Automatic Monitoring of Logistics Processes using

Distributed RFID based Event Data

Kerstin Werner

1

and Alexander Schill

2

1

SAP Research CEC Dresden, Chemnitzer Straße 48, 01187 Dresden, Germany

2

Technische Universität Dresden, Nöthnitzer Straße 46, 01062 Dresden, Germany

Abstract. Decreasing sizes and a static decline in production costs are fostering

the use of RFID tags and sensors in cross-company logistics networks. Addi-

tionally, the EPCIS specification comprises interface standards for capturing

and querying RFID based event data and storing it in a standardized data for-

mat. This contribution examines the potential of the given technological means

for the automatic monitoring of complex inter-organizational logistics

processes. We identify requirements for the monitoring of individual quality

objectives using distributed event data and describe the architecture of a moni-

toring system addressing them. Furthermore, we argue that such a system can

be nearly seamlessly integrated into existing EPCglobal compliant RFID infra-

structures.

1 Introduction

The RFID technology is nowadays mainly used in intra-organizational settings to

capture identification and status information of trade items. Currently, inter-

organizational applications are developed and investigated because of their potential

to enable new beneficial business scenarios. To foster their adoption among multiple

industries, EPCglobal

1

develops and ratifies standards to enable cross-company RFID

application scenarios and to overcome problems caused by heterogenic RFID infra-

structures. Complex logistics processes exhibit a predestined utilization context for

these standards. They comprise combined point-to-point transportation and distribu-

tion or consolidation processes of goods between partners in a logistics network. The

primary objective is to move goods along supply chains by complying with specific

requirements concerning conditions of transported goods or the transportation process

itself. These conditions cover for example times or locations of departure and deli-

very as well as quantities or conditions of transported goods. They mainly result from

customer needs, competitive pressure or laws. We refer to these requirements as Ser-

vice Level Objectives (SLOs) which are negotiated and defined on an individual

shipments and transportations legs base.

1

http://www.epcglobalinc.org

Werner K. and Schill A. (2009).

Automatic Monitoring of Logistics Processes using Distributed RFID based Event Data.

In Proceedings of the 3rd International Workshop on RFID Technology - Concepts, Applications, Challenges , pages 101-108

DOI: 10.5220/0002194501010108

Copyright

c

SciTePress

Logistics Service Providers (LSPs) have to ensure the compliance to several SLOs

during logistics process execution. To realize this, they negotiate dedicated contracts

with subcontracted Carriers. These contracts are called Forwarding Instructions.

They serve as a basis for documents called Waybills which are used as accompanying

documents for transported trade items by Carriers. RFID related event data is current-

ly used for Tracking and Tracing [1] applications to monitor SLOs associated with

transportation processes and transported goods. Unfortunately, these applications are

either proprietary developments or require the availability of Electronic Data Inter-

change (EDI) communication infrastructures. These imply extensive integration ef-

forts and thus cannot easily be provided by small or medium businesses. Furthermore,

they are restricted to the evaluation of single events against thresholds and thus neg-

lect the potential of correlating event data which could be used to monitor more com-

plex SLOs. To benefit from this potential, efficient mechanisms that integrate event

data from distributed EPCglobal compliant RFID infrastructures have to be developed

and combined with mechanisms that correlate it to business relevant monitoring in-

formation [2]. This contribution addresses the question, how a system for the moni-

toring of individual SLOs during transportation process execution can be designed

respecting existing interface and data format standards to enable minimal adoption

efforts. Furthermore, our work focuses on the development of mechanisms to inte-

grate distributed RFID based event data and to correlate it to detect anomalies during

the execution of complex transportation processes.

The remainder of this paper is structured as follows: Section 2 describes the tech-

nologies our work is based on. Section 3 defines the requirements a monitoring sys-

tem has to meet in this individual context. In Section 4 an architecture and its compo-

nents are presented which address the given requirements. Related work in this area is

evaluated in Section 5. Section 6 summarizes our work and gives an overview about

future work directions and objectives.

