DIFFERENTIAL-DRIVE STEERING SYSTEM USING PLANETARY

GEARING FOR OMNIDIRECTIONAL MOBILE ROBOT

Hideo Kitagawa

Department of Electronic Control Engineering, Gifu National College of Technology

Kamimakuwa, Motosu, Gifu, Japan

Takashi Ohno, Yuki Ueno, Kazuhiko Terashima

Department of Production Systems Engineering, Toyohashi University of Technology

Hibarigaoka, Tempaku, Toyohashi, Japan

Keywords:

Mobile robots, Movement, Robot kinematics, Vehicles, Wheels, Ride comfort.

Abstract:

Holonomic omnidirectional mobile robot is useful with its high mobility in narrow or crowded area, and

omnidirectional robot equipped with normal tires is desired for difference excess, vibration suppression and

ride comfort. Caster-drive mechanism using normal tire has been developed to realize a holonomic omni-

diredctional robot, however, there remains some problems. This paper presents effective systems to control

the caster-drive wheels of omnidirectional mobile robot. Differential-Drive Steering System (DDSS) using

planetary gearing is proposed to improve the operation ratio of motors. DDSS generates driving and steering

torque effectively from two motors. Simulation results show the proposed system is effective for holonomic

omnidirectional mobile robots.

1 INTRODUCTION

An omnidirectional robot is highly maneuverable in

narrow or crowded area including residences, offices,

warehouses and hospitals. It can be applied to an

autonomous mobile robot in a factory, a wheelchair

and so on. Several kinds of omnidirectional mobile

robots and their applications have been developed by

(West, 1992), (Pin, 1994), (Damoto, 2002) and (Kita-

gawa, 2008). However, these robots realized their

omnidirectional motion by using special wheels such

as mechanum wheels, ball wheels, omni-disks and

omni-wheels.

To improve the ride comfort, vibration suppres-

sion, slippage reduction and ability of difference ex-

cess, omnidirectional robots equipped with normal

tires have been strongly required. (Arai, 1981) pro-

posed an omnidirectional vehicle equipped with nor-

mal tires. However, it was a non-holonomic vehicle

which has to adjust the direction of wheels before

changing the moving direction of vehicle.

Holonomic omnidirectional vehicles, which can

move in any direction without changing the direc-

tion of tires beforehand, equipped with normal tires

include dual-wheel type by (Wada, 2000) and caster-

drive(active-caster) type by (Wada, 1996).

The dual-wheel type has problems as follows.

Number of wheels is limited to two, and it is impos-

sible to get high friction or to adapt a rough terrain

by synchronous drive of many wheels. Moreover, a

passive wheel is needed to stabilize the posture of ve-

hicle.

The caster-drive wheel has offset between the

steering axis and the center of wheel. The wheel

can move in any direction by controlling the steer-

ing axis and the driving wheel independently by using

two motors. A holonomic omnidirectional motion of

a robot can be realized by using two or more caster-

drive wheels.

However, the caster-drive wheel has a problem as

follows. When the vehicle is in steady motion includ-

ing straight motion and rotation with constant curva-

ture, only the driving motor works and the steering

motor becomes idle. When the vehicle changes its

moving direction, high load is applied to the steering

motor. Therefore, high power is required both for the

driving and steering motor. It causes increase of mass.

The aim of our research is to develop a holonomic

omnidirectional mobile robot with caster-drive wheel

minimizing the motor power by using the interference

of output of two motors. New gearing mechanism is

proposed to realize the interference.

171

Kitagawa H., Ohno T., Ueno Y. and Terashima K. (2009).

DIFFERENTIAL-DRIVE STEERING SYSTEM USING PLANETARY GEARING FOR OMNIDIRECTIONAL MOBILE ROBOT.

In Proceedings of the 6th Inter national Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 171-176

DOI: 10.5220/0002191101710176

Copyright

c

SciTePress

Steering axis

r

s

w

O

X

Y

Y

w

X

w

s

O

w

(x

w

,y

w

)

