PATTERN RECOGNITION

FOR DOWNHOLE DYNAMOMETER CARD IN OIL ROD PUMP

SYSTEM USING ARTIFICIAL NEURAL NETWORKS

Marco A. D. Bezerra

†

, Leizer Schnitman

†

, M. de A. Barreto Filho

†

† Dept of Electrical Engineering, Universidade Federal da Bahia (UFBA), Salvador, Bahia,. Brazil

J. A. M. Felippe de Souza

††

†† Dept of Electromechanical Engineering, University of Beira Interior (UBI), Covilhã, Portugal

Keywords: Artificial neural network, Pattern recognition, Oil well rod pump, Dynamometer cards.

Abstract: This paper presents the development of an Artificial Neural Network system for Dynamometer Card pattern

recognition in oil well rod pump systems. It covers the establishment of pattern classes and a set of

standards for training and validation, the study of descriptors which allow the design and the

implementation of features extractor, training, analysis and finally the validation and performance test with

a real data base.

1 INTRODUCTION

Oil is one of the main assets in the world economy

and are found in the subsoil and only rarely it has

energy to reach the Earth surface naturally.

Normally it is necessary to raise the oil artificially in

order to get it.

The most popular elevation mechanism used in

the oil industry is the “Rod Pump System”, which is

basically composed by three elements: the “Pumping

Unit”; the “Sucker Rod” and the “Pump” itself. The

main diagnostic measure tool is the “Downhole

Dynamometer Card” which is formed by the values

of position of the pumping unit and the pressure in

the connection junction of the sucker rod and the

pump.

The use of an automatic system for pattern

recognition of downhole dynamometer cards allows

anticipating the problems with its earlier

identification and therefore to take both corrective

and prevention measures for it.

Several works have appeared about mechanisms

of automatic classification of downhole

dynamometer cards (Foley & Svinos, 1987;

Dickinson & Jennings, 1988; Derek, Jennings and

Morgan, 1988; Abello, Houang and Russel, 1993;

Schinitman et al, 2003; P. Xu et al, 2006).

The present work proposes to investigate in the

literature a set of classes of anomalies of downhole

dynamometer cards, to artificially generate one data

training set, to study the feature extractor’s

mechanisms, to implement and train Artificial

Neural Networks (ANN) for recognizing these

patterns. Finally, it also proposes to test the result

with cards obtained from real rod pump system

systems.

