A NEW APPROACH OF THE NEURAL PREDICTIVE CONTROL

APPLIED IN A THERMOELECTRIC MODULE

Adhemar de Barros Fontes, Pablo Amorim and M´arcio Ribeiro da Silva Garcia

Departamento de Engenharia El´etrica, Universidade Federal da Bahia, Rua Aristides Novis 2 Federac˜ao, Salvador, Brazil

Keywords:

Neural Control, Neural Networks, Nonlinear systems, Predictive Control.

Abstract:

This article presents an efficient solution for predictive control based on neural networks with feedfoward

multilayer, as a model for a thermoelectric module. It is shown the capability of a neural network to learn

the entire nonlinear dynamics and the advantage of using these nonlinear models for the calculation of the

predicted variables. It is also suggested a new control law capable of minimize the cost function using the

Newton-Raphson and the descendent gradient optimization rules. For this application it is shown that a sig-

nificant reduction in the number of iterations and application in real-time systems when compared to other

optimization techniques.

1 INTRODUCTION

The recursive neural networks have shown to be a

very important tool in several control applications in

nonlinear dynamic systems. This article has the ob-

jective os presenting a development and its results ob-

tained from a prediction-based algorithm through a

recursive neural network applied in a thermoelectric

chamber with nonlinear dynamics.

The Generalized Preditive Controller (GPC) was

introduced by (Clarke, 1994) and is being used for

control of industrial process with profitasble perfor-

mance in the control of non-minimum phase plants,

unstable plants or plants with unknown dead time

(Clarke, 1994). The GPC uses initially a linear predic-

tion model. If a nonlinear model is used then it is also

necessary to make use of a nonlinear algorithm. Ex-

pressive results are obtained regarding efficiency and

computational performance. The prediction feature of

the GPC when using a neural model, with the capa-

bility of learning the entire dynamic of the plant, it is

more efficient than the standard nonlinear modelling

techniques. It is well known that the plant model is di-

rectly related to the accuracy of the prediction (Fontes

et al., 2008). The most used techniques to modelling

nonlinear plants, as the linearization around the op-

erating points (Lee and Ricker, 1994; Li and Biegler,

1988) or approximated models, do not guarantee the

required accuracy when compared to the neural mod-

els.

The control signal update rule in the present work

is based on the first and second derivatives of the cost

function. A new hybrid control law is proposed based

on the Newton-Raphson rules and the decrecent gra-

dient. The computational cost related to the computa-

tion of the control signal is associated to the Hessian.

However, the reduced number of iterations guarantee

an excelent performance of the algorithm when it is

applied in real-time control systems.

For simulation and real trials of the proposed con-

trol technique a Peltier cell was mounted in a set

named the thermoeletric chamber. The results ob-

tained caracterize a suitable solution for the proposed

system, as well as the potential of this tool in the mod-

elling and control of nonlinear systems, whenever it

is real-time or not. In the section 2, the structure of

a recursive neural network is presented as well as the

equations that describe it. In the section 3, the neces-

sary equations for the determination of the proposed

control law. The section 4 presents the description

and modelling of the system as well as the results ob-

tained in the trials.

2 NEURAL NETWORK

ARCHITETURE

The model of a plant used in a neural generalized pre-

dictive controller (NGPC) is a neural network and it

is important to evaluate the architeture of the network

to be used. It is known that a recursive neural net-

189

de Barros Fontes A., Amorim P. and Ribeiro da Silva Garcia M. (2009).

A NEW APPROACH OF THE NEURAL PREDICTIVE CONTROL APPLIED IN A THERMOELECTRIC MODULE.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 189-194

DOI: 10.5220/0002193001890194

Copyright

c

SciTePress

work with three layers, one of them hidden, is capa-

ble of representing any linear or nonlinear function.