s

Contact point

θ

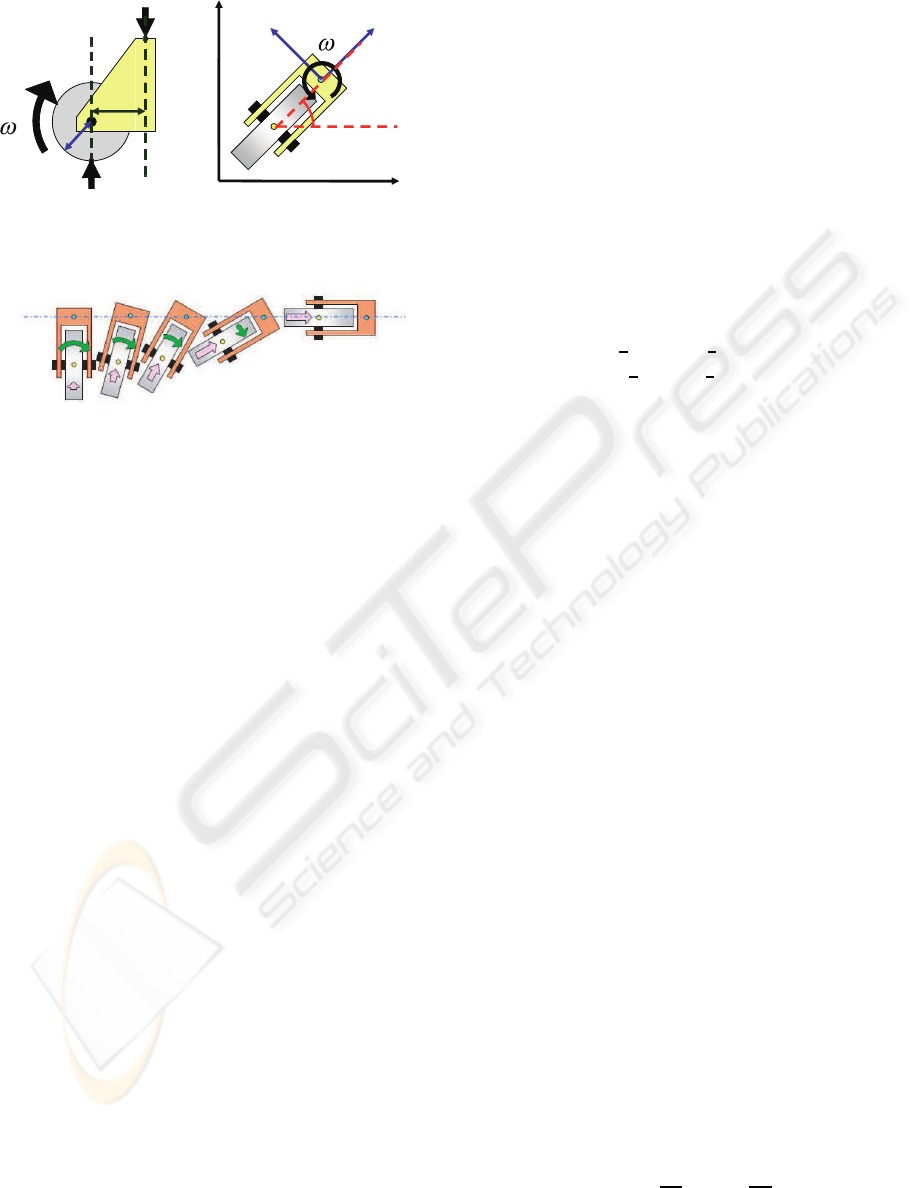

Figure 1: Caster-drive wheel.

Figure 2: Lateral motion to right.

2 PRINCIPLE

2.1 Omnidirectional Motion using

Caster-Drive Wheel

The principle of holonomic omnidirectional motion

using caster-drive wheels is described in this section.

Figure 1 shows the caster-drive wheel. The position

and orientation of wheel can be represented by the po-

sition O

w

(x

w

,y

w

) of steering axis and the orientation

θ

s

from the contact point between the wheel and the

ground to the steering axis with reference to the fixed

frame O− XY.

By rotating the driving wheel with the angular ve-

locity ω

w

, velocity ˙x

w

= rω

w

generates in the direc-

tion of X

w

axis. Here, r is the radius of driving wheel.

By rotating the steering axis with the angular velocity

ω

s

, velocity ˙y

w

= −sω

s

would generate at the cen-

ter of wheel in the direction of Y

w

axis. Here, s is

the offset between the steering axis and the center of

driving wheel in the direction of X

w

. However, react-

ing velocity ˙y

w

= sω

s

generates at the steering axis in

the direction of Y

w

axis, because the position of the

driving wheel is fixed by the friction with the ground.

Therefore, the velocity (˙x

w

, ˙y

w

) of caster-drive wheel

can be controlled by changing ω

w

and ω

s

.

Figure 2 shows an example of motion. The initial

orientation θ

s

of the wheel is set to be θ

s

= π/2 in

the frame O − XY. The motion as shown in Fig. 2

can be given by changing ω

w

and ω

s

appropriately.

Even though the rotating wheel itself can not generate

lateral motion to the right, the lateral motion of the

robot, which is fixed to the steering axis, is realized.

Each wheel does not have to control the orienta-

tion of the robot by itself.

The direct kinematic equation is denoted by the

state vector x

w

= [x

w

,y

w

]

T

and the input vector u

w

=

[ω

w

,ω

s

]

T

as

˙x

w

= B

w

u

w

, (1)

where

B

w

=

rcosθ

s

−ssinθ

s

rsinθ

s

scosθ

s

. (2)

The inverse kinamatic equation becomes

u

w

= B

−1

w

˙x

w

, (3)

where

B

−1

w

=

1

r

cosθ

s

1

r

sinθ

s

−

1

s

sinθ

s

1

s

cosθ

s

. (4)

Holonomic omnidirectional motion (˙x, ˙y,

˙

θ) of a

mobile robot can be achieved by using two caster-

drive wheels or more. Furthermore, synchronous

drive with arbitrary number of wheels and rotation

mechanism yields three dimensional holonomic om-

nidirectional motion by three motors.

