FUZZY TRAJECTORY TRACKING FOR AN AUTONOMOUS

MOBILE ROBOT

Carlos Fernández Caramés, Vidal Moreno Rodilla

Departamento de Informática y Automática, University of Salamanca, Plaza de los Caídos S/N, Salamanca, Spain

Belén Curto Diego, José Andrés Vicente Lober

Departamento de Informática y Automática, University of Salamanca, Plaza de los Caídos S/N, Salamanca, Spain

Keywords: Mobile robot, Heading sensor, Fuzzy controller.

Abstract: This paper proposes a fuzzy controller embedded in a closed-loop control system designed to make a robot

track a straight line. The system uses a heading sensor to measure the error in the orientation of the robot. A

real robot is simulated in Matlab so as to test and accelerate the development process of the fuzzy controller.

Finally, experimental results of the simulated and the real robot are presented, showing the effectiveness of

our approach under strong disturbances such as unexpected robot rotations.

1 INTRODUCTION

There is no doubt whatsoever that moving from one

place to another is a must for every mobile robot.

The type of movements that a robot will perform

will nonetheless be different depending on if it is

familiarized with its surroundings or not. When a ro-

bot is exploring an unknown environment, it will

typically wander aimlessly either trying to build a

map, trying to locate itself, or both things at the

same time. However, when a robot is within a

previously known environment, its movements will

generally be planned by a high level path planner,

provided that a map is available.

Path planning, together with map building and

localization, is one of the three fundamental tasks a

robot has to master to fully solve the navigation

problem, and it is the area of navigation which has

received the most attention (Murphy, 2000). The

path planning problem consists in designing a path

between an initial position and a target position such

that (a) the robot does not collide with any static or

dynamic obstacles in the environment and (b) the

planned motion is consistent with the kinematic

constraints of the vehicle (Zou et al., 2006). The

kinematics of a vehicle are determined by the

steering mechanism, being differential drive and

Ackermann drive two of the most frequently used

steering mechanisms for mobile robots.

There are many different approaches to path

planning, both for differential and for Ackermann

steered robots, but in the end, the final result of any

path planner is a sequence of path segments (Baltes

and Hildreth, 2001). Many planners use a sequence

where each segment is either a straight line, a full

left turn or a full right turn, based on the early work

of Reeds and Shepp (Reeds and Sheep, 1990), which

proves that the shortest path for any vehicle can be

planned using exclusively these three types of

segments.

Once the path is planned, the robot should be

able to follow the planned segments as accurately as

possible. The aforementioned maneuvers —straight

lines and full turns— may seem easy to perform by a

human driver with some experience, but they are not

straightforward at all for an autonomous mobile

robot. Tracking a straight line is somewhat difficult

than tracking full turns, and this is particularly true

for a differential drive robot. Moving the wheels of a

differential robot at the very same speed is not

enough to achieve a straight line, because different

wheel radii or wheel slippage, among other reasons

(see (Borenstein et al., 1996)), will cause the robot

to get out of its intended trajectory sooner or later.

Ackermann steered robots, although more robust for

straight line tracking than differential steered robots,

are also difficult to be driven along a straight line.

359

Fernández Caramés C., Moreno Rodilla V., Curto Diego B. and Andrés Vicente Lober J. (2009).

FUZZY TRAJECTORY TRACKING FOR AN AUTONOMOUS MOBILE ROBOT.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 359-362

DOI: 10.5220/0002198603590362

Copyright

c

SciTePress

For example, in our robotics research group we own

an unmanned forklift truck (reverse Ackermann

steering), whose main difficulty is that it has a high

degree of looseness in its steering wheel.

The conventional approach for controlling these

robots and make them follow a straight line would

be to design a PID (Proportional, Integral and

Derivative) controller. Consequently, we would need

to know every physical detail about the robot and its

environment so as to be able to model such a system

mathematically (Marzi, 2006). However, we humans

do not need accurate information from the

environment or from a vehicle to control it and

perform successful maneuvers. Most of the time we

deal with approximate reasoning rather than precise,

and it can be expressed linguistically by a series of

if-then rules. Luckily, this rationale is not only

available humans, since fuzzy logic provides us with

a mathematical framework to translate our linguistic

expert knowledge into numerical data which can be

used by robots.

In this paper we present a fuzzy approach to

solve the problem of straight line tracking for

differential robots using an Attitude and Heading

Reference System (AHRS).