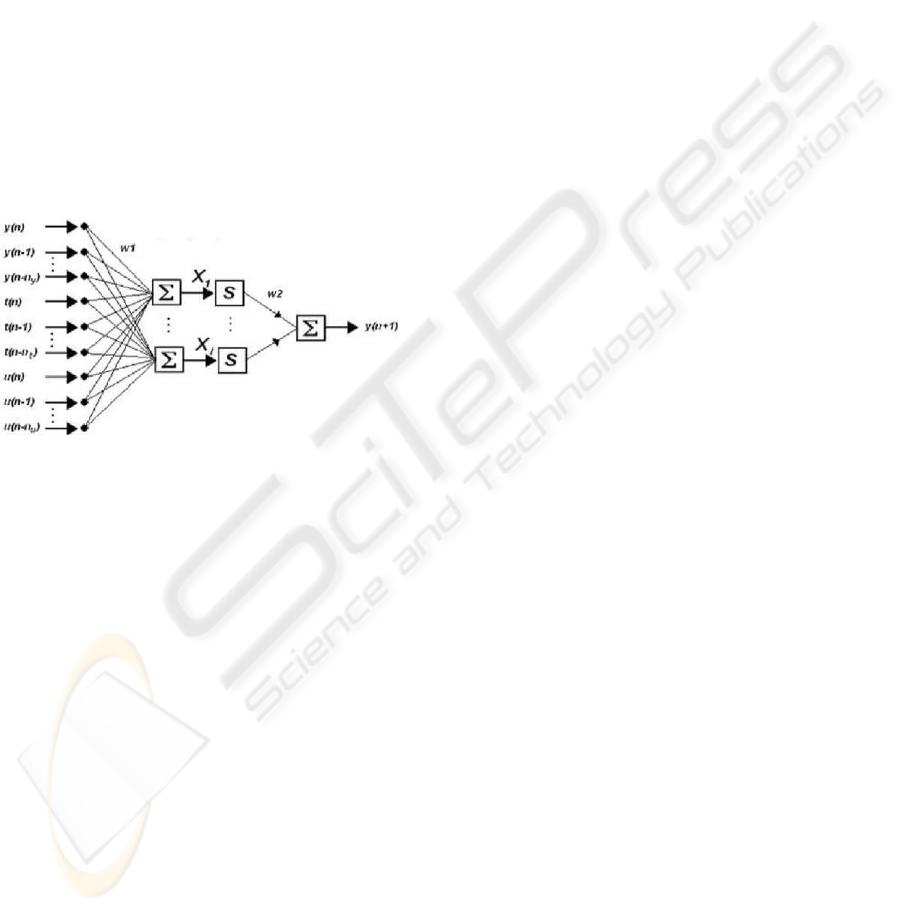

The Figure 1 describes a multilayer feedforward neu-

ral network with all its structure of delayed inputs and

outputs signals. In (Hao et al., 1993), it was presented

in details the mathematical representation of nonlin-

ear plants and the respective considerations in order

to determine the order of the neural model in terms of

the regressors of the inputs, disturbances and outputs,

namely, u(n), t(n) and y(n). For each perceptron of

the hidden layer there is an activation function. The

neural network is described by the following equa-

tion:

y(n+ 1) = f(y(n), y(n− 1), . . . , y(n − n

y

), t(n), . . . ,

t(n− n

t

), u(n), . . . , u(n− n

u

)),

(1)

or, in a detalied view,

Figure 1: The recursive neural model structure.

y(n+ 1) =

N

∑

i=1

w

2

(1, i)S(X

i

), (2)

with,

X

i

=

∑

n

y

j=1

w

1

(i, j)y(n− j)+

∑

n

t

j=0

w

1

(i, n

y

+ 1+ j)t(n− j)+

∑

n

u

j=0

w

1

(i, n

y

+ n

t

+ 2+ j)u(n − j),

(3)

where:

• y(n+ 1) is the output of the neural network;

• S(.) is the output function of the i − th nodes of

the hidden layer;

• N is the number of nodes in the hidden layer;

• n

y

is the number of inputs nodes associated to y(.);

• n

t

is the number of inputs nodes associated to t(.);

• n

u

is the number of inputs nodes associated to

u(.);

• w

1

(i, j) represent the weights associated of the j−

th input to the node j;

• w

2

(1, i) represent the weights associated of the i−

th hidden node to the output node;

• y(.) represents the output past values;

• t(.) represents the ambient temperature past val-

ues;

• u(.) represents the input past values.

3 OPTIMIZATION

For the presented application it is necessary the use

of a cost function with finite prediction horizon. The

NGPC algorithm must satisfy the following optimiza-

tion problem:

∆u(k) = min

∆u

n

J =

∑

N

2

i=N

1

||ref(n+ i) − ˆy(n+ i)||

2

+

λ

∑

N

u

i=1

||∆u(n+ i)||

2

o

,

(4)

where:

• N

1

is the minimum prediction horizon;

• N

2

is the maximum prediction horizon;

• N

u

is the control horizon;

• ref(n+ i) is the reference signal;

• ˆy is the output signal predicted by the neural

model;

• λ is the weight at the control signal;

• ∆u(n+ i) is the variation of the control signal de-

fined as u(n+ i) − u(n+ i− 1).