2.2 Differential-Drive Steering System

(DDSS)

In this section, we develop a useful method for con-

structing a caster-drivewheel using Differential-Drive

Steering System (DDSS). The DDSS outputs driv-

ing and steering velocities from two motors using

differential-drive gearing.

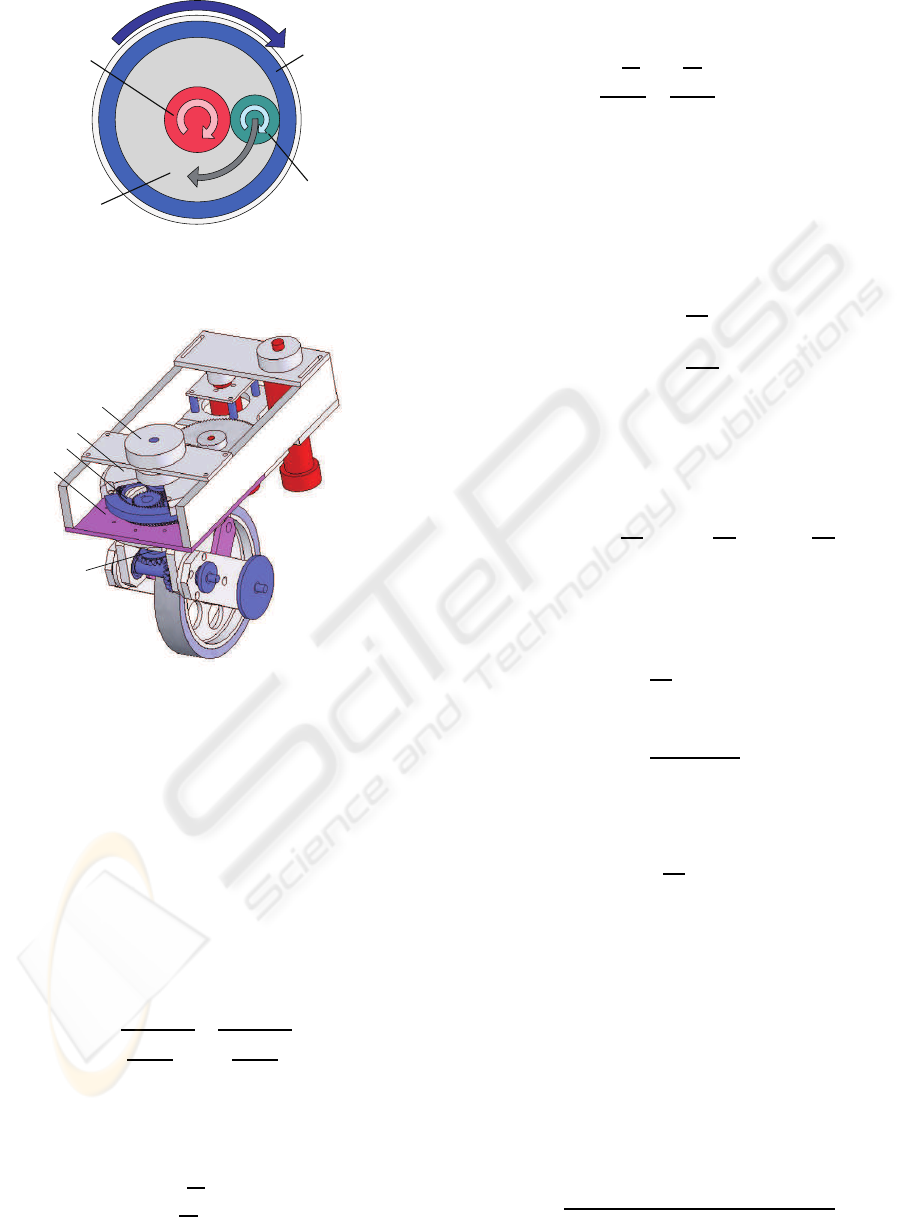

Figure 3 shows the principle of the DDSS. Just

like a usual planetary gearing, it is composed of sun

gear(A), outer ring gear(B), planet gear(C) and planet

carrier(D). The planet carrier(D) holds the planet

gear(C) and rotates relative to the sun gear(A) and the

outer ring gear(B). However, unlike usual planetary

gearing, the DDSS is 2-input 2-output system with-

out fixing any component. A and B are independently

driven by two motors. C and D provide output torque.

Figure 4 shows the mechanism of the DDSS. D,

which is fixed to the chassis(E), provides the steering

torque, and C, which leads to the driving wheel via

the bevel gear, provides the driving torque.

Let ω

A

, ω

B

, ω

C

and ω

D

be the angular velocity of

A, B, C and D in Fig. 3, and Z

A

, Z

B

and Z

C

be the

number of teeth of A, B and C, respectively.