2 Technology Background

The Uniform Business Language (UBL)

2

document standard allows for the XML

representation of common business documents including Forwarding Instructions and

Waybills. It is driven by the not-for-profit consortium OASIS (Organization for the

Advancement of Structured Information Standards). Due to this standard, a set of

common SLOs concerning transportation processes can be described in XML docu-

ments and processed automatically. Modern RFID and sensor technologies enable the

automatic identification (Auto-ID) of tagged items by eligible readers in combination

with environmental information [3] and thus can be used to monitor SLOs. Sensors

are able to detect physical or chemical changes in the surrounding of goods or the

goods themselves. The information of interest and thus the actual sensors applied

depend on their utilization context. Especially, in logistics scenarios the sensor infor-

mation of interest is often about temperature, humidity and vibration settings of

transported goods. Data captured by sensors can be stored on tags or directly sent to

2

http://ubl.xml.org

102

readers mainly depending on the power management of associated RFID tags. Read-

ers can be statically installed at multiple locations along supply chains, like goods

issue or goods receipt gates, or dynamically moving with transportation vehicles to

capture data of tagged goods. In logistics the utilization of passive UHF tags which

exclusively store an identifier is common due to minimal production costs and efforts

as well as small sizes. This identifier is referred to as Electronic Product Code (EPC)

[4]. It allows for the unique identification of goods within the EPCglobal Network.

EPCglobal is an industry consortium fostering the standardization of technologies for

the automatic identification of objects. The so far ratified standards represent a key

driver for cross-company RFID usage scenarios because they are already adopted by

several industries. The most relevant outcome of the EPCglobal consortium for our

work is the EPC Information Services Specification which includes interfaces for

capturing and querying RFID based event data in a specified data format [5]. Soft-

ware systems implementing these interfaces and data formats are called EPCIS Repo-

sitories which enable inter-organizational access and exchange of EPC related event

and meta data. Stored data can be queried by either ad-hoc queries with immediate

responses or by so called Standing Queries (Subscriptions). These Subscriptions for

specific queries are periodically evaluated by an EPCIS Repository and matching

event data is sent to the requesting application. Data stored in EPCIS Repositories is

enriched by information about an object’s business context, location, and condition at

the time of detection by an RFID reader. Additionally, mechanisms for user defined

extensions are provided to represent any possible kind of information associated with

tagged objects like data captured by sensors. Modern event processing technologies

enable the correlation of such data according to specified processing instructions.

There are currently several solutions available which process events to derive rich

business relevant information like Esper

3

, Coral8

4

and Streambase

5

.

The combination of these technologies provides the potential to use RFID based

event data for the automatic and near real time monitoring of transportation processes

in logistics networks to detect anomalies according to specified SLOs.

3 Requirement Analysis

RFID based event data is captured in EPCIS Repositories of partner companies par-

ticipating in a transportation process. Carriers use vehicles equipped with RFID read-

ers that periodically capture RFID data and pass it to the respective EPCIS Reposito-

ry. An LSP has access to a monitoring system which integrates and correlates cap-

tured event data to evaluate the compliance to concrete SLOs. Such a system would

support LSPs with their management of complex logistics processes and allow partic-

ipating partners to be informed about problems or succeeded deliveries immediately

and to react accordingly. Therefore, it has to meet the following requirements:

3

http://esper.codehaus.org

4

http://www.coral8.com

5

http://www.streambase.com/complex-event-processing.htm

103

R1: Fine-grained Description of Process Individual SLOs. An LSP has to be pro-

vided with fine-grained description mechanisms for the SLOs which are to be moni-

tored. Furthermore, logical rules like negations, disjunctions or conjunctions on these

SLOs have to be expressed which can be automatically processed by the monitoring

system. An appropriate data format has to be provided and respective documents have

to be put in a dedicated document repository which can be accessed by the monitoring

system.

R2: Integration of Distributed RFID Event Data. As described in Section 3, RFID

based event data is captured in distributed EPCIS Repositories. Only relevant event

data has to be sent to the monitoring system in near real time for further processing.

R3: SLO based Monitoring Instructions Generation. SLOs are individually nego-

tiated for any transportation process. Therefore, monitoring instructions like event

patterns [6] have to be defined frequently. The definition of monitoring instructions

has to be executed automatically, because a definition done by users would imply too

high expectations on their programming skills and not scale due to the high number

of transportation processes which are to be coordinated in short time intervals.

R4: Processing of Monitoring Instructions and Event Data. The processing and

matching of automatically generated monitoring instructions with the event data ga-

thered from distributed EPCIS Repositories has to be performed by an appropriate

event processing engine. It has to correlate event data resulting from different sources

according to the given instructions. Furthermore, it has to create notification events if

a certain set of incoming event data matches an instruction. Then, either a violation or

a successful fulfillment of a specific SLO has been detected.

R5: Management of Monitoring Results. The monitoring system produces results

in the form of notification events which mainly correspond to the output of the in-

stalled event processing engine. The system has to support two kinds of output: in-

stantaneous notifications and historical log files. The historical log files have to be

persistently stored in combination with the associated SLO descriptions. This allows

for the later processing or exchange of this data.