For the cost defined in (4) there are four tuning

parameters: N

1

, N

2

, N

u

and λ. As the dead time is

much smaller than the sampling time, it is fair to ad-

mit N

1

= 1 and, as a consequence, N

2

= N

u

. It may

be verified also that, while the cost is minimized, the

resulting control signal allows the plant to track the

reference signal.

As mentioned before, the proposed control law

presents an update algorithm based on the rules of

Newton-Raphson and the decrecent gradient. The use

of two methods allows the adding of the weight α,

according to (5). This way, the control law contem-

plates one more degree of freedom and as a conse-

quence a gain in the dynamics of the controller. The

control law proposed for the update of the control sig-

nal U(k+ 1) is given by,

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

190

U(k+ 1) = U(k) − α

∂J

∂U

− (

∂

2

J

∂U

2

)

−1

∂J

∂U

(5)

It is easily observed that there’s an addition of a

new degree of freedom α, besides the one defined in

(4). The optimal value of J in terms of U is obtained

after each iteration of the optimization algorithm. In

the iterative process, for each value of J the future in-

puts vector U(k) is also calculated, with the Jacobian

and Hessian matrices defined as:

∂J

∂U

=

∂J

∂u(n+1)

∂J

∂u(n+2)

···

∂J

∂u(n+N

u

)

, n = 1, . . . , N

u

(6)

∂

2

J

∂U

2

=

∂

2

J

∂u(n+1)

2

. . .

∂

2

J

∂u(n+1)∂u(n+N

u

)

···

.

.

.

···

∂

2

J

∂u(n+N

u

)∂u(n+1)

. . .

∂

2

J

∂u(n+N

u

)

2

,

(7)

and the predicted output is given by:

ˆy(n+ k) =

N

∑

i=1

w

2

(1, i)S(X

i

). (8)

The iterations are interrupted when the percentage

of the variation U(k) is smaller than a given ε. For

each iteration k the elements of the Jacobian and the

Hessian are calculated for the given control law.

It is necessary that efficient routines are elaborated

for the calculation of the gradient, used in the mini-

mization of the cost, when the iterations of the opti-

mization algorithm are used in real-time.