When ω

D

= 0, the steering angular velocity ω

s

be-

comes zero, and we obtain

ω

A

= −

Z

B

Z

A

ω

B

= −

Z

C

Z

A

ω

C

, (5)

ω

D

= 0. (6)

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

172

ω

B

A

B

C

D

ω

D

ω

A

ω

C

Figure 3: Principle of Differential-Drive Steering System

(DDSS).

A

B

C

D

E

Figure 4: Mechanism of DDSS.

When ω

C

− ω

D

= 0, the driving angular velocity

ω

w

becomes zero because C does not rotate between

A and B, and we obtain

ω

A

= ω

B

= ω

C

= ω

D

. (7)

The direct kinematic equation, which derives driv-

ing and steering output u

w

= [ω

w

,ω

s

]

T

from motor in-

put u

P

= [ω

A

,ω

B

]

T

, can be described as

u

w

=

ω

C

− ω

D

ω

D

= B

P

u

P

, (8)

where

B

P

=

"

−

Z

A

Z

B

Z

C

(Z

A

+Z

B

)

Z

A

Z

B

Z

C

(Z

A

+Z

B

)

Z

A

Z

A

+Z

B

Z

B

Z

A

+Z

B

#

. (9)

The inverse kinematic equation becomes

u

P

= B

−1

P

u

w

, (10)

where

B

−1

P

=

"

−

Z

C

Z

A

1

Z

C

Z

B

1

#

. (11)

Next, we derive the motor power ratio of the

DDSS. Joint torques T

A

, T

B

, T

C

and T

D

of A, B, C

and D, respectively, are given by

T

C

T

D

=

"

−

Z

C

Z

A

Z

C

Z

B

Z

A

+Z

C

Z

A

Z

A

+Z

C

Z

B

#

T

A

T

B

, (12)

where positive direction of each torque is same as that

of angular velocity in Fig. 3.

For an omnidirectional mobile robot with the

DDSS, steady motion including straight motion and

rotation with constant curvature is achieved by ω

s

(=

ω

D

) = 0. When ω

s

= 0 (T

D

= 0), the joint torques are

given from (12) by

T

A

= −

Z

A

Z

B

T

B

, (13)

T

C

= −

2Z

C

Z

A

T

A

, (14)

T

D

= 0. (15)

The power ratio of two motors is given from (5) and

(13) by

P

A

: P

B

= T

A

ω

A

: T

B

ω

B

=

−

Z

A

Z

B

T

B

−

Z

C

Z

A

ω

C

: T

B

Z

C

Z

B

ω

C

= 1 : 1 (16)

On the other hand, when ω

w

= 0 (T

C

= 0), the joint

torques are given from (12) by

T

A

=

Z

A

Z

B

T

B

, (17)

T

C

= 0, (18)

T

D

=

2(Z

A

+ Z

C

)

Z

A

T

A

. (19)

The power ratio is given from (7) and (17) by

P

A

: P

B

= T

A

ω

A

: T

B

ω

B

=

Z

A

Z

B

T

B

ω

B

: T

B

ω

B

= Z

A

: Z

B

. (20)

Letting the diameter of sun gear and planet gear be

the same in Fig. 1 yields

P

A

: P

B

= 1 : 3. (21)

2.3 Operation Ratio of Motors

In this section, we discuss the operation ratio of mo-

tors by comparing the DDSS to a conventional caster-

drive wheel. We define the operation ratio δ of motors

as

δ =

(Sum of motor power in motion)

(Sum of rated power of motors)

. (22)