2 GENERAL SYSTEM

DESCRIPTION

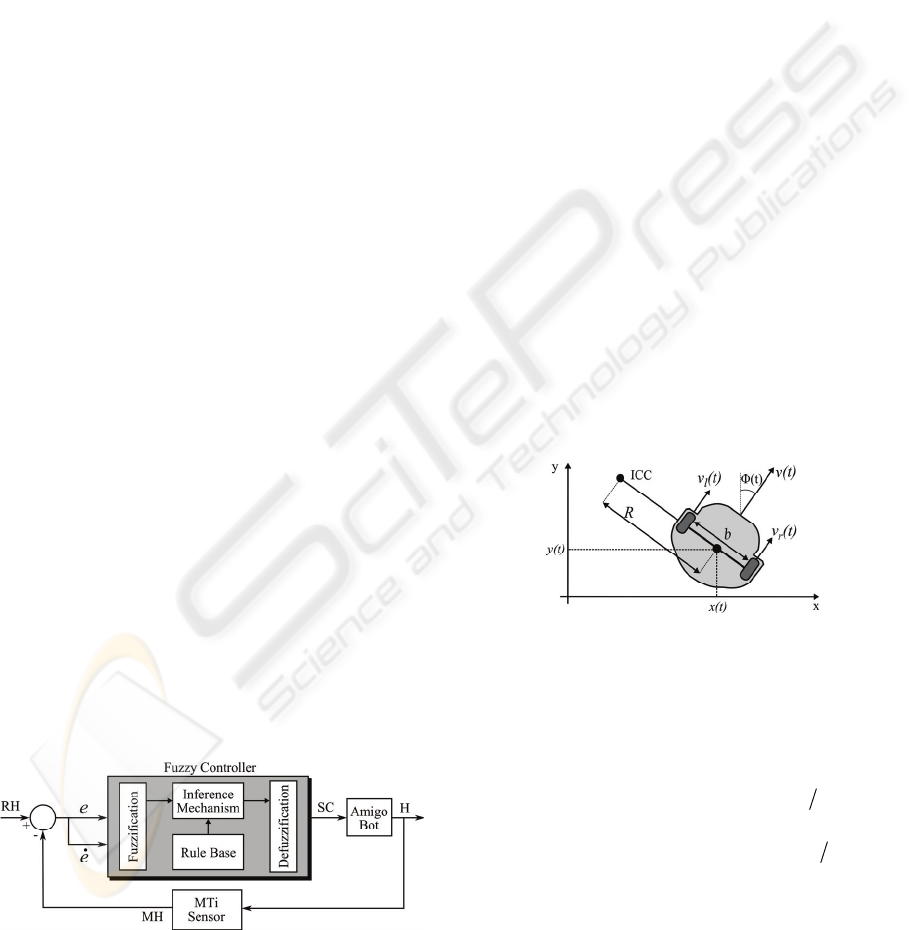

The general block diagram of our system is depicted

in Fig. 1, which shows a fuzzy controller embedded

in a closed-loop control system. The system works

by selecting a reference heading (RH), which the

robot will have to follow. Then, the MTi sensor

measures the heading (MH) of our robot

(AmigoBot). The difference between this two data is

used to calculate the heading error (e) and its

derivative (ė). Next, these data are used as the inputs

of the fuzzy controller, which determines the change

in speed (SC) needed to correct the heading (H) of

the robot.

Figure 1: General system description.

The core of the system is the fuzzy controller,

which consists of four components: (1) the “rule

base” is the set of rules that control the system. (2)

The inference mechanism evaluates which control

rules are relevant. (3) The fuzzification interface

modifies the inputs to the fuzzy controller so that

they can be interpreted and compared to the rules in

the rule base. (4) The defuzzification interface

transforms the conclusions reached by the inference

mechanism into the input to the robot.

The MTi is a low-cost Attitude and Heading

Reference System (AHRS) from Xsens

technologies. We use it to measure the heading angle

of the robot. The mobile robot we have chosen is the

AmigoBot from MobileRobots Inc.

3 KINEMATIC MODEL OF THE

ROBOT

The kinematic model of the AmigoBot is depicted in

Fig. 2. There, ICC stands for Instantaneous Center of

Curvature; v

l

(t) and v

r

(t) are the linear velocity of the

left and right wheel; R is the curvature radius

described by the middle point of the wheel axis, and

b is the distance between wheels. When the linear

velocities of the left and right wheel are different,

the robot turns around the ICC with angular velocity

w(t).

