A CASE STUDY OF AUTOMATED INVENTORY

MANAGEMENT

Abrar Haider

School of Computer and Information Science, University of South Australia

Mawson Lakes, South Australia 5095, Australia

Keywords: IT asset, Tracking, Integration.

Abstract: Maintaining a knowledgebase the location and condition of IT assets in large organisation is a problem.

Knowledge of exact number of these assets is important for a number of reasons, which include controlling

or eliminating procuring multiple assets for the same job or task; cost savings on maintenance contracts in

accordance with the exact number of assets to be maintained; reduction in man hours spent in locating these

assets; and checking theft. This paper presents a case study of a large sized Australian utility that is

grappling with the same problems. In addition to these issues the company is also looking for looking for

improved security of fixed/removable/mobile IT assets used by staff, integration of IT asset movement

information with the staff access card and associated systems currently in use. This paper, therefore,

presents a set of options available to the company to track the movement of their assets, and using the same

technical architecture to integrate asset information with the information of the staff moving the asset.

1 INTRODUCTION

With improvements in computer power and

miniaturisation of the components of microchip

technology, automated identification technologies

are now being used in various applications in

governments, business, supply-chain management,

logistics and retail. Since early days of the current

decade numerous applications have been developed

using automated identification technologies. Among

these are applications like luggage tracking, tracking

individual parts along the production line; tagging

and tracking of patients; smart shelves for

pharmaceutical products, and smart toolbox etc.

Even though these identification technologies have

been used in a variety of settings, however, the

fundamental feature of tracking and traceability of

these technologies continues to hold great promise.

IT assets that get lost or misplaced add to the

total cost of ownership of these IT assets and thus

contribute to the costs of managing business

operations. Organisations generally use passive

technologies such as barcodes, which makes it

extremely difficult to track the IT assets and almost

impossible to maintain a history of the movements

of these assets. It is expected that the

implementation of the Radio frequency

identification (RFID) technology for asset tracking

will help to keep this cost in check. Using RFID

technology, it will be possible to not only track

assets but also maintain a history for every asset

which will prove to be a useful aid if an asset turns

put to be lost or misplaced. With integration of the

identification/access cards, the history could also

contain the details of personnel last responsible for

moving the asset. It will be possible not only to

monitor assets using RFID technology but also keep

track of the status of the assets which could be

viewed by anyone across the organisation through

related computer systems who would want access to

that asset. The adoption of RFID technology in

Australia is only recently escalating due to the new

standards that have emerged which have worldwide

acceptance as opposed to the previous ones which

were highly region-specific. This paper presents a

case study where RFID technology is applied to

track movement of IT assets in a large sized public

sector organisation, and the same architecture

integrates information of the asset with that of the

staff that moves or is responsible for the asset.

141

Haider A. (2009).

A CASE STUDY OF AUTOMATED INVENTORY MANAGEMENT.

In Proceedings of the 11th International Conference on Enterprise Information Systems - Software Agents and Internet Computing, pages 141-148

DOI: 10.5220/0002019401410148

Copyright

c

SciTePress

2 CASE BACKGROUND

This case involves a major utility in one of the

largest state in Australia. This organisation has

major problem in tracking the location of all of its IT

and related assets as well as finding out the exact

number of working IT assets. As a result not only

that the organisation keeps on procuring redundant

assets, but it also uses a rounded figure in signing

support and software licensing agreements. With

exact information on the number of assets, it will be

easy to manage resources effectively and to develop

maintenance contacts in accordance with the exact

number of assets to be maintained. For example, if

the current IT asset inventory states 5000 assets then

the support and licensing agreements are signed for

the same number regardless of the condition of the

assets. Information of exact number of assets, their

condition, and their location will help in reduction of

costs of support and licensing agreements, as well as

the man hours spent in locating these assets. In

addition, it will also eliminate the chance of

redundant purchase of IT assets. The company is

now looking for improved security of

fixed/removable/mobile IT assets used by staff,

integration of IT asset movement information with

the staff access card and associated systems

currently in use. It should be noted that the IT assets

include laptops, desktop computers, printers, servers,

hubs, scanners, plotters, data loggers, UPS units,

switches, routers, projectors, and smart boards.

3 CHOOSING APPROPRIATE

TECHNICAL FOUNDATION

Barcodes have traditionally been used for the

purpose of item tracking and warehouse

management. However, barcodes only identify a

class of items and cannot identity particular items.

