in the supply chain.

The system works as follows:

1. Tags pass their EPC into the readers.

2. Readers pass the data to the unified savant servers (if readers support

same protocols then skip step 2).

3. Readers pass the data to the savant servers.

4. Each actor’s EPC Information System passes the data into the EPC Global

and a central web interface that contains a database.

5. When the web server receives an update ping (new product add or product

place status update) automatically generates an RSS Feed which contains

the updated product information.

6. Each client that is subscribed to the product channel automatically rece-

ives the generated RSS Feeds.

7. RSS Feed aggregator stores Feeds into a local database for further

processing.

8. Client’s information system processes the Feeds in order to provide the

real-time downstream traceability information and keeps a product history

in order to provide off-line upstream traceability information.

9. Client’s information system queries the product classification ontology.

The ontology gives a feedback of certain information that allows user

manage products efficiently.

95

In the next paragraphs we will describe some of the elements of the above archi-

tecture.

4.1.1 Web Service Implementation

The web interface was developed with use of PHP 5.2.0 and MySQL 5.0.27. The web

service runs on Apache 2.2.3 server. It consists of a central login page that supports

128-bit encryption for maximum security, the central database and an RSS Feed ge-

nerator. The feeds are generated from database fields of the updated products.

Fig. 2. Central product database.

The server is integrated with an on-line processing system that provides statistics

such as portage percentage, traceability system usage and manufacturer unreliability.

The system queries the central product database, processes the results and displays

them in several chart types. The charts are generated with use of Fusion Charts soft-

ware that is embedded in the web interface.

4.1.2 Client Implementation

The client is developed with the use of Visual Basic 2008, SQL server 2005 and

XML 1.0. It consists of an RSS Feeds aggregator, a local database and a product

classification ontology. The aggregator is responsible for reading the Feeds and stor-

ing them into the database.

The system primarily categorizes products according to their plant of origin. When

a certain product is selected, the user can see the current location of the product in the

supply chain, the product name and its ingredients, as well as the product location

history. When a certain place of a product is selected the user can see the exact date

and time that this product was located in this particular place. All the required infor-

mation is being retrieved from the central database (Figure 2). A mini web browser

connected with the web interface is also available (Figure 3). This provides the user

with real-time feedback of the statistics and the database status. Finally the user has

96

the ability to classify products according to the category they belong to or according

to the attributes of the ontology.

Fig. 3. Client for real-time traceability and intelligent product management.

Fig. 4. Client dataset.

The client retrieves data from the web interface through RSS Feeds. In order to re-

ceive the HTTP retrievable RSS Feeds the client does the following:

1. Sends a web request to the specified RSS URL.

2. Gets response of the RSS Feeds stream.

3. Stores Feeds temporarily.

4. Converts response data into XML Document.

5. Loads the XML.

6. Reads the specified items.

Further processing of the generated XML involves LINQ. The LINQ Project is a

codename for a set of extensions to the .NET Framework that encompass language-

integrated query, set, and transform operations. It extends Visual Basic with native

language syntax for queries and provides class libraries to take advantage of these

capabilities. In this project LINQ is used to query the complicated XML that de-

scribes the ontology.

Once we read the feed we need to store the received information into the local da-

tabase. For data representation the client uses the dataset illustrated in Figure 4.