2 THE PUMP SYSTEM

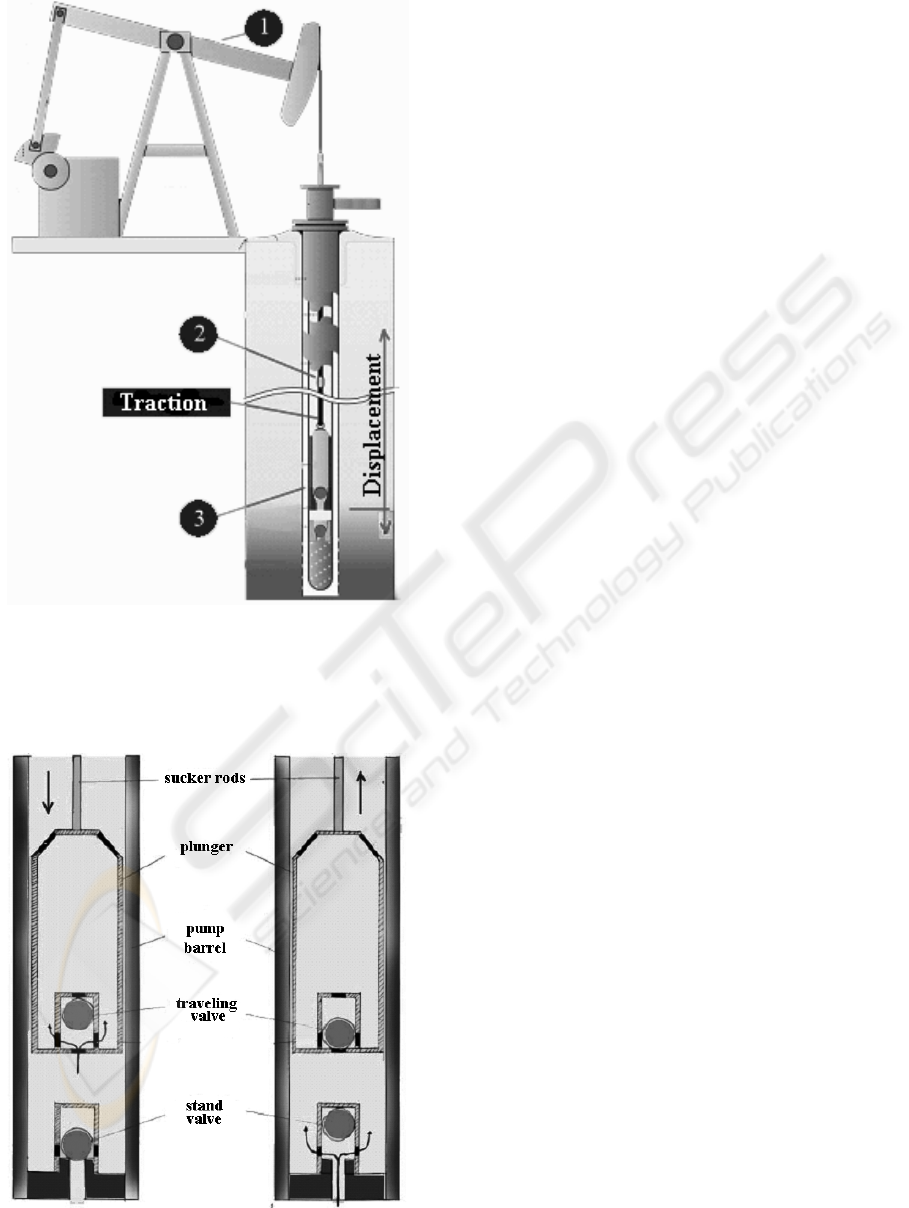

Figure 1 shows the main components of the system,

which are: the pumping unit; the sucker rod; the

pump itself.

The pumping unit is normally connected to an

electrical engine or an internal combustion engine

through a gearbox of torque transmission which

transform the spinning movement of the engine into

an alternate movement at the top of the sucker rod.

The sucker rod on its hand transmits the mechanical

energy received at the surface to the pump. Some

energy is lost in friction during this process.

351

A. D. Bezerra M., Schnitman L., de A. Barreto Filho M. and A. M. Felippe de Souza J. (2009).

PATTERN RECOGNITION FOR DOWNHOLE DYNAMOMETER CARD IN OIL ROD PUMP SYSTEM USING ARTIFICIAL NEURAL NETWORKS.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Artificial Intelligence and Decision Support Systems, pages

351-355

DOI: 10.5220/0002000403510355

Copyright

c

SciTePress

Figure 1: The Pump Mechanical System.

Finally, the pump, which is shown in details at

Figure 2, transmits the mechanical energy received

to the polyphasic fluid (oil, gas, sediments and

water).

Figure 2: The pump.

The main components of the pump are the

plunger, the barrel and the traveling valve and the

standing valve. They together form the pump system

of a positive displacement pump type.

In the downward course the traveling valve

opens and the standing valve shuts. In this way the

weight of the fluid column is supported by the sub-

set of the standing valve and it is transmitted by to

the tubing though the barrel. The plunger’s interior

is flooded by the fluid. Plunging the column of rods

in the fluid causes a small production due to the

volume which was shifted.

In the upward course the traveling valve shuts

and the standing valve opens. The fluid shifted by

the plunger shows up at the surface whereas the

barrel is refilled through the standing valve. In this

way, the weight of the fluid in the tubing is

transmitted to the columns of rods.

The dynamics described here can be seen as a

simple harmonic motion of a mass corresponding to

the columns of rods and the fluid load accumulated

at a single point.

That approach is no longer true if, for example,

the depth increases; or, if the fluid load increases; or,

if either the friction or the rotation rises; or, if the

physical properties of the equipments change. These

cases require a more accurate study on the

operational conditions and this leads to solving

damping wave equations to describe the motion.

The periodic evaluation of the system is done

through:

a) Plunging the pump: determined by the level of the

dynamic level.

b) Downhole dynamometer card: obtained by the

readings of the rod displacement and its

corresponding traction force.

c) Other indicators obtained through production

tests, or verifying the temperature of the rods, or also

pressurization tests of the equipment.

The downhole dynamometer card is the main

tool, and also the richest device, for monitoring the

system. It was created in 1936 when Walton E.

Gilbert published his work (Gilbert, 1936) that

describes the its use for diagnosing the rod pump

system.

To better diagnose the working conditions of the

rod pump system several papers have appeared later,

pointing out to the pioneer work of Gibbs & Neely

(1966) that used mathematical modeling and

computer techniques to determine the conditions on

the sub-surface from measurements conducted on

the surface.

