HYBRID DCA-PCA MULTIPLE FAULTS DIAGNOSIS METHOD

Funa Zhou

1,2

, Tianhao Tang

2

and Chenglin Wen

3

1

Computer&Information Engineering School, Henan University, Kaifeng, Henan, China

2

Department of Electrical & Control Engineering, Shanghai Maritime University, Shanghai, China

3

Institute of Information and Control, Hangzhou Dianzi University, Hangzhou, China

Keywords: Unknown fault pattern, Multiple faults, DCA, PCA, Fault diagnosis.

Abstract: As it can avoid the pattern compounding problem of PCA, designated component analysis (DCA) can be

used to implement multiple fault diagnosis for a multivariate process. But designated fault pattern must be

defined in advance, which limited its application in unknown fault diagnosis. In this paper, a hybrid DCA-

PCA method is developed for unknown multiple faults diagnosis. the main idea is: Implement DCA in the

first step. Removing the designated fault pattern from the observation data, then implement PCA to the

residual, and use the first loading vector as the new fault pattern to extend the fault pattern base. In the third

step, implement DCA for the new fault pattern and compute the significance of the new fault pattern.

Simulation for data involved 4 faults shows the efficiency of the progressive DCA fault diagnosis method.

1 INTRODUCTION

Fault diagnosis is critical for large scale system

since failure in a part may cause breakdown of the

system or even disastrous accident (Zhou, 2000).

In general, fault diagnosis methods can be

classified into 3 classes: quantitative model-based

method, qualitative model-based method and

process history based method, also called data

driven method (Venkat,2003, Wen, 2008, Ku, 1995).

With the widely application of DCS and

intelligent instrument in industry field, it is

convenient to acquire and store a large amount of

data on system operation. Since these data isn’t

efficiently used in monitoring, it is not surprise to

face “data rich, information poor” problem. People

are now realizing the significance of data driven

monitoring method (Venkat, 2003, Yue, 2001).

Common used data driven diagnosis method

includes: expert system method, ANN based method

and statistical method (Venkat, 2003, He, 2007).

Among data driven methods, statistical method

seems to have been well studied and applied. And

PCA/PLS based methods are the dominant ones.

These PCA based methods are efficient in abnormal

detection. But pattern compounding effect of PCA

makes it unavailable to fault pattern recognition,

especially for multiple faults diagnosis (Liu, 2002).

DCA is also a multivariate statistical information

extraction method. It can avoid the pattern

compounding problem of PCA, thus can be used to

diagnose multiple faults (Liu, 2002, Zhou, 2009).

But

1) DCA requires all the designated patterns are

orthogonal, which is impractical in most application;

2) DCA diagnosis method is validated only for

those known fault patterns defined in advance.

The first problem has been solved in (Zhou,

2009). This paper focuses on developing a hybrid

DCA-PCA method for unknown fault diagnosis.

2 PCA BASED FAULT

DIAGNOSIS

The essence of PCA is a linear transform

ybv

T

ii

= (1)

Where principal component

i

v is the projection of

observation variable

1

12

[, , , ]

Tp

p

yyy y R

×

=∈"

on loading vector

1

12

[, ,, ]

Tp

iii ip

bbb b R

×

=∈" ,

which is the

ith eigenvector of

y

’s covariance

matrix

y

Σ

. For a sample size of n , equa. (1)

expands into the following matrix form

T

VBY= (2)

where

pn

YR

×

∈

is the observation matrix,

pn

VR

×

∈ is the scoring matrix.

PCA decompose the observation matrix

Y

as a

sum of

p

matrices of rank 1

367

Zhou F., Tang T. and Wen C. (2009).

HYBRID DCA-PCA MULTIPLE FAULTS DIAGNOSIS METHOD.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 367-370

DOI: 10.5220/0002201103670370

Copyright

c

SciTePress

∑∑

+==

+=

p

mi

T

ii

m

i

T

ii

vbvbY

11

(3)

Where

m is the number of key principal

component selected,

∑

+=

=

p

mi

T

ii

vbE

1

is the residual.

Implement abnormal detection via the statistics

2

T

and

SPE

(MacGregor, 1995, Zhang,2000).

But they can not correctly recognize fault pattern.