4 TRIALS

4.1 System Description

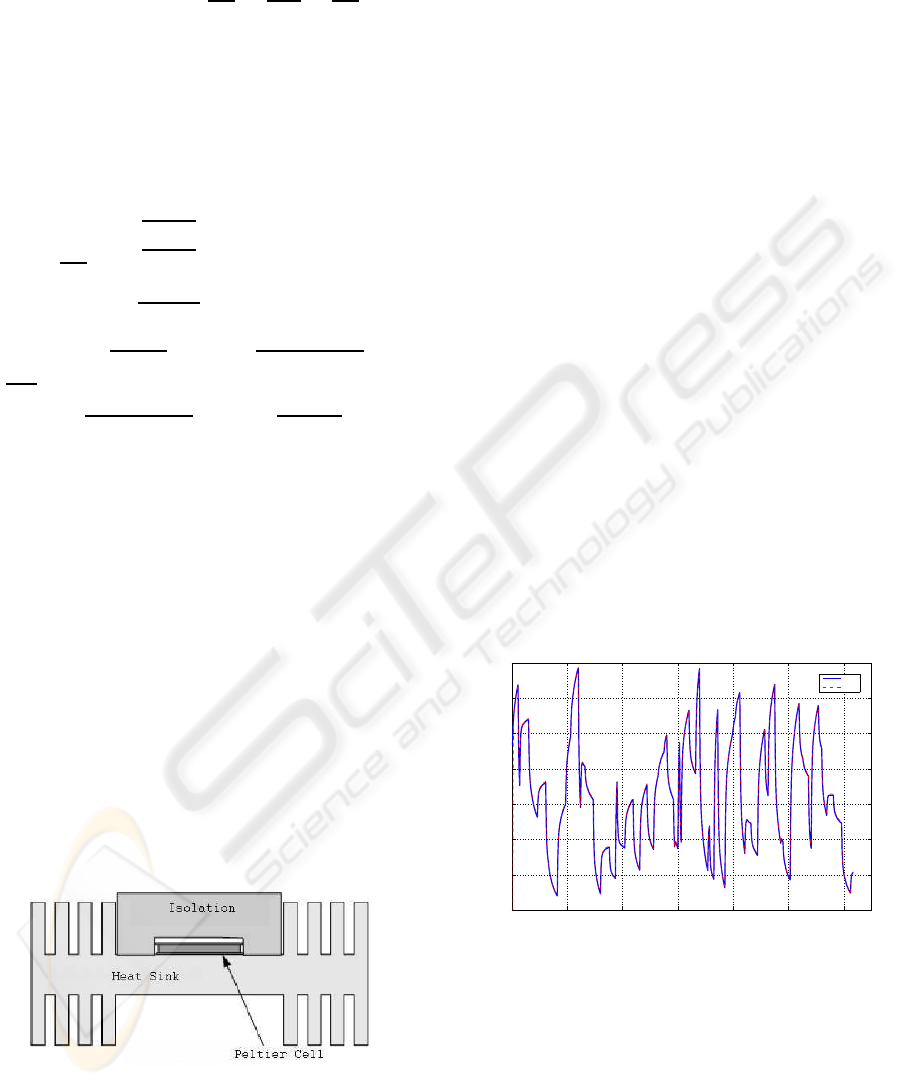

Figure 2: Thermoelectric module.

A Peltier cell, also know as thermoelectric module

(TEM),is a component composed of several semi-

conductors plates placed side-by-side and electrically

isolated from the external environment by a ceramic

coat. Through two terminals connected to the cell

a electric current circles, causing the heat to pump

between its faces. This phenomenon is know as the

Peltier efect and it is the opposite of the Seebeck

efect, which caracterizes the thermocouples. The heat

pumpingdirection depends on the direction of the cur-

rent flow, which allows the Peltier cells to be used as

actuators in cooling systems as much as in heating

systems.

The TEM is widely used in temperature control in

specific applications (Fontes et al., 2008). In some

of them a physical model is used, (Fontana, 2001;

Almeida, 2003). These applications vary from cool-

ing modules, medical instruments composition and

small refrigerators, etc (Mel, 1999).

A thermoelectric module is composed of a ther-

mic chamber, where the Peltier cell is associated to a

heat sink. The Figure 2 presents an illustration of the

set used in the experiments of heat pumping. The pro-

cess variable is the upper face temperature, controlled

by the manipulation of the applied current. The infor-

mation of the ambient temperature is also informed to

the neural net as a load disturbance. Other works in-

volving the thermic chamber present a caracterization

of the module by nonlinear parametric models (So-

brinho et al., 2006; Lima, 2007; Almeida, 2004) and

bilinear state-space models (Garcia, 2008).

4.2 Neural Network Training

0 100 200 300 400 500 600

35

40

45

50

55

60

65

70

Temperature (

o

C)