DIFFERENTIAL-DRIVE STEERING SYSTEM USING PLANETARY GEARING FOR OMNIDIRECTIONAL

MOBILE ROBOT

173

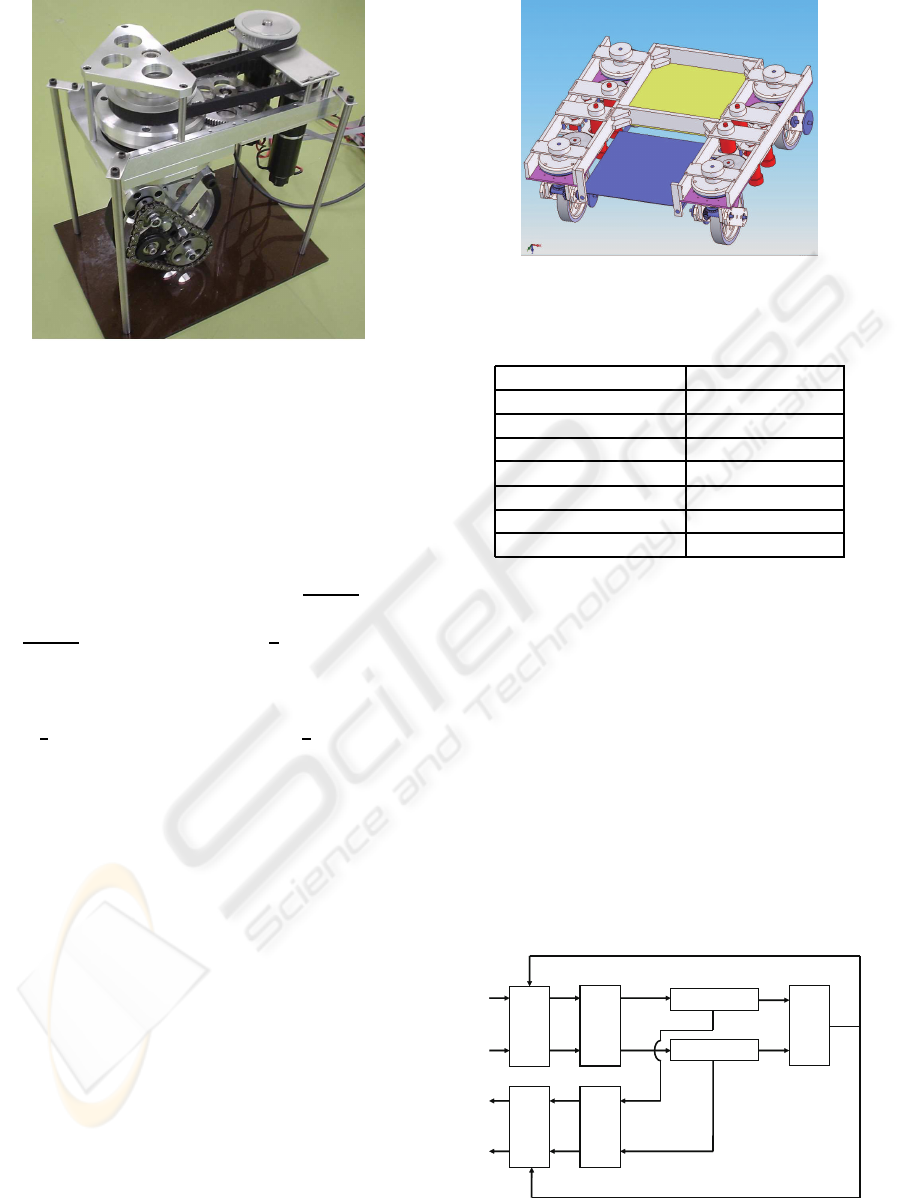

Figure 5: Prototype DDSS.

The ratio (P

A0

: P

B0

) of rated power of two motors

used in the DDSS is set to be 1:1. The ratio of rated

power used in conventional method is also set to be

1:1 as denoted in (Wada, 1996).

We calculate the operation ratio δ in case of driv-

ing motion (T

D

= 0). Let P be the sum of motor

output power needed to achieve the motion. The re-

sult of the conventional method is δ =

P

P

A0

+P

B0

= 0.5

from P

A0

= P

B0

= P. The result of the DDSS is

δ =

P

P

A0

+P

B0

= 1 from P

A0

= P

B0

=

P

2

.

Next, we calculate δ in case of steering motion

(T

C

= 0). The result of conventional method is P

A0

=

P

B0

= P and δ = 0.5. The result of the DDSS is P

A0

=

P

B0

=

3

4

P and δ = 0.67, because P

B0

=

3

4

P from (21).

The output power of motors can be decreased by

using the DDSS as a caster-drive wheel because of its

high operation ratio of motors. It means that the size

of robot become smaller by using the DDSS.

3 CONSTRUCTION OF

OMNIDIRECTIONAL MOBILE

ROBOT

We constructed a prototype model of the DDSS to

check the availability of proposed mechanism as

shown in Fig. 5. Torques of two motors are trans-

mitted to the sun gear(A) and the outer ring gear(B)

by the timing belts, and driving and steering torques

are generated. Effectiveness of the proposed DDSS

was confirmed by this apparatus.

Figure 6 and Table 1 show picture and specifi-

cation of an omnidirectional mobile robot with four

DDSS wheels, respectively. The proposed omnidi-

rectional robot has capability of climbing slope of 10

Figure 6: Omnidirectional Mobile Robot.

Table 1: Specification of Omnidirectional Mobile Robot.

Size (D × W) 600 × 600 [mm]

Weight 70 [kg]

Motor power 150 [W] × 8

Max. velocity 6 [km/h]

Max. acceleration 0.5 [m/s

2

]

Max. slope angle 10 [deg]

Max. step difference 60 [mm]

Max. loading weight 100 [kg]

[deg], accelerating 0.5 [m/s

2

] and exceeding differ-

ence of 60 [mm] with carrying load of 100 [kg].

4 SIMULATION

4.1 Simulation Method

To show the performance of the DDSS, simulations

are conducted. The simulation model is constructed

by SolidWorks and DADS. The radius r of the wheel

and the offset s shown in Fig. 1 were given as r = 80

[mm] and s = 50 [mm], respectively.

sr

ω

rM 1

ω

B

P

-1

B

W

-1

Unit

model

r

x

r

y

B

P

B

W

x

y

wr

ω

rM 2

ω

T

G1

T

G2

θ

w

ω

s

ω

Motor model 1

Motor model 2

1M

ω

2M

ω

s

.