3 DCA BASED FAULT

DIAGNOSIS

The designated patterns are defined as

T

ipiii

dddd ],,,[

21

"= , where

ij

d is 0 or 1

determined by the relation between fault and its

symptom(Zhou,2009, Liu, 2004). Then, project

y

on

i

d to get the designated components

ydw

T

ii

= (4)

For a sample size of

n

T

WDY=

(5)

Thus

Y

can also be expressed as sum of

p

matrices of rank 1

1

p

ii

i

Ydw

=

=

∑

(6)

If there are only

pl

≤

variation pattern is

designated, then (Zhou, 2009)

1

l

ii

i

YdwE

=

=+

∑

(7)

Convergence of (7) has been proved in (Zhou,

2009).

Compute the significance of every designated

pattern to determine whether the fault has occurred

%var()/ ()

iiy

Pwtrace=Σ (8)

But DCA is invalidated for unknown faults

diagnosis. A hybrid DCA-PCA method will be

developed to solve this problem.

4 HYBRID DCA-PCA MULTIPLE

FAULT DIAGNOSIS METHOD

As it is known to all, PCA is a complete data-driven

method. Although fault pattern PCA revealed makes

no physical sense, it can determine a significant

variation pattern of the abnormal system without any

prior information. In this section, we develop a

hybrid DCA-PCA multiple fault diagnosis method

for the case when unknown new fault occurs.

First, define

l

)( pl

≤

designated pattern as in

(Zhou,2009), and implement DCA to the

observation data; Then, remove the designated

patterns defined in advance from the observation

data to get the residual

E

; Determine whether new

fault is comprised in the residual according to the

energy significance of the residual defined as

F

E

.

1

l

ii

i

EY dw

=

=−

∑

is large in the sense

F

E

δ

> means that new fault occurred.

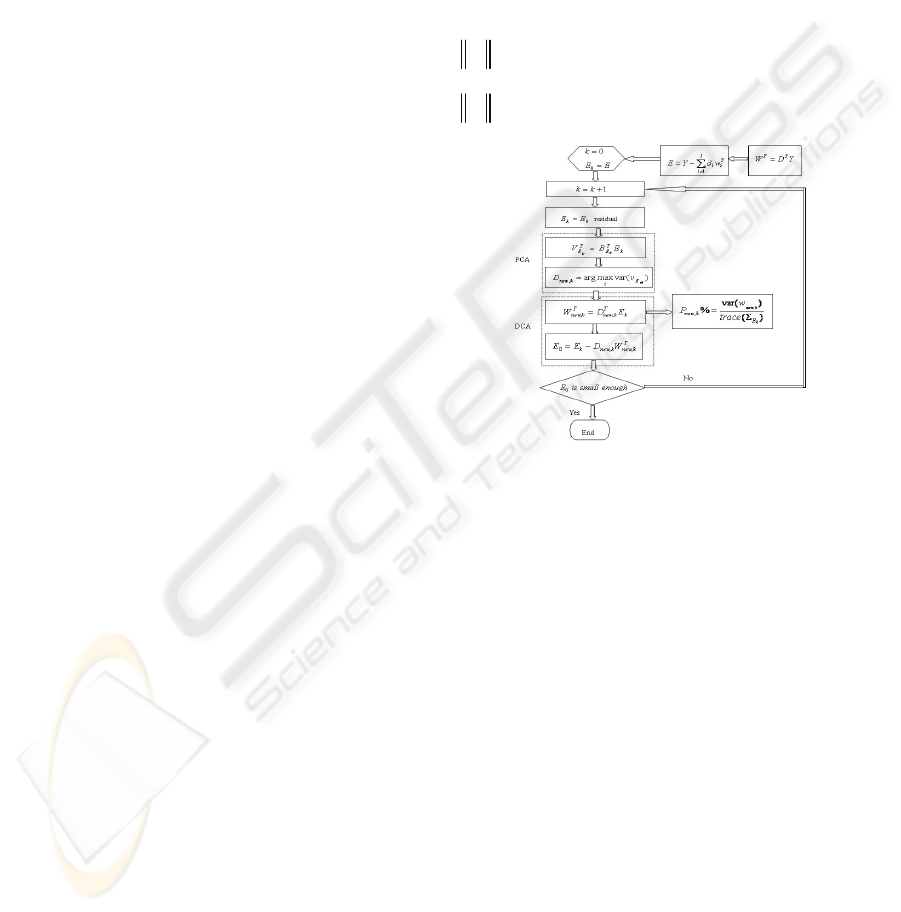

Figure 1: Hybrid DCA-PCA diagnosis method.