Real

Model

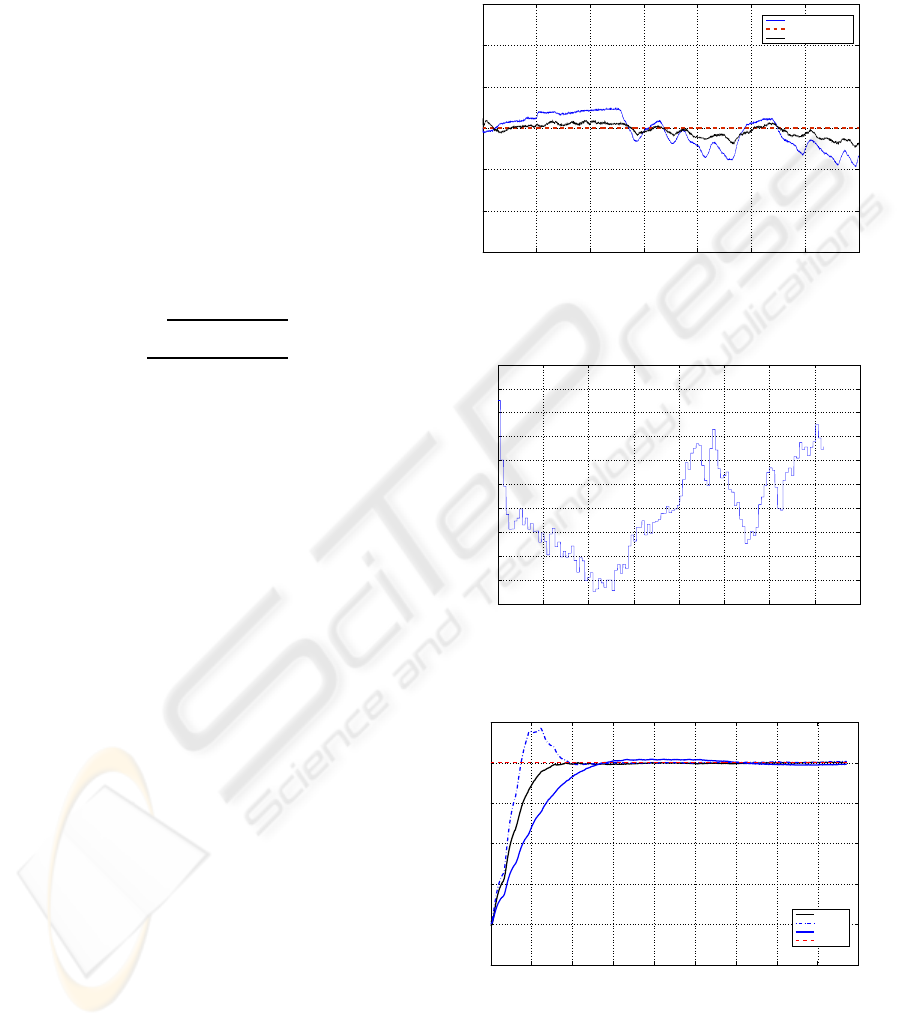

Figure 3: Neural model plot versus system’s real data.

For the network trainning, the system response for

a Pseudo-random signal input (PRS) was obtained

along the entire operation range (30

o

C a 80

o

C). The

proposed architeture for the neural model contem-

plates 3 layers, with 3 regressors in the hidden layer

and one in the output layer, 3 exogen regressors and

the Hyperbolic Tangent as the activation function;

During the training phase the weights were ad-

justed iteratively, as proposed in (Hagan and Men-

A NEW APPROACH OF THE NEURAL PREDICTIVE CONTROL APPLIED IN A THERMOELECTRIC MODULE

191

haj, 1994). For the feedforward architeture proposed,

the performance was measured in acordance with the

minimization of the squared error criterion between

the network and the system’s real outputs for the

same input signal. Several training algorithms were

used, as the resilient backpropagation, the Fletcher-

Reeves rule with backpropagation of the conjugated

gradient, the Polak-Ribiere rules, the decrescent gra-

dient, among others. The algorithm of Levenberg-

Marquardt presented the best overall results and it was

used for the system modeling. The Figure 3 presents

the output of the neural model compared to the real

system’s output.

For validation, another PRS was generated and ap-

plied to the system and its response was compared to

the model response. The mean squared error between

the system (y

r

) and the model ( ˆy

m

) outputs for the N

points, defined as

E

mq

(%) =

q

∑

N

i=1

(y

r

− ˆy

m

)

2

N

∗ 100, (9)

was 1, 148%

The closed-loop system was implemented accord-

ing to the well-known receiding horizon principle

((Propoi, 1963; Camacho and Bordons, 2004; Za-

marreo and Vega, 1999)). It is fair to say that the good

computationalperformanceof the proposedcontroller

is based on the choice of the algorithm defined in

the optimization block. The choice of the controller

parameters can be done by several criteria: Num-

ber of iterations for the resolution of the control sig-

nal, computational cost and accuracy of the solution.

It is necessary though, to develop fast optimization

algorithms. In this works a solution is presented,

which applies the Newton-Raphson method added by

the decrecent gradient which can be implemented as

optimization technique in highly nonlinear real-time

applications. A computational analysis showed that

there was no significant increase in the computational

cost associated with the optimization of the control

signal with the increment of the decendent gradient

method. The terms of the decrecent gradient to be

calculated are the same as the onse of the Newton-

Raphson’s method.