.

.

.

Figure 7: Control system of DDSS.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

174

0 2 4 6 8 10

Vx[m/s]

time[s]

y positon[m]

time[s]

x positon[m]

y positon[m]

x positon[m]

time[s]

time[s]

Vy[m/s]

time[s]

ωMs[rad/s]

time[s]

ωs[rad/s]

time[s]

ωw[rad/s]

time[s]

ωMr[rad/s]

-1

0

1

2

0 2 4 6 8 10

-0.2

0

0.2

0 2 4 6 8 10

-500

0

500

1000

0 2 4 6 8 10

-1000

-500

0

500

1000

0 2 4 6 8 10

-20

0

20

0 2 4 6 8 10

0

5

10

0 2 4 6 8 10

0

5

10

0 2 4 6 8 10

-0.1

-0.05

0

0.05

-0.06 -0.04 -0.02 0

-2

0

2

4

6

8

10

Reference

Simulation

0.02

Figure 8: Simulation results (Vx = 6 km/h, Vy = 0 km/h).

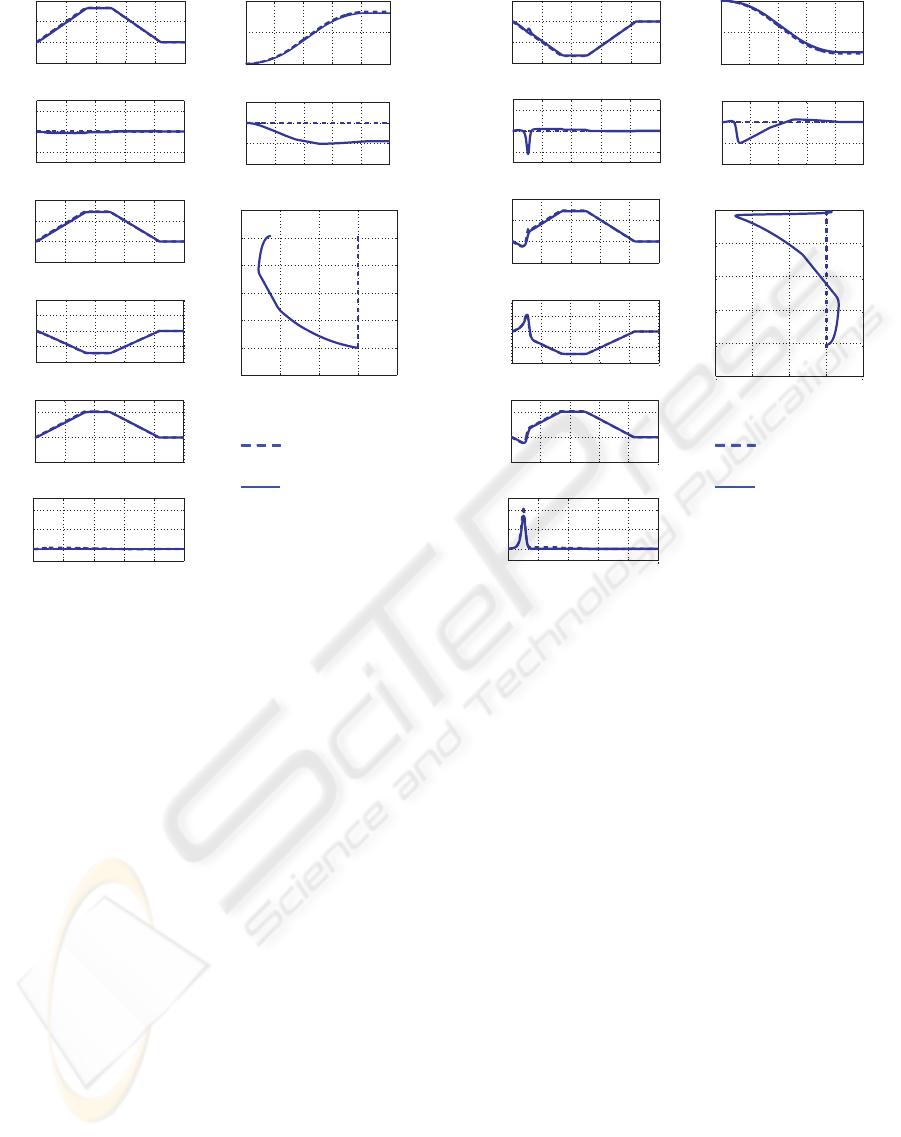

Figure 7 shows the control system of a wheel used

in this simulation. The reference angular velocities

ω

M1r

and ω

M2r

are given by (3) and (10). The velocity

(˙x, ˙y) of the DDSS is given from the angular velocities

ω

M1

and ω

M2

and the steering angle θ

s

.