ICEIS 2009 - International Conference on Enterprise Information Systems

352

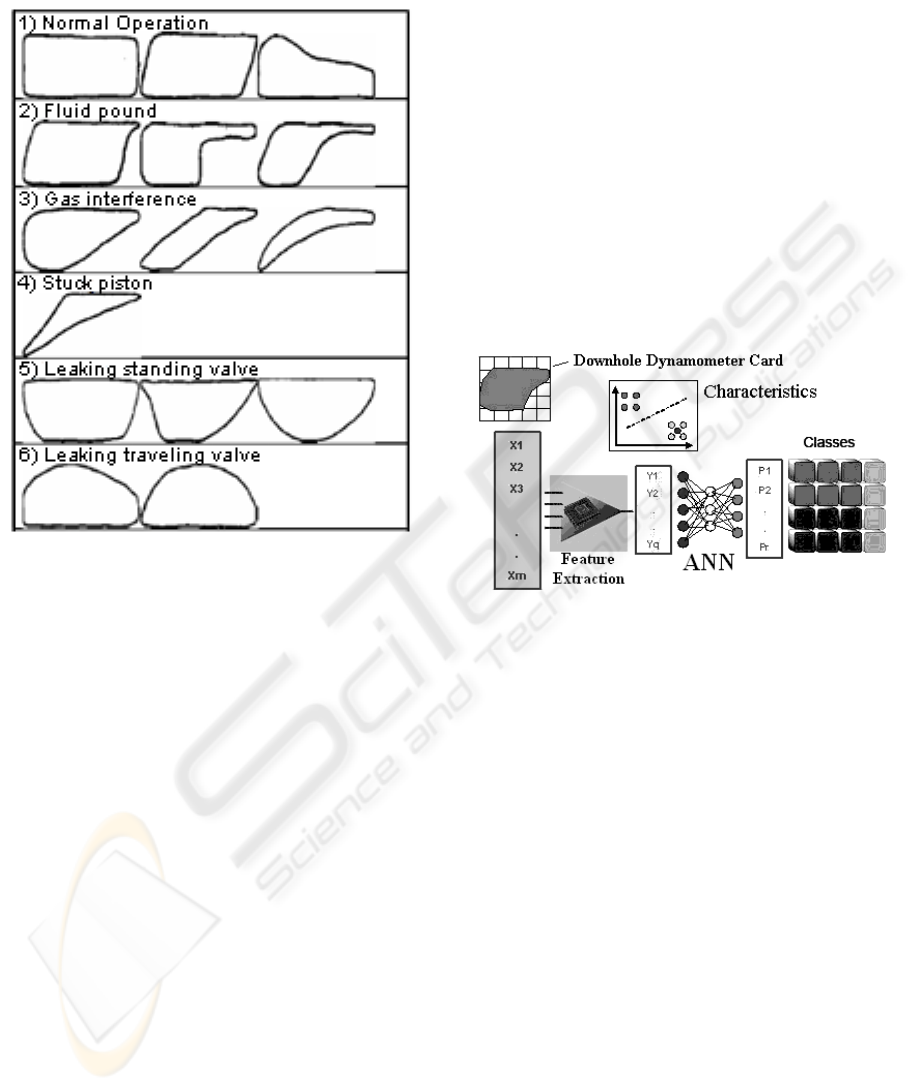

Table 1: Classes for downhole dynamometer cards (a

sample).

Eickmeier (1966) presents the Delta II

dynamometer and its corresponding data analysis.

Electronic sensors arranged as a load cell and a

potentiometer are used together with analogical

recording.

Several schemes have been done in order to get

an automatic diagnostic for the downhole

dynamometer cards using both statistical and

syntactic methods, artificial neural networks (ANN),

and even symbolic neural networks. One can

establish a wide set of classes that are used for

pattern recognition of the downhole dynamometer

card behavior (Table 1).

3 METHODOLOGY

The proposed process for pattern recognition of an

occurrence has two stages: The first stage is the data

acquisition, which is presently accomplished by field

instrumentation and its corresponding processing,

where a computational solution for the model, as

described in section 2, transforms a surface

dynamometer card, which is formed by values of

displacement and tension of the rods acquired by

using sensors that are placed on the surface

equipment, into a downhole dynamometer card,

which is also a set of displacement and tension

values, but, however, conceived for the position

corresponding to the junction between the column of

rods and the plunger.

The second stage the tool for pattern recognition

itself (Figure 3), which has two parts (Haykin,

1998):

1

st

) the feature extraction, which does the a

transformation of the vector X from an observation

space of dimension ‘m’, which is the downhole

dynamometer cards data, into the characteristic

space of dimension ‘q’, where q < m, in order to

simplify the classification task.

2

nd

) the classifier, comprised of a ANN that

associates the vector of characteristics Y of

dimension ‘q’ into one of the classes of the decision

space which has dimension ‘r’.