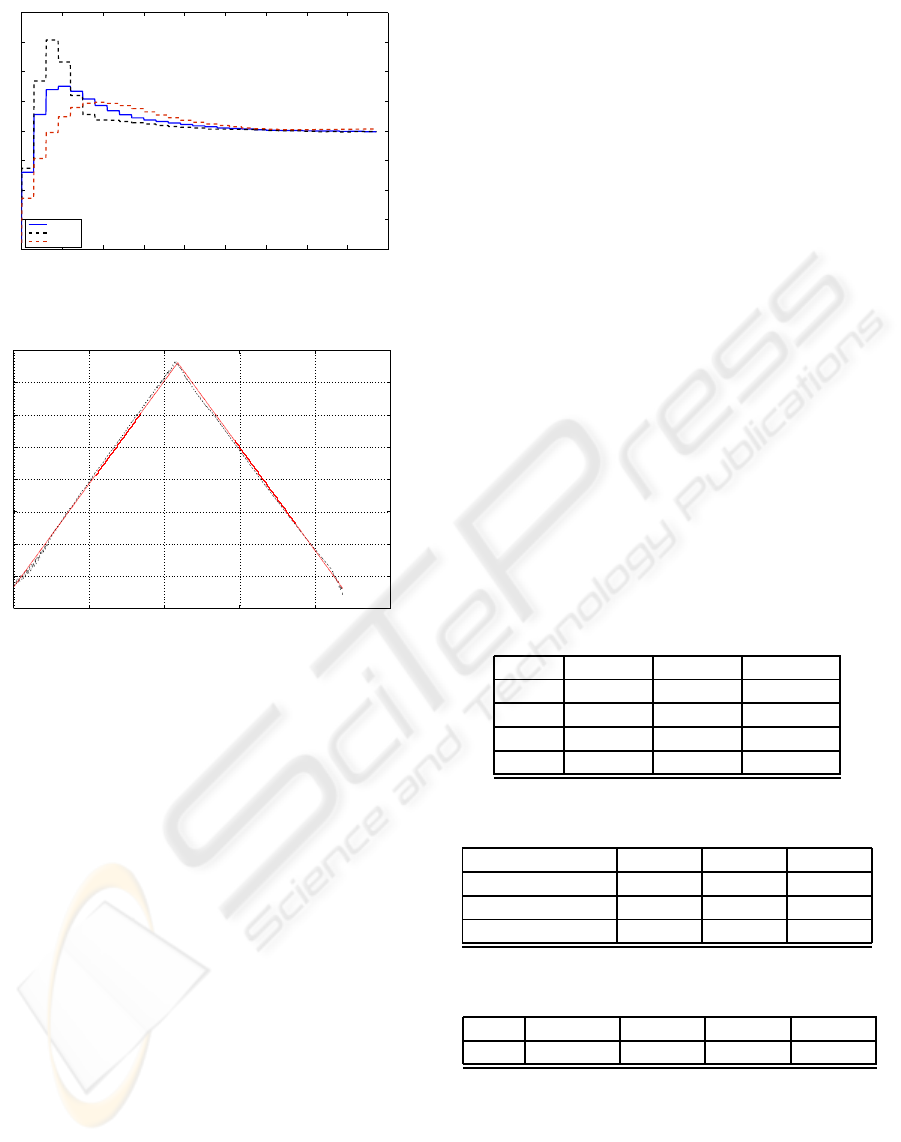

4.3 Results

The trials were performed for three distinct cases: The

algorithm 01 represents the system proposed in this

article with parameters λ = 2000 and α = 0.00008.

The algorithm 02 refers to the same algorithm with

a more agressive tuning (α = 0.0000955). The algo-

rithm 03 refers to an existing algorithm, without the

addition of the term related to the decrecent gradient,

with λ = 2000. The prediction horizon is Ny = 10.

The small values of α are due to the system’s large

static gain, but the variation of these parameters be-

tween the algorithms 1 and 2 is 20%.

0 1000 2000 3000 4000 5000 6000 7000

−3

−2

−1

0

1

2

3

Ambient temperature

Reference

Controled Temperature

Figure 4: System response to load disturbances.

0 1000 2000 3000 4000 5000 6000 7000 8000

0.488

0.49

0.492

0.494

0.496

0.498

0.5

0.502

0.504

0.506

0.508

Time (s)

Control Signal (V)

Control Signal With The NGPC − Regulator Case

Figure 5: Control signal for the regulator case.

0 200 400 600 800 1000 1200 1400 1600 1800

30

35

40

45

50

55

60

Time (s)

Controlled Temperature (ºC)

System Response With The NGPC Controller

Algorithm 1

Algorithm 2

Algorithm 3

Reference

Figure 6: System response for a step in the reference.