R6: Notification of External Business Applications. The monitoring system has to

provide mechanisms to notify external business applications if an SLO violation or its

fulfillment has been detected. Therefore, it has to expose an interface which could be

accessed by applications to subscribe for certain kinds of notifications. They would

then be informed as soon as a respective notification occurs by the monitoring sys-

tem.

R7: Minimal Integration Efforts Into the EPCglobal Architecture Framework.

The integration effort of the monitoring system into existing EPCglobal compliant

RFID infrastructures has to be kept at a minimum. This implies that interfaces and

data formats specified by EPCglobal have to be supported to allow users with com-

pliant infrastructures to use the system with minimal efforts in time and costs.

104

4 Conceptual Design

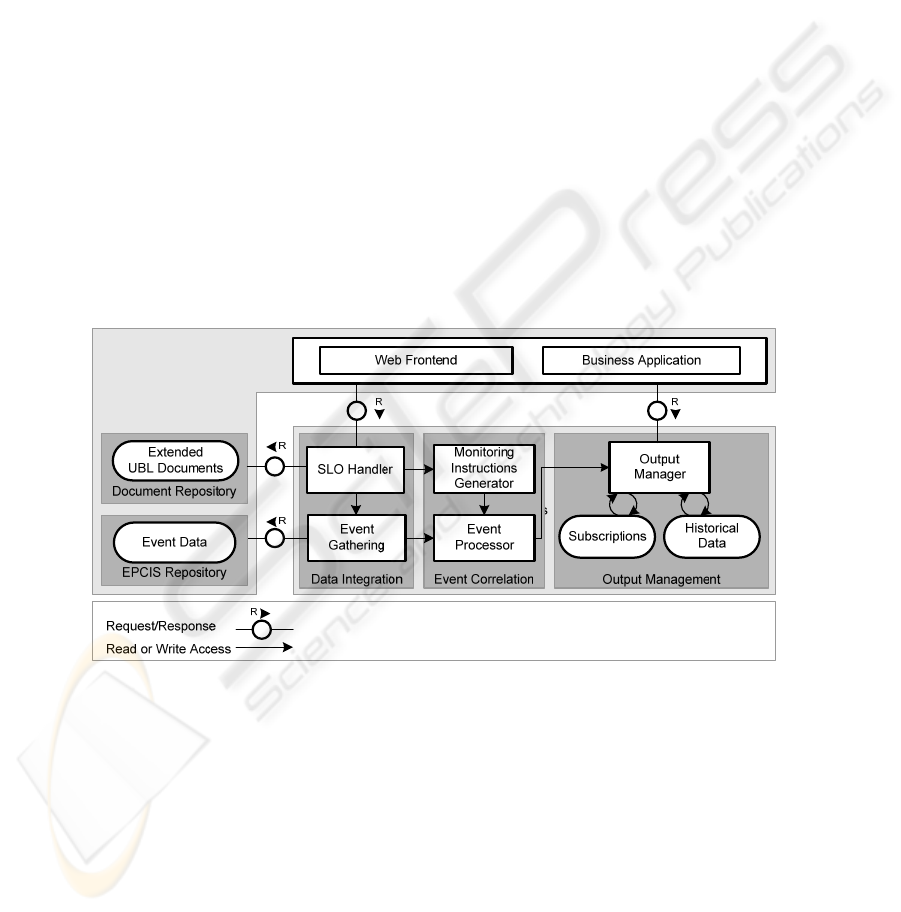

This section describes the architecture of a monitoring system which integrates event

data from distributed EPCIS Repositories to automatically monitor individual SLOs

and addresses the requirements defined in Section 3. Figure 1 gives an overview of its

components and their interactions. There are two areas distinguished in the figure

which could be referred to as external system components like data sources and ac-

cessing applications and the inner monitoring system. An accessing application might

be a Web Frontend for direct access to the monitoring system which would be used

by an LSP or a Business Application like a planning tool which could be hosted by

the monitoring systems owner or partner companies which want to be informed about

certain monitoring results. Furthermore, EPCIS Repositories and the Document Re-

pository are considered to be external system components as well. The EPCIS Repo-

sitory is hosted by each partner company of a supply chain which wants to capture

data related to trade items. The Document Repository is hosted by an LSP and offers

access to stored Forwarding Instructions or Waybills which are put in there by LSPs

or Carriers after negotiations. The documents contained are called Extended UBL

Documents. They are instances of an UBL document standard extension we devel-

oped to enable fine-grained SLO and dependency descriptions between several doc-

uments. Together, the Document Repository and the extension of the UBL XML

schema address R1.