Figure 3: Characteristic Extractor and Classifier (ANN).

The Characteristic Extractor has two approaches,

the first being to eliminate the redundant information

and the second being the linear or nonlinear

transformation into the observation space dimension.

Here, the proposed scheme is a multiple layers

feed forward ANN with a supervised training device

(Haykin, 1998).

As for the training the proposed structure is to

generate artificially a set of standards using the class

models as shown in Table 1, with a random noise

introduced.

In order to have an approximation closer to

reality, where the values of the cards are attained by

sampling in regular time intervals, a simplification

was conducted, where the sucker rod motion is the

vertical projection of a point in simple harmonic

motion with a constant angular velocity.

4 RESULTS AND DISCUSSION

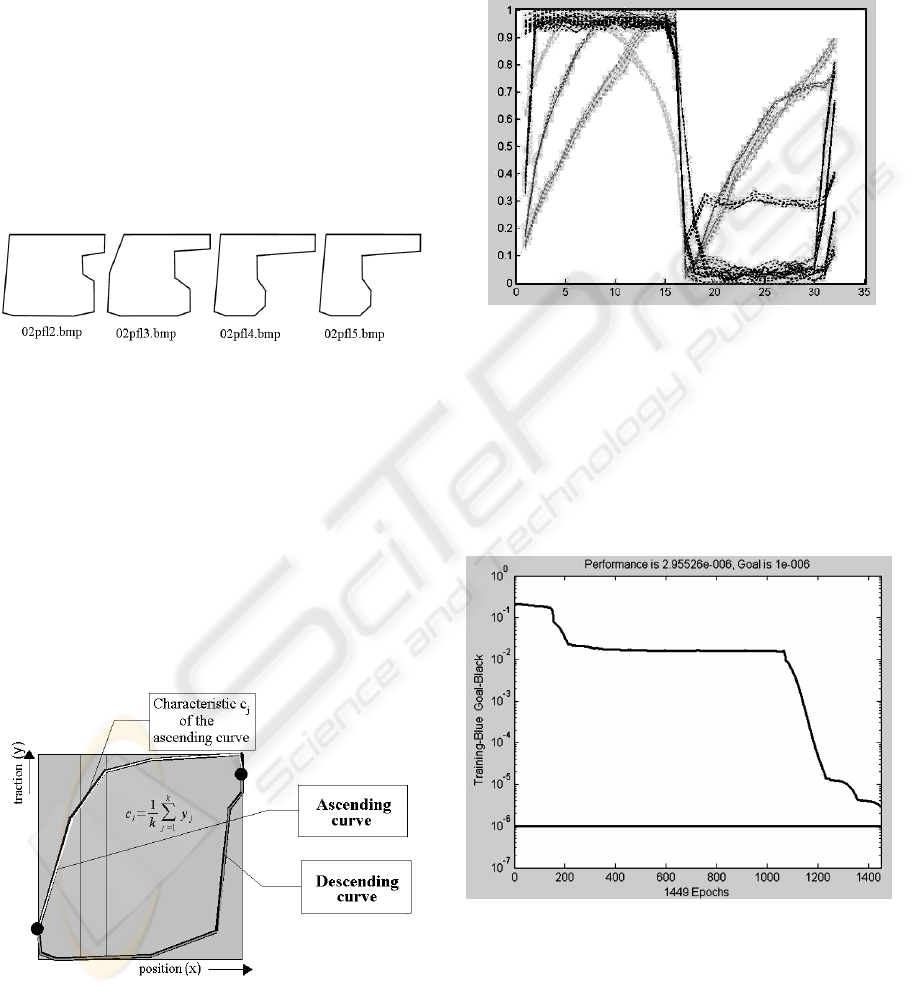

Initially, an application was done with the aim of

using the proposed methodology to a set of 6,101

PATTERN RECOGNITION FOR DOWNHOLE DYNAMOMETER CARD IN OIL ROD PUMP SYSTEM USING

ARTIFICIAL NEURAL NETWORKS

353

cards from real oil wells and each one composed of

a set of 100 points, which were previously classified

by a human expert.

The first step to obtain the artificial standards

was to generate an image set in bit map, based on

models, and using image manipulation software

(Photoshop ver. 8.0.1). Figure 4 illustrate a set of 4

images that represents the class of cards with fluid

pound and in situations ranging from small to large

gravity.

A set of 100 points was obtained from each

image. These points are arranged in values of

position (x axis)

and traction (y axis), where half of

them establishes the ascending curve of the pump

whereas the other half forms the descending curve of

the pump.

Figure 4: Bit maps from some fluid pound models.