The Figure 4 shows the system response to a dis-

turbance caused by the variation of the ambient tem-

perature. It is easy to observe that the controller is ca-

pable of rejecting the distubance, keeping the system

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

192

0 200 400 600 800 1000 1200 1400 1600 1800

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Time (s)

Control Signal (V)

Control Signal With The NGPC − Servo Case

Algorithm 1

Algorithm 2

Algorithm 3

Figure 7: Control signals for the servo case.

0 0.5 1 1.5 2 2.5

x 10

4

30

35

40

45

50

55

60

65

70

Time (s)

System’s Response − Ramp Reference

Figure 8: System response for a ramp reference.

output inside the desireble range, presenting a very

small offset of 0.3

o

C, inside the accuracy range of

the sensors, for an ambient temperature variation of

1.5

o

C. The output signal of the controller for this case

is shown in the Figure 5.

The system response for a deviation of 20

o

C in

the setpoint for the three controllers implemented is

shown in the Figure 6, in which the dashed line rep-

resents the system output for the algorithm 02, while

the black and blue lines represent the algorithms 01

and 03 respectivaly. The control signal for the three

algorithms are expressed in the Figure 7.

For better evaluation of the performance of the

controllers, the indices presented in (Goodhart et al.,

1994) were used, which are the mean and variance of

the controller outputs ( ¯u and σ

u

, respectivaly), the In-

tegral of the Absolute Error (IAE), which penalizes

the error between the reference and the system vari-

able and the Integral with Time of the Absolute Error

(ITAE), which penalizes the absolute error through-

out the time line. The calculated indices are shown in

the Table 1 and the time parameters of the closed-loop

system is presented in the Table 2. It is easy to see that

the algorithm proposed in the present work presents

a better performance in relation to the tracking error

and a smaller mean control effort(¯u). The settling time

is also smaller. The rise time for the second algorithm

is smaller, but it also presents a large overshoot which

may not be viable in real applications. For the regula-

tory trial, the results obtained were E

qm

= 0.0755%,

IAE = 0.104, ITAE = 145.108.

The third and last trial was the analyzis of the

system response for a ramp reference. The control

law does not contemplate a second integral action,

necessary for the ramp tracking. Still, the algorithm

provided good results when compared to other tech-

niques. In this work, the proposed methodology was

compared to three other results obtained for differ-

ent controllers for the same case: The algorithm B

is a single model based GPC presented in (Lima,

2007). The algorithms C and D are described in (San-

tana, 2008) in a multi-model environment, with the

controllers based on gain margin and phase margin

metrics, respectively. The algorithm A is the one

proposed in this work, with Ny = 2, λ = 3000 and

α = 0.000095. The ramp started in the temperature of

33.5

o

C covering all modeled range with variation of

0.1915

o

C at each 60 seconds, which corresponds to

one sampling time. The overall results are shown in

Table 3

Table 1: Performance indices for the controllers.

Alg. 01 Alg. 02 Alg. 03

¯u 0.5295 0.5332 0.5196

σ

u

0.0031 0.0063 000038

IAE 0.6728 0.6226 1.1550

ITAE 77,1668 81,7647 244,9661

Table 2: Time indices for the controllers.

Alg. 01 Alg. 02 Alg. 03

Rise Time 200s 118s 358s

Settling Time 296s 354s 972s

Max. Overshoot 0% 21.66% 2.21%

Table 3: Mean squared error for a ramp reference.

Alg. A Alg. B Alg. C Alg. D

Eqm 0.3191% 2.214% 1.482% 1.418%

The neural networks is capable of capturing the

entire dynamic of the system. Performance indices

based on the number of iterations and the computa-

tional effort when only the jacobian is used was pre-

sented in (Soloway and Halcy, 1996). It is fair to af-

firm that the reduced number of iterations performed

by the NGPC algorithm ranges from 6 to 12 times

A NEW APPROACH OF THE NEURAL PREDICTIVE CONTROL APPLIED IN A THERMOELECTRIC MODULE

193

faster, even with the calculation of the Hessian requir-

ing a high computational effort.

5 CONCLUSIONS

In this work a new approach of the Neural GPC was

presented which complies a little modification in the

control law, given by the adding of one more degree

of freedom associated to the decrecent gradient. This

modification caused a significant improvement in the

control effort and in the general system’s closed-loop

response without significant increase of the compu-

tational effort. Furthermore, the algorithm becomes

much more flexible when compared to other one-

degree of freedom based strategies.