Figure 2: Kinematic model of the Amigobot.

Additionally, if we designate R

l

and R

r

as the

curvature radii described by the left and the right

wheel, respectively, then R = (R

l

+ R

r

)/2. Taking

this into account, and the fact that v

l

(t) = w(t)·R

l

and

v

r

(t) = w(t)·R

r

, the linear velocity of the robot can be

expressed as

()

2)()()()( tvtvRtwtv

lr

+

=

=

. If we

continue developing, we can obtain the angular

velocity of the robot as

()

btvtvtw

lr

)()()( −= .

The state of the robot is represented by the

variables x(t), y(t) and Φ(t)

, and it can be obtained

by integrating (1). We use it to study the

performance of the robot in a simulated

environment.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

360

()

()

⎥

⎦

⎤

⎢

⎣

⎡

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

)(

)(

10

0)(cos

0)(sin

)(

)(

)(

tw

tv

t

t

t

ty

tx

φ

φ

φ

(1)

4 FUZZY LOGIC CONTROLLER

The definition of a fuzzy system can be broken

down in several parts (Passino and Yurkovich,

1998): a) variables and values, b) rule set and c)

membership functions.

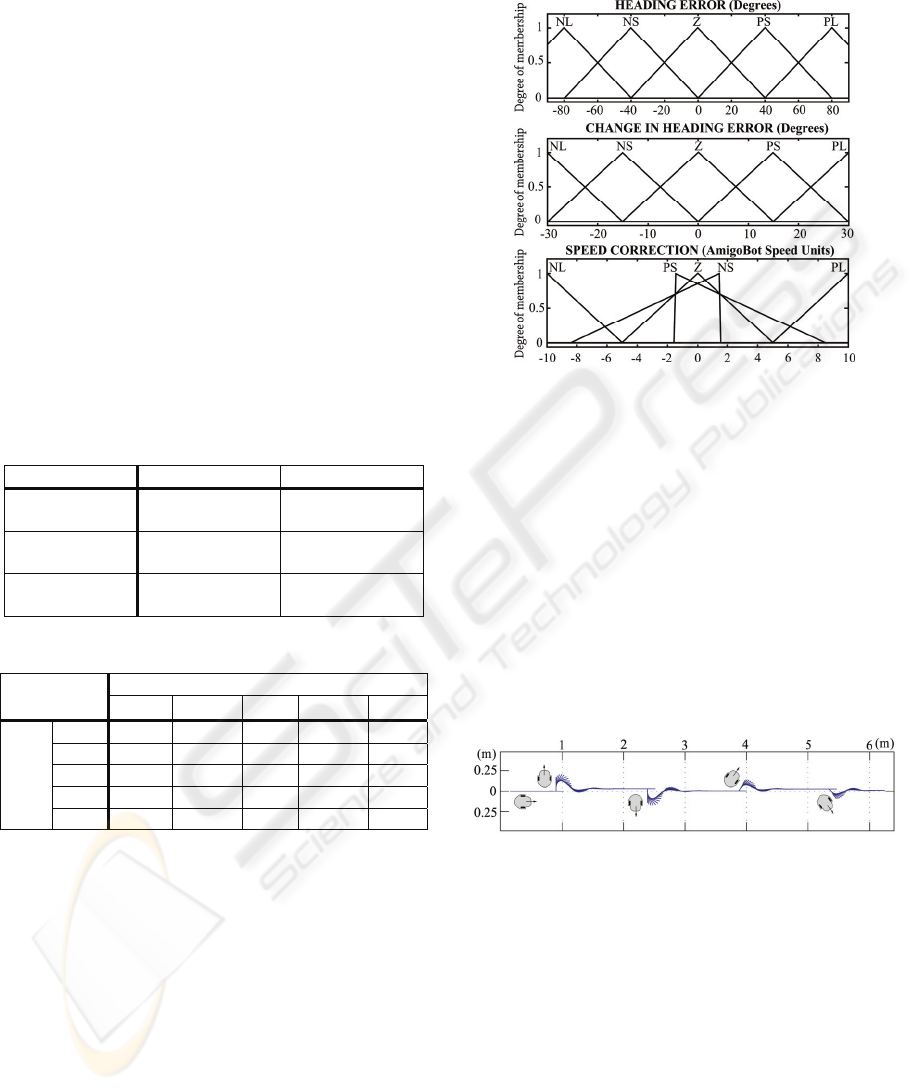

We have used three linguistic variables: “heading

error”, “change in heading error” and “speed

correction”, and 5 different linguistic values for each

variable: NL (negative large), NS (negative small), Z

(zero), PS (positive small) and PL (positive large).