For example, a barcode identifies a 500 ml of a coke

bottle but it is insufficient to identify the exact

location of that bottle. Similarly, information on

origin and manufacturing of an item could be related

to its barcode, but barcodes cannot provide

information regarding its movement after

manufacturing or commissioning, and current

condition. Another of their drawback is that barcode

technology is only effective in line of sight with the

reader, such that each item has to be scanned

individually. Hence for the purpose of item location

and tracking, Radio Frequency Identification (RFID)

is a suitable alternative. This technology has been

successfully deployed in different parts of the world

for various applications using its tracking and

identification allowance. The significant level of

interest in RFID technology’s development and

uptake has made it cost-effective and scalable (Wyld

2006). RFID technology falls under the

classification of Automatic Identification and Data

Capture technologies (Wamba et al. 2006). It

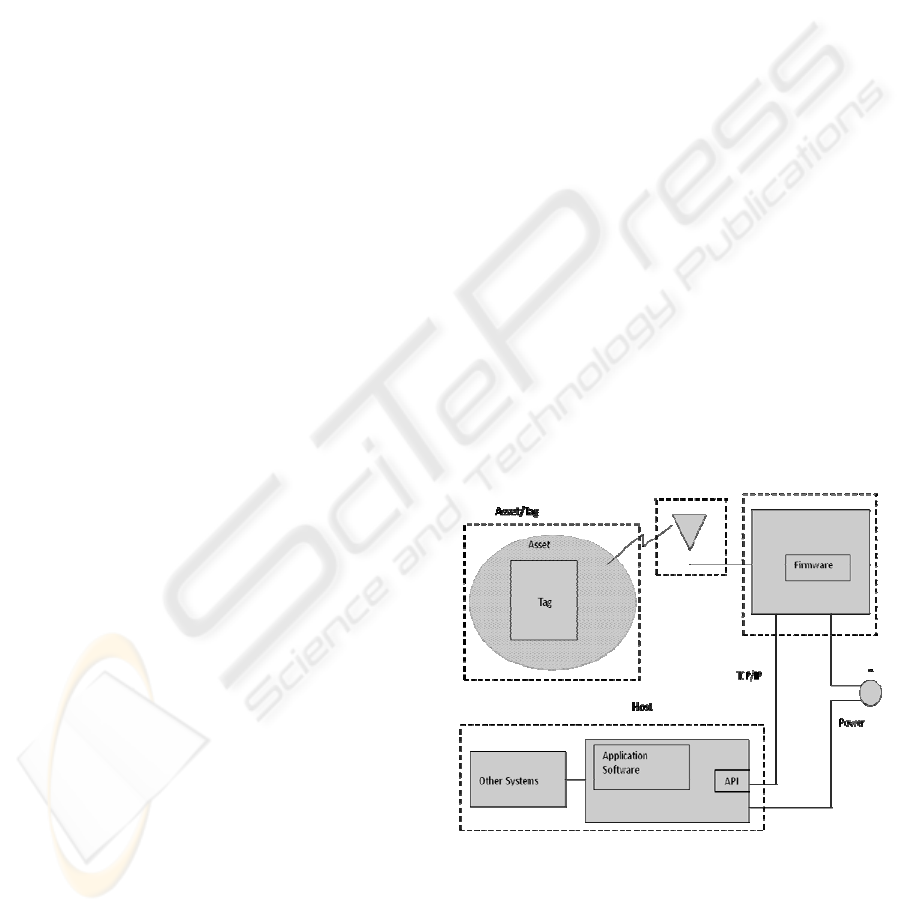

consists of three components, an RFID tag, a reader,

and a Tag/Reader management systems or a

middleware. RFID tags are made up of a small

microcontroller and antenna available in many

different packages. They provide a contact free form

of identification through the use of radio

frequencies. Each tag has an electronic product code

(EPC) or an identification number embedded into

the tag microcontroller that is used to uniquely

identify each tag, which can also be termed as the

RFID’s version of a bar code. When an RFID tag is

placed close enough to the reader it is powered up

through a magnetic field emitted by the reader thus

powering the microcontroller of the tag, such that it

transmits the EPC to the reader. RFID tags do not

require line of sight between tags and readers for

them to be detected and therefore make it possible

for tags attached to items to be identified from a

single point. Therefore it makes RFID a viable

option to address the issues at hand. The following

sections provide an analysis of how this technology

could be used to resolve the problems posed to the

case organisation.