97

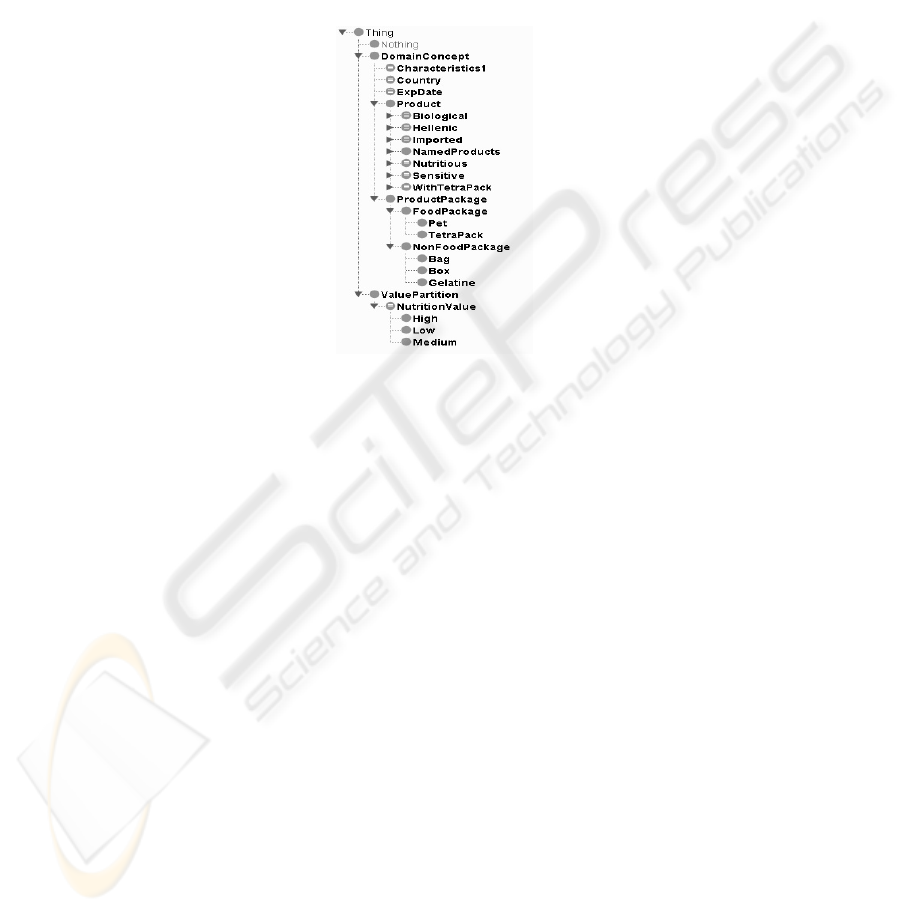

4.1.3 Ontology Development

A precisely defined product terminology, relevant for linking and classifying product

information, can enable accurate information integration in the enterprise.

In order to build the ontology we used OWL [3] and Protégé 4.0 beta editor. OWL

is the most recent development in standard ontology languages and has been devel-

oped from the World Wide Web Consortium (W3C). Protégé OWL is based on a

different logical model which makes it possible for concepts to be defined as well as

described.

Fig. 5. Inferred product classification ontology.

When the logical model development is completed we can use a reasoner which

checks whether or not all of the statements and definitions in the ontology are consis-

tent. The reasoner can also recognise which concepts fit under which definitions. In

this project in order to examine the product classification ontology for consistency we

used the Fact++ reasoner.

The ontology we developed describes several named products, their attributes and

the relations that hold between them. This structured representation enables the sys-

tem to query the XML that contains the ontology and pass the results into the graphi-

cal user interface. Figure 5 shows the inferred ontology developed. The inferred on-

tology can be exported in different formats. We chose to export ontology in XML

format in order to be embedded and deployed by the client software.