Four translational motions toward +X, –X, +Y and

–Y direction with maximum velocity of 6 [km/h] (=

1.67 [m/s]) and maximum acceleration of 0.5 [m/s

2

]

were examined. The initial value of θ

s

was set to be

zero in any case.

4.2 Simulation Results and Discussion

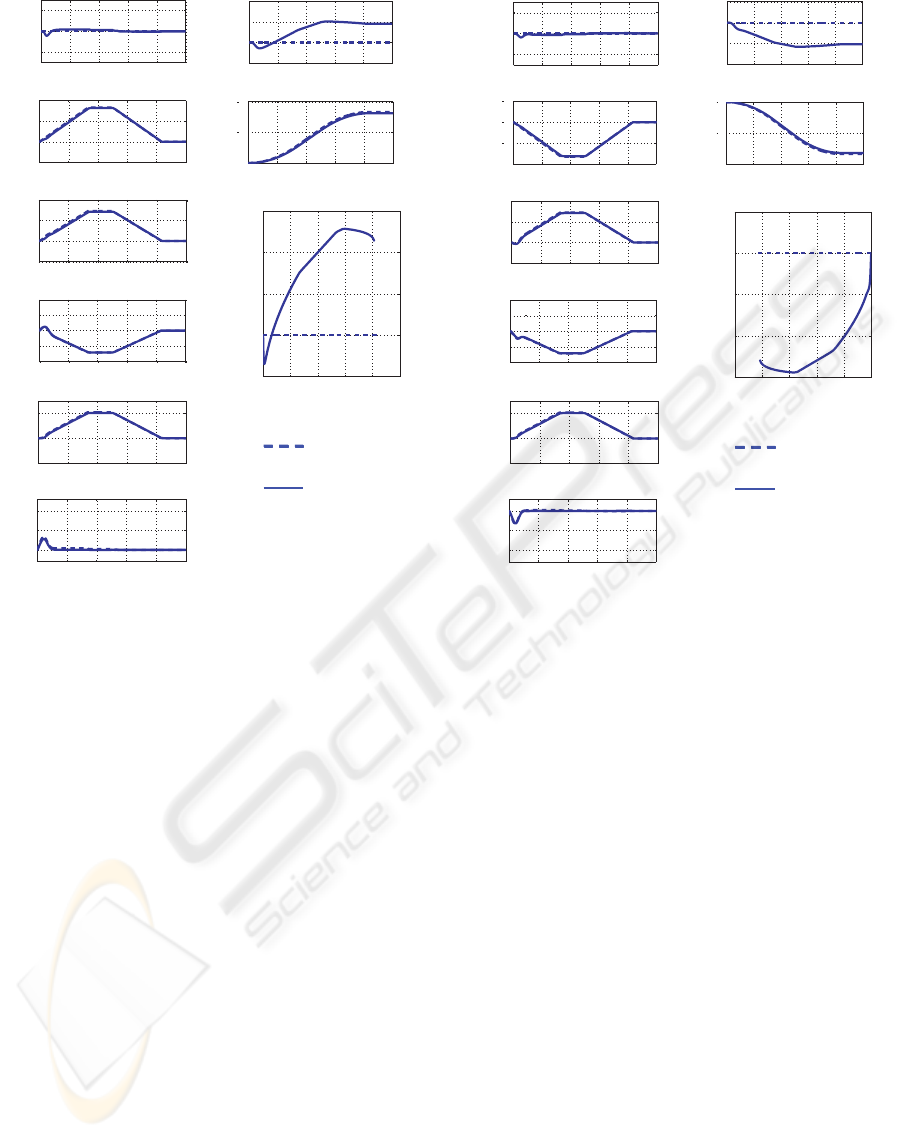

Figures 8 through 11 show the simulation results of

motions toward +X, –X, +Y and –Y direction, respec-

tively, from the initial state θ

s

= 0. Here, V

x

, V

y

, ω

Ms

,

ω

Mr

, ω

w

and ω

s

indicate the velocity in X-direction,

the velocity in Y-direction, the angular velocity of sun

gear motor, the angular velocity of outer ring gear mo-

tor, the angular velocity of wheel and the angular ve-

locity of steering axis, respectively.

As seen from these graphs, error from the refer-

ence trajectory is within 6 [cm] in any case. We can

also see the feature of caster-drive wheel. In Fig. 9,

the angular velocity ω

s

of steering axis becomes large

0 2 4 6 8 10

-2

-1

0

1

time[s]

Vx[m/s]

0 2 4 6 8 10

-0.1

-0.05

0

0.05

time[s]

y positon[m]

0 2 4 6 8 10

-10

-5

0

time[s]

x positon[m]

-0.06 -0.04 -0.02 0 0.02

-10

-8

-6

-4

-2

0

y positon[m]

x positon[m]

0 2 4 6 8 10

-0.2

0

0.2

time[s]

Vy[m/s]

0 2 4 6 8 10

-500

0

500

1000

time[s]

ωMs[rad/s]

0 2 4 6 8 10

0

5

10

time[s]

ωs[rad/s]

0 2 4 6 8 10

-20

0

20

time[s]

ωw[rad/s]

0 2 4 6 8 10

-1000

0

1000

time[s]

ωMr[rad/s]

-500

500

Reference

Simulation

Figure 9: Simulation results (Vx = – 6 km/h,Vy = 0 km/h).

in the beginning of motion because the moving direc-

tion is opposite to the initial direction θ

s

= 0.