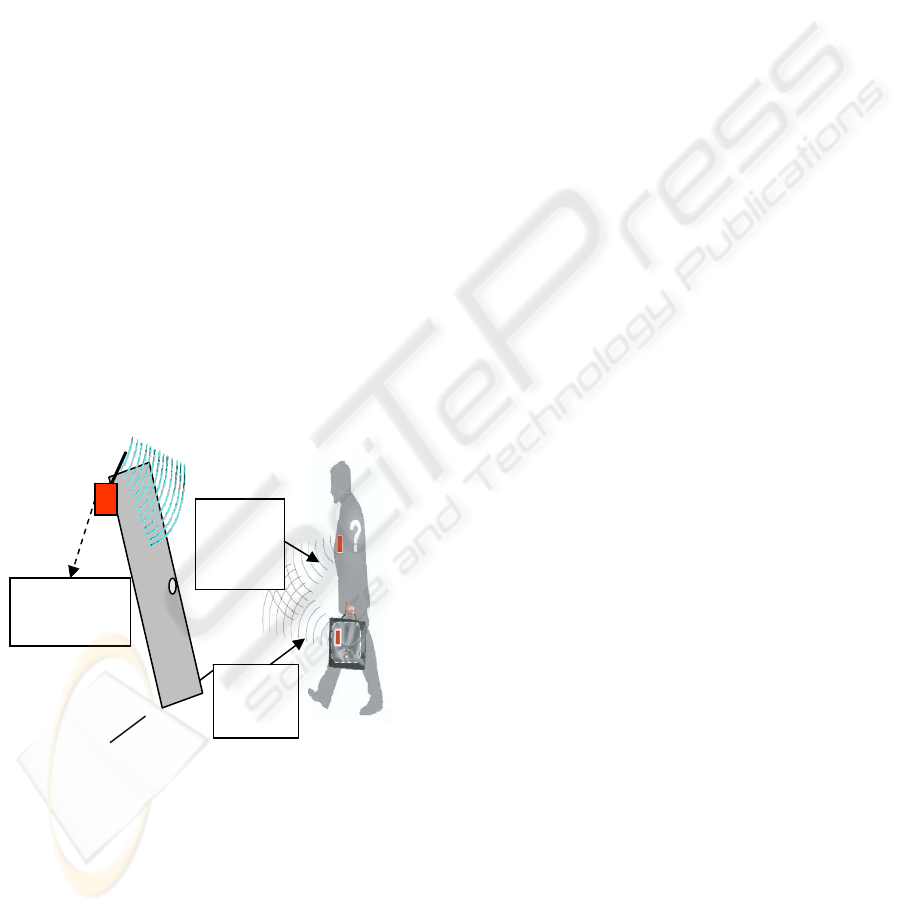

Figure 1: RFID System Components.

ICEIS 2009 - International Conference on Enterprise Information Systems

142

4 AUSTRALIAN TECHNICAL

ENVIRONMENT

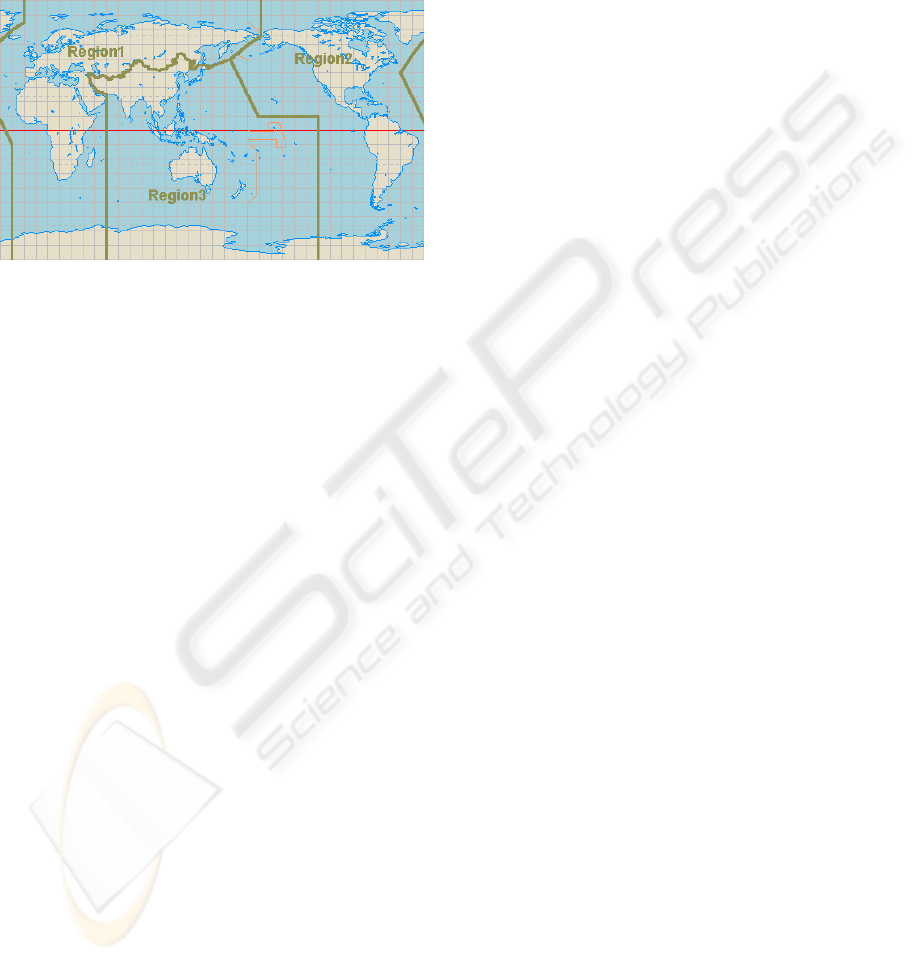

The International Telecommunication Union has

developed the ITU Radio Regulations. These

regulations form the basis of the Australian

Radiofrequency Spectrum Plan.

Figure 2: Automatic scanning using HF Tags.

The Radio Regulations divide the different radio

frequencies into bands and allocates services to each

band according to three geographic regions. These

regions are defined as Region 1, 2 and 3 (Australian

Communications Authority 2005). Region 1 is

composed of most of Europe, Africa and the Middle

East. Region 2 is composed of the Americas. Region

3 is made up of the Asia-Pacific region. Thus,

Australia is located in Region 3 (Australian

Communications Authority 2005). ISO/IEC 15693 is

a global standard for 13.56 MHz HF RFID tags

(Class 1) and reader electronics. The ISO/IE C

15693 protocol conforms to FCC (USA), ETSI

(Europe) and MPT (Japan) regulations worldwide.