Implement PCA to

E

, and select the first

loading vector as new fault pattern

1,new

D

.

Another round of DCA is carried out for

1,new

D

.

Repeating this process until residual is insignificant.

YDW

TT

=

(9)

1

l

ii

i

EY dw

=

=−

∑

(10)

T

EE

VBE= (11)

)var(max

1,

i

E

i

new

vD

=

(12)

EE

=

1

(13)

,1 1,1 1

T

new new

WDE= (14)

2 1 ,1 ,1new new

EEDW=− (15)

22

2

T

EE

VBE=

(16)

)var(max

22,

i

E

i

new

vD

=

(17)

#

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

368

Figure 1 depicts the hybrid DCA-PCA multiple

fault diagnosis process.

5 SIMULATIONS

Simulations parameters used are: 15

=

p ,

1000=n , 6=l .

The observation data is generated by the

composition of 10 variation patterns

10

1

ii

i

Ydw

=

=

∑

(18)

Where

2

~(0, )

ii

wN

σ

is the simulated designated

component,

1p

i

dR

×

∈

)10,,2,1( "

=

i are the 10

variation patterns to generate observation data

Y

.

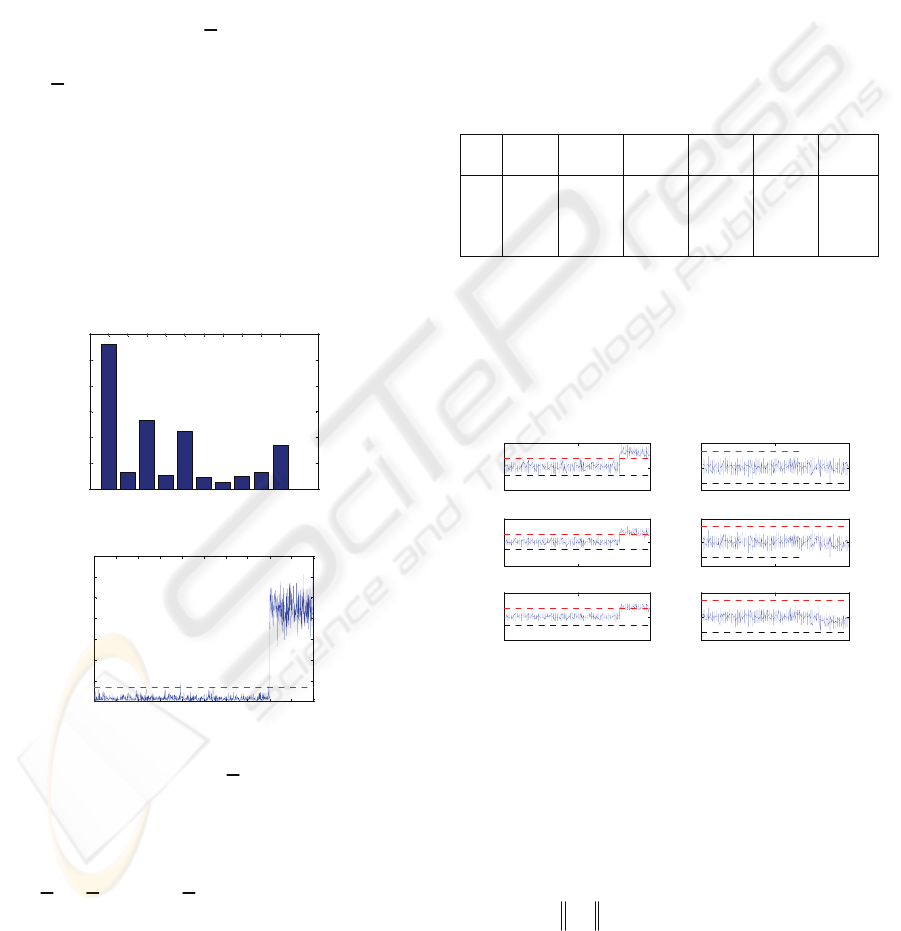

figure 2 depicts the contribution of each

i

d to

Y

.

The first 6 pattern

61

,, dd " are the designated

pattern we selected,

531

,, ddd is the fault pattern,

10

d is a fault pattern unconsidered in advance.

1 2 3 4 5 6 7 8 9 10

0

1

2

3

4

5

6

Figure 2: DC values for Generating observation.