The way these terms are used is indicated in Table 1,

where CW and CCW stand for clockwise and

counterclockwise, respectively.

Table 1: Meaning of the linguistic terms.

Positive Negative

Heading error Robot is rotated

CCW

Robot is rotated

CW

Change in

heading error

Robot is rotating

CCW

Robot is rotating

CW

Speed

Correction

Robot needs to

rotate CCW

Robot needs to

rotate CW

Table 2: Rule table for the Amigobot.

Speed

Correction

Change in heading error (

ė)

NL NS Z PS PL

Heading

error

(

e

)

NL PL PL PL PS Z

NS PL PL PS Z NS

Z PL PS Z NS NL

PS PS Z NS NL NL

PL Z NS NL NL NL

Using the linguistic quantification stated in the

previous subsection, we have designed a set of rules

(see Table 2) that describe how to make the robot

follow a straight line. Finally, the membership

functions of the system are depicted in Fig. 3.

Because of a hardware limitation, the linear

speed of the Amigobot wheels can only be set to

multiples of 20 mm/s. Thus, we have designed the

membership function of the speed correction

variable taking into account this peculiarity, and

hence each unit in the x axis means 20 mm/s. Once

the fuzzy system computes an output speed

correction, this value is added to the current right

wheel speed and subtracted from the current left

wheel speed. Thus, the required torque is achieved

and the robot rotates toward the desired direction

while the linear speed remains constant.

Figure 3: Membership functions.