5 CONCLUSIONS

We proposed Differential-Drive Steering System

(DDSS) for caster-drive wheel of holonomic omnidi-

rectional mobile robot. The DDSS can provide high

operation ratio of motors rather than conventional

caster-drive wheel. Numerical analysis, examination

by prototype model and simulation results showed ef-

fectiveness of the DDSS.

Future works include

• construction of an omnidirectional mobile robot

and experiments,

• posture control on rough terrain,

• application to an omnidirectional wheelchair.

ACKNOWLEDGMENTS

This work was supported by Scientific Grant-in-Aid

(No.19560271) and G-COE (Global Center of Excel-

DIFFERENTIAL-DRIVE STEERING SYSTEM USING PLANETARY GEARING FOR OMNIDIRECTIONAL

MOBILE ROBOT

175

10

Vx[m/s]

time[s]

y positon[m]

time[s]

x positon[m]

y positon[m]

x positon[m]

time[s]

time[s]

Vy[m/s]

time[s]

ωMs[rad/s]

time[s]

ωs[rad/s]

time[s]

ωw[rad/s]

time[s]

ωMr[rad/s]

0 2 4 6 8 10

-500

0

500

1000

0 2 4 6 8 10

-1000

-500

0

500

1000

0 2 4 6 8 10

-20

0

20

0 2 4 6 8 10

0

5

10

0 2 4 6 8 10

-1

0

1

2

0 2 4 6 8 10

-0.05

0

0.05

0.1

0 2 4 6 8 10

-0.02

0

0.02

0.04

0.06

0 2 4 6 8

-0.2

0

0.2

0 2 4 6 8 10

0

5

10

Reference

Simulation

Figure 10: Simulation results (Vx = 0 km/h, Vy = 6 km/h).

lence) Program “Frontier of Intelligent Human Sens-

ing” by the Japanese Ministry of Education, Culture,

Sports, Science and Technology.

REFERENCES

Arai, T., Nakano, E., Hashino, H., and Yamaba, K., 1981.

The Control and Application of “Omni-Directional

Vehicle (ODV)”. Proc. 8th IFAC World Congress,

1855–1860.

Damoto, R and Hirose, S., 2002. Development of Holo-

nomic Omnidirectinal Vehicle “Vuton-II” with Omni-

Discs. Journal of Robotics and Mechatronics, Vol.14,

No.2, 186–192.

Kitagawa, H., Miyoshi, T., and Terashima, K., 2008. Skill-

Assist Control of Omnidirectional Wheelchair Using

Human-Friendly Interface. Proc. IEEE Int. Conf. on

Robotics and Biomimetics, TuPA7.13.

Pin, F. G. and Killough, S. M., 1994. A new family of omni-

directional and holonomic wheeled platforms for mo-

bile robots. IEEE Trans. on Robotics and Automation,

vol.10, 480–489.

Wada, M. and Mori, S., 1996. Holonomic and omnidirec-

tional vehicle with conventional tires. Proc. IEEE Int.

Conf. on Robotics and Automation, 3671–3676.

Vx[m/s]

time[s]

y positon[m]

time[s]

x positon[m]

y positon[m]

x positon[m]

time[s]

time[s]

Vy[m/s]

time[s]

ωMs[rad/s]

time[s]

ωs[rad/s]

time[s]

ωw[rad/s]

time[s]

ωMr[rad/s]

-10 -8 -6 -4 -2 0

-0.06

-0.04

-0.02

0

0.02

0 2 4 6 8 10

-0.2

0

0.2

0 2 4 6 8 10

-2

-1

0

1

0 2 4 6 8 10

-0.1

-0.05

0

0.05

0 2 4 6 8 10

-10

-5

0

0 2 4 6 8 10

-1000

-500

0

500

1000

0 2 4 6 8 10

-500

0

500

1000

0 2 4 6 8 10

-10

-5

0

0 2 4 6 8 10

-20

0

20

Reference

Simulation

Figure 11: Simulation results (Vx = 0 km/h, Vy = – 6 km/h).

Wada, M., Takagi, A., and Mori, S., 2000. A Mobile

Platform with a Dual-wheel Caster-drive Mechanism

for Holonomic and Omnidirectional Mobile Robots.

Journal of Robotics Society of Japan, Vol.18, No.8,

1166–1172.

West, M. and Asada, H., 1992. Design of a holonomic

omnidirectional vehicle. Proc. IEEE Int. Conf. on

Robotics and Automation, 97–103.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

176