These sets have been normalized and two sets of

artificial cards were generated: one for the training

of the network and another one for the validation.

Each of these sets consists in 8 different classes with

300 downhole dynamometer artificial cards by each

class.

Here a characteristic extractor that uses vertical

projections of the ascending and descending curves

was used. This is shown in Figure 5. Acceptable

results were obtained with a set of 16 projections of

the descending curve and also 16 projections of the

ascending curve.

Figure 5: Characteristic extractor.

This allowed a reduction of the dimension of the

space from 200 (corresponding to 100 pairs of

values of potion and traction) to just 32.

Figure 6 shows the output of the 32 outcomes

from the plunger hitting top for the several families

of artificial downhole dynamometer cards.

One can verify that each family of artificial

downhole dynamometer cards holds a well-defined

recognizable signature.

Figure 6: Output of the characteristic extractor.

Several tests were carried out and the results

achieved were satisfactory. The ANN type used was

feed forward with 32 inputs, 16 neurons in the

hidden layer and 8 neurons at the possible output

layer. Sigmoid transfer function was used in the two

last layers.

Figure 7 shows the network training results, for

which it was used the algorithm TRAINGDX.

Figure 7: Training results from the ANN classifier.

After the training the network validation was

performed using now the second set of artificial

cards with 100% correct results.

For the final test the 6101 real downhole

dynamometer cards were used and the following

result was achieved:

ICEIS 2009 - International Conference on Enterprise Information Systems

354

a) 11 card were not classified since the neurons

at the output layer held values below the limit

established by the criteria (0,1).

b) 69 cards were wrongly classified. However,

from these 69 cards, 30 of them were cards pre-

diagnosed as “plunger hitting top” when in fact they

were “normal”

Figure 8: Error analysis in the classification.

When the above results were shown to a human

expert, he observed that he would have considered

as an acceptable diagnosis produced by the artificial

neural network. That represents a considerable

improvement in the results.

Summing it up, from the 6,101 cards which were

tested, the total classification error was found to be

1,31%.

5 CONCLUSIONS

The present work shows that the generation of

artificial standards for training neural networks in

order to analyze the pump mechanic system in oil

elevation is feasible. The results shown here leave

open the possibility of creating a scheme that not

only incorporate the complete set of classes of

anomalies, but which is also able to integrate the

data base of real automation systems.

ACKNOWLEDGEMENTS

To PETROBRAS for letting available information

on real data for realizing the tests here. Also to the

Graduation Program in Mechatronics of UFBA

(Universidade Federal da Bahia) for the support

given.

REFERENCES

Abello, J., A. Houang and J. Russell. (1993). A Hierarchy

of Pattern Recognition Algorithms for Diagnosis of

Sucker Rod Pump Wells, IEEE 08186-4212-2/93, pp

359-364.

Derek, H. J., J. W. Jennings and S. M. Morgan. (1988).

EXPROD: Expert Advisor Program for Rod Pumping,

SPE 17318.

Dickinson, R. R. and J. W. Jennings. (1988). The Use of

Pattern Recognition Techniques in Analyzing

Downhole Dynamometer Cards, SPE 17313.

Eickmeier, J. R. (1966). Applications of the Delta II

Dynamometer Technique, 17th Annual Technical

Meeting, The Petroleum Society of C.I.M., Edmonton,

maio/1966.

Haykin, Simon (1998). "Neural Networks: A

Comprehensive Foundation", Second Edition. Prentice

Hall.

Foley, W. L. and J. G. Svinos. (1987). EXPROD: Expert

Advisor Program for Rod Pumping, SPE 16920.

Gibbs, S. G. and A. B. Neely. (1966). Computer Diagnosis

of Down-Hole Conditions in Sucker Rod Pumping

Wells, Journal of Petroleum Technology, jan/1966, pp

91-97.

Gilbert, W. E. (1936). An Oil-Well Pump Dynagraph.

Production Practice, Shell oil Co., pp 94-115.

Schinitman, L., G. S. Albuquerque, J. F. Corrêa, H.

Lepikson and Bitencourt, A. C. (2003). Modeling and

implementation a system for sucker rod downhole

dynamometer card pattern recognition, SPE 84140.

Xu, P., S. Xu and H. Yin. (2006). Application of self-

organizing competitive neural network in fault

diagnosis of suck rod pumping system, Journal of

Petroleum Science & Engineering, 58 (2007) pp 43-

48.

PATTERN RECOGNITION FOR DOWNHOLE DYNAMOMETER CARD IN OIL ROD PUMP SYSTEM USING

ARTIFICIAL NEURAL NETWORKS

355