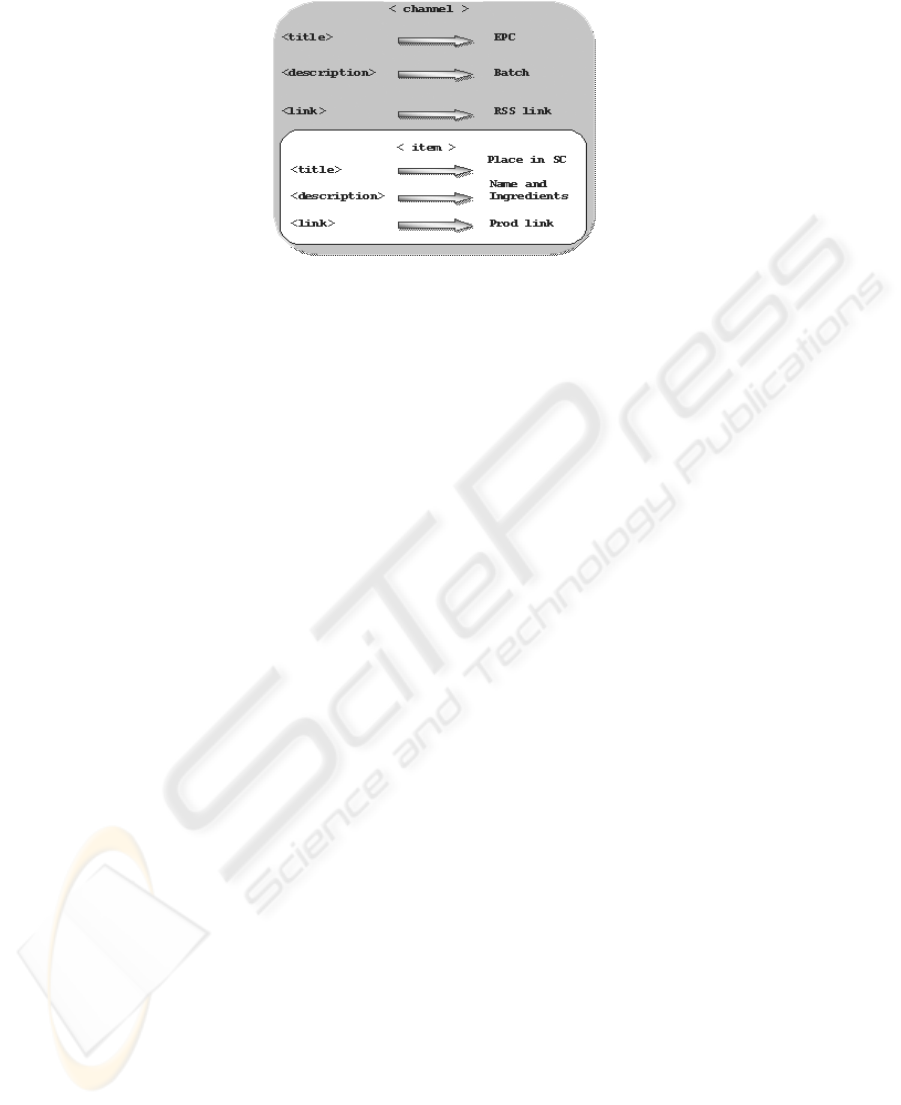

4.2 RSS-based Product Information

As mentioned before RSS feeds are XML representations of the entries in frequently

updating websites, which enable users to subscribe to those syndicated contents using

suitable software, called feed readers. Moreover, since feeds are XML documents,

they can be extended to include other semantic data besides titles and descriptions of

products, such as traceability data.

98

Fig. 6. RSS-based product information.

Figure 6 shows a simple correspondence of the standardized basic RSS tags with

the desired product traceability information. This correspondence can be extended

with other standardized optional RSS tags in order to transmit more detailed informa-

tion.

In this case overwhelming data stream may take place, thus we need to consider

the available network resources.

5 System Evaluation

In this paper we introduce an intelligent and effective traceability system. Nowadays

the adoption of protocols such as EDI for transmitting traceability data in B2B appli-

cations is a common practice. However this could be very expensive because we

usually need WAN connections with large bandwidth, maintenance engineers and

operational staff. Also in case of connection loss the whole system breaks down and

certain part of the data is being lost.

The use of RSS for transmitting data provides us the advantage of using the Web

instead of a straight forward, expensive and unreliable WAN connection. As de-

scribed in previous sections the system is designed to be autonomous, so we don’t

need extra operation staff for this purpose.