The standard allows tags to travel around the world

under optimal conditions for operation with region

specific RFID readers (Attaran 2007). Hence the

standards for HF radiolocation are accepted all over

the world. However, for UHF radiolocation,

although, the frequency band assigned is from 860 to

960 MHz, not all the frequencies in this band are

usable. Both U.S. and Europe have different

frequencies in this band for radiolocation. In

Australia (Region 3), most of the frequencies in this

UHF band are used by mobile phone service

providers. Hence, the available frequency band that

may be used is from 915 to 928 MHz so that the

operation does not interfere with other applications

(Australian Communications Authority 2005). The

EPC has developed two standards, Class 0 and Class

1 for the UHF RFID tags. In December 2004, in

order to promote interoperability, they introduced

the Generation 2 standard to replace Class 0 and

Class 1. These Gen 2 tags are now being promoted

world-wide for their interoperability and their higher

memory capacity (Li et al. 2006).

The other regulation in Australia has to do with

the power output of the RFID readers. Current

Australian RFID services are governed by the

ACMA through the class of license for Low

Interference Potential Devices (LIPD). These

regulations limit the RFID services operating in the

915 to 928 MHz frequency band to a maximum

power of 1 watt EIRP (effective isotropic radiated

power). No licenses are required for applications up

to 1 Watt but anything between 1 and 4 Watts

requires a scientific license from GS1 Australia

(GS1 Australia 2008). Read range for RFID tags

depends on the power output of the RFID readers,

and the difference between 1 Watt and 4 Watt is

approximately a 300% improvement in read distance

and efficiency (i.e. improving the average read range

from 1 metre to 3 metres). Much of the World now

uses 4 Watt (GS1 Australia 2008). However, this

means that services operating at 4 Watts EIRP may

interfere with other services like mobile

communications which also operate in the same area

and around the RFID UHF frequency band. Both 1

Watt and up to 4 Watt have been used by GS1

Australia in various RFID pilots; with 1 Watt

suitable for shorter range applications, such as hand

held devices, and up to 4 Watt more suited to RFID

gateways or other applications where accurate reads

at a distance are needed (GS1 Australia 2008).

5 AVAILABLE OPTIONS

There following section discusses the options

available to address the issues at hand in this paper.

5.1 First Option

High frequency tags can be used for asset tracking in

the company. The tags operating at the frequency of

13.56 MHz are very cost effective and flexible. They

are available in paper as well as filmic inlays which

makes embedding with the assets very convenient.

The ISO/IEC 15693 standard for 13.56 MHz is

accepted worldwide and the protocols conform to

FCC (USA), ETSI (Europe) and MPT (Japan)

regulations which constitute the three Regions

determined by the International Telecommunications

Union (ITU). The standard allows tags to travel

around the world under optimal conditions for

operation with region specific RFID readers (Attaran

A CASE STUDY OF AUTOMATED INVENTORY MANAGEMENT

143

2007). Australia being in Region 3, according to the

Australian Communications Authority, the HF

frequency band can be used for radiolocation

(Australian Communications Authority, 2005). The

tracking of assets using HF tags may be done in two

different ways:

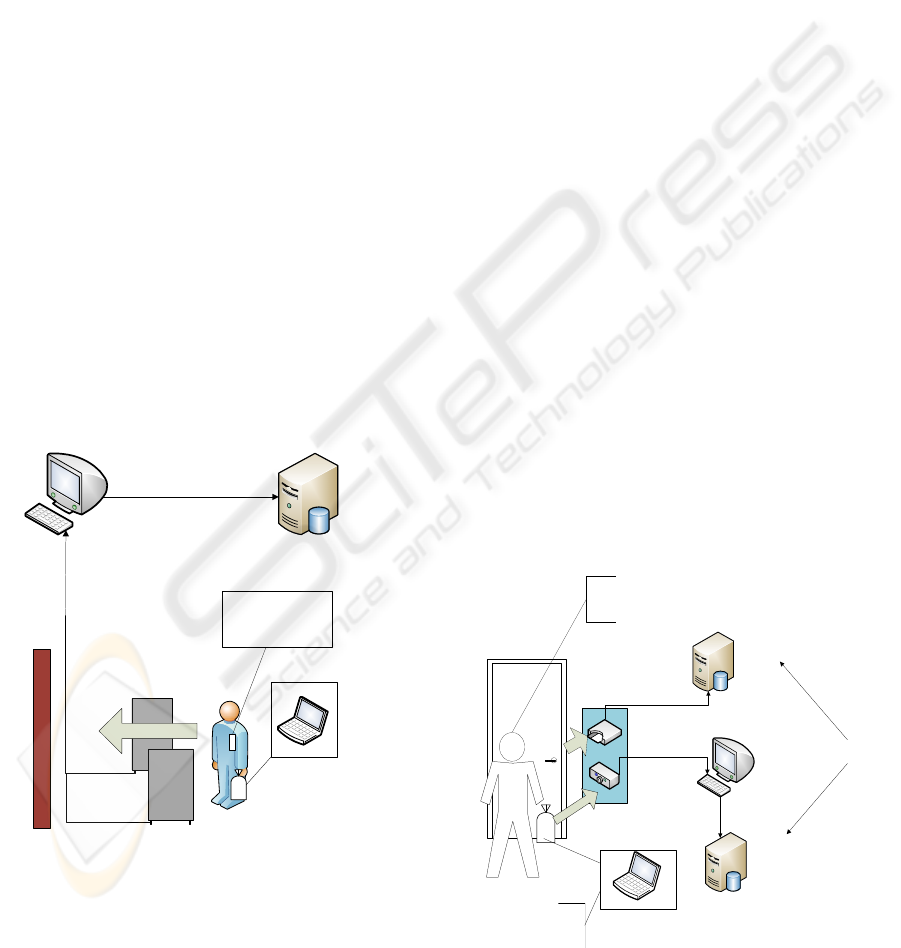

In this case, there are two RFID tags. One

attached to the IT asset and the other enabled on the

staff access/identity card. In this scenario, HF

readers are either mounted on the doorways or at

convenient locations similar to the ones present in

the anti-theft systems at supermarkets may be

installed before of after doorways (see figure 3).

Since the access/identity cards assigned to staff are

also equipped with HF tags, details like IT assets

assigned to them, asset configuration, maintenance

history, special operating requirements, and other

details can also be stored on the tags. In this

scenario, when staff enter or leave the room

equipped with RFID readers, the readers will

automatically read staff as well as IT asset tag. The

information captured will be compared against the

existing record to see if the IT asset being carried by

the staff members actually belongs to them or has

been issued to them. Upon confirmation, it will be

considered a valid ‘check-out’ event and relevant

information will be entered in the ‘asset movement

database’.

Figure 3: Automatic scanning.

This database will obviously be related to

employee/staff database and IT asset inventory

database. In case, the asset does not belong to the

staff member who is trying to take it out of the

room. They will need to make appropriate changes

to IT inventory database before leaving the room. In

case these changes are not made, the system will

generate an alarm and inform the security system.

When the employee returns with the asset to the

room, the same reader will be read the staff as well

as the asset tag, and the relevant ‘check-in’ event

will be recorded in the ‘asset movement database’.

The other option available is that of manual

scanning. This option is similar to the self-service

counters available at supermarket check-out or the

check-out systems available in many libraries. In

this case, the access/identity cards may not be

equipped with RFID tags, however, the assets are to

be tagged with HF tags. However, an RFID station

consisting of a reader and an access card scanner

needs to be present next to the door on the way out

of the room. When a staff member wishes to leave

the room with an asset, he/she will need to swipe his

card through the card scanner so as to invoke an

instance of the check-out event. Once his card has

been read, he will present the asset to the reader

which will read the HF tag and transmit this

information to the computer system. The system will

tie the employee data to the asset tag data and create

a ‘check-out’ entry in the ‘asset movement

database’. At the same time, the HF asset tag will be

deactivated and the employee can then leave the

room after the asset is ‘issued’ to him. If the

employee decides to leave without deactivating the

tag at the RFID station, an alarm will be raised and

the security system will be notified. The employee

can leave the room at anytime without going through

any scanning procedure if he is not carrying any

asset.

Figure 4: Manual scanning.

Tagged

Asset

RFID

Antenna

and Reader

RFID Host Database

Doorway

Tagged

Employee

Employee

Access card

Reader

RFID

Reader

RFID Host

Asset

Database

Doorway

First, employee has to scan his

access card through the card

reader

Next, the asset to be

checked out has to be

scanned at the scanner

Tagged Asset

Employee

Database

Tied at the

backend

ICEIS 2009 - International Conference on Enterprise Information Systems

144

When the employee wishes to return the asset, he

will have to scan his card which will bring up the

existing record and when the asset is presented to the

reader, the ‘check-out’ entry will be cleared as part

of the ‘check-in’ process. Also the tag will be

reactivated and ready for its next check-out event. It

should be noted that the HF tags and readers have

low read ranges and hence the automatic scanning

method might not be feasible unless the placement

of the antennas and readers is tested and the

optimum position is determined.

5.2 Second Option

Due to the read ranges provided by UHF (EPC Gen

2) tags, the automatic scanning method is feasible

when these tags are used for asset tracking. The tags

operate between the frequencies of 918 and 926

MHz in Australia and are available in many different

formats like paper, film, hard tags, discs and even

tamper-proof tags. Although these tags are designed

to operate in the frequency band of 860-960 MHz,

the Australian frequency spectrum plan only allows

operation in the 918 to 926 MHz range as the

remaining frequencies on either side of this band are

utilised by mobile service operators (Australian

Communications Authority, 2005). Various pilots

have been carried out in Australia to test the Gen 2

tags by GS1 Australia. One such pilot entailed the

implementation of EPC Gen 2 tags in the supply

chain of Patties Foods in Victoria along with their

logistics partners, Montague Cold Storage (GS1

Australia, 2008).

These tags only have provision for storing the

EPC which can be used as an identifier for the asset

to which the tag is attached. The EPC has been

designed to enumerate all objects and accommodate

all current naming methods. The EPC serves as a

reference to information on the computer network.