Fig. 1. Architecture of the monitoring system including accessing applications on the left and

data sources on the top.

The monitoring system in the center of Figure 1 is subdivided into three logical

parts: Data Integration, Event Correlation and Output Management. The Data Inte-

gration part includes system components that gather relevant information from exter-

nal information sources and prepare it for further processing. The SLO Handler is

activated when an accessing application initiates the monitoring of a specific trans-

portation process. It queries the Document Repository to extract the relevant Waybills

for all transportation legs of the given transport process. It uses the documents re-

105

turned to determine its expected duration, the involved partner companies and one or

more EPCs of the goods included in the shipment which is to be monitored. This data

is sent to the Event Gathering component. Furthermore, the SLO Handler extracts

SLO descriptions from the Waybill documents and sends them to the Monitoring

Instructions Generator. The Event Gathering component addresses R2. It receives

data from the SLO Handler which identifies the relevant EPCIS Repositories which

have to be queried to receive event data concerning a specific shipment. This compo-

nent sends event queries as Subscriptions to the given EPCIS Repositories which

persist during the expected duration of the transportation process and are deactivated

afterwards. During that time the submitted queries are executed periodically accord-

ing to a time schedule defined by the Event Gathering component. Resulting event

data from EPCIS Repositories is sent to this component and passed to the Event

Processing Engine.

The Event Correlation is the second logical part of the monitoring system. It in-

cludes the Monitoring Instructions Generator component which addresses R3. It uses

data submitted by the SLO Handler to automatically create event patterns. The gener-

ated event patterns describe correlations of single events to complex events which are

translated into a new semantic meaning. To evaluate for example if the transportation

duration of a certain shipment does not exceed 24 hours after the departure from its

origin it has to be searched for an event indicating the departure and an event indicat-

ing the final arrival at the shipments destination. Additionally, it has to be examined if

the time interval between the time of departure and the time of arrival is less than 24

hours to infer that this SLO has been met. Event patterns have to express this event

correlation and constraints information. Operators supported by common pattern

description languages include disjunctions, conjunctions, negations or temporal se-

quences and periods. Our architecture design proposes a processing of patterns and

event data by an Event Processing Engine which relates to R4. It receives event pat-

terns from the Monitoring Instructions Generator and matches them against incoming

event data from the Event Gathering component. The Event Processing Engine gene-

rates notification events and sends them to the Output Manager if event patterns are

matched by sets of certain events.

The third logical part of the monitoring system is the Output Management which

addresses R5 and R6. The system produces historical and instantaneous monitoring

data. Historical monitoring data is stored in an internal database by the Output Man-

ager. It can be queried by eligible users or applications. Instantaneous monitoring

notifications are produced by the Event Processing Engine. They are sent to accessing

applications by the Output Manager which beforehand evaluates Subscriptions stored

in its internal database to discover which applications are interested and where to

send the notifications.

For clarity reasons Figure 1 does not depict any interfaces which are used by the

system components to expose and access functionality and in addition address R7:

The EPCIS Repository implements the interfaces specified in [5]. These include the

Query Interface to provide access to stored event data for applications and the Cap-

ture Interface which can be accessed by appropriate RFID middleware solutions to

send RFID based event data to a Repository. The monitoring system itself implements

a Query Callback Interface which is accessed by an EPCIS Repository when event

data is sent according to a Subscription.

106

5 Related Work

The monitoring of individually negotiated quality objectives of transportation

processes is nowadays nearly exclusively practically performed in the cool chain

industry. This implicates that research in this area concentrates on this industry. It is

mainly investigated how data could be efficiently captured using sensor or Auto-ID

technologies and how it can be stored in rather proprietary software systems [7], [8].

The correlation of resulting event data to more complex information is not consi-

dered. Furthermore, it is often assumed that relevant data is stored centrally and

cross-company usage scenarios are not examined.

Additionally, there are approaches that aim to detect anomalies in distributed

event data in near real time. In this context anomalies suggest the presence of coun-

terfeit products. Other approaches describing the monitoring of certain quality objec-

tives do mainly work with fixed policy descriptions [9], [10]. Altogether, they do not

consider the automatic generation of processing instructions like event patterns based

on these policies which is essential for practical adoptions. Still, there are some ap-

proaches in research which study the evaluation of distributed RFID based event data

to proof authenticity of goods [11], [12]. However, they do not describe how distri-

buted event data can be integrated for such an evaluation. They rather provide an

additional database to redundantly store the event data of interest. In addition, they do

not describe how the evaluation of event data can be automatically performed instead

of time consuming and error prone interpretations by consumers.