RSS-based product information can be extended with other standardized optional

XML tags in order to transmit more detailed information that suits a particular enter-

prise. The combination of these information and real-time tracking of a particular

product, results the complete transparency in the supply chain.

Current RFID applications in the supply chain use EPC, which is a standard that

identifies products according to owners and types. The system we implemented in-

corporates an ontology that creates relations among different types of products of

different manufacturers. This provides user with an intelligent tool that has the ability

of submitting more descriptive queries to the database.

The system we developed supposes that all the supply chain actors share the same

database. In the future we are going to extend the service in order to support addition-

al data representations by developing patterns for the RSS-generator. Thus the system

will be interoperable.

99

6 Conclusions

This paper puts forward a solution of a RFID system architecture for real-time tracea-

bility and intelligent product management in the supply chain. A RSS-based product

information model for transmitting traceability data is also proposed, as well as a

simple product classification ontology. In this paper we specialized in the sector of

food and drinks. Nevertheless the system works for most enterprises as well, with

little modification and special ontology incorporation. The system can also work with

barcode data as but in this case real-time traceability is unfeasible. The proposed

system provides enterprises with the opportunity to apply a low cost traceability sys-

tem which allows transparency of products in the supply chain. The incorporation of

the ontology optimizes the product management system which obtains intelligence.

7 References

1. Bray, T., Paoli, J., Sperberg-McQueen, C. M., Maler, E., & Yergeau, F. (2008, Nov.).

Extensible Markup Language (XML) 1.0 (5th Edition). W3C. Retrieved December 5, 2008.

2. Chidambaram, S., Whitman, L., & Cheraghi, S.H. (1999). A Supply Chain Transformation

Methodology. Proc. of the 4th Annual Inter. Conf. on IETAP, San Antonio, USA

3. Horridge, M., Knublauch, H., Rector, A., Stevens, R., & Wroe, C. (2004). A Practi-

cal Guide To Building OWL Ontologies Using The Protege-OWL Plugin and CO-

ODE Tools Edition 1.0, The University Of Manchester.

4. Ketkar, V., Whitman, L., & Malzahn, D. (2002). Ontology-based product tracking system.

Proceedings of the Industrial Engineering Research Conference.

5. Lamont, M. (n.d.). Savant Web Server. Retrieved July 18, 2008, from

http://savant.sourceforge.net/index.html

6. Myerson, J. (2006). RFID in the Supply Chain: A Guide to Selection and Implementation,

Auerbach Publications.

7. Nakano, Y., Sagawa, H., & Tarumi, H. (2005). A Proposal of RSS WebCrawler Model of

Product Information Product Information Service with RSS 1.0, Proceedings of the IEEE

International Conference on Active Media Technology, 147-151.

8. Syed, A., & Mohammad, Y. (2008). RFID Handbook Applications, Technology, Security

and Privacy. CRC Press, Taylor & Francis.

9. UNSPSC (n.d.). United Nations Standard Products and Services Code. Retrieved July 21,

2008, from http://www.unspsc.org/Defaults.aspv

10. van Goor, A.R, Ploos van Amstel, M.J, Ploos van Amstel, W. (1996). Physical Distribu-

tion: Thinking in Added Value, Stenfert Kroese, Leiden.

11. Vernede, R., Verdenius, F., & Broeze, J. (2003).

Traceability in food processing chains : state of the art and future developments Agrotech-

nology & Food Sciences Group, (Rapport 015 ), 46.

12. Winer, D. (2003, July). RSS 2.0 at Harvard Law. Berkman Center. Retrieved December 5,

2007, from http://cyber.law.harvard.edu/rss/rss.html

13. Zhang, M., Li, W., Wang, .Z, LI, .B, & Ran, X. (2007). A RFID-based Material

Tracking Information System, Proc. of the IEEE Inter. Conf. on Automation and Logistics.

100