In order to describe the physical objects that the tags

are connected to, a language called the Product Data

Markup Language (PDML) is used. PDML is based

on XML and it uses a schema describing the

common aspects of physical objects. Using PDML,

data about the assets like configuration details,

service or maintenance history, physical attributes,

special operating requirements and so on can be

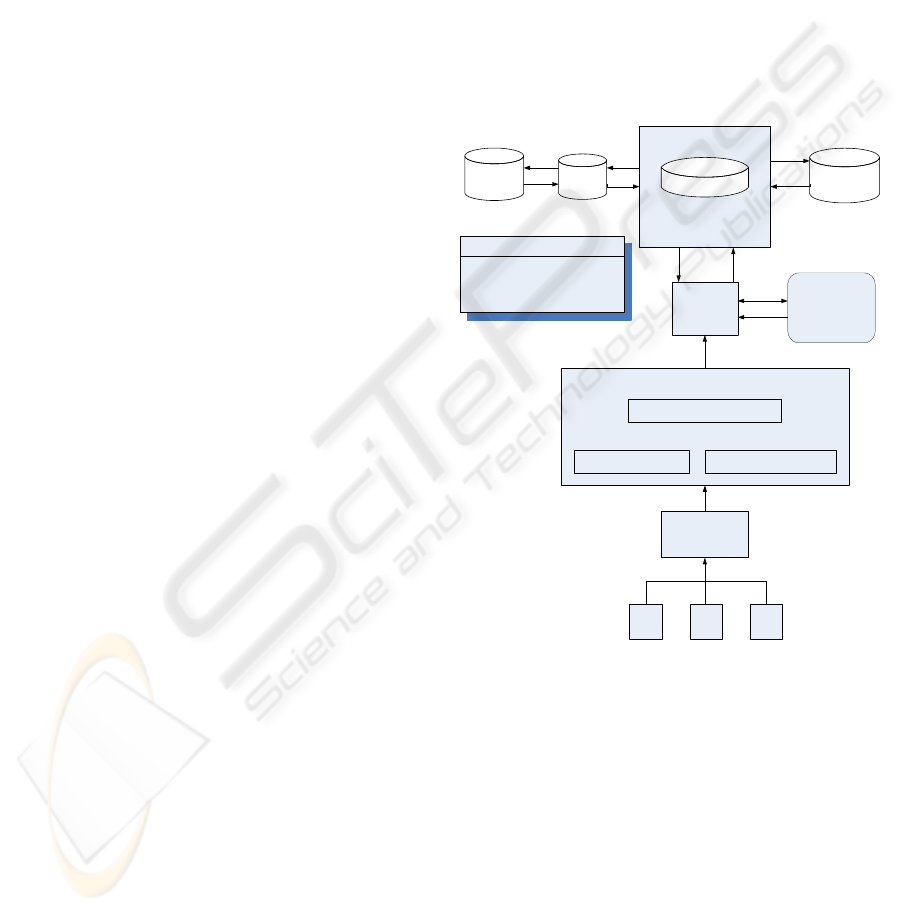

stored in a database. In this scenario (Figure 5), tags

attached to each IT asset are read by a reader fixed at

the convenient location, which passes the EPC

information to the middleware or savant. A savant

acts as buffer between the reader and other

organisational information systems, and consists of

various modules or sub programs with each module

performing specific functions. The savant remains

connected to the readers and act as a router of the

RFID network with the primary functions of EPC

related data smoothing, data forwarding and data

storage; along with reader coordination, and task and

event management. Savant need to be based on open

standards so as to provide for easy information

interoperability. Since the EPC is the only

information stored on the tag, it has to be used in

such a way that it provides additional information

about the IT asset that EPC is attached to. Data

exclusive to IT asset could be stored on a server

located on a connected local area network or the

Internet, by an application of the concept of domain

name service (DNS).

Figure 5: EPC framework (Adopted from Brock 2001).

The EPC stored in the savant is interpreted into a

unique address of an object naming service (ONS),

which is basically an automated network service

which when given an EPC number, returns a server

address where the corresponding PDML file is

located. The ONS service thus behaves similarly to

the DNS used in IP networks, in the way that DNS

converts the IP address of a computer connected to a

network into a domain name for communication

with other computers on the network (Brock, 2001).

The PDML file corresponding to the EPC can

Object

Name

Service

ONS

Cache

EPC Database

EPC Information Service

Serial number tracking,

Transaction tracking

PML Server

ERP or other

applications

Information

Exchange

RFID Middleware

Data filtering, smoothing, forwarding &

storage

Reader Manager

Event Filter & Log

RFID Reader

Tag Tag Tag

EPC

01 0000A37 00063C 000213BF7

Converts to an ONS and works like a

DNS

A CASE STUDY OF AUTOMATED INVENTORY MANAGEMENT

145

contain any type and length of information about IT

asset.

For automatic scanning, the staff access card

needs to be equipped with RFID tags as well as the

IT asset. In this scenario (figure 6), when an

employee leaves a room with an asset, the UHF

reader will scan the staff as well as the asset tag.