5 EXPERIMENTAL RESULTS

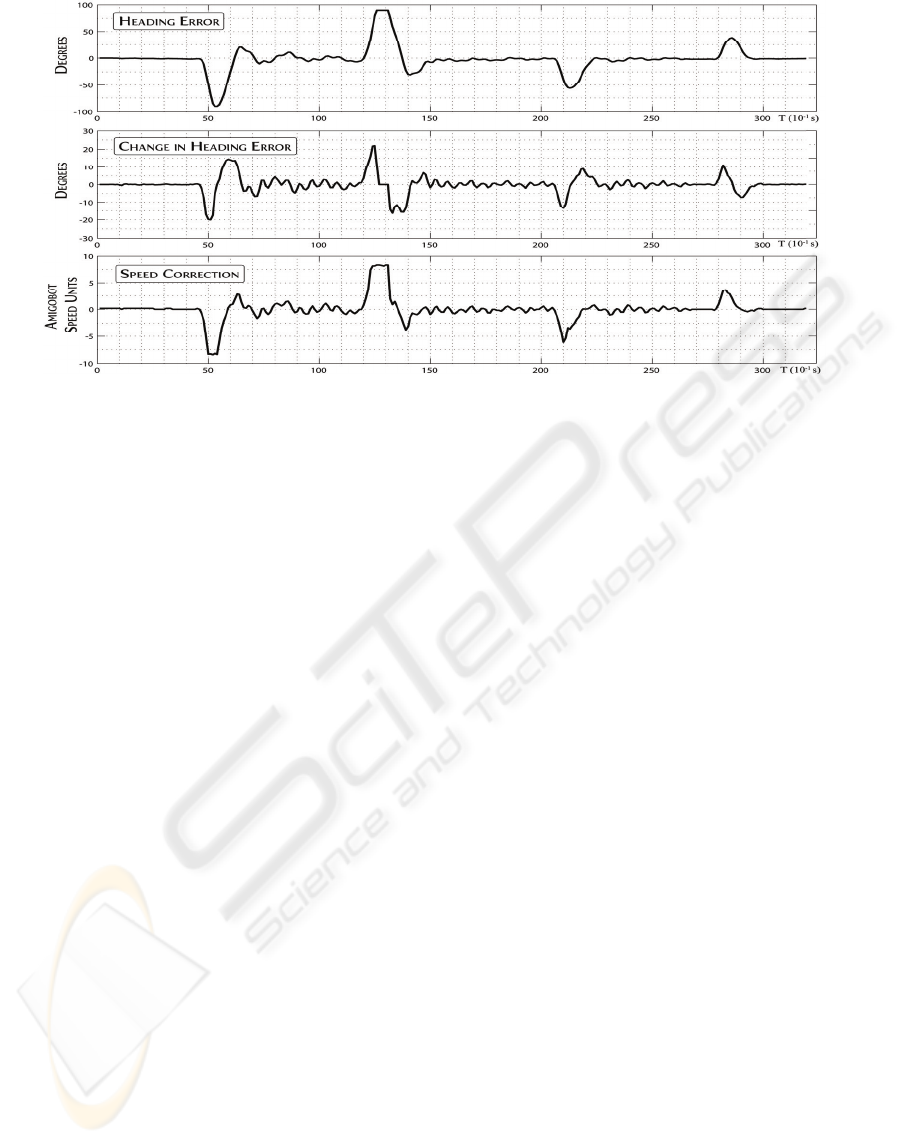

We have simulated the movements of AmigoBot

using the kinematic model (1) and the readings from

the heading sensor, where we have added random

white noise to mimic the specifications of the MTi

unit. The simulation results were very similar to the

real world results, and therefore, we only show the

performance of the real robot. During the tests, the

robot was commanded to travel at a constant speed

of 0.2 m/s, and it was subjected to four strong

disturbances of ≈-90º, ≈90º, ≈-45º and ≈45º.

Figure 4: Simulated robot trajectory.

An illustration of the trajectory followed by the

robot is shown in Fig. 4, where the robot is

represented as a short segment. Next to each

deliberated turn, the robot is depicted. The

corresponding input and output variables for the

simulation of the fuzzy system are shown in Fig. 5.

As it can be seen, the robot gets stabilized quickly

and smoothly after the unexpected rotations. When

the robot is subjected to 45º turns, it offers fast

response times (it is stabilized in 1s) and excellent

performance: it does not virtually oscillate at all. On

the other hand, when it is presented with strong

disturbances (90º turns approximately), its response

FUZZY TRAJECTORY TRACKING FOR AN AUTONOMOUS MOBILE ROBOT

361

Figure 5: Real robot experimental results.

is still acceptable although the heading takes more

time (2-3 s) to get stabilized because of oscillation.

6 CONCLUSIONS

Path planners are widely used when a mobile robot

is within a known environment. Many path planning

methods give as a result a sequence of straight line

segments and full turns, because it has been proved

that the shortest path between two points can be

achieved that way. Taking into account that full

turns are less difficult to perform, we have proposed

and implemented a fuzzy controller that is capable

of following straight lines under strong disturbances.

The fuzzy controller is embedded in a closed-loop

control system, and relies on a AHRS unit —used as

a heading sensor— to guarantee that the robot faces

the right direction.

The performance obtained with the real robot is

quite similar to the simulation results, and the robot

is capable of tracking a straight line even under

unexpected turns of 90º. Although the real robot

includes a nonlinearity by which the linear speed of

each wheel can only be set in 20 mm/s increments,

the fuzzy controller performs equally well under this

circumstance.

Future work includes modifying this system and

adapting it to a real forklift truck. Such a system is

being tested, and it is giving excellent results in the

simulation stage.

ACKNOWLEDGEMENTS

This work has been partially funded by the Spanish

JCYL in conjunction with the European Social

Fund, under the FPI grants program: ORDEN

EDU/1453/2005 de 28 de octubre. It also has been

funded by the Spanish JCYL under project ref.

SA030A07, and the Spanish MEC under project ref.

DPI2007-62267.

REFERENCES

Baltes, J. and Hildreth, N. (2001). Adaptive path planner

for highly dynamic environments. Lecture Notes in

Computer Science, 2019:76 – 85.

Borenstein, J., Everett, H. R., and Feng, L. (1996). Where

am I? sensors and methods for mobile robot

positioning. Technical report, The University of

Michigan.

Marzi, H. (2006). Fuzzy control of an inverted pendulum

using ac induction motor actuator. In Proceedings of

the 2006 IEEE International Conference on

Computational Intelligence for Measurement Systems

and Applications, pages 109–114.

Murphy, R. (2000). Introduction to AI Robotics. MIT

Press.

Passino, K. M. and Yurkovich, S. (1998). Fuzzy Control.

Addison-Wesley.

Reeds, J. and Shepp, L. (1990). Optimal paths for a car

that goes both forward and backward. Pacific Journal

of Mathematics, 145(2):367 – 393.

Zou, A.-M., Hou, Z.-G., Tan, M., and Liu, D. (2006). Path

planning for mobile robots using straight lines. In

Proceedings of the 2006 IEEE International

Conference on Networking, Sensing and Control,

pages 204 – 208.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

362