0 100 200 300 400 500 600 700 800 900 1000

0

5

10

15

20

25

30

35

95% c ont rol li mit

Figure 3: SPE chart for PCA.

For normal observation,

i

w can be generated in

MATLAB using “randn” and some linear operation

For fault case,

13510

,,,dddd are amplified

from sampling time 801 to 1000

5var( )

ii i

ww w=+

1, 3, 5, 1 0i =

(19)

5.1 PCA based Fault Diagnosis

The SPE chart of PCA are shown in figure 3. Figure

3 indicates that system considered is abnormal from

801st sample point. However, SPE chart can not tell

what faults occur.

5.2 Hybrid DCA-PCA Multiple Faults

Diagnosis

Implement DCA to the observation, and illustrate

the significance of each designated pattern in table 2.

From table 2, we can see that, the fist, the third and

the fifth variation pattern are the 3 significant ones

of the 6 designated patterns. According to the

significance of the observation to each designated,

we can conclude that faults corresponding to these 3

designated patterns have occurred in the system.

Table 2: Significance of the designated pattern in D.

1

d

2

d

3

d

4

d

5

d

6

d

%

i

d

0.41

23

0.036

8

0.1946

0.035

9

0.1839

0.037

8

Figure 6 draws the Shewhart chart of every

designated component in. It indicates that the 1

st

, 3

rd

,

and 5

th

designated component’s Shewhart chart

exceed the control limit from 801 to 1000. Figure 6,

confirms that faults corresponding to the 1

st

, 3

rd

, and

5

th

designated patterns have occurred in the system.

0 500 1000

-1 0

0

10

the 1s t dc

LCL

UCL

0 500 1000

-5

0

5

the 2nd dc

LCL

UCL

0 500 1000

-1 0

0

10

the 3 dc

LCL

UCL

0 500 1000

-5

0

5

the 4th dc

LCL

UCL

0 500 1000

-1 0

0

10

the 5th dc

LCL

UCL

0 500 1000

-5

0

5

the 6th dc

LCL

UCL

Figure 6: Shewhart chart for 6 DC.

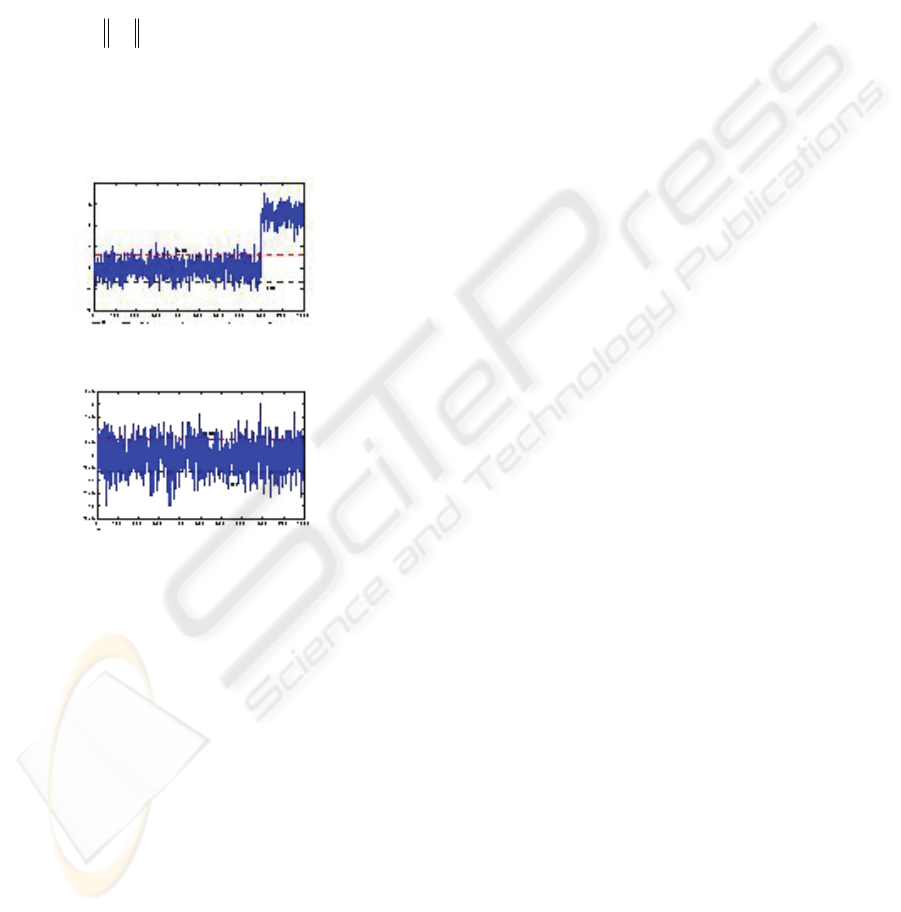

For the case 15

=

p , 1000=n and 6=l ,

statistical result of more than 100 times

simulation shows that the threshold is reasonable

10

=

δ

(20)

Removing the 6 designated variation pattern to

get the residual

0

E . The norm of the residual is

0

12.7524

F

E

δ

=

>

(21)

It is possible that at least one new fault is still

included in the residual. Implement PCA to the

residual

0

E , and take the first load vector as a new

HYBRID DCA-PCA MULTIPLE FAULTS DIAGNOSIS METHOD

369

fault pattern. Then implement DCA to

0

E for

1new

d . And compute its significance

6083.0%

1

=

new

d (22)

The Shewhart chart of this new designated

component is depicted in figure 7. Figure 7 tells us

that fault corresponding to

1new

d has occurred in the

system. Removing the new fault pattern

1new

d from

0

E we have the residual of this DCA step

1

7.2042

F

E = (23)

To the residual

1

E , Shewhart chart for the

secondnew designated component, figure 8 is within

the control limit, which will confirm that

10

=

δ

is

reasonable

Figure 7: Shewhart chart for the 1

st

new dc.

Figure 8: Shewhart chart for the 2

nd

new dc.

From the above simulation research, we can

conclude that

1

d ,

3

d ,

5

d and

10

d occurred in the

system. This is basically the same as the simulation

manner that we used to generate

Y

.

6 CONCLUSIONS

DCA can avoid pattern compounding problem of

PCA. But it is invalidated for unknown faults

diagnosis. In this paper, a hybrid DCA-PCA method

for unknown multiple fault diagnosis.

Some data driven methods other than PCA can

be used to the residual to estimate the new fault

pattern to make it physical sense.

ACKNOWLEDGEMENTS

This paper is supported by NSFC (60804026);

International cooperation project of Zhejiang

(2006C24G2040012), Natural science fund of

Henan (2009A510001) International cooperation

project of Henan (094300510043), Key disciplines

of Shanghai Municipality (J50602), Development

Project (08YZ109) from Shanghai Municipal

Education Commission.

REFERENCES

Donghua Zhou, Yinzhong Ye, 2000. Modern fault

diagnosis and tolerant control[M], Beijing, Qstinghua

Publishing House (in Chinese).

Venkat Venkatasubramanian, Raghunathan Rengaswamy,

Kewn Yin, Surya N. Kavuri,2003. A review of process

fault detection and diagnosis Part I[J]: quantitative

model-based methods. Computers and Chemical

Engineering 27 (2003):pp293-311.

Qingbo He, 2007. Application Multivariate statistical

analysis in machine state monitoring and diagnosis

[D], PHD thesis, University of Science and

Technology of China (in Chinese).

Yue H H, Qin S J, 2001. Reconstruction based fault

identification using a combined index. Industrial and

Engineering Chemistry Research[J], 40(20): 4403-

4414

J.F. MacGregor and T. Kourtl, 1995. Statistical process

control of multivariate processes[J], Control Fag.

Practice, VoL 3, No. 3, pp. 403-414.

Yegang Liu, 2002. Statistical control of multivariate

processes with applications to automobile body

assembly (D). PHD, University of Michigan.

Jie Zhang, Xianhui Yang. Multivariate statistical

control[M], Beijing, Chemistry Industry Publishing

House, 2000 (in Chinese).

Funa Zhou, Chenglin Wen, Tianhao Tang, 2009. DCA

based multiple faults diagnosis method, accepted by

ACTA AUTOMATICA SINICA (in Chinese).

Chenglin Wen, Jing Hu, Tianzhen Wang, Zhiguo Chen.

RPCA and it’s application in data compression and

fault diagnosis, ACTA AUTOMATICA SINICA

34(9) : 1128-1139 (in Chinese).

Ku, W., Storer, R.H., and Georgakis,C, 1995. Disturbance

detection and isolation by dynamic principal

component analysis [J], Chemometrics and Intelligent

Laboratory Systems, 30:179-196.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

370