This data will be sent to the middleware and

onwards to the PDML files and ‘asset movement

database’. The data from staff will then be related to

the data from the asset and a ‘check-out’ entry will

be created in a database that can be interfaced with

other existing systems so that this information is

available to all the related systems. As mentioned in

the earlier scenario, the identity of the staff will be

matched with the IT asset and if they don’t match

then alarms will be raised and relevant procedures

invoked. When the employee enters the room with

the asset, the staff and asset tags will be scanned

again and a ‘check-in’ entry will be made. The UHF

paper and filmic inlays are very thin and their

compact nature makes their application very

flexible. These tags have been used successfully for

baggage identification in the airline industry. As

mentioned earlier, due to their compact nature, it is

possible to enclose the tags in the barcode labels

such the tags are concealed and the barcode is

visible. This will prevent possible tampering of tags.

Figure 6: Automatic Scanning with UHF Tags.

If manual scanning option is south then as

explained in the manual scanning option for HF tags,

there need to be a RFID reader and an access card

scanner available at the exit door. When a staff

member exist the room with an IT asset, he/she will

have to manually scan the access card and the RFID

reader will automatically read the card. The data

thus captured will be matched to see if the person

carrying the IT assets is the one whom the asset has

been assigned. If not, an alarm will be raised.

Therefore, anybody who wants to take the asset out

of the room will have to ensure that the asset is

‘issued’ to them.

Apart form these options there is a third option

available under this category, which uses microwave

tags. The UHF range microwave tags operating at

the frequency of 2.45 GHz can also be used for asset

tracking. They have longer read ranges than the

UHF 860-960 MHz range tags. The use of the 2.45

GHz frequency for the purpose of radiolocation is

permitted in Australia according to the Australian

Communications Authority. Due to the long range

nature of tags, the tags may be read in multiple

positions. Using this feature of the long-range tags

and with multiple antennas connected to readers at

appropriate positions, tracking of assets on the entire

floor is possible. This will result in real-time

tracking of assets and staff who take those assets.

These tags also employ the EPC standard and so, all

the information about the personnel and assets has to

be stored in a database separately and identified

using the EPC. Hyper-X and Balogh RFID solutions

offered by Electro-com in Australia use these long

range tags.