Already well established approaches to perform long term evaluations regarding

the compliance of service providers to concrete Key Performance Indicators (KPIs)

are supported by Data Mining mechanisms on data stored in huge Data Warehouses

[13]. These mechanisms can be applied to RFID based event data. They differ from

our approach in their potentially redundant representation of stored data and in their

long term character by allowing high response times due to very complex computa-

tions. This is mainly due to the long term character of KPI definitions which are un-

like the short term intention of SLOs for transportation processes.

6 Conclusions and Future Work

In this contribution we argued that current standards compliant RFID infrastructures,

technologies for event correlation, and XML based business document standards

enable service oriented logistics monitoring applications that require less integration

efforts than existing tracking solutions. This is reflected by our investigation on me-

chanisms that build upon the EPCglobal Framework to automatically integrate and

use distributed RFID based event data for the monitoring of transportation processes.

We have introduced a set of requirements a monitoring system needs to implement.

Considering these, we presented a conceptual design of an architecture addressing

these requirements and proposed mechanisms that integrate and correlate event data

to perform the monitoring of transportation processes regarding to specific SLOs. The

events stored in EPCIS Repositories cover exactly the information needed to evaluate

the compliance of a given transportation process to specified SLOs. The monitoring

107

system integrates this data by processing its structure as well as accessing and imple-

menting the interfaces which are specified in the EPCIS Specification. Due to that,

the system complements the vision of EPCglobal by using the given infrastructure to

derive business relevant information and putting cross-company separated event data

in a new context.

Our future work focuses on the development of an algorithm to automatically

generate monitoring instructions based on given SLO descriptions. To support the

notification of external business applications by the monitoring system, we are going

to model possible notification events. A data model which has to be exchanged be-

tween cooperating companies external applications will enable them to immediately

process notifications as they are received. Additionally, we are continuously engaged

in developing the prototypical implementation of our concepts which will be later

used for their evaluation. For example, we are going to analyze the influence of miss-

ing or distorted event data on the results of the monitoring system.

References

1. Rakesh Agrawal, Alvin Cheung, Karin Kailing, and Stefan Schonauer. Towards Traceabili-

ty across Sovereign, Distributed RFID Databases. In IDEAS ’06: Proceedings of the 10th

International Database Engineering and Applications Symposium, pages 174–184, Wash-

ington, DC, USA, 2006. IEEE Computer Society.

2. KerstinWerner. Service Level Agreement Compliance Monitoring based on RFID Events.

In IADIS International Conference WWW/Internet, 2008.

3. Michael Clasen. RFID/EPC und Sensorik - Einführung, Einsatzgebiete und

Standardisierung. GS1 Germany, November 2006.

4. EPCglobal Inc. EPCglobal Tag Data Standards version 1.4, Juli 2008.

5. EPCglobal Inc. EPC Information Services (EPCIS) version 1.0.1 Specification, 2007.

6. David Luckham. The Power of Events: An Introduction to Complex Event Processing in

Distributed Enterprise Systems. Addison-Wesley Longman, 2002.

7. Ruud Riem-Vis. Cold Chain Management using an Ultra Low Power Wireless Sensor

Network. Working paper of IP01 SA, 2004.

8. Alexander Mirow and Stephan Eisen. Temperaturüberwachung und Transportlogistik im

Lebensmittelhandel. Lebensmittel-Technologie, 37:2–3, 2004.

9. Ali Dada and Frédéric Thiesse. Sensor Applications in the Supply Chain: The example of

quality-based Issuing of Perishables. In IOT, pages 140–154, 2008.

10. Alexander Ilic, Thomas Andersen, Florian Michahelles, Elgar Fleisch. Analyzing Product

Flows with the Supply Chain Visualizer. Demo at Internet of Things Conference, 2008.

11. Thorsten Staake, Frédéric Thiesse, and Elgar Fleisch. Extending the EPC Network: The

Potential of RFID in Anti-Counterfeiting. In SAC ’05: Proceedings of the 2005 ACM sym-

posium on Applied computing, pages 1607–1612, New York, NY, USA, 2005. ACM.

12. Robin Koh and Thorsten Staake. Nutzen von RFID zur Sicherung der Supply Chain der

Pharmaindustrie. In Elgar Fleisch and Friedemann Mattern, Editors, Das Internet der

Dinge, pp. 161–175. Springer Berlin Heidelberg, 2005.

13. William H. Immon. Building the Data Warehouse. QED Technical Pub Group, 1992.

108