The trials were executed in a real-time nonlin-

ear physical system with complex dynamics, with

non-minimum phase states and highly nonlinear static

gains along the diferente operation ranges. The neu-

ral model was able to represent with very good accu-

racy the system dynamics, which shows the efficiency

of the neural networks when applied in the nonlinear

system identification. The system was implemented

to prove in practice the superior performance of the

proposed technique. The same algorithm may be ap-

plied in the control of important industrial process,

as in multivariable control, level, concentration and

temperature. The developed algorithm may estim-

ulate new applications involving the ideas presented

in this work. The low computational cost allows the

practical implementation of the proposed algorithm in

real-time existing embedded systems.

REFERENCES

(1999). Theromeletric coolers and accessories. Melcor

Corporation, first edition.

Almeida, L. A. L. (2003). Modelo de Histerese para

Transic˜ao Semicondutor-Metal em Filmes Finos de

VO2. PhD thesis, Universidade Federal de Campina

Grande.

Almeida, L. A. L. (2004). Modelo dinmico n˜ao-linear para

m´odulo termoel´etrico. In XV Congresso Brasileiro de

Automtica.

Camacho, E. F. and Bordons, C. (2004). Model predictive

control. Springer-Verlag Limited.

Clarke, D. W. (1994). Advanced in model-based predictive

control. Oxford Univesity Press.

Fontana, M. (2001). Caracterizac˜ao e modelagem das pro-

priedades ´opticas de sensores de di´oxido de van´adio.

Master’s thesis, Universidade Federal de Campina

Grande.

Fontes, A. B., Dorea, C. E. T., and Garcia, M. R. S. (2008).

An iterative algorithm forconstrained mpc with stabil-

ity of bilinear systems. In 16th Mediterranean Confer-

ence on Control and Automation, pages 1526–1531.

Garcia, M. R. S. (2008). Controle preditivo por realimen-

tac˜ao de estado de sistemas bilineares sob restric˜oes

aplicado a um m´odulo termoel´etrico. Master’s thesis,

Universidade Federal da Bahia.

Goodhart, S. G., Burnham, K. J., and James, D. J. G.

(1994). Bilinear self-tuning control of a high temper-

ature heat treatment plant. IEE Proc.-Control Theory

Appl., 141(1):12–18.

Hagan, M. T. and Menhaj, M. (1994). Trainning feedfor-

ward networks with the marquadt algorithm. IEEE

Transactions on Neural Networks, 5(6):989–993.

Hao, J., Tan, S., and Vandewalle, J. (1993). One step ahead

predictive control of nonlinear systems by neural net-

works. In Proceedings of 1993 International Joint

Conference on Neural Networks.

Lee, J. H. and Ricker, N. L. (1994). Extended kalman filter

based nonlinear model predictive control. Ind. Eng.

Chem. Res., 33(6):1530–1541.

Li, W. C. and Biegler, L. T. (1988). Process control strate-

gies for constrained nonlinear systems. Ind. Eng.

Chem. Res., (27):1421–1433.

Lima, J. S. (2007). T´ecnicas de controle preditivo bilinear

aplicado a um m´odulo termoel´etrico. Master’s thesis,

Universidade Federal da Bahia.

Propoi, A. I. (1963). Use of lp methods for synthesiz-

ing sampled-data automatic systems. Automn Remote

Control, 24.

Santana, M. J. C. (2008). Controle preditivo multimod-

elo aplicado a um m´odulo termoel´etrico: Uma nova

m´etrica. Master’s thesis, Universidade Federal da

Bahia.

Sobrinho, M. O. S. L., Lima, J. S., Souza, V. O. S. T.,

Fontes, A. B., and Almeida, L. A. L. (2006). Car-

acterizac˜ao de um m´odulo termoel´etrico por modelo

param´etrico bilinear. Congresso Brasileiro de Au-

tomtica.

Soloway, D. and Halcy, P. J. (1996). Neural generalized pre-

dictive control, a newton-raphason implementation. In

Symposium on Intelligent Control.

Zamarreo, J. M. and Vega, P. (1999). Neural predictive con-

trol. application to a highly non-linear system. En-

gineering Applications of Artificial IntelligenceJapan,

(12):149–158.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

194