5.3 Third Option

The third option includes active tags. These tags are

powered by batteries and can be automatically

activated at control points in a building. They can

broadcast non line-of-sight to small receivers

networked on the existing corporate LAN/WAN,

VPN or Internet over IP. They operate on dual

frequencies, one to activate the tag and the other for

transmission of data. They can be used for real-time

tracking of assets in the building. The read points

can also be grouped into zones to locate an asset or

person within a specific zone, as well as monitor

movement between zones. The memory on these

tags allows storage of a unique code and other

information like location, status information, etc. In

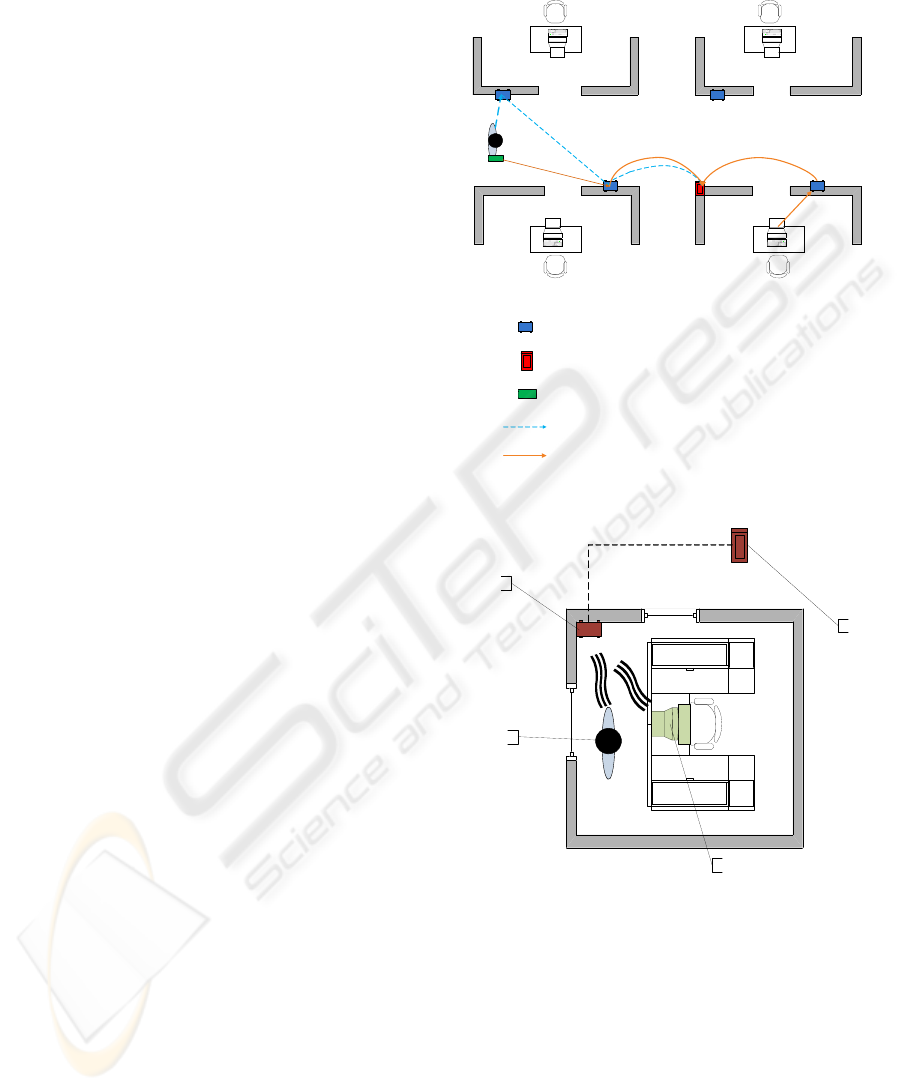

this scenario (figure 7a&b) a tagged personnel enter

the premises, access may be granted without swiping

a card or entering a code using active tags embedded

on their access/identity cards. The active tags, using

their battery power, transmit data at every control

point like a beacon, which is forwarded to the

reader. So when an employee enters a room, the

tracking system will detect him based on the data

transmitted by his access card.

Using the asset tracking system, assets can be

assigned to authorised staff. A work-request system

RFID

Reader

RFIDHost&

Database

RFID

Enabled

AccessCard

RFID Asset

Tag

Asset

Employee

ICEIS 2009 - International Conference on Enterprise Information Systems

146

may be employed for this purpose. As that employee

moves with his asset in or out of the room, the

access card as well as the tag on the asset is read by

the control point and the data is sent to the system.

The system compares the data with the records

created by the work-request and when a match is

found, confirms that the employee is an authorised

user of the asset. Tamper-proof tags are available

which raise an alarm if removal of the tags is

attempted. If an employee other than the authorised

user attempts to take the asset, the system senses the

mismatch between the personnel tag data and asset

tag data and an alarm is raised. Also, if an employee

leaves his personnel tag behind (say in his cabin)

and attempts to take the asset, he has to go through

the coverage area of many different control points.

The control points relay the movement of the asset

to the system and the system senses that the asset is

being moved without its authorised user. So an

alarm is raised in this event as well.

The active tags can also be used for populating

automatic inventory. The tags broadcast their data

periodically at predetermined intervals to the control

points like beacons. This allows the system to

maintain an inventory of all the assets currently

available. In this way, employees can check on

availability of assets in real-time and if an asset has

been checked-out, the status can be displayed on the

system. Active tags however are the most expensive

and cost in the range of 30 Australian dollars to 75

Australian dollars each.

6 CONCLUSIONS

This paper has presented options for tracking IT

asset using RFID technology and using the same

architecture to integrate asset information with the

information of the staff moving the asset or

responsible for the asset. One of the biggest risks in

the project would be trying to manage all the

expectations from the technology. It is necessary to

understand the drawbacks of the technology and

challenges that other organisations have encountered

while implementing this technology. Most important

among these are the privacy concerns, since the

same technology could be used to track employees

as well. One of the major risks in the project is

system and application integration. Seamless

integration of the RFID system with existing

systems with few changes is vital. If such integration

proves to be infeasible, the fate of this project might

be uncertain as the costs and efforts involved to

bridge the gap would be enormous.

Figure 7a: Active tags for automatic access.

Figure 7b: Active tags for automatic access.

REFERENCES

Attaran, M, 2007, ‘RFID: An enabler of supply chain

operations’, Supply Chain Management: an

International Journal, Vol. 12, Issue 4, p249-257.

Australian Communications Authority, 2005, ‘Australian

Radiofrequency Spectrum Plan’, Australian

Communications and Media Authority, viewed 11

December 2008,

http://www.acma.gov.au/webwr/radcomm/frequency_

planning/spectrum_plan/arsp05.pdf

Employee

Asset

Control Point

Tagged Mobile Asset

RFID Reader

Response from personnel tag

Response from asset tag

Control Point

Tagged Employee

Tagged Asset

Reader

A CASE STUDY OF AUTOMATED INVENTORY MANAGEMENT

147

Brock, D. L, 2001, ‘The Electronic Product Code (EPC):

A Naming Scheme for Physical Objects’, Auto-ID

Center, Massachusetts, viewed 3 November 2008,

http://www.autoidlabs.org/uploads/media/MIT-

AUTOID-WH-002.pdf

GS1 Australia, 2008, 4 Watt License Program, viewed 12

November 2008,

http://www.gs1au.org/products/epcglobal/4watt/

Li, S, Visich, J, K, Khumawala, B, M, Chen, Z, 2006,

‘Radio frequency identification technology:

applications, technical challenges and strategies’,

Sensor Review, Vol. 26, Issue 3, p193-202.

Wyld, D. C, 2006, ‘RFID 101: The next big thing for

management’, Management Research News, Vol. 29,

Issue 4, p154-173.

Wamba, S. F., Lefebvre, L. A., Lefebvre, E, 2006,

‘Enabling intelligent B-to-B eCommerce supply chain

management using RFID and the EPC network: a case

study in the retail industry’, Proceedings of the 8th

international Conference on Electronic Commerce,

ACM, New York, Vol. 156, p281-288.

ICEIS 2009 - International Conference on Enterprise